How to Speed Up a Pulverizer

A pulverizer is a machine that is used to grind or crush materials into smaller pieces. It is commonly used in the industrial sector to reduce the size of raw materials, such as coal, rock, and cement, into a finer powder. However, like any other machine, a pulverizer can become sluggish and slow down over time, reducing productivity and efficiency. Fortunately, there are several things that you can do to speed up a pulverizer and ensure that it’s operating at peak performance. In this article, we’ll explore some of the most effective ways to speed up a pulverizer. How to Speed Up a Pulverizer? Here are 4 items that you can check:Many user of Pulverizer, finds that after a period of using the machine, the output effectiveness is not good as before, the capacity are reducing. What’s the problem?

1. To check if any clog in dust collector bag cloth and screen:

The screen on a pulverizer is designed to help control the size of the particles that are produced during the grinding process. If the screen is worn or damaged, it can affect the pulverizer’s performance and slow it down. To speed up a pulverizer, you should check the screen and see if it needs to be replaced. If it does, make sure to get a new screen that is the right size for your pulverizer.

In the market, there are many machine are using the dust collecting bag cloth, this structure advantage is cheap, disadvantage is will clog if long time use and not frequently to clear it. And the clog causes reverse suction. This will reduce the capacity. To upgrade this, can change the cloth bag to dust-free tube. which can avoid the clog happen in dust collector;

Size Customization

Click to Buy New Pulverizer Dust Collector Cloth

Our factory can support to customize according to your grinder cloth size and specification.

2. Check if the material feeder working as normal:

If material feeder not put in right place, or get stuck, the material feeding speed will slow down, this also impact the capacity;

Size Customization

Click to Buy Screw Feeder

Our factory can support to customize screw feeder according to your grinder.

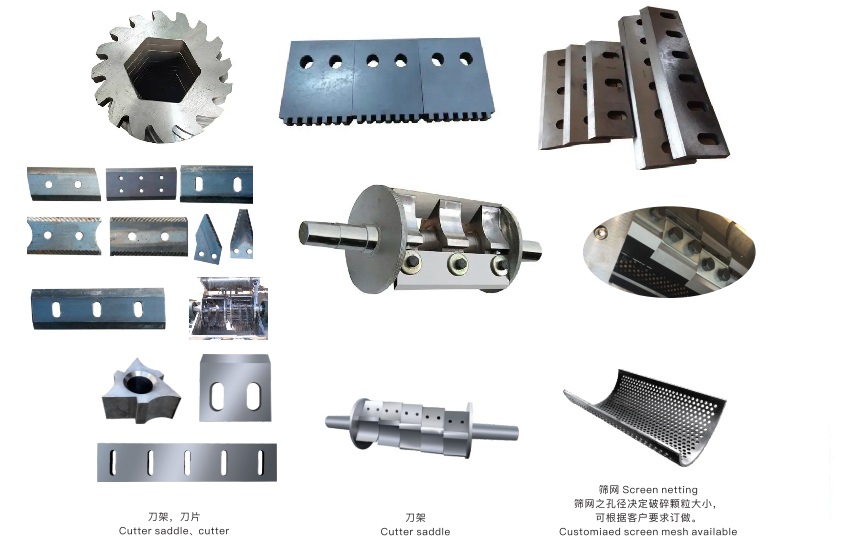

3. Test the worn condition of cutting knife:

Knife & screen

We provide knife and screen customization.

Click to customize your own size specification.

4. If the Voltage are stable or not:

Electric power voltage is the resources of energy, if the electric power not stable, will cause motor transfer not stable. Moreover, it will also short the life time of motor. You can avoid to use the electricity to ensure the stability of voltage, which will also helpful to increase grinding efficiency.

5. Clean the Pulverizer’s Interior

Over time, debris and dirt can accumulate inside a pulverizer, which can slow it down and reduce its efficiency. To speed up a pulverizer, you should clean its interior regularly. This can be done by opening the machine up and removing any debris or dust that you find. Make sure to wear appropriate protective gear, such as gloves and a dust mask, when cleaning a pulverizer.

6. Adjust the Pulverizer’s Grinding Speed

The speed at which a pulverizer grinds raw materials can also affect its performance. If the speed is too slow, it can take longer to grind the materials and reduce the machine’s efficiency. To speed up a pulverizer, you should check the speed settings and see if they need to be adjusted. If they do, make sure to follow the manufacturer’s instructions carefully when making any changes.

7. Check the Pulverizer’s Airflow

The airflow inside a pulverizer is important because it helps to cool the machine down and prevent overheating. If the airflow is blocked or restricted, it can slow down the machine and reduce its efficiency. To speed up a pulverizer, you should check the airflow and make sure that it’s not being blocked by any debris or dust. If it is, you can clean out the air ducts to improve the airflow.

8. Replace the Pulverizer’s Motor

If you’ve tried all of the above methods and your pulverizer is still running slow, it may be time to replace the motor. The motor is responsible for providing power to the machine, and if it’s worn or damaged, it can slow down the pulverizer’s performance. To replace the motor, you should consult with a professional who can help you select the right replacement and install it properly.

9. Maintain the Pulverizer Regularly

One of the most important things you can do to speed up a pulverizer is to maintain it regularly. This includes cleaning it, checking its components, and replacing anything that is worn or damaged. By keeping your pulverizer well-maintained, you can ensure that it’s operating at peak performance and that it’s not slowing down your production.

In conclusion, a slow and sluggish pulverizer can be frustrating and costly.

We also need to consider the 4 points before we buy the pulverizer machine:

1. Raw Material Features:

The nature of the raw materials have many kinds of properties. Such as brittleness, toughness, fibrous, sugar, oil, etc. These shall determine the nature of the raw material before crushing. Then the different nature of the material take different approaches. Such as high sugar, high oil materials, in the case of without external force can together, will not be able to use the method of grinding brittle materials to pieces.

2. Water Content:

The water content of the raw material, the water content of the mill is very high, generally can not exceed 10%. Because the powder is fine, the water is sufficient, increase the proportion of the material, make many particles stick together. If the material water content is higher will crush increased difficulty, so that the yield is also reduced.

3. Maintenance:

The maintenance of the equipment, regular maintenance of the equipment is to ensure the service life of the mill and the output of the grinding fineness mill, the equipment needs to be regularly filled with lubricating oil, check the aging degree of the seals, the wear of the grinding medium and other problems.

4. Fineness:

Fineness of the feed, no matter you buy which manufacturer of crusher, the instructions will indicate the incoming fineness. Generally under 1 mm, feed fineness is too big for the machine had a greater influence on the lifetime. Moreover, smash up also is very difficult. In fact, just like we eat this truth, have to eat slowly, to help digestion.

According to the characteristics of aquatic animals and the requirements of the living environment, in order to ensure the best feed utilization rate and reduce the pollution of feed to the water environment, feed should be easier to digest and absorb. It is more important for aquatic feed, because many aquatic animals have no stomach and short intestine. And their digestive capacity is much lower than that of livestock and poultry. Different aquatic animals and different growth periods have different requirements on the size of raw materials.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com