CRYFS-450 Industrial Peanut Grinder

Seasam and Peanut Grinder

- Feeding Granularity: 10~15mm;

- Powder Size: 20-40mesh

- Capacity: 60-2000kg/h

- Motor Power (KW): 4-30kw;

- Axis Rotating Speed(r/min):2200~5300;

- Dimension(mm):500*500*1200~1800*1200*2500.

- FOB Unit Price: 1 unit $ 2,862~17,538. More than 5 units: $2,585~1,5785 Video

- Application: metal, Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

I. Introduction

Industrial Peanut Grinder:

An industrial peanut grinder is a heavy-duty machine used to crush and grind large quantities of peanuts. It’s commonly used in factories or big kitchens to make things like peanut butter or peanut flour. These grinders are really strong and can handle a lot of peanuts at once, making the process faster. They can also be adjusted to make the peanuts finely ground or a bit chunkier, depending on what’s needed. These machines are super important for making peanut products in big amounts for businesses that sell food.

Types of Peanut Grinder:

There are a few different types of peanut grinding machines that serve various purposes. Here are a couple of common ones:

Peanut Butter Mills: These machines are specially designed to turn peanuts into creamy peanut butter. They have powerful motors and grinding components that crush the peanuts into a smooth paste. Some models also allow you to adjust the texture of the peanut butter, so you can make it chunkier or smoother according to your preference.

Peanut Flour Grinders: Peanut flour is often used in baking and cooking. Peanut flour grinders are designed to finely grind peanuts into a powder-like consistency. These machines are equipped with mechanisms that can create a very fine texture, which is ideal for incorporating peanut flavor into various recipes.

Commercial Nut Choppers: While not exclusive to peanuts, these machines are capable of chopping peanuts into smaller pieces, suitable for adding to salads, baked goods, or garnishing dishes. They offer versatility in achieving various nut sizes and textures.

Multi-Purpose Food Processors: Some heavy-duty food processors come with grinding attachments that can handle peanuts and other nuts. These machines offer flexibility in the types of food they can process and can be used for various grinding needs.

Industrial Grinding Systems: In larger food production facilities, industrial grinding systems might be used. These are highly efficient machines capable of processing large quantities of peanuts and other ingredients to create products like peanut butter, spreads, and nut-based pastes on a commercial scale.

These different types of peanut grinding machines cater to specific culinary and commercial requirements, making peanut processing more versatile and efficient across different industries.

III. Design and Construction of a Industrial Peanut Grinder:

An industrial peanut grinder has a specific design and various components that work together to efficiently process peanuts. Here’s an explanation of its design and key parts:

Design:

An industrial peanut grinder is typically designed for heavy-duty use in commercial settings. It aims to crush and grind a large volume of peanuts into different textures, like peanut butter or flour. The design focuses on durability, efficiency, and ease of use.

Components:

In summary, an industrial peanut grinder has a well-thought-out design with components like the hopper, grinding chamber, motor, grinding mechanism, adjustable settings, cooling system, safety features, discharge chute, frame, and cleaning access. All these components work together to efficiently process peanuts and create various peanut-based products on a larger scale.

Working principle of Industrial Peanut Grinder:

The working principle of an industrial peanut grinder is quite straightforward. Imagine a machine with strong blades or discs inside that spin really fast. Here’s how it works:

Loading Peanuts: You start by putting a bunch of peanuts into the machine’s hopper, which is like a big container where the peanuts go in.

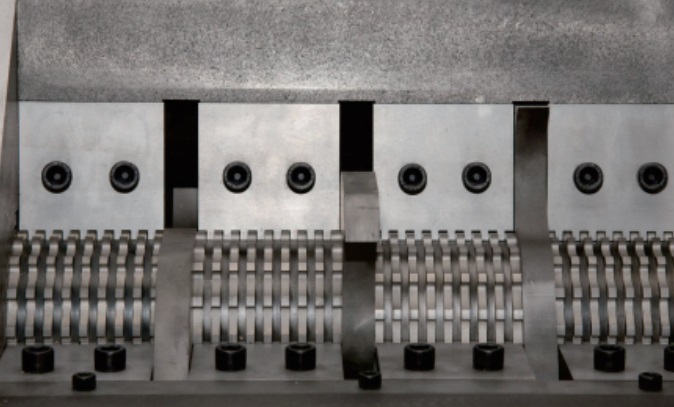

Feeding Mechanism: The peanuts are then fed into the grinding chamber, which is where the action happens. This chamber has those fast-spinning blades or discs we talked about earlier.

Grinding Action: As the peanuts move into the grinding chamber, the spinning blades or discs grab hold of them and break them down into smaller pieces. Imagine it like the blades chopping the peanuts into tinier and tinier bits.

Friction and Pressure: As the peanuts get chopped up, there’s a lot of friction and pressure happening. This causes the peanuts to release their natural oils and turn into a paste-like consistency. This is the stage where peanuts start turning into peanut butter.

Adjusting Texture: The machine often has settings that let you control how fine or chunky you want the end product to be. So, if you’re making peanut butter, you can adjust it to be really smooth or a bit thicker, depending on your preference.

Collection: Once the peanuts are ground to the desired texture, they move through a chute and are collected in a container. This could be a big tub or something similar.

Cooling: Grinding can create some heat, so some machines have ways to keep things cool, ensuring the quality of the final product.

Repeat: The process keeps going as long as you keep adding peanuts to the hopper. The powerful motor and the grinding mechanism work together to handle a lot of peanuts without getting tired.

So, in a nutshell, an industrial peanut grinder takes in peanuts, grinds them up with fast-spinning blades or discs, and depending on the settings, turns them into products like peanut butter or flour. It’s like a peanut-smashing machine that’s designed to make lots of peanut-based goodies efficiently!

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Electric Cabinet with UL Certification

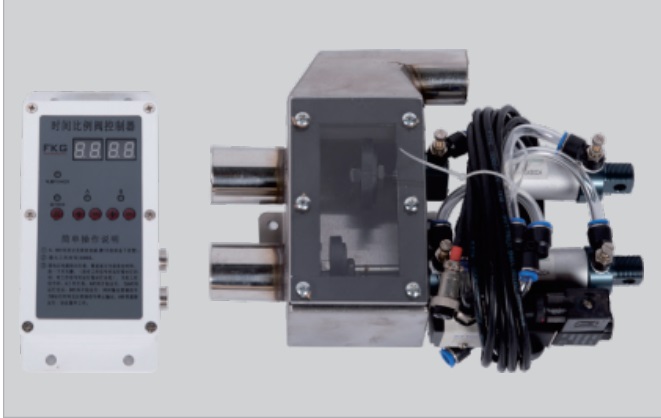

Cyclone Processor and Motors:

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small machines for sea shipment, it is important to take measures to ensure that the machines are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small machines for sea shipment:

- Clean and dry the machine: Before packing, the machine should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the machine in protective material: The machine should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the machine in a sturdy box: The wrapped machine should then be placed in a sturdy box that is appropriate for the size and weight of the machine. The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the machine from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the machine’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small machine in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large Machine Packing:

Packing a large machine for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large machine for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large machine for sea shipment:

- Clean and prepare the machine: Before packing, the machine should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the machine to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the machine from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the machine from moving or shifting during transit.

- Securely fasten the machine: The machine should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the machine’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large machine for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the machine arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the machine is properly packed and prepared for sea shipment.

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

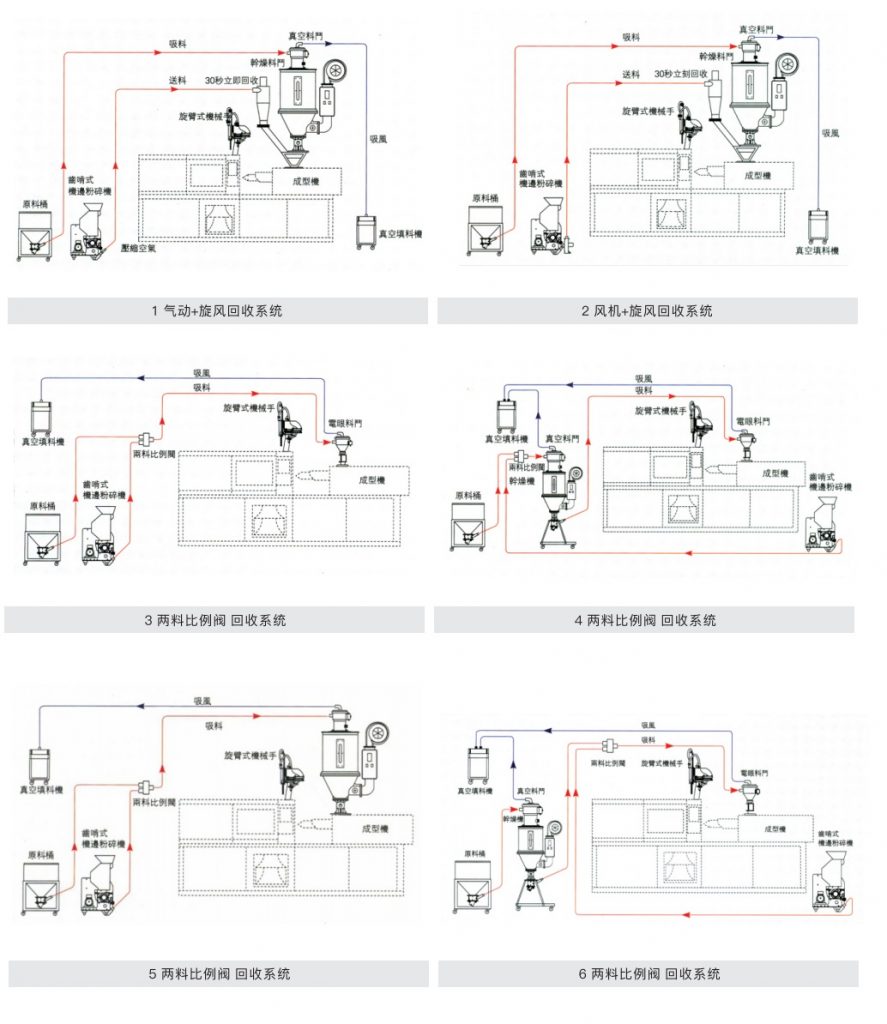

Installation Layout:

Maintenance and Safety Measures

Proper maintenance practices for the machine

Proper maintenance practices are essential for ensuring the efficient and safe operation of a universal grinder. Here are some maintenance practices that should be followed:

- Regular cleaning – The machine should be cleaned regularly to remove any debris, dust, or coolant that may accumulate on the machine’s surfaces. This can be done using a soft brush, air hose, or a cleaning solution.

- Lubrication – The machine’s moving parts should be lubricated regularly to reduce friction and wear. The manufacturer’s recommendations for lubrication intervals and types should be followed.

- Inspection – The machine should be inspected regularly for any signs of wear, damage, or misalignment. Any issues should be addressed immediately to prevent further damage or safety hazards.

- Replacement of worn or damaged parts – Worn or damaged parts should be replaced immediately with genuine parts from the manufacturer.

- Calibration – The machine should be calibrated regularly to ensure that it is operating within the specified tolerances and accuracy.

- Operator training – Proper operator training is essential for ensuring the safe and efficient operation of the machine. Operators should be trained on the proper operation, maintenance, and safety procedures for the machine.

- Record keeping – A maintenance log should be kept to track the machine’s maintenance history, including cleaning, lubrication, inspection, and repairs. This can help identify any trends or issues that need to be addressed.

Following these maintenance practices can help ensure the safe and efficient operation of a universal grinder, prolong its lifespan, and reduce the risk of downtime and costly repairs.

Safety measures for operators and workers

Safety measures for operators and workers are crucial when using a universal grinder. Here are some safety measures that should be followed:

- Personal protective equipment (PPE) – Operators and workers should wear appropriate PPE, including safety glasses, hearing protection, gloves, and safety shoes.

- Machine guards – The machine should be equipped with proper machine guards to prevent access to the grinding wheel during operation. The guards should be in good condition and properly installed.

- Lockout/tagout procedures – Lockout/tagout procedures should be followed to ensure that the machine is not accidentally started or energized during maintenance or repair.

- Training – Operators and workers should receive proper training on the safe operation of the machine, including the use of PPE, machine guards, and lockout/tagout procedures.

- Inspection – The machine should be inspected regularly for any signs of wear, damage, or misalignment that may pose a safety hazard.

- Proper use of grinding wheels – Operators should ensure that the grinding wheel is properly installed, dressed, and aligned. The grinding wheel should not be overloaded or forced into the material being ground.

- Proper handling of coolant – If coolant is used, operators should ensure that it is properly mixed, applied, and contained. Coolant should not be allowed to accumulate on the floor, as it can create a slipping hazard.

- Emergency procedures – Emergency procedures should be established and communicated to all operators and workers in case of an accident or injury.

Following these safety measures can help prevent accidents and injuries when using a universal grinder. It is important to prioritize safety and ensure that all operators and workers are trained and informed about the potential hazards of the machine.

Universal Food Grinder:

The Universal Food Grinder is a versatile kitchen tool that can grind and mince a variety of foods, including meat, vegetables, nuts, and fruits. It is a manual hand-crank grinder that is easy to use and clean, with a sturdy construction that ensures long-lasting durability.

The Universal Food Grinder comes with different sized grinding plates, allowing you to choose the coarseness of your grind and achieve the desired texture for your dishes. It is also easy to disassemble, making it easy to clean and maintain.

Overall, the Universal Food Grinder is a great addition to any kitchen, providing a quick and easy way to grind and mince food for a variety of dishes, from meatballs and burgers to salsa and dips.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Universal Grinder Youtube Video (See More)

FAQ(Click and See More)

How does a peanut grinder work?

How Does a Peanut Grinder Work? A Nutty Transformation

Have you ever wondered how those tasty spreads like peanut butter come to life? Well, it’s thanks to a nifty machine called a peanut grinder. This magical device takes ordinary peanuts and turns them into smooth, creamy goodness. Here’s how it works:

Step 1: Loading Up:

You start by putting raw peanuts into the machine. This is like putting ingredients into a cooking pot.

Step 2: Grinding Chamber:

Inside the machine, there’s a special area called the grinding chamber. It’s like a secret workshop where the peanuts go to change.

Step 3: The Action Begins:

The machine uses something like blades or discs that spin really fast. These blades are like the superhero helpers that do the hard work.

Step 4: Breaking Down:

As the peanuts go into the grinding chamber, the fast-spinning blades or discs chop them up. It’s like they’re breaking the peanuts into small pieces.

Step 5: Oils Are Released:

As the peanuts get chopped up, they start releasing their natural oils. This is what makes peanut butter smooth and creamy.

Step 6: Texture Magic:

The cool thing is, you can adjust the machine to make the peanut butter smooth or chunky. This is like having a remote control for the texture of your spread.

Step 7: Collection Time:

After the peanuts are all chopped and the oils are out, the peanut butter is ready. It comes out of the machine and you can collect it in a container.

What is the best tool for making peanut butter?

The best tool for making peanut butter at home is a food processor. A food processor is like a versatile kitchen gadget that can chop, blend, and grind ingredients. When it comes to making peanut butter, a food processor’s powerful motor and sharp blades are ideal for breaking down peanuts into a creamy and smooth consistency.

Here’s why a food processor is a great choice:

Powerful Motor: A food processor usually has a strong motor that can handle the tough task of grinding peanuts. This ensures that the peanuts get blended thoroughly without straining the machine.

Sharp Blades: The sharp blades in a food processor are designed to crush and grind ingredients effectively. When you’re making peanut butter, these blades break down the peanuts into tiny pieces, releasing their natural oils and turning them into a smooth paste.

Texture Control: Most food processors come with settings that allow you to control the processing time. This means you can choose how smooth or chunky you want your peanut butter to be by adjusting the processing time according to your preference.

Ease of Use: Using a food processor is pretty straightforward. You just add the peanuts and let the machine do the work. It’s a convenient way to make homemade peanut butter without a lot of effort.

Versatility: Beyond peanut butter, a food processor can be used for various other kitchen tasks, like making sauces, chopping vegetables, or even creating dough. This makes it a versatile tool to have in your kitchen.

Affordability: Food processors come in a range of prices, so you can find one that suits your budget. They’re a good investment for anyone who enjoys making their own nut butters and other culinary creations.

In conclusion, if you’re looking to make peanut butter at home, a food processor is your best bet. Its powerful motor, sharp blades, and texture control make it a reliable tool for transforming raw peanuts into delicious, homemade peanut butter.

Can a meat grinder grind peanuts?

Yes, a meat grinder can indeed be used to grind peanuts. While meat grinders are primarily designed for grinding various types of meats, they can also be repurposed to process other ingredients, including nuts like peanuts. However, there are a few important points to consider if you plan to use a meat grinder for this purpose:

Grinder Type: Electric meat grinders are more suitable for grinding peanuts than manual ones. Electric grinders have more power and can handle the tougher texture of nuts.

Blade and Plate: Ensure that you use the appropriate blade and plate for nut grinding. Meat grinders typically come with different blade and plate sizes for varying meat textures. For grinding nuts, you would want to use a fine plate to achieve a smoother consistency.

Maintenance: Grinding nuts can be a bit more abrasive on the grinder’s parts compared to meat. After grinding peanuts, it’s important to thoroughly clean the grinder to prevent any nut residues from mixing with meat in the future.

Small Batches: It’s advisable to grind peanuts in smaller batches to avoid overloading the grinder and to achieve a consistent texture.

Oil Content: Peanuts contain natural oils that can be released during grinding. While this can contribute to a smoother consistency, be mindful that excessive oil might affect the grinder’s performance. Some people even chill the nuts in the refrigerator before grinding to reduce oiliness.

Texture Control: The texture of the ground peanuts will depend on the type of meat grinder you have and how fine the blade and plate are. You might need to experiment a bit to achieve the desired peanut butter-like consistency.

In summary, while a meat grinder can be used to grind peanuts, it’s important to consider the type of grinder, use the right blade and plate, maintain the machine properly, and be prepared for a different texture compared to using a dedicated nut grinder or food processor. If you plan to grind nuts frequently, investing in a dedicated nut grinder or a powerful food processor might be a more optimal choice.

Can you make peanut butter in grinder?

Absolutely, you can definitely make peanut butter using a grinder! Whether it’s a specialized nut grinder, a food processor, or even a meat grinder, these machines can help you turn plain peanuts into delicious peanut butter. Here’s how:

Prepare the Peanuts: Start by using roasted, unsalted peanuts. If they’re not roasted, you can roast them in the oven for a few minutes until they’re slightly golden and aromatic. Let them cool down before moving on.

Load the Machine: Place the roasted peanuts into the grinder’s hopper or the food processor’s container. Make sure not to overload it; you might need to do this in batches.

Grind Away: Turn on the machine and let it do its magic. The blades or grinding mechanism will break down the peanuts into smaller and smaller pieces. As you grind, the peanuts will release their natural oils, which is what makes the butter creamy.

Texture Control: Depending on the machine and your preferences, you can adjust the processing time to achieve the texture you want. If you like smoother peanut butter, grind for a bit longer; if you prefer it a bit chunky, stop grinding sooner.

Be Patient: The process might take a few minutes, especially if you’re aiming for a really smooth texture. Be patient and let the machine work its charm.

Scraping the Sides: Occasionally, you might need to stop the machine and scrape down the sides of the container to ensure that all the peanuts are being evenly processed.

Taste and Adjust: Once you’ve achieved the desired texture, give your homemade peanut butter a taste. If you like, you can add a pinch of salt or a touch of sweetener to enhance the flavor. Blend again to incorporate these if needed.

Storage: Transfer your freshly made peanut butter into a clean, airtight container. It can be stored at room temperature for a week or two, or in the refrigerator for a longer shelf life.

And there you have it—homemade peanut butter straight from the grinder! It’s a simple and delicious way to create your own nutty spread without any added preservatives or artificial ingredients. Just remember to clean the machine properly afterward, especially if you plan to use it for other foods in the future.