Industrial Seeds Grinder

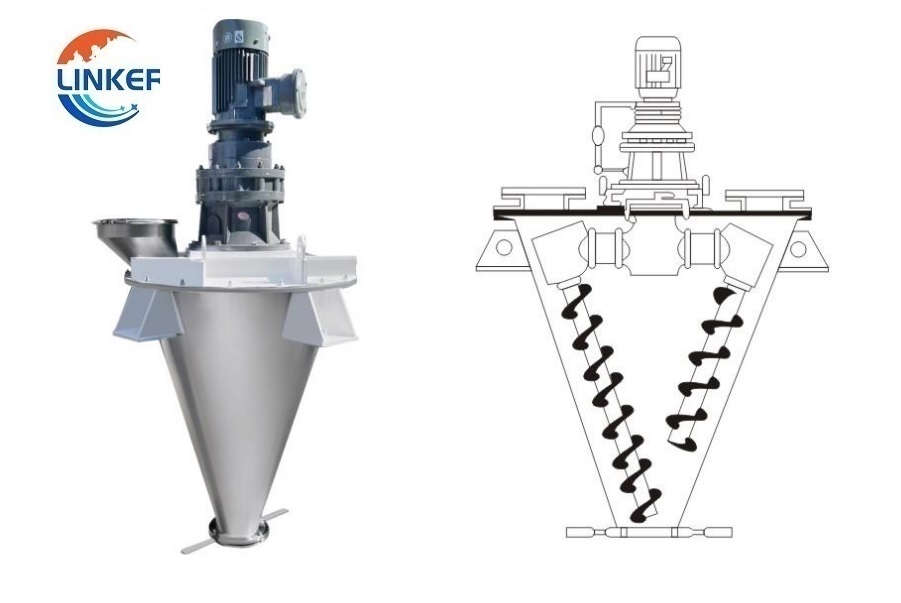

SG Double Shaft Grinder

- Feeding granule size: <5mm;

- Powder Size: 20~40 mesh;

- Capacity: 1~4000kg/h(according to different modes and raw materials);

- Motor Power (KW): 11~15kw;

- FOB Unit Price: 1 unit $ 6,646~10,154. More than 5 units: $5,982~9,138. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

Industrial Cumin Seeds Grinder Youtube Video

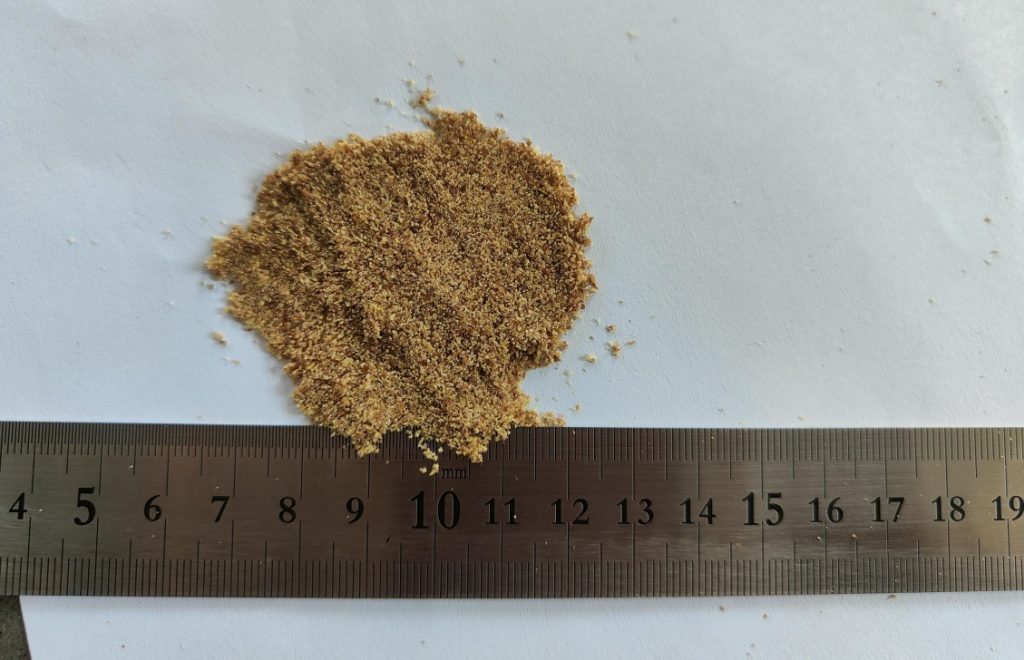

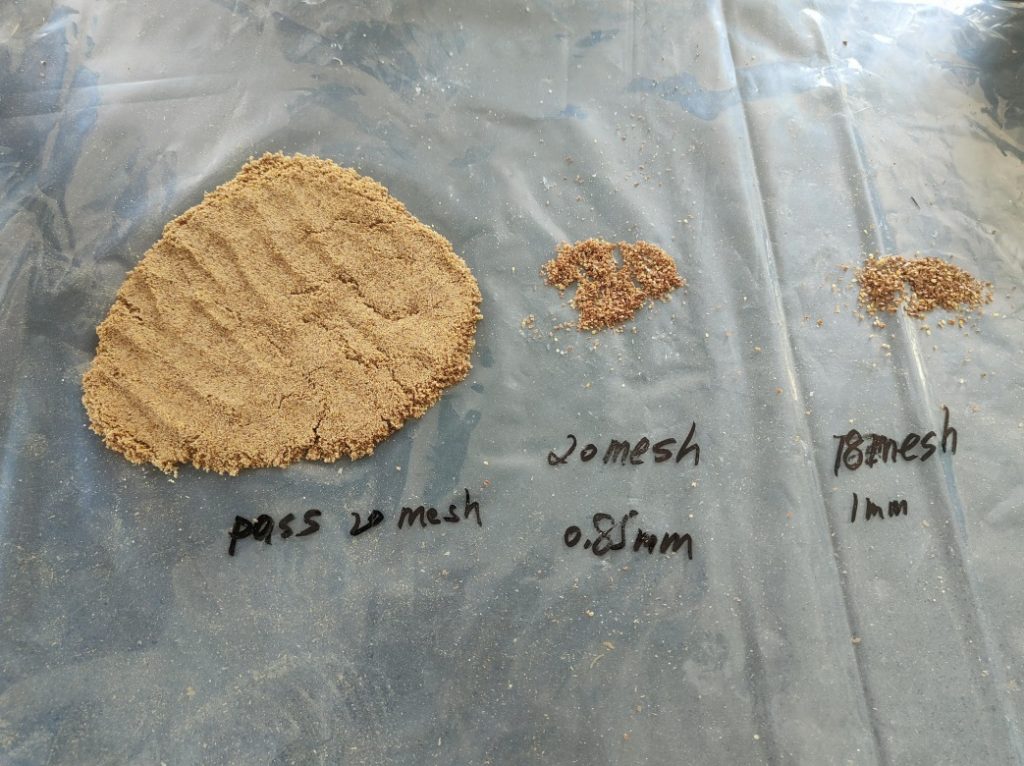

Test Report for Flax Seed Grinder:

A flax seed grinder is a type of seed nut grinder specifically designed for grinding flax seeds. Flax seeds are small, hard seeds that are packed with nutrition and are commonly used in baking and cooking. Grinding flax seeds helps to unlock their nutrients and make them easier to digest.

Flax seed grinders typically feature sharp blades or burrs that rotate to crush the flax seeds into a fine powder. This powder can then be used in a variety of recipes, such as smoothies, baked goods, and yogurt toppings. Some flax seed grinders are manual and require hand-cranking, while others are electric and feature powerful motors for faster grinding.

When choosing a flax seed grinder, it’s important to look for one with durable blades or burrs that can withstand the hard texture of flax seeds.

I. Introduction

An industrial seeds grinder is a machine that is used to grind various types of seeds into flour or powder. It is commonly used in the food industry to process seeds such as sesame, sunflower, flax, and chia, among others. The grinder operates by using a motor to rotate two or more discs that grind the seeds between them. The resulting powder can be used as an ingredient in various food products, including baked goods, sauces, and dressings. Industrial seed grinders are often designed with high capacity and efficiency to meet the demands of commercial food production. They are typically made of durable materials such as stainless steel to withstand the wear and tear of continuous use.

Importance of industrial seed grinder in food industry

An industrial seed grinder is an essential piece of equipment in the food industry. It is designed to grind seeds into a fine powder or paste, which can be used in a variety of food products. Here are some of the key reasons why industrial seed grinders are important in the food industry:

- Consistency and quality: Industrial seed grinders can grind seeds to a consistent particle size, which is essential for achieving consistent quality in food products. This is particularly important for products like spices, where the particle size can affect the flavor and aroma of the final product.

- Efficiency: Industrial seed grinders are designed to process large quantities of seeds quickly and efficiently. This makes them essential for food manufacturers who need to produce large volumes of products.

- Versatility: Industrial seed grinders can be used to grind a wide variety of seeds, including sesame, flax, mustard, and poppy seeds. This makes them a versatile piece of equipment that can be used in a range of food products.

- Safety: Industrial seed grinders are designed to operate safely and efficiently, with features like automatic shut-off and overload protection. This helps to ensure that food manufacturers can produce products safely and consistently.

Overall, industrial seed grinders play a crucial role in the food industry, helping to ensure consistent quality and efficient production of a wide range of food products.

II. History and Development of Industrial Seed Grinder

Early seed grinding methods

Seed grinding has been an important food processing technique for thousands of years, and early humans developed a number of methods to grind seeds into flour or paste. Some of the early seed grinding methods include:

- Mortar and pestle: This is one of the oldest and most simple methods of seed grinding. A mortar and pestle consists of a bowl (the mortar) and a club-shaped tool (the pestle) that is used to grind the seeds. The seeds are placed in the bowl, and the pestle is used to crush and grind them into a paste or powder.

- Saddle quern: This method involves using a large stone with a depression in the middle (the saddle) and a smaller stone that is used to grind the seeds. The seeds are placed in the depression, and the smaller stone is moved back and forth to grind them into flour.

- Rotary quern: This is a more advanced version of the saddle quern, and it involves using a hand-operated rotary tool to grind the seeds. The rotary quern was more efficient than the saddle quern and allowed for larger quantities of seeds to be ground at once.

- Water-powered mills: As civilizations became more advanced, water-powered mills were developed to grind seeds and other grains. These mills used the power of water to turn large grinding stones, which were used to grind the seeds into flour.

Overall, early seed grinding methods were simple but effective, and they allowed early humans to process seeds and other grains into food products that could be stored and consumed over long periods of time.

Advances and innovations in seed grinding technology

Over the years, there have been several advances and innovations in seed grinding technology that have improved the efficiency, speed, and precision of the process. Here are some examples:

- Electric grinders: The invention of electric grinders in the 20th century made seed grinding faster and more efficient. These machines use electric motors to power the grinding blades, which can grind seeds quickly and produce a consistent particle size.

- High-speed mills: High-speed mills are a type of electric grinder that uses centrifugal force to grind seeds at high speeds. These mills can produce fine powders and pastes quickly and efficiently, and they are used in a variety of industries, including the food industry.

- Cryogenic grinding: Cryogenic grinding is a relatively new technology that involves grinding seeds at very low temperatures (-196°C). This process helps to preserve the flavor and nutritional value of the seeds, and it can produce very fine particle sizes.

- Ultrasonic grinding: Ultrasonic grinding is a newer technology that uses ultrasonic waves to break down seeds into smaller particles. This process is fast and efficient and can produce very fine powders and pastes.

- Computer-controlled grinding: Computer-controlled grinding uses software and sensors to control the grinding process. This allows for very precise control over the particle size and can improve the consistency and quality of the final product.

Overall, advances in seed grinding technology have made the process faster, more efficient, and more precise, which has benefited a wide range of industries, including the food industry, pharmaceuticals, and cosmetics.

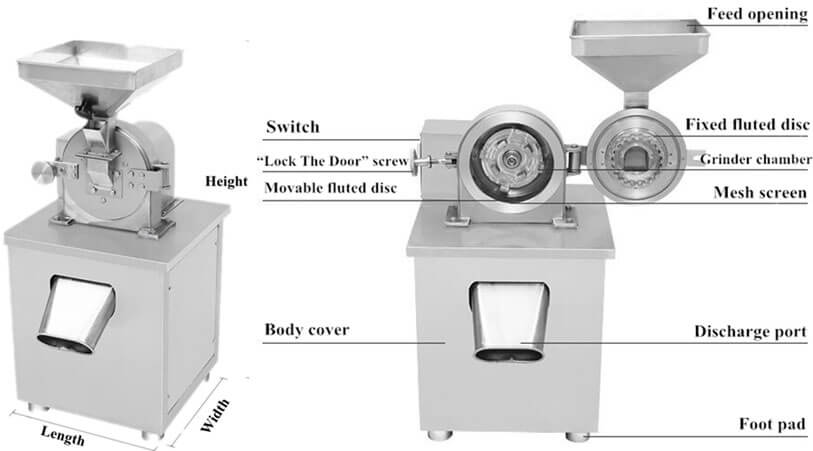

III. Components of Industrial Seed Grinder

Industrial seed grinders are complex machines that consist of several components that work together to grind seeds into a fine powder or paste. Here are the main components of an industrial seed grinder:

- Hopper: This is the top part of the grinder where the seeds are loaded into the machine. The hopper can be either manual or automatic and can vary in size depending on the model of the grinder.

- Grinding mechanism: The grinding mechanism is the heart of the industrial seed grinder. It consists of a series of blades, plates, or burrs that grind the seeds into a fine powder or paste. The type of grinding mechanism can vary depending on the type of seeds being ground and the desired particle size.

- Motor: The motor is responsible for powering the grinding mechanism. Industrial seed grinders usually have high-powered electric motors that can handle large volumes of seeds and operate continuously for extended periods of time.

- Discharge chute: Once the seeds have been ground, they need to be collected and transported out of the grinder. The discharge chute is the part of the machine that directs the ground seeds into a container or downstream processing equipment.

- Controls: Industrial seed grinders are usually equipped with a control panel that allows the operator to adjust the speed, grinding time, and other parameters of the grinding process.

- Safety features: Industrial seed grinders are equipped with safety features to protect the operator and the machine. These features can include emergency stop buttons, overload protection, and safety interlocks.

Overall, the components of an industrial seed grinder are designed to work together to produce consistent, high-quality ground seeds efficiently and safely.

IV. Types of Industrial Seed Grinder

Vertical vs. horizontal orientation Industrial Seed Grinder

Industrial seed grinders come in two main orientations: vertical and horizontal. Here are the differences between these two orientations:

- Vertical orientation: In a vertical industrial seed grinder, the grinding plates are arranged vertically. This means that the seeds are fed into the top of the grinder and are ground between the plates as they fall towards the bottom of the machine. Vertical grinders are typically used for high-volume production and are well-suited for processing large quantities of material.

- Horizontal orientation: In a horizontal industrial seed grinder, the grinding plates are arranged horizontally. This means that the seeds are fed into the side of the grinder and are ground between the plates as they move horizontally through the machine. Horizontal grinders are typically used for lower-volume production and are well-suited for processing smaller quantities of material.

The choice between a vertical or horizontal industrial seed grinder will depend on a variety of factors, including the specific application, the volume of material that needs to be processed, and the desired particle size of the final product. Vertical grinders are generally preferred for high-volume production, while horizontal grinders are better suited for smaller-scale operations. Additionally, the orientation of the grinder may affect the texture of the final product, with vertical grinders generally producing a finer grind than horizontal grinders.

Batch vs. continuous operation Industrial Seed Grinder

Industrial seed grinders can be operated in two main modes: batch or continuous operation. Here are the differences between these two modes:

- Batch operation: In batch operation, the industrial seed grinder processes a fixed quantity of material at a time. The machine is loaded with a specific amount of seeds, which are then ground into a fine powder or paste. Once the batch is complete, the grinder is emptied and cleaned before the next batch is processed. Batch operation is well-suited for small-scale operations or for applications where different types of seeds or spices need to be ground separately.

- Continuous operation: In continuous operation, the industrial seed grinder processes material continuously, without interruption. The seeds are fed into the grinder at a constant rate and are ground into a fine powder or paste as they move through the machine. Continuous operation is well-suited for high-volume production and for applications where a consistent product is required.

The choice between batch or continuous operation will depend on a variety of factors, including the specific application, the volume of material that needs to be processed, and the desired particle size of the final product. Batch operation is generally preferred for smaller-scale operations or for applications where different types of seeds or spices need to be ground separately. Continuous operation is generally preferred for high-volume production, where a consistent product is required.

Single vs. multi-stage grinding Industrial Seed Grinder

Industrial seed grinders can be designed for single-stage or multi-stage grinding. Here are the differences between these two designs:

- Single-stage grinding: In a single-stage industrial seed grinder, the seeds are ground to the desired fineness in one pass through the machine. This means that the grinder has one set of grinding plates that are used to reduce the seeds to the desired particle size. Single-stage grinding is generally preferred for applications where a coarse or medium grind is required.

- Multi-stage grinding: In a multi-stage industrial seed grinder, the seeds are ground in multiple passes through the machine. This means that the grinder has multiple sets of grinding plates, each of which is used to reduce the seeds to a finer particle size. The material is passed through each set of plates in sequence, with the particle size becoming progressively smaller with each pass. Multi-stage grinding is generally preferred for applications where a fine or very fine grind is required.

The choice between single-stage or multi-stage grinding will depend on a variety of factors, including the specific application, the desired particle size of the final product, and the properties of the material being ground. Single-stage grinding is generally faster and more efficient for coarse or medium grinds, while multi-stage grinding is preferred for finer grinds.

Seed Nut Grinder

A seed nut grinder is a kitchen tool used to grind nuts and seeds into fine powders or pastes. These grinders typically feature a cylindrical or conical hopper with sharp blades or burrs inside that rotate to crush the seeds or nuts. The ground material is then collected in a container that is attached to the bottom of the grinder.

Seed nut grinders are commonly used for grinding a variety of nuts and seeds, such as almonds, peanuts, sesame seeds, flax seeds, and chia seeds. They are often used in baking and cooking to make nut and seed butters, flours, and pastes, or as a topping for dishes such as oatmeal or yogurt.

There are various types of seed nut grinders available on the market, ranging from manual hand-crank models to electric versions with more powerful motors. Some models come with different attachments for grinding different types of nuts and seeds, while others feature adjustable settings to control the fineness of the grind.

Chia seed grinder

A chia seed grinder is a type of seed nut grinder specifically designed for grinding chia seeds. Chia seeds are small, hard seeds that are packed with nutrition and are commonly used in baking and cooking. Grinding chia seeds helps to unlock their nutrients and make them easier to digest.

Chia seed grinders typically feature sharp blades or burrs that rotate to crush the chia seeds into a fine powder. This powder can then be used in a variety of recipes, such as smoothies, baked goods, and puddings. Some chia seed grinders are manual and require hand-cranking, while others are electric and feature powerful motors for faster grinding.

When choosing a chia seed grinder, it’s important to look for one with durable blades or burrs that can withstand the hard texture of chia seeds. Additionally, some models may come with extra features such as adjustable settings for controlling the fineness of the grind or different attachments for grinding other types of seeds or nuts.

Sesame seed grinder

A sesame seed grinder is a type of seed nut grinder specifically designed for grinding sesame seeds. Sesame seeds are small, oil-rich seeds commonly used in a variety of cuisines, particularly in Middle Eastern and Asian dishes. Grinding sesame seeds helps to release their oil and enhance their flavor.

Sesame seed grinders typically feature sharp blades or burrs that rotate to crush the sesame seeds into a fine powder or paste. This powder or paste can then be used in a variety of recipes, such as hummus, tahini, and sesame cookies. Some sesame seed grinders are manual and require hand-cranking, while others are electric and feature powerful motors for faster grinding.

When choosing a sesame seed grinder, it’s important to look for one with durable blades or burrs that can withstand the hard texture of sesame seeds. Additionally, some models may come with extra features such as adjustable settings for controlling the fineness of the grind or different attachments for grinding other types of seeds or nuts.

Mustard seed grinder

A mustard seed grinder is a type of seed nut grinder specifically designed for grinding mustard seeds. Mustard seeds are small, hard seeds that are commonly used in cooking to make various condiments, including mustard and pickles. Grinding mustard seeds helps to release their pungent flavor and aroma.

Mustard seed grinders typically feature sharp blades or burrs that rotate to crush the mustard seeds into a fine powder or paste. This powder or paste can then be used in a variety of recipes, such as marinades, salad dressings, and sauces. Some mustard seed grinders are manual and require hand-cranking, while others are electric and feature powerful motors for faster grinding.

When choosing a mustard seed grinder, it’s important to look for one with durable blades or burrs that can withstand the hard texture of mustard seeds. Additionally, some models may come with extra features such as adjustable settings for controlling the fineness of the grind or different attachments for grinding other types of seeds or nuts.

Electric seed grinder

An electric seed grinder is a type of kitchen appliance that uses electricity to grind seeds and nuts into fine powders or pastes. Unlike manual hand-cranked grinders, electric seed grinders feature powerful motors that make the grinding process faster and more efficient.

Electric seed grinders come in a variety of sizes and styles, from small countertop models for home use to larger commercial-grade versions for use in restaurants or bakeries. Some models may feature adjustable settings for controlling the fineness of the grind, while others may come with different attachments for grinding different types of seeds and nuts.

Electric seed grinders are commonly used for grinding a variety of seeds and nuts, such as flax seeds, chia seeds, almonds, and peanuts, and are often used in baking, cooking, and making nut butters.

Coffee seed grinder

A coffee seed grinder, also known as a coffee bean grinder, is a kitchen appliance specifically designed for grinding whole coffee beans into a fine powder. The consistency of the grind is an essential factor in brewing coffee, and a coffee seed grinder allows users to adjust the grind size to their preferred level of coarseness or fineness.

Coffee seed grinders come in a variety of types and sizes, ranging from manual hand-cranked models to electric grinders with more powerful motors. Some models feature different settings for adjusting the grind size, while others may come with additional features such as timers or dose control for precise measurement.

Using a coffee seed grinder to grind whole coffee beans just before brewing can result in a fresher, more flavorful cup of coffee.

| 1 Unit Pirce(FOB USD) | 5 Units Wholesale Unit Price (FOB USD) | |

| SG-600 | 6646 | 5982 |

| SG-800 | 10154 | 9138 |

Feature:

Industrial seed grinders are specialized machines that are designed to grind seeds and other materials into a fine powder or paste. Here are some features that are commonly found in industrial seed grinders:

- High throughput: Industrial seed grinders are designed to process large volumes of seeds quickly and efficiently. They are often used in production environments where a high throughput is essential.

- Variable speed: Many industrial seed grinders have variable speed controls, which allow the operator to adjust the speed of the grinding mechanism. This feature is useful for achieving a consistent particle size and for processing different types of seeds.

- Customizable grinding plates: Some industrial seed grinders come with customizable grinding plates that can be swapped out to accommodate different types of seeds and produce different particle sizes.

- Easy to clean: Industrial seed grinders are designed to be easy to clean and maintain. They often feature removable grinding plates, hopper, and discharge chute that can be easily cleaned and sanitized.

- Heavy-duty construction: Industrial seed grinders are built to withstand heavy use and are constructed with durable materials such as stainless steel or hardened alloys. This ensures that the machine can withstand the rigors of daily use and last for many years.

- Versatility: Industrial seed grinders can often be used to process a variety of materials in addition to seeds, such as nuts, grains, and spices.

Overall, the features of an industrial seed grinder are designed to make the grinding process fast, efficient, and consistent, while also being easy to use and maintain.

Parameters:

Model Name | SG-600 | |

| Crushing Capacity(kg/h) | 1000~2000 | |

| Power(kw) | 11 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Model Name | SG-800 | |

| Crushing Capacity(kg/h) | 2000~4000 | |

| Power(kw) | 15 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

Ampere of Motors Customization for Seeds Grinder:

| KW | HP | Ampere |

| 75kw | 100HP | 135A |

| 55kw | 75HP | 99A |

| 30kw | 40HP | 54A |

| 22kw | 30HP | 39A |

| 2.2kw | 3HP | 3.9A |

| 1.5kw | 2HP | 2.7A |

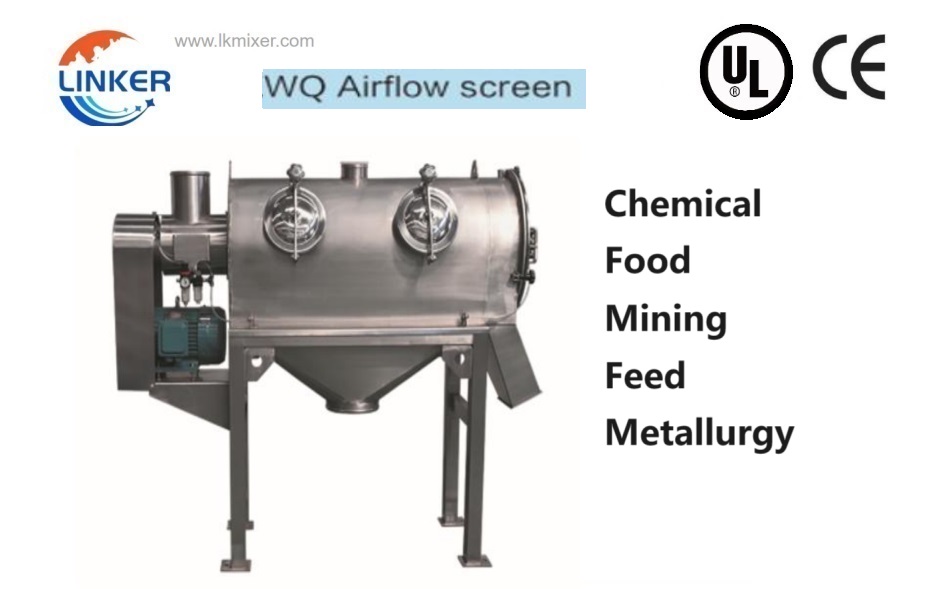

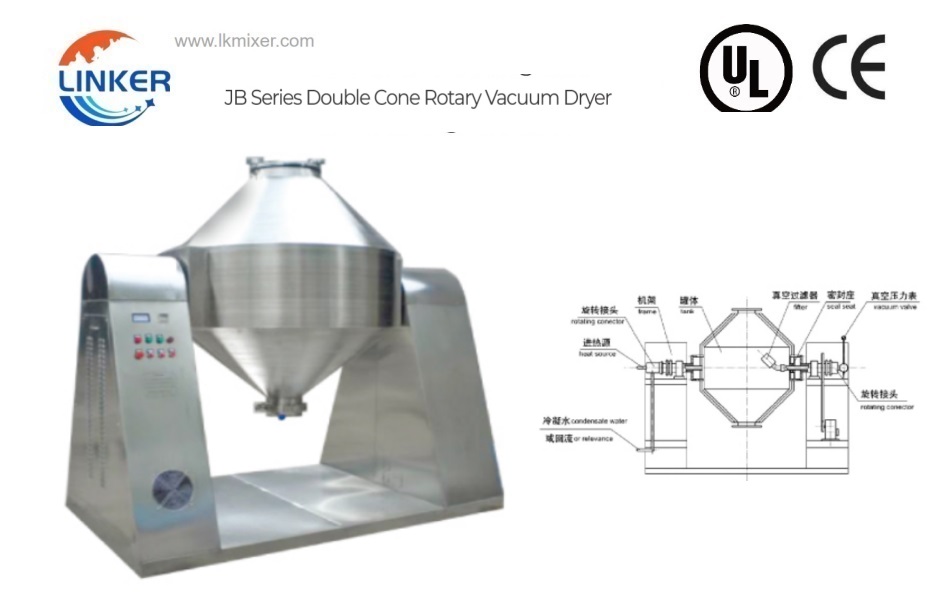

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Electric Cabinet with UL Certification

Cyclone Processor and Motors:

Spare Parts:

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

Operation Instruction

General Provisions

The operation instructions for a commercial grinder may vary depending on the specific model and manufacturer. However, here are some general guidelines that may apply to many high speed grinders:

- Safety precautions: Before operating the high speed grinder, it is important to review all safety precautions and warnings provided in the user manual. Safety precautions may include wearing appropriate personal protective equipment, such as eye protection and hearing protection, and avoiding loose clothing or jewelry that could become caught in the grinder.

- Preparation: The high speed grinder should be placed on a stable and level surface, and all necessary components should be assembled according to the manufacturer’s instructions. The grinder should also be connected to a power source that is appropriate for its voltage and wattage.

- Loading the grinder: The material to be ground should be loaded into the grinder according to the manufacturer’s instructions. Overloading the grinder may cause damage to the machine and result in poor grinding performance.

- Starting the grinder: The grinder should be started according to the manufacturer’s instructions. This may involve pressing a button, turning a dial, or flipping a switch. The user should ensure that their hands are clear of the grinder and that the material to be ground is positioned properly.

- Adjusting the speed and settings: The speed and other settings of the high speed grinder may be adjusted according to the material being ground and the desired outcome. The user should follow the manufacturer’s instructions for making adjustments to the grinder.

- Monitoring the grinding process: The user should monitor the grinding process to ensure that it is progressing smoothly and that the material is being ground to the desired size and consistency. Any issues or abnormalities should be addressed promptly to prevent damage to the machine.

- Shutting down the grinder: When the grinding process is complete, the grinder should be shut down according to the manufacturer’s instructions. The user should ensure that the machine is completely stopped and that all moving parts have come to a complete stop before attempting to clean or service the grinder.

Overall, the operation instructions for a commercial grinder may involve a number of steps and safety precautions. It is important to carefully review the manufacturer’s instructions and follow proper operating procedures to ensure safe and effective use of the machine.

Preparation Work

Before running a commercial grinder, there are several important preparation steps that should be taken to ensure safe and effective operation of the machine. Here are some general guidelines for preparing to run a high speed grinder:

- Read the user manual: The first step in preparing to run a high speed grinder is to carefully read the user manual provided by the manufacturer. The user manual will provide important information about the specific model of grinder being used, including its features, specifications, and safety precautions.

- Select the appropriate grinding wheel: The grinding wheel used in a high speed grinder should be selected based on the material being ground and the desired outcome. It is important to use the correct type of grinding wheel to prevent damage to the machine and ensure optimal grinding performance.

- Inspect the grinder: Before running the grinder, it is important to inspect it for any signs of damage or wear. The user should check for loose or missing components, cracks or other signs of damage to the machine’s housing or other parts, and any other issues that could affect the grinder’s operation.

- Install the grinding wheel: The grinding wheel should be installed according to the manufacturer’s instructions, making sure that it is securely fastened and aligned properly. The user should also check the wheel for any cracks or other signs of damage before installation.

- Secure the workpiece: The workpiece to be ground should be securely clamped or held in place before starting the grinder. This will help to ensure safe and effective operation and prevent the workpiece from becoming dislodged or damaged during grinding.

- Connect the power source: The high speed grinder should be connected to a power source that is appropriate for its voltage and wattage. It is important to use a properly grounded power source to ensure safe and reliable operation of the machine.

- Test run: Before beginning actual grinding operations, it may be useful to perform a test run to ensure that the grinder is functioning properly and that the grinding wheel is aligned and balanced properly. The user should follow the manufacturer’s instructions for performing a test run.

By following these preparation steps, users can ensure safe and effective operation of a high speed grinder and achieve optimal grinding results.

Treatment of inspection

Inspection of a commercial grinder is an important maintenance procedure that helps ensure safe and effective operation of the machine. Here are some general guidelines for inspecting a high speed grinder:

- Disconnect power source: Before performing any inspection or maintenance on a high speed grinder, the power source should be disconnected to prevent accidental startup.

- Check for wear and damage: The user should inspect the grinder for any signs of wear or damage, such as cracks in the housing, worn or damaged grinding wheels, or loose or missing parts. Any issues should be addressed promptly to prevent further damage to the machine.

- Check alignment and balance of grinding wheel: The grinding wheel should be inspected for proper alignment and balance, as these factors can affect the quality of the grinding operation. If the grinding wheel is not properly aligned or balanced, it should be adjusted or replaced as necessary.

- Check for proper lubrication: The high speed grinder should be inspected for proper lubrication, as inadequate lubrication can cause excessive wear and damage to the machine’s moving parts. The user should follow the manufacturer’s instructions for lubrication, and add lubricant as necessary.

- Inspect electrical components: The electrical components of the high speed grinder, including the wiring, switches, and control panel, should be inspected for any signs of wear, damage, or loose connections. Any issues should be addressed promptly to prevent electrical problems.

- Test run: After completing the inspection, it may be useful to perform a test run of the high speed grinder to ensure that it is functioning properly and that any issues have been addressed.

By following these inspection guidelines, users can help ensure safe and effective operation of a high speed grinder and minimize the risk of damage or injury during grinding operations.

Operation Attention

Running a commercial grinder can be a dangerous operation if proper precautions are not taken. Here are some general guidelines for safe operation of a high speed grinder:

- Personal protective equipment: The user should wear appropriate personal protective equipment, such as safety glasses, hearing protection, and gloves, to prevent injury from flying debris, noise, and contact with the grinding wheel.

- Secure workpiece: The workpiece being ground should be securely clamped or held in place to prevent it from becoming dislodged during grinding.

- Use proper grinding wheel: The user should select the appropriate grinding wheel for the material being ground and ensure that it is installed correctly and securely. The grinding wheel should be inspected for cracks or other damage before use.

- Adjust grinding wheel speed: The speed of the grinding wheel should be adjusted according to the manufacturer’s instructions to ensure optimal grinding performance and prevent damage to the machine or workpiece.

- Avoid excessive pressure: The user should avoid applying excessive pressure to the grinding wheel, as this can cause the wheel to overheat and wear out more quickly.

- Avoid overheating: The high speed grinder should not be operated continuously for extended periods of time, as this can cause overheating and damage to the machine.

- Monitor grinding operation: The user should closely monitor the grinding operation to ensure that the workpiece is being ground properly and that the grinding wheel is functioning correctly.

- Disconnect power source: After completing grinding operations, the power source should be disconnected to prevent accidental startup.

By following these guidelines, users can operate a high speed grinder safely and effectively, and achieve optimal grinding results. It is important to follow the manufacturer’s instructions and all applicable safety regulations when operating any type of machinery.

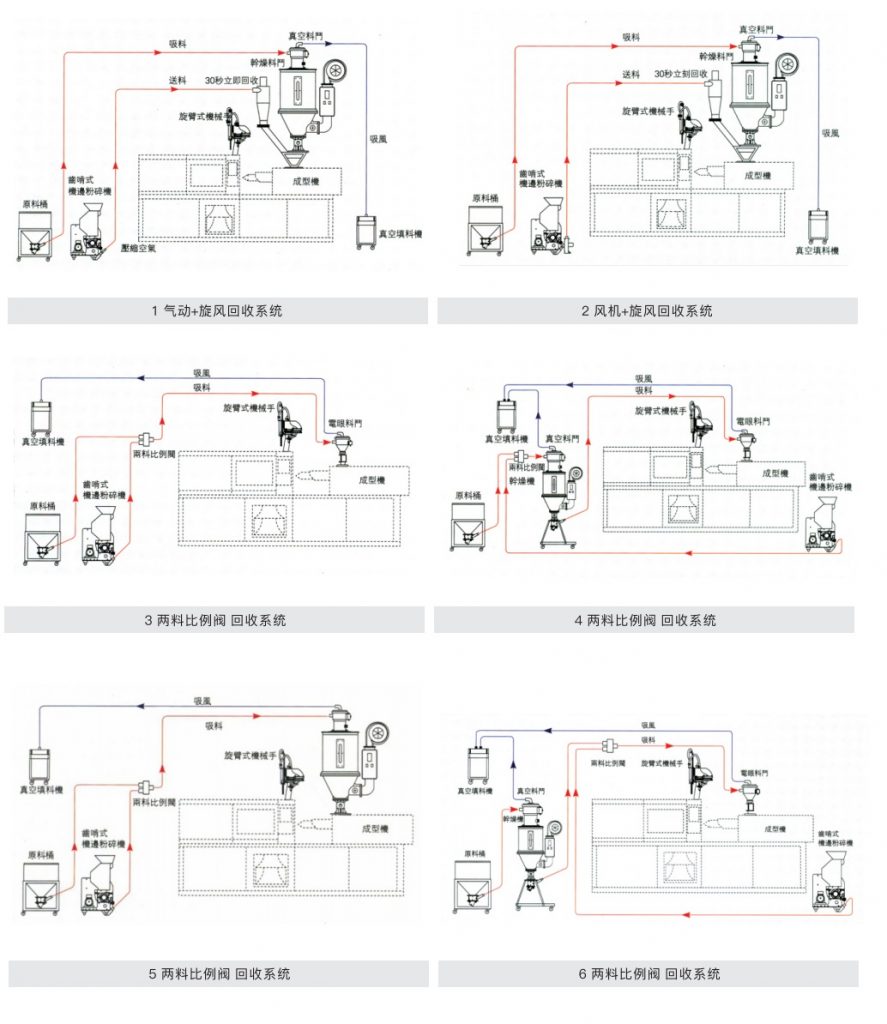

Installation Layout:

Applications of Industrial Seed Grinder

Industrial seed grinders are used in a variety of applications across many industries. Here are some of the most common applications of industrial seed grinders:

- Food industry: Industrial seed grinders are used extensively in the food industry to grind seeds, nuts, and spices into fine powders or pastes. These powders and pastes are then used in a variety of products such as sauces, seasonings, and spreads.

- Pharmaceutical industry: In the pharmaceutical industry, industrial seed grinders are used to grind plant material into a fine powder, which is then used to make medicines and supplements.

- Cosmetics industry: Industrial seed grinders are also used in the cosmetics industry to grind plant material into a fine powder or paste, which is then used in products such as face masks, scrubs, and exfoliants.

- Agricultural industry: Industrial seed grinders are used in the agricultural industry to process seeds, such as soybeans, into animal feed.

- Chemical industry: In the chemical industry, industrial seed grinders are used to grind materials such as resins, pigments, and dyes into a fine powder.

- Renewable energy industry: Industrial seed grinders are also used in the renewable energy industry to process biomass into a fine powder, which is then burned to generate electricity.

Overall, industrial seed grinders are versatile machines that are used in many different industries for a variety of applications. They are essential for processing plant material into fine powders and pastes that can be used in many different products.

Customization Seeds Grinder According to your Capacity:

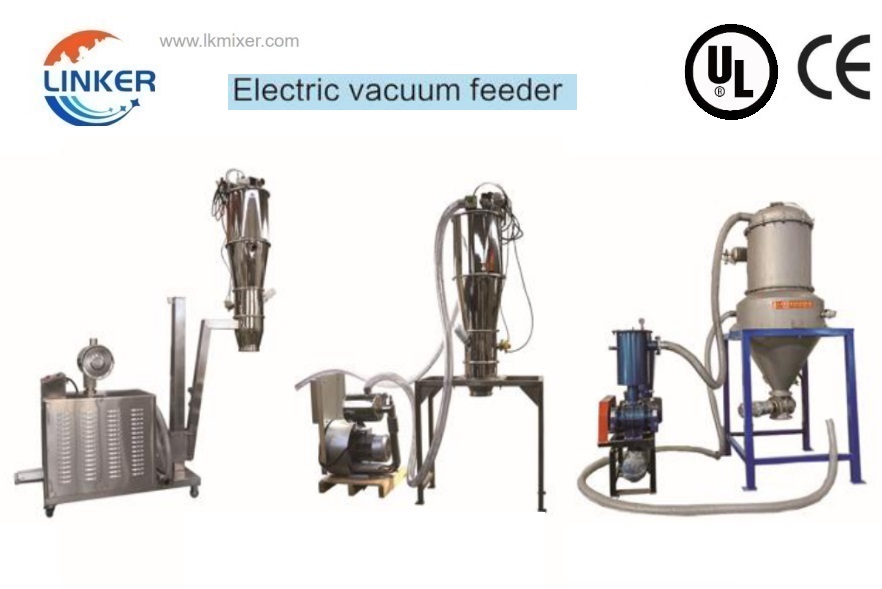

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

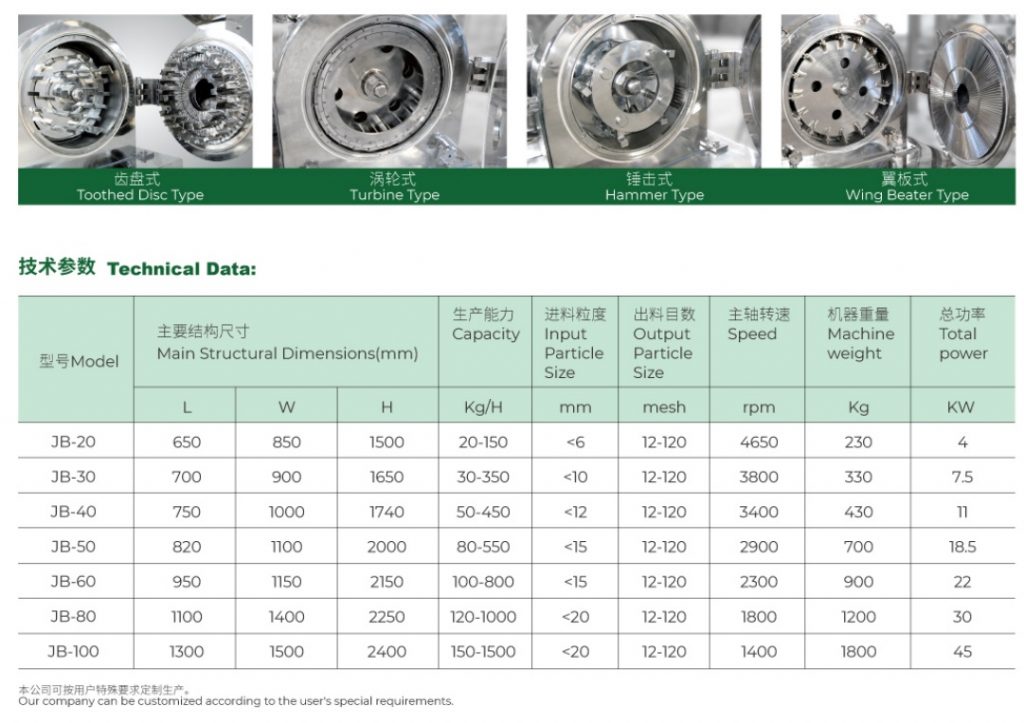

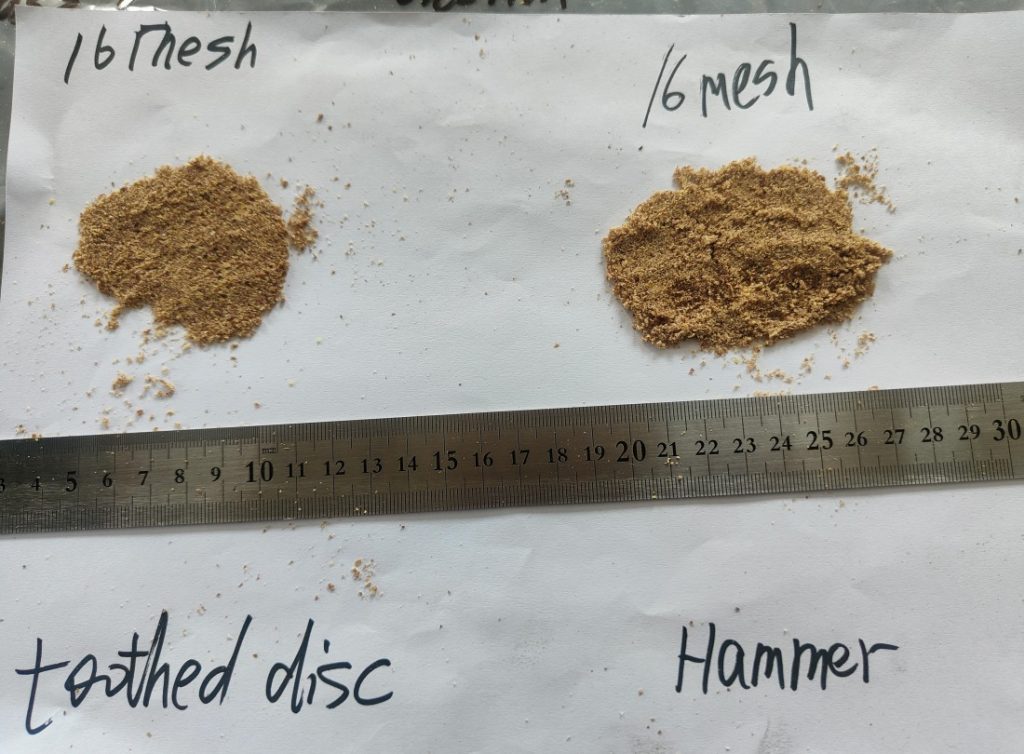

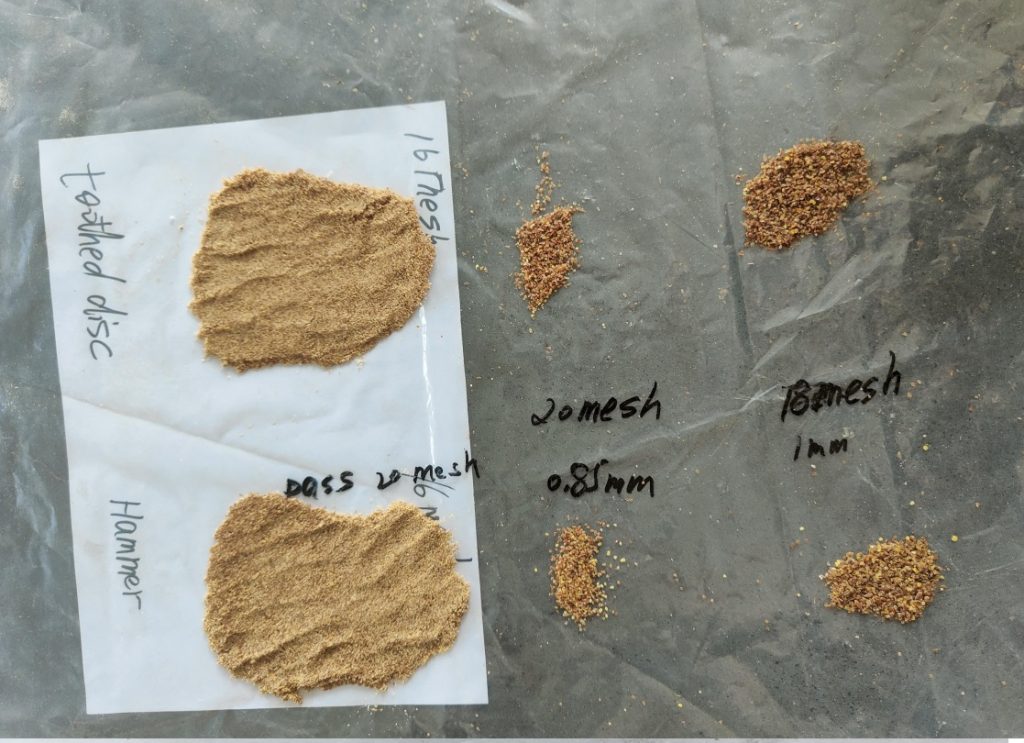

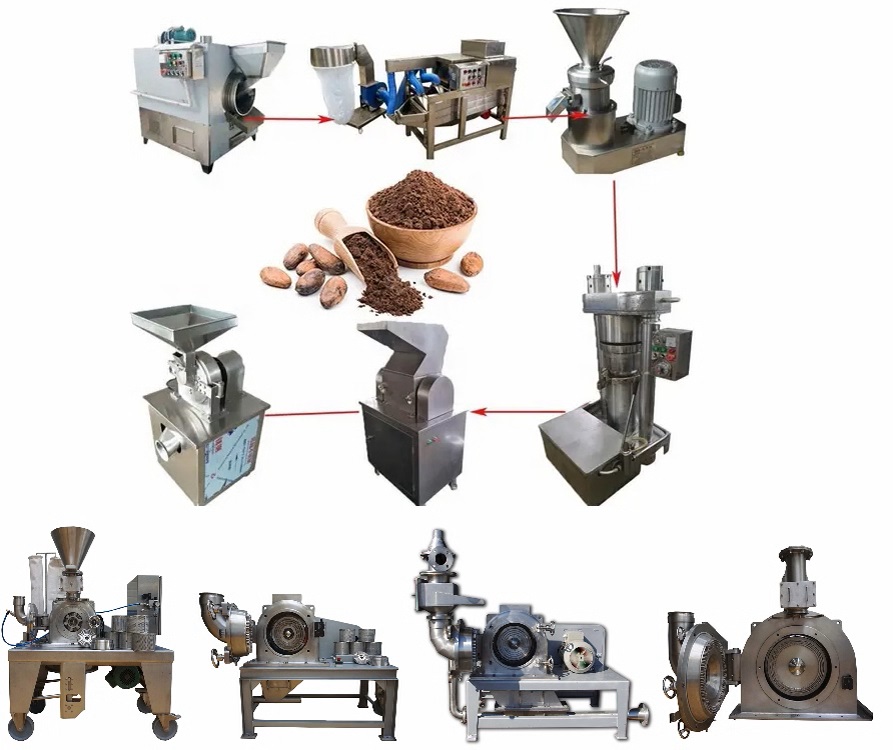

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com