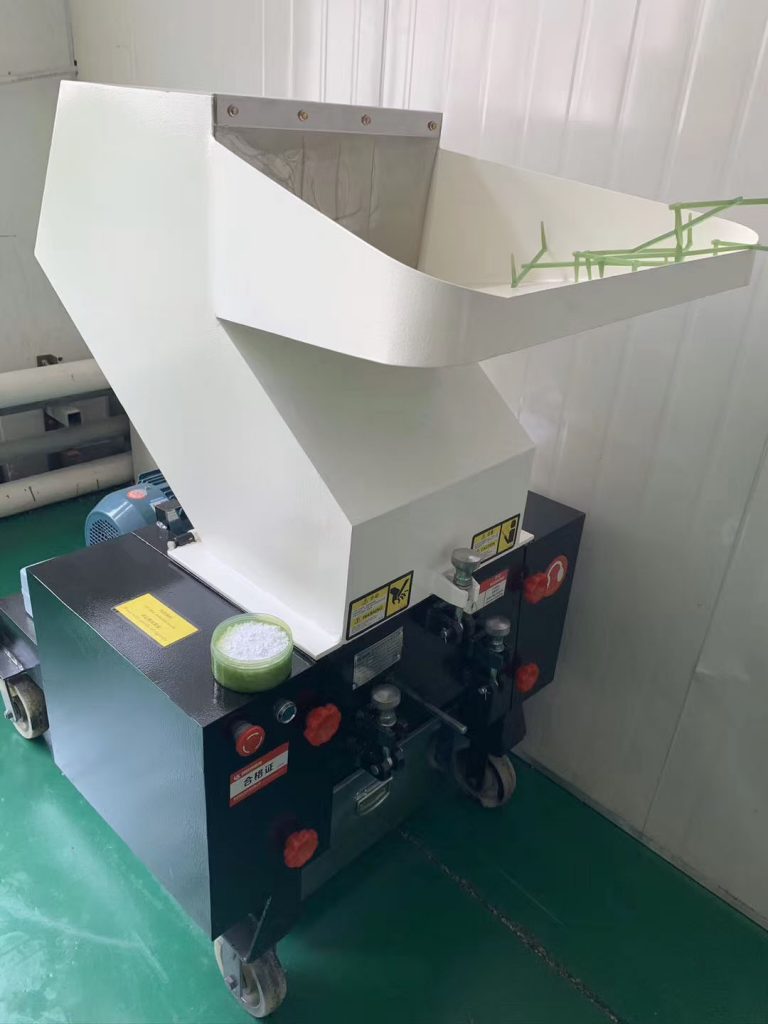

Powerful Shredder

Powerful Shredder Machine: (Size and Capacity can be customized)

Industrial Powerful Shredder Machine Wholesale Manufacturer

- Voltage: 380V(3 phase);

- Torque: 1696-4574;

- Dimension(mm):850*500*1300~1200*600*1550.

- Price: $ 50-1,179.

Powerful Shredder Machine:

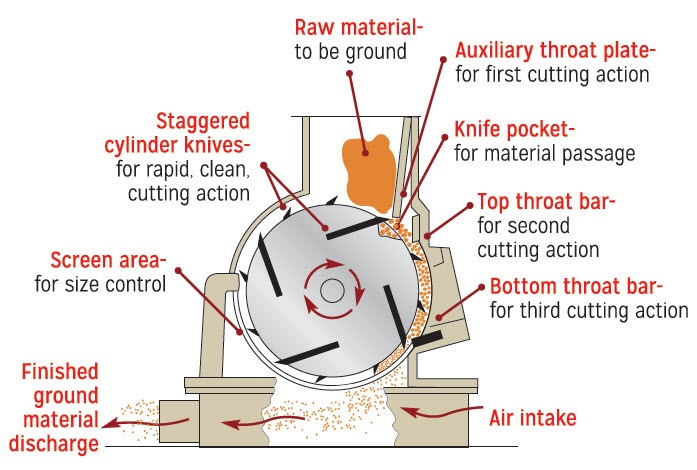

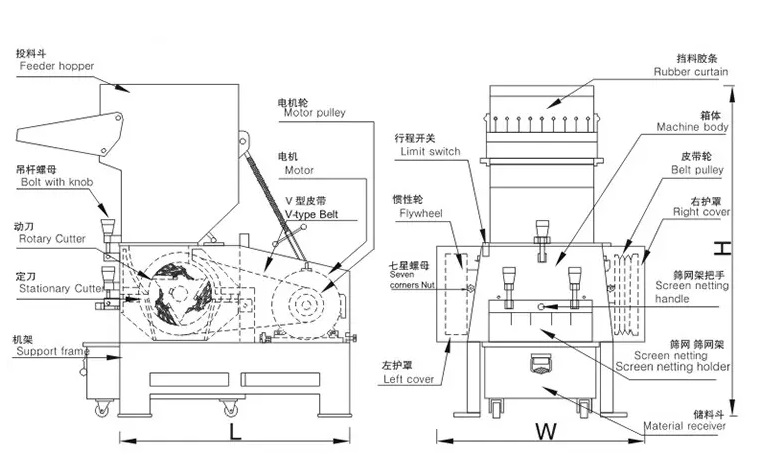

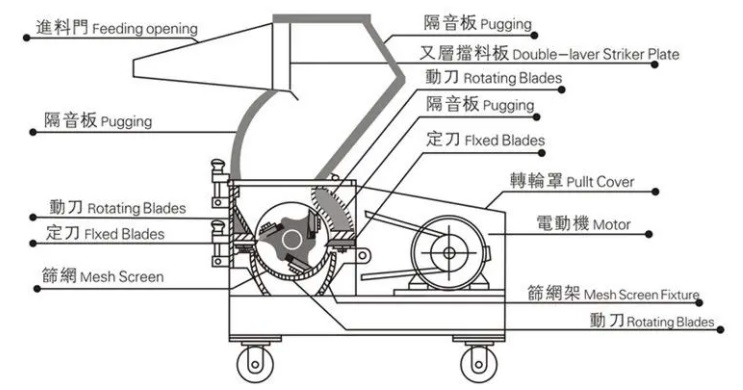

Powerful shredder refers to the plastic recycling equipment used for crushing plastic waste, defective products, scraps, plastic rods, plastic sticks, plastic bottles, plastic frames, plastic shells, plastic films and so on, sometimes also known as plastic shredder, strong crusher, chip crusher, silent crusher and so on. The powerful shredder is mainly composed of a horizontal rotor with a series of blade blades and a cylindrical housing with one or two fixed blades. The powerful shredder is provided with a hopper along the surgical axis. The speed of the rotor is very large, and the incoming material is cut into pieces at the smaller intersection gap between the fixed knife and the blade to (also called moving knife). The pieces are discharged from the bottom of the shell and can be screened through the filter screen if necessary.

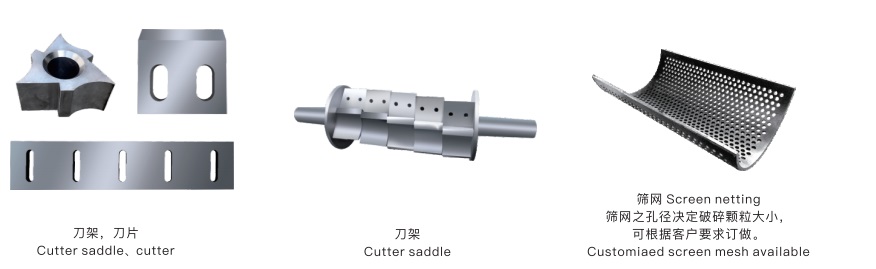

Powerful Shredder Vulnerable Parts:

This highly secure shred style is the standard for government organizations that require the highest level of privacy and protection.

The basic elements of a shredder include a rotor, a counter blade or counter blades, housing, motor, feeding, power system, and a control system and can include grabbing. Rotor – The rotor on a shredder has saw teeth cutters that mesh with knives to shred scrap and waste.

Advantages:

- 1.Equipped with power seats for the trapezoidal design, the use of for ce debris decomposition, resulting in chip power- told increase;

- 2.Heavy load-bearing and oil seal device, and a soundproof partition, can effectively prevent vibration, ensure that the processing material not pollute;

- 3.Motor with overload protection system, and power supply chain system, with cleaning tool protection system, to ensure the safety of cleaning;

- 4.Cutting tools installation design can be adjust, more ground after using blunt, repeatedly used, long iTe;

- 5.Separator design, drop hopper, crushing chamber filter, facilitating unpick and wash;

- 6.Small machining outfit casters, convenient to move the mainframe computer with adjustable shock absorber feet, work smoothly.

What is the use of Powerful Shredder?

Application: Powerful Shredder are suitable for very wide scope: plastic , rubber, chemical, paper, wood industries. This LKEB series machine are suitable for plastic recycling industry. Power crusher used to break extremely hard materials, such as ferrochrome, ferrotungsten, etc. It is mainly composed of frame, moving jaw, connecting rod part, elbow plate part, adjustment part and transmission part.

Ferroalloy power crusher belongs to double elbow plate simple swing jaw crusher. It is mainly composed of frame, moving jaw, connecting rod part, elbow plate part, adjustment part and transmission part. When the crusher works, the motor drives the eccentric shaft to rotate through the triangular belt and belt wheel, so that the connecting rod body moves up and down, drives the elbow plate to push the jaw forward and back, so that the material entering the crushing chamber is broken under the impact, extrusion, bending and other loads.

Here are some showcase videos:

Plastic Basket Shredder

Soft Rubber Recycling Grinder

TPE, PP, PC Shredder:

Soft Rubber Tube Shredder:

| Model Name | 180 | 250 | 300 | 400 | 500 | 600 | 800 | 1000 |

| Grinding Capacity(kg/h) | 50-100 | 150-200 | 200-300 | 250-450 | 400-700 | 450-800 | 650-1300 | 750-1500 |

| Motor Power(kw) | 1.5/2.2 | 4 | 5.5 | 7.5 | 11 | 15 | 30 | 37 |

| Motor Power(hp) | 2P/3P | 5.5 | 7.5 | 10 | 15 | 20 | 37 | 50 |

| Rotating Knife quantity(pcs) | 9 | 6 | 9 | 12 | 15 | 18 | 24 | 30 |

| Fix Knife quantity(pcs) | 2 | 2 | 2 | 2 | 2 | 4 | 4 | 4 |

| Rotating Diameter | 148 | 225 | 240 | 270 | 280 | 350 | 400 | 400 |

| Screen Diameter(mm) | 6 | 8 | 8 | 10 | 10 | 10 | 12 | 12 |

| Knife Rotating Speed(r/min) | 520 | 617 | 617 | 650 | 627 | 576 | 480 | 480 |

| Feeder Mouth (mm) | 630*520*950 | 900*700*1050 | 1000*750*1180 | 1060*800*1320 | 1150*1000*1450 | 1200*1060*1650 | 1850*1410*2130 | 1950*1580*2500 |

| Weight(kg) | 120 | 230 | 330 | 430 | 550 | 620 | 1700 | 2800 |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

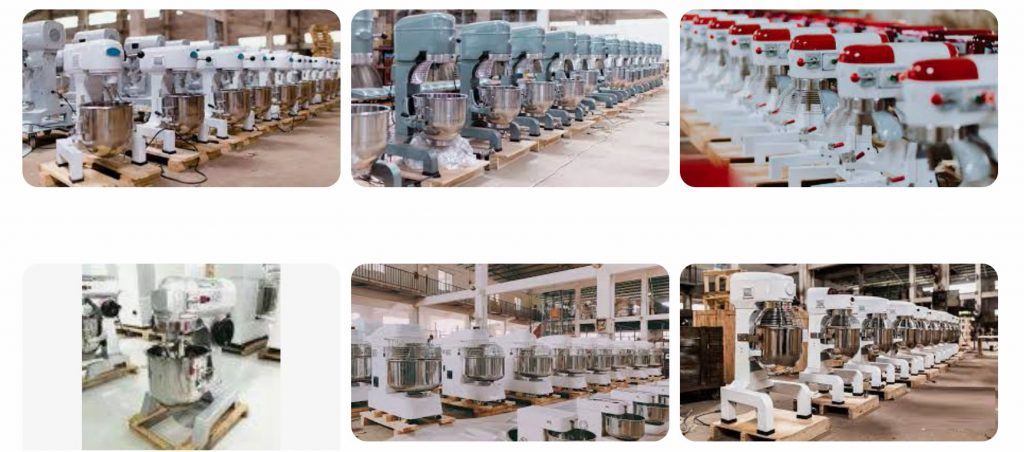

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Electric Cabinet with UL Certification

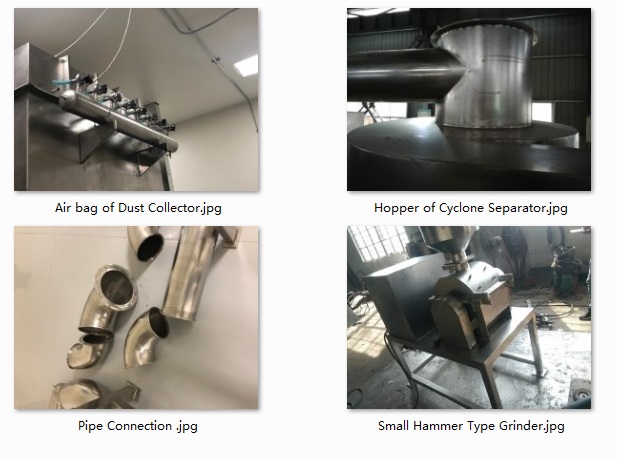

Cyclone Processor and Motors:

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

Large Machine Packing:

Shipment:

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

Operation Instruction

General Provisions

The first reprint machine, shredder driver must be trained, to achieve the “three understanding” (understand the structure, understand the performance, understand the principle), “four” (will use, will maintain, will maintain, will deal with the fault), after the training test qualified, obtain a certificate, quasi post operation.

Article 2 Cooperate closely with the scraper conveying driver of the working face and the belt conveyor driver of the transportation lane, make unified signal contact, and start and stop in order. When large lump coal and gangue are accumulated and spilled at the feed port of the crusher, the operation of the scraper conveyor should be stopped. If there are large lumps of coal, gangue cannot enter the broken plane or there are metal objects, it must be shut down for treatment.

Preparation Work

1. Tools: wrench, pliers, screwdriver, hammer, spade, etc.

2, necessary spare parts: all kinds of short chain, chain link, bolts, nuts, crusher insurance dowel, etc.;

3. Lubricating oil and turbine oil

Treatment of inspection

1, motor, reducer, hydraulic coupling, head, tail and other parts of the connection must be complete, intact, tight. Reducer, hydraulic shaft joint should have no oil leakage, oil leakage, oil quantity should be appropriate.

2, signal must be sensitive and reliable, no signal is not allowed to start. Make sure the spray sprinklers are in good condition.

3. Power cables and operation lines must be hung neatly without being squeezed;

4, the coal, gangue, sundries near the nose and the coal dust of the motor and reducer must be cleaned;

5, face scraper conveyor head and reprint machine tail lap to be suitable;

6. The scraper chain plate is of moderate importance, and the scraper and screws must be fully fastened;

7, reprinting machine walking trolley must be stable and reliable;

8. When the machine is partly turned on, the operation of each part should have no abnormal sound, and the scraper, chain and connecting ring should have no torsion, twist and bend deformation;

9. The roadway support at the shredder and shredder must be intact and firm.

10, the safety protection net and protection device of the crusher, to ensure that no deformation no failure, safe and reliable;

11. The roadway support of the reprinting machine and the shredder must be intact and firm.

Precautions

Trial run

1. Switch on the power grid switch;

2. Manually press the click button for the trial run of the machine;

3. Start and idling for 1 ~2 weeks;

4. Joint operation of reprinting machine and shredder;

5. Check that there is no abnormality and send a startup signal.

6, the operation of the machinery and motor should be no vibration, sound and humidity should be normal, the bearing temperature should not exceed 75℃, motor temperature should not exceed the nameplate provisions.

7. The chain tightness of the reprinting machine must be consistent. Under the condition of full load, the chain tightness is not allowed to exceed the length of two chain rings.

8. After the fusible plug or fried piece of the joint of the reprinting machine is damaged, wood or other materials shall not be used instead.

9. The safety device of the protective net of the crusher should be kept in good condition, and should be checked frequently in the working process. If there is any damage, it should be stopped immediately.

10, reprinting machine tail protection and other safety devices must be ensured intact.

11, transfer and transfer machine.

(1) Clean the floating coal and gangue in the tail, on both sides of the fuselage and under the bridge;

(2) Protect cables, water pipes, oil pipes, and hang them neatly;

(3) Check the roadway support, and push the reprinting machine under the condition of ensuring safety;

(4) The walking trolley and the tail frame of the belt conveyor should have good contact, do not run off, and have good lap after moving, prevent large plastics from hurting the tape, and ensure smooth coal flow;

(5) After the transfer machine, the nose and tail should be kept flat, straight and stable, and the jack live rod should be recovered.

Operation Attention

1, plastic crusher and power unit to install firmly. If need long-term fixed operation, plastic crusher should be fixed on the cement base; If the plastic crusher is needed for mobile operation, the unit should be installed on a base made of Angle iron, and ensure that the power machine (diesel engine or motor) and the belt pulley groove of the plastic crusher are in the same rotary plane. 2. After the installation of the plastic crusher, the fasteners of all parts should be checked and tightened if they are loose. At the same time to check the belt tightness is appropriate.

3. Before starting the plastic crusher, first rotate the rotor by hand to check whether the jaw, hammer and rotor are flexible and reliable, whether there is collision in the crushing room, whether the rotating direction of the rotor is consistent with the direction indicated by the arrow of the machine, and whether the lubrication of the power machine and plastic crusher is good.

4, do not casually replace the belt pulley, in case the speed is too high resulting in the explosion of the crushing chamber, or the speed is too low affecting the working efficiency of the crusher.

5. After starting the plastic crusher, it should be kept idling for 2~3min, and then feeding after there is no abnormal phenomenon.

6, the work should always pay attention to the operation of the plastic crusher, first of all, the feeding should be uniform, to prevent blocking the crushing chamber; Second, don’t overwork for a long time. If there is vibration, noise, bearing and body temperature is too high, spraying material and other phenomena, should immediately stop the machine for inspection, troubleshooting before continuing to work.

Maintenance :

1, should be placed in a ventilated position, the motor work heat distribution, extend its life.

2. Lubricating oil should be added to bearings regularly to ensure lubricity between bearings.

3, regular check the tool screw, after 1 hours, use the tool to tighten the moving tool, the screw of the fixed tool, the fixity between the blade and the tool holder.

4. For the sharpness of the cutting tool, the cutting tool should be checked regularly to reduce the unnecessary damage to other parts caused by the blunt edge.

5. When replacing the tool, the gap between the moving tool and the fixed tool: 0.8MM for the crusher above 20HP is the best, 0.5MM for the crusher below 20HP is the best. The thinner the recycled material is, the gap can be appropriately enlarged.

6. Before starting, the remaining debris in the engine room should be cleared first to reduce the starting resistance. The inertia cover and belt wheel cover should be opened regularly to clear the ash outlet below the flange, because the powder discharged from the plastic crusher chamber into the rotating shaft bearing.

7. The machine should be well grounded.

8, regular check whether the plastic crusher belt slack, timely tighten.

Bearing fault maintenance

The rotating shaft rotates through the bearing support, which is the heaviest load part and easy to wear.

① Fault check

Check in operation;

When the rolling bearing is short of oil, it will hear the sound of “commonplaces”; If you hear the discontinuous “stalk” sound, it may be the bearing ring is broken. When there are sand and other sundries in the bearing or bearing parts have slight wear, slight noise will be produced.

Inspection after disassembly;

First check whether the bearing rolling body and inner and outer ring of the crusher are damaged, rust, scar, etc., then pinch the inner ring of the bearing with your hand, and make the bearing flat, and push the outer ring with your other hand. If the bearing is good, the outer ring should rotate smoothly, without vibration and obvious stagnation in rotation, and the outer ring will not regress after stopping. Otherwise, the bearing can no longer be used. The left hand jams the outer ring, the right hand pinches the inner ring, and pushes it hard in all directions. If it feels loose when pushing, it is seriously worn.

② Fault repair

The rust on the outer surface of the bearing can be erased with No. 00 sandpaper, and then cleaned in gasoline; Or when the bearing has cracks, the inner and outer rings are broken or the bearing is excessively worn, a new bearing should be replaced. When replacing a new bearing, the same bearing as the original model should be selected.

Fixed and rotor core fault repair

The stator and rotor are composed of mutually insulated silicon steel sheet, which is the magnetic circuit part of the motor. The damage and deformation of rotor core are mainly caused by the following reasons.

① Excessive wear or poor assembly of the bearing crusher, resulting in stator and rotor friction, the surface damage of the iron core, and then cause short circuit between the silicon steel sheets, increase the iron loss of the motor, the motor temperature rise is too high. At this time, the burr should be removed with tools such as fine file, and the short bonding of silicon steel sheet should be eliminated. After cleaning, insulating paint should be applied, and heating and drying should be done.

(2) When removing the old winding, the force is too large, so that the stolen slot skew and open outwards. At this time, needle-nose pliers, wood hammer and other tools should be used to repair, so that the tooth error can be reset, and hard insulating materials such as green shell paper and rubber board should be added between the silicon steel sheets with gaps that are difficult to reset.

③ Corrosion on the surface of the iron core is caused by dampness and other reasons. At this time, sandpaper should be used to polish clean, after cleaning with insulating paint.

④ High heat is generated around the connecting ground to burn the core grains or teeth. Use chisel or scraper and other tools to remove the molten deposits, coated with insulating paint to dry.

⑤ If the connection between the iron core and the frame is loose, the original positioning screws can be tightened. If the positioning screw fails, the positioning hole can be redrilled in the frame and tapped to tighten the positioning screw.

Rotating shaft fault maintenance

① Journal wear;

When the journal wear is not large, a layer of chromium can be plated on the journal and then ground to the required size. Wear more, can be surfacing on the journal, and then to the lathe cutting polishing; If the journal wear is too large, it is also turned on the journal 2-3mm, and then a sleeve is turned on the journal while it is hot, and then turned to the required size.

② Shaft bending;

If the shaft bending of the crusher is not large, it can be repaired by polishing the journal and slip ring. If the bending exceeds 0.2mm, the rotating shaft can be placed under the press and corrected at the bending place under pressure. The surface of the corrected shaft can be polished by lathe. If the bending is too large, a new shaft is needed.

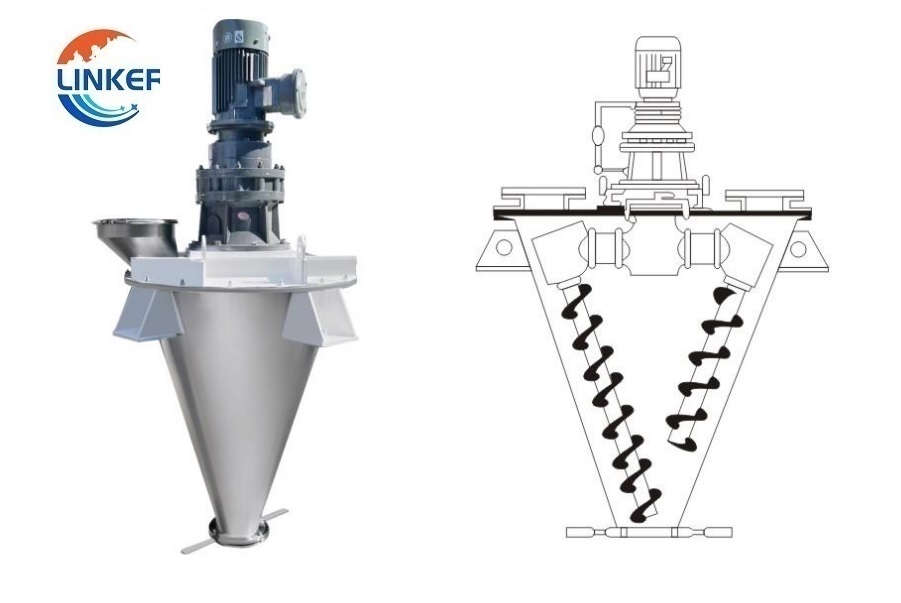

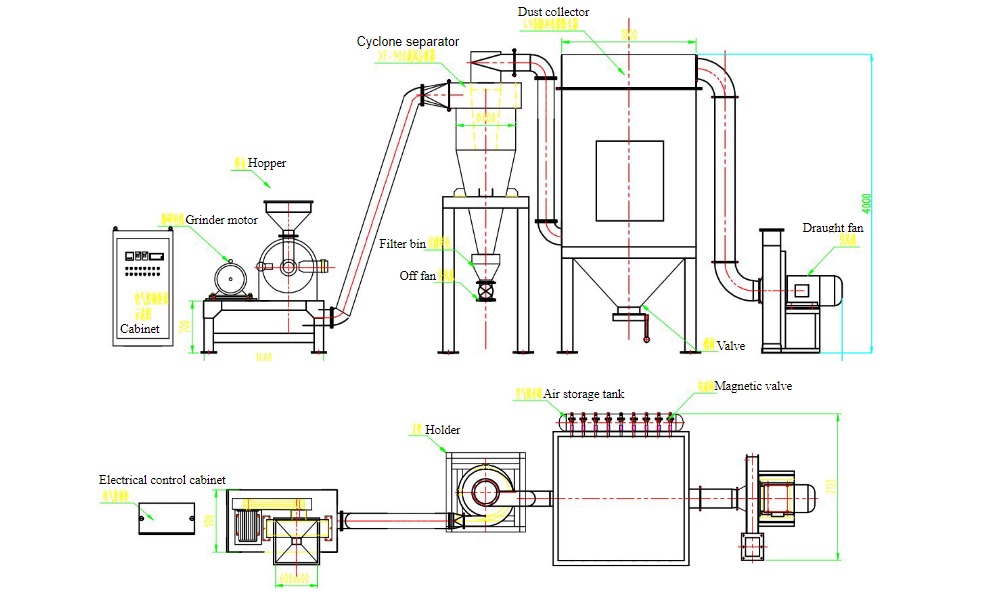

Schematic Diagram:

Powerful single shaft shredder:

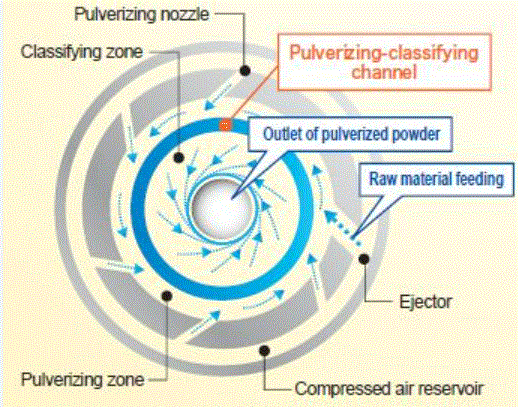

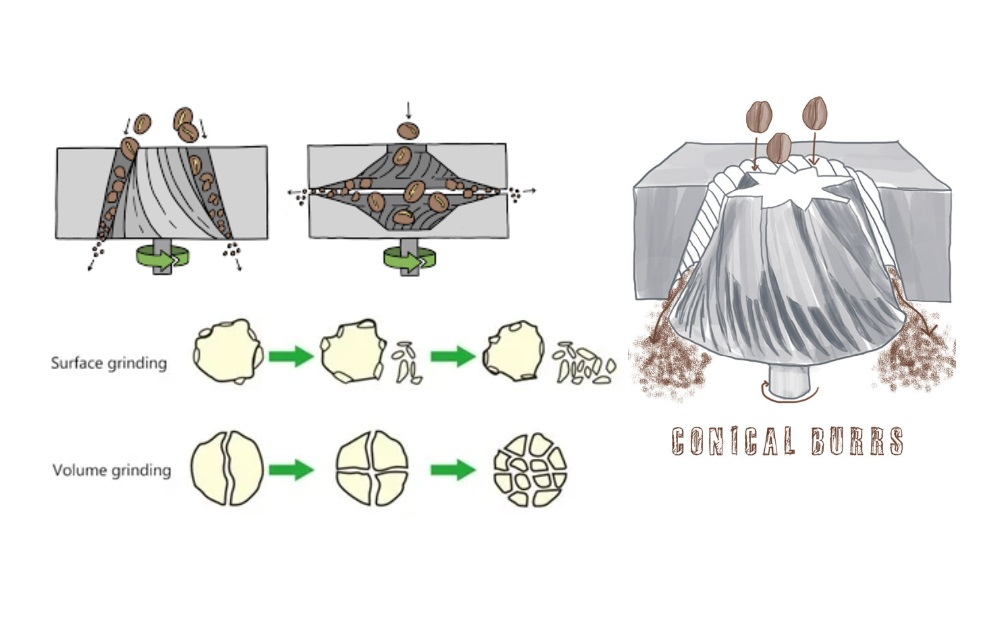

Powerful Grinder & pulverizer: (Size and Capacity can be customized)

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com