Commercial Sugar Grinder WF Impolse

Sugar Crusher & Grinder

- Application: To grind sugar to powder, suitable for various grains;

- Mesh: 0.5-730mm, 20-320 mesh, <10μm;

- Cutting knife type: hammer type, cutter type;

- Motor: electric;

- Raw material: stainless steel; ceramic;

- Price: $ 800~48,000.

What is a Commercial Sugar Grinder?

A commercial sugar grinder, also known as a commercial sugar mill, is a machine used in the food processing industry to grind granulated sugar into a fine powder. It is commonly used in the production of confectionery, baked goods, and other sweet treats. The grinder typically consists of a rotating shaft with multiple blades or burrs that crush and grind the sugar into a uniform powder. Commercial sugar grinders come in various sizes and capacities to meet the needs of different food manufacturers and can be manually operated or fully automated.

“Sugar” this word actually means much more than we commonly understand. Normally we think about “Saccharose” and know always as “Sugar”. Sugar is greatly grind for various usages, such as for chocolate, jams or jellies, ice cream, drinks or bakery products, like cookies.

Sugar crusher machine has becomes the universal equipment especially used widely in sugar and salt production. Fine grind sugar make sure very short time for melting during the process. And it can be used also to decorate desserts. Various particle sizes are requested for various usage. And LK Mixer can tally meet those various requirements.

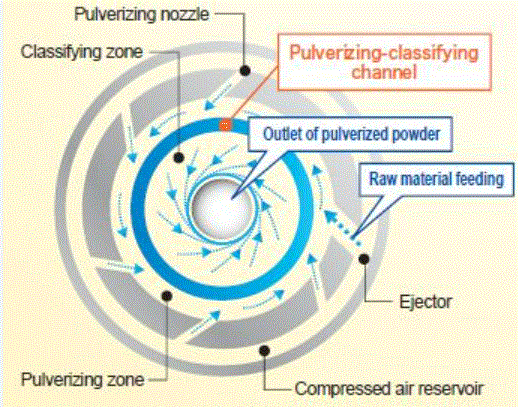

In the past, only conventional pin mills were used. Today, considerably higher throughputs can be obtained using so-called blast mills.

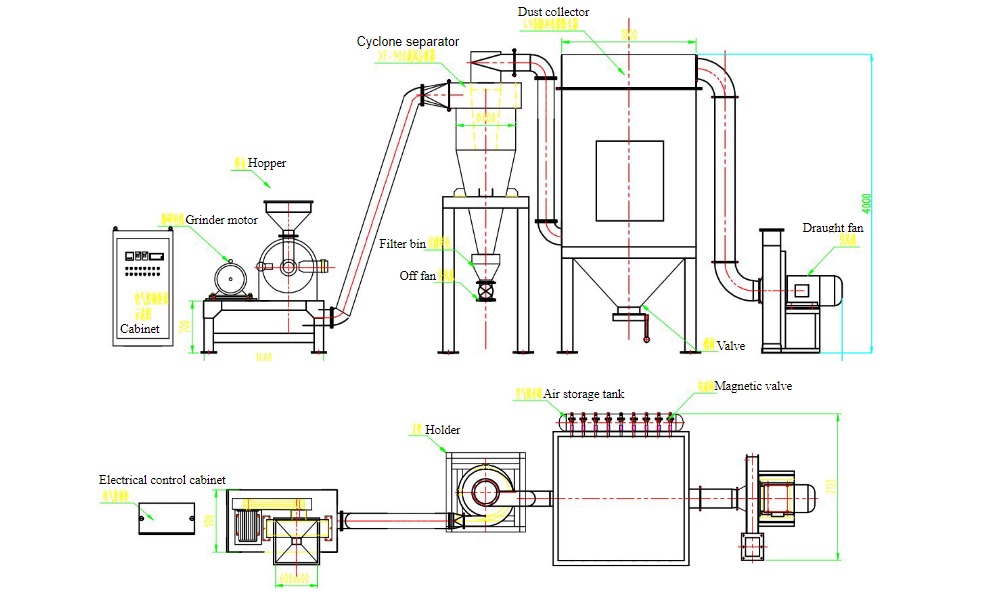

Consists of 4 major portions:

Pim Mill, Pneumatic conveying system, Blower & dust collector, and Rotary airlock valve. The Sugar Crusher & Grinder complete system make sure the retention of the properties of Sugar such as color and taste. At the same time, it is with no dust to protect well for enviornment. Sugar can be designed to ground to two stages. First stage is to do coarse grinding, and then the sugar goes to second stage for re-grinding into more fine particles and powders. Finally, sugar goes for packing.

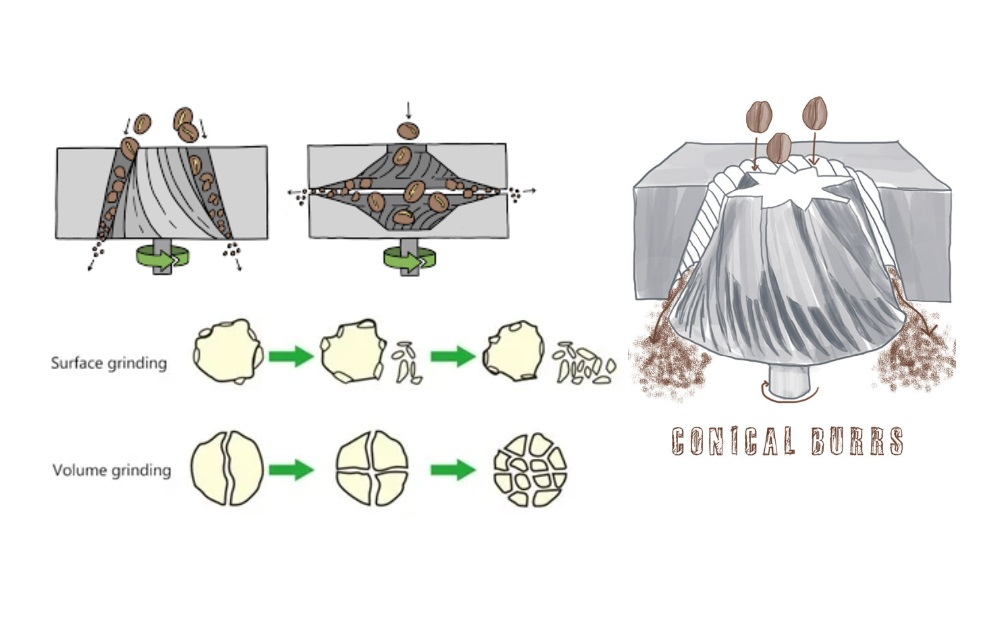

According to the size of the crushed material, coffee grinding machine can be divided into coarse crushing, and also the ultra- fine crushing.

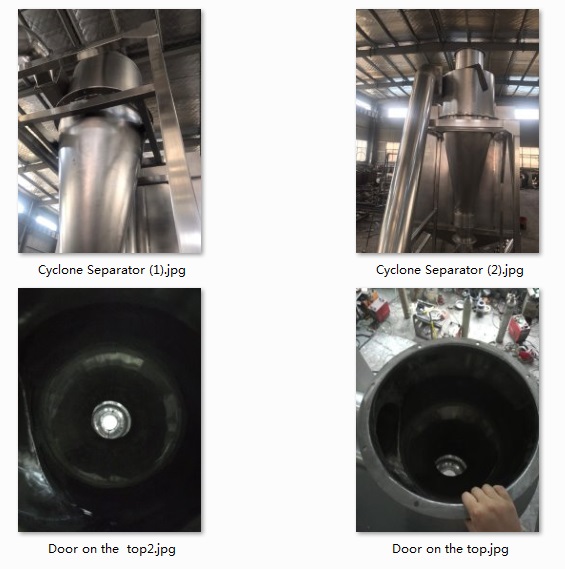

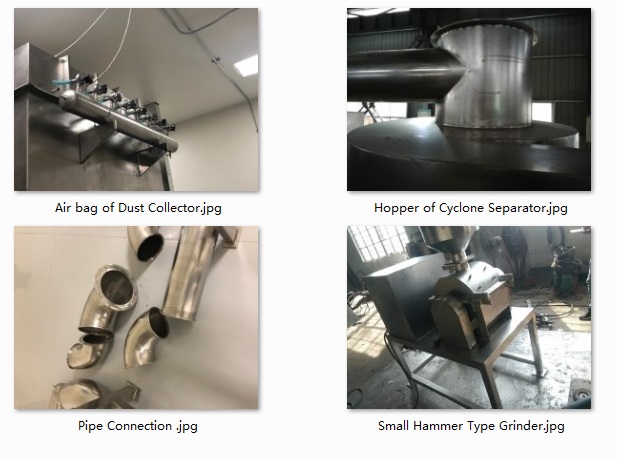

Corn grinder machine, cyclone separator, dust colloector and rotary valve, these portions consists of dust collector grinder group to achieve the purpose of the crusher in the form of high-speed and high effect impact.

Hopper or Feed Inlet

Hopper is for raw material feeding to the grinding machine. We have automatically feeder that can totaly automatic transfer the raw material into the Hopper of the grinding machine. This is the parts that beginning of the process.

Crushing Chamber

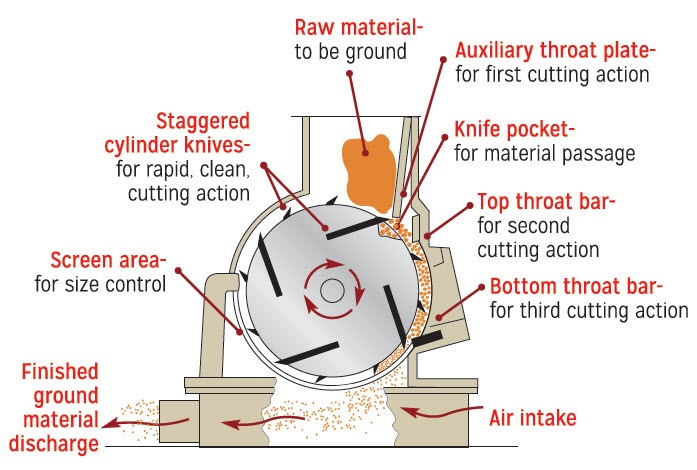

Chamber is working chamber, this is the part that the powders and materials are grind down into powders.

Door or Window

The door or window that observable. This two parts helps us can see clearly the inner working status of chamber. With this two parts you can know if the whole working process are in normal running or not.

Mesh Screen

The screen is part of filters for powder in mm or in mesh. We have vibrating table which can connect with the output of the outlet of grinder, so that can realize automatically production line.

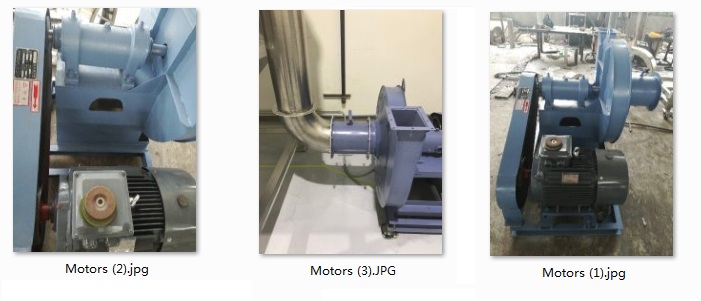

Motor

Motors we have UL Certification, CE Certification or if any Certification you need, we can book the Certification motors for you. So Please kindly let us know if the voltage and motors certification need customization when you send inquiry to us.

Cooling Component (There are 3 types of cooling system):

1.Water cooling Jacket:

Cooling parts are double wall jacket for cool water,

2. Air cool inlet:

also have inlet of cool air for cooling system to keep the temperature in a settle degree. Such as to keep the grinding process temperature in -4~-8 degrees centigrade. The air inlet can connect directly with the air cooler machine.

3. Liquid nitrogen cooling

Liquid nitrogen cooling is a process of using liquid nitrogen (LN2) to cool or freeze materials and equipment. Liquid nitrogen is a colorless, odorless, and extremely cold substance that boils at -196°C (-320.8°F) at atmospheric pressure. When used for cooling purposes, liquid nitrogen is typically stored in a vacuum-insulated container, such as a dewar flask, to prevent it from boiling off too quickly.

The process of liquid nitrogen cooling involves transferring the liquid nitrogen to a cooling chamber or container, where it evaporates rapidly and removes heat from the surrounding materials. This rapid evaporation creates a cooling effect that can be used to cool or freeze various materials, such as food products, electronics, and biological samples.

Liquid nitrogen cooling is commonly used in a variety of industries, including food processing, biotechnology, and electronics. In food processing, it can be used to rapidly freeze food products to preserve their quality and freshness. In biotechnology, it is used to preserve biological samples and to cool equipment during experiments. In electronics, it is used to cool computer chips and other components to improve their performance and reliability.

4. Discharge Port

The discharge port if for material result granules output. It is the finish of grinding and before screening. The grinder discharge port is the outlet or opening on a grinder machine through which the ground material exits the grinding chamber and is collected. It is typically located at the bottom of the grinding chamber and may be connected to a collection container or system. The size and shape of the discharge port can vary depending on the type and model of the grinder machine, as well as the intended application. In some cases, the discharge port may be adjustable to control the size and consistency of the ground material being produced. Proper design and management of the discharge port are critical to ensuring the efficient operation of the grinder machine and achieving the desired particle size and consistency of the ground material.

Cinnamon Sugar Grinder:

A cinnamon sugar grinder is a type of commercial grinder that is specifically designed for grinding cinnamon sticks and granulated sugar together to create a fragrant and sweet seasoning blend. Cinnamon sugar is a popular seasoning that is commonly used in baking and dessert recipes, as well as on toast, pancakes, and other breakfast foods.

Cinnamon sugar grinders typically feature a specialized grinding mechanism that is designed to handle the tough and fibrous texture of cinnamon sticks, as well as the granulated texture of sugar. The grinder may also feature a heating element or other mechanism to help release the natural oils and flavors of the cinnamon during the grinding process.

To use a cinnamon sugar grinder, the operator simply feeds cinnamon sticks and granulated sugar into the machine through the feeding mechanism. The grinding mechanism then grinds the cinnamon sticks and sugar together into a fine powder, which is collected in a container or receptacle at the bottom of the machine. The resulting cinnamon sugar blend can be used immediately or stored for later use.

Cinnamon sugar grinders are commonly used in commercial bakeries, restaurants, and food production facilities, as well as in home kitchens. They are an efficient and convenient way to create a high-quality cinnamon sugar blend with consistent particle size and flavor.

Home Sugar Grinder

A home sugar grinder is a kitchen appliance that is designed for grinding granulated sugar into a fine powder for use in baking and cooking. Home sugar grinders are typically compact, easy to use, and affordable, making them a popular choice for home bakers and cooking enthusiasts.

Home sugar grinders may feature a variety of grinding mechanisms, including blades, burrs, or even mortar and pestle-style grinding. Some models may also include adjustable settings for controlling the particle size of the ground sugar.

To use a home sugar grinder, the operator simply adds granulated sugar to the grinder and activates the grinding mechanism. The ground sugar is then collected in a container or receptacle, ready to be used in a variety of recipes.

In addition to grinding sugar, many home sugar grinders can also be used to grind other dry ingredients such as spices, coffee beans, and nuts, making them a versatile tool in the kitchen.

When choosing a home sugar grinder, it is important to consider factors such as size, durability, and ease of use. Some models may also include additional features such as built-in scales or timers to help streamline the baking and cooking process.

Overall, a home sugar grinder can be a valuable addition to any kitchen, providing a convenient and efficient way to create high-quality powdered sugar for a variety of culinary applications.

Working Principle and Layout of Commercial Sugar Grinder:

The working principle of a commercial sugar grinder involves the crushing and grinding of granulated sugar into a fine powder. The machine typically consists of a hopper or feeder that feeds the sugar into the grinding chamber, where it is crushed and ground by rotating blades or burrs. The ground sugar is then collected in a receptacle or container at the bottom of the machine.

The layout of a commercial sugar grinder can vary depending on the specific model and manufacturer. However, most sugar grinders will have a similar layout that includes the following components:

- Hopper or feeder: This is the top part of the machine where granulated sugar is loaded into the grinder. It can be a simple funnel-shaped opening or a more complex mechanism that regulates the flow of sugar into the grinding chamber.

- Grinding chamber: This is the part of the machine where the actual grinding takes place. It contains rotating blades or burrs that crush and grind the sugar into a fine powder.

- Motor: The motor is what powers the rotating blades or burrs in the grinding chamber. It can be located inside the machine or mounted externally.

- Collection container: This is the receptacle or container where the ground sugar is collected after it has been processed by the grinder. It can be located at the bottom of the machine or connected to a separate collection system.

- Control panel: Some commercial sugar grinders may include a control panel that allows the operator to adjust the speed and other settings of the machine.

Overall, the layout and components of a commercial sugar grinder are designed to efficiently and effectively grind granulated sugar into a fine powder for use in various food products.

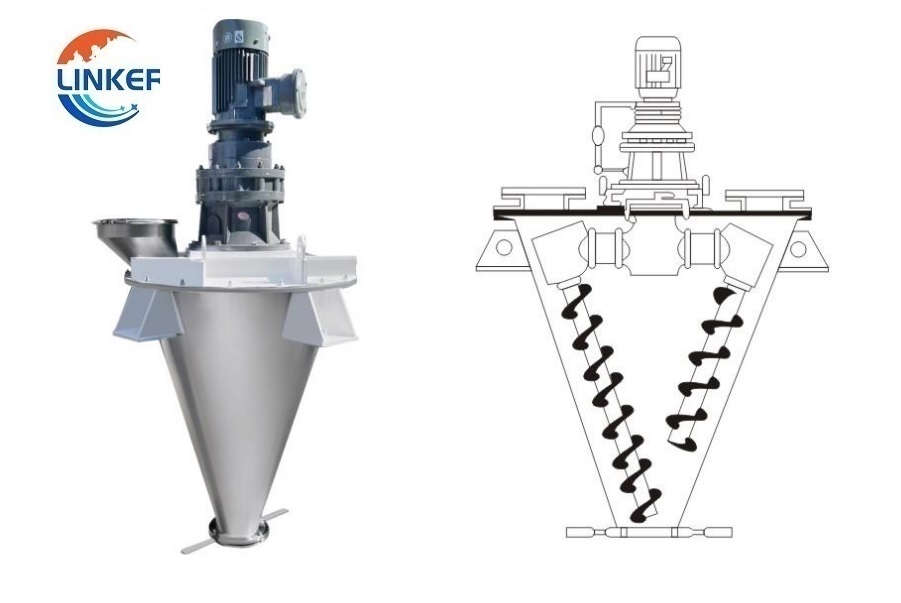

Ultra-fine Grinder Layout

Sugar Grinder Showcase and Ultra-fine grinder Working Principle Video

Working Principle is : By ways of relative motion between movable and fixed plates, the material is grind by the impact and friction of the teeth plate. The particles goes to the cyclone separator and particles output by separator. Automatic unloading pulse dust removal coarse crusher the dust goes to the dust collector.

Application of Commercial Sugar Grinder:

Commercial sugar grinders are commonly used in the food processing industry to grind granulated sugar into a fine powder for use in various food products. Some of the most common applications of commercial sugar grinders include:

- Confectionery: Sugar grinders are used in the production of confectionery products such as candies, chocolates, and chewing gum.

- Baked goods: Sugar powder is often used in the production of baked goods such as cakes, pastries, and cookies.

- Beverages: Sugar powder is commonly used as a sweetener in hot and cold beverages such as coffee, tea, and smoothies.

- Desserts: Sugar powder is used to sweeten and decorate desserts such as ice cream, pudding, and fruit salads.

- Pharmaceutical industry: Sugar grinders are also used in the pharmaceutical industry to grind sugars for use in various medications.

Overall, the commercial sugar grinder is an essential tool in the food processing industry for producing fine sugar powder for a wide variety of applications.

What Other Food Products Can an Icing Sugar Grinding Machine Work On? What are Sugar Crusher & Grinder used for?

Sugar Grinding machine are in very wide usage which is suitable for the pharmaceutical, chemical metallurgy, food and other industries. It can grind for other powders and particles.

As a matter of fact, you can also use these icing sugar grinding machines for other powders and particles. In fact, here’s a table of some of the most common applications of this type of grinding equipment.

Features:

The Sugar Grinder and Crusher is mainly used to process brown sugar, ice sugar into final size around 60-380 mesh. Result mesh is adjustable.

| Model No. | WFJ, WF, CSJ, | Automatic Grade | Automatic |

| Cylindrical Grinder Type | Universal Cylindrical Grinder | Precision | High Precision |

| Certification | ISO 9001, CE, SGS, ISO, GMP | Condition | New |

| Name | Large grinder, Industrial grinder, superfine high efficiency mill, | Other Name | Stainless Steel Grinder; Multi-Use Grinding Machine |

| Dust Collection | Bag Filter | Mesh Size or mm size | 0.5-730mm, 20-320 mesh, <10μm |

| Separator | Cyclone Separator | Material | SUS304 SUS316 |

| Power | 380V 220V 415V; or any customize according to request. | Production | Continuous |

| Shipping Method | By Sea | Grinder Chamber | Turbo type; window type |

| HS Code | 8479820090 | Transport Package | Wooden Case and container, or Bulk shipment |

| Trademark | LINKER | Origin | JiangSu, China |

| Production Capacity | 5000Set/Year | Warranty | 1 year |

| After-sales Service: | Technical Support; on-line teach lessons | Processing Object | Curve |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

Since over decades, LINKER has always dedicate itself in solving the problems of manufacturer in production process. Our machine are reliable, easy-to-maintain, and also very expertly crafted and suited for grinding heat-sensitive materials. At the same time, the dust collector control and protect the environment. LINKER Sugar Crusher & Grinder provide a one-step solution for the whole production line, from the sugar material input, to crush and output. Also Packing machines after the grinding process.

As a professional Industrial Sugar Grinder manufacturer and factory in China, we LINKER manufacture and supply various kinds of large Industrial Sugar Grinder with high quality and high efficiency. Our main products including Grinding Machine, Industrial Mill, Industrial Pulverizer, Electric Dryer, Automatically Screw Feeder, Belt And Screw Conveyor for Raw Materials, Vibration tables for screen,Z Type Elevator, Ribbon Blender and mixer,Salt Crushing Machine, Food Chopper, Pulse Jet Dust Collector, Auto Batching System, Rotary Dryer, Masala Processing Plant, Rotary Airlock Valve, Rotary Sieve, Vibro Sifter, Waffle Maker, Electric Deck Oven, Display Counters, Chicken Feather Cleaning Machine, Packing Machines, Oil Dryer, Diesel Bhatti, Kitchenware Products, etc. We provide to our customer with high quality and reasonable price.

Our workers and employees are well trained with over decades of experience who knows very well about Pulverizer whole production line. We are reliable small and large industrial sugar grinder supplier for you from China.

Certifications:

Electric Cabinet with UL Certification

Cyclone Processor and Motors:

Spare Parts & Accessories:

Other Pictures(Cyclone separator, Dust Collector, Electric Cabinet, Main grinding machine, Motors)

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

Large Machine Packing:

Recommend Industrial Sugar Grinders:

Recommend Other Food Mill:

Recommend Other Commercial Grinder:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

1. Packaging Details

For small machine, we pack it Fumigation wooden box or container with export standard package. For super big machine, we normally separate the machine into several parts and pack it with raping film. and then we fix the parts in container with steel to avoid any shaking or moving during the shipping.

2. How to get quotation quickly

In order to get the right model for you and provide accurate quotation exact meet your real situation, please kindly provide the following information when you send inquiry: 1. What is your Grinding materials:Like chili, sugar, herbs…etc 2. What is the raw material size before grinding? :Such as 10 mm,15 mm…etc 3. What is your expect capacity: Like 50 kg/hr, 300 kg/hr,500 kg/hr..etc 4. What is the Grinding fineness of the result particles? mm mm (for example:0.8 mm) 5. Do you need to customize the Voltage according to your country real situation? to say write down :______V, Frequency:______HZ, phase 6. How about the Contact material 304/SS304/316L stainless steel?

3. What are your terms of payment?

Our terms of payment is 50% T/T in advance and 50% T/ T before shipment.

4. Do you inspect the finished products?

Yes. Before shipment 100% of inspection is necessary. We always do the sample test and send videos to you for your shipment confirmation of green light. We will not do the shipment before receiving your green light. Each step of products will be carried out by QC department until shipping.

5. How Fine Can an Icing Sugar Grinding Machine Grind?

Various model of sugar grinding machines yields different results. Therefore, it’s important for us to confirm which model is right for you to buy and purchase.

The size of measurement for fineness of sugar is in “mesh”. Normally, sugar crusher and grinding machines can produce range of mesh from 50 to 200. High quality sugar crushing and grinding machines can produce the sizes of mesh between 300 to 350 mesh.