Blog

11

How much is a cassava grinding machine?

How long do electric grinders last?

Is cassava processing profitable?

What is a portable grinding machine?

What is the difference between a pneumatic grinder and an electric grinder?

Is it better to hand grind or use a grinder?

What is the difference between a toothless grinder and a grinder?

What is a machinist grinder?

Are bigger grinders better?

What are ultra fine grinders?

What’s the difference between a blender and a grinder?

What are the different types of industrial grinders?

Are metal or plastic grinders better?

What sizes do grinders come in?

What is the best budget grinder?

How to choose a commercial grinder?

Should l toast seeds before grinding?

Does grinding seeds destroy nutrients?

What can work as a grinder?

What is the alternative to a grinding machine?

What is the best thing to grind seeds with?

What machine grinds bones?

What are the four types of grinding machines?

Can you grind bones for calcium?

What are the disadvantages of grinding machines?

What is the best spice grinder?

How to crush bone into powder?

What is a grain grinder called?

Does a bone crusher crush long bones?

What is the difference between a grinder and a grain mill?

Why is grinding so precise?

How do we use a grinder safely?

How to use a grinder step by step?

How accurate is a grinding machine?

Can you put ginger in a grinder?

What is the work speed for grinding?

Can a food processor grind ginger?

What is the most powerful spice grinder?

Why is pepper grinder better?

ribbon blender with screw conveyor

How to grind and dry ginger?

ribbon blender vs v blender

What is the best pepper grinder ever made?

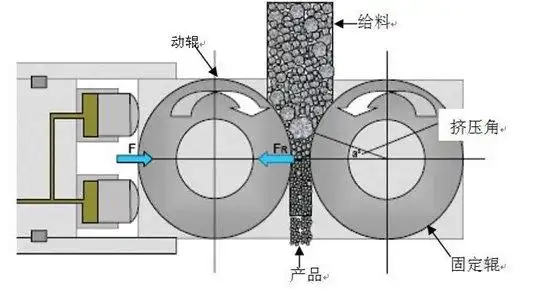

What is the difference between a pulverizer and a hammer mill?

Can l use a blender to grind spices?

Why are herb grinders so expensive?

What is the meaning of pulverizer?

What is the difference between a vertical grinder and a horizontal grinder?

Can you use a mortar and pestle instead of a spice grinder?

About LKMixer

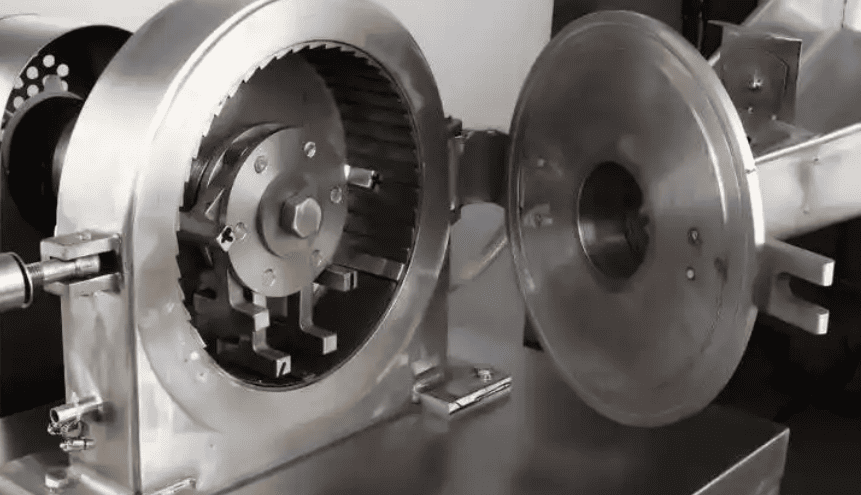

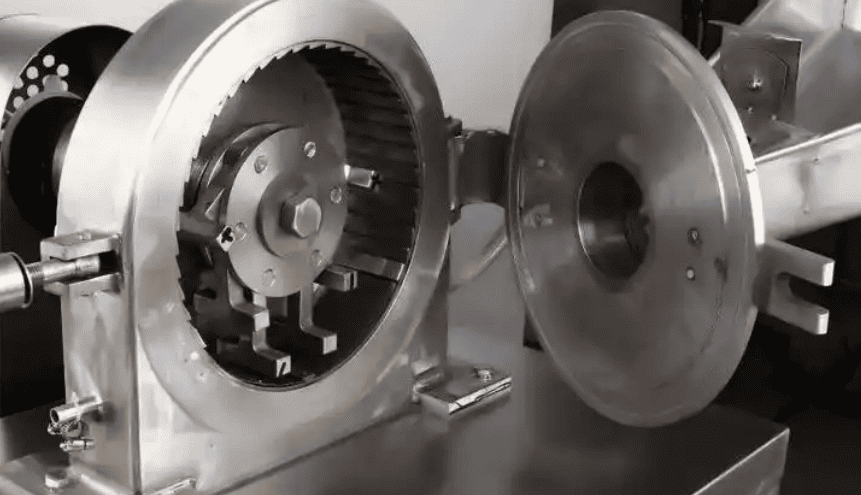

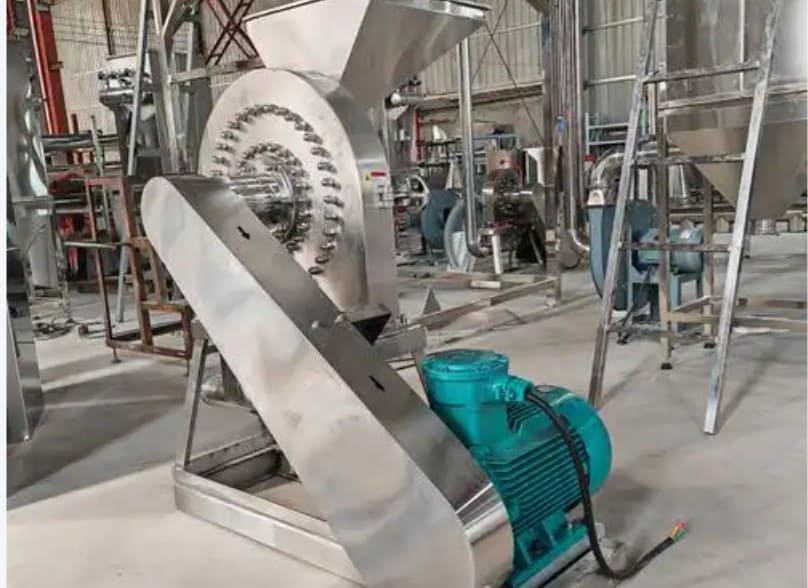

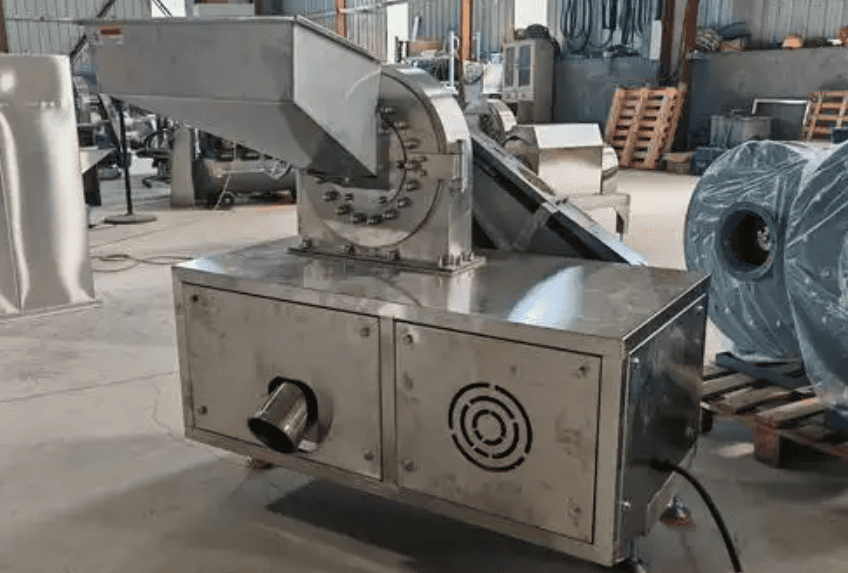

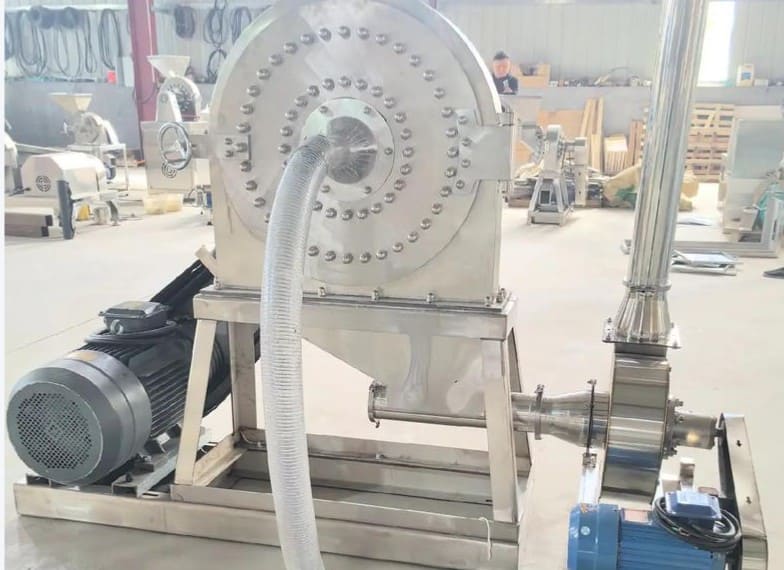

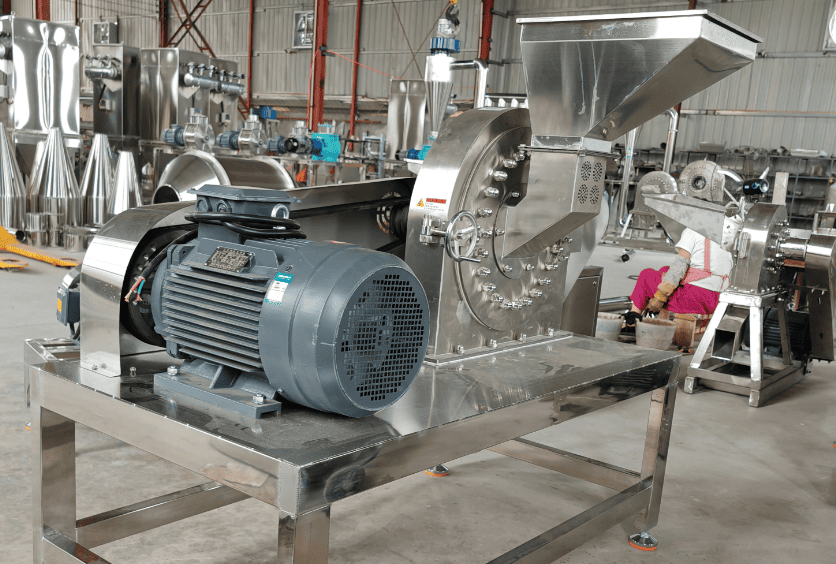

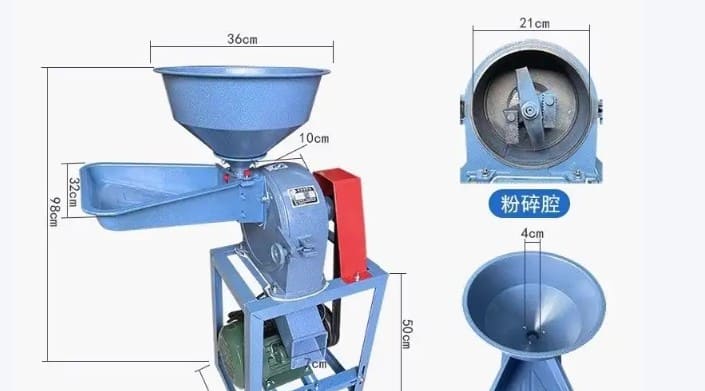

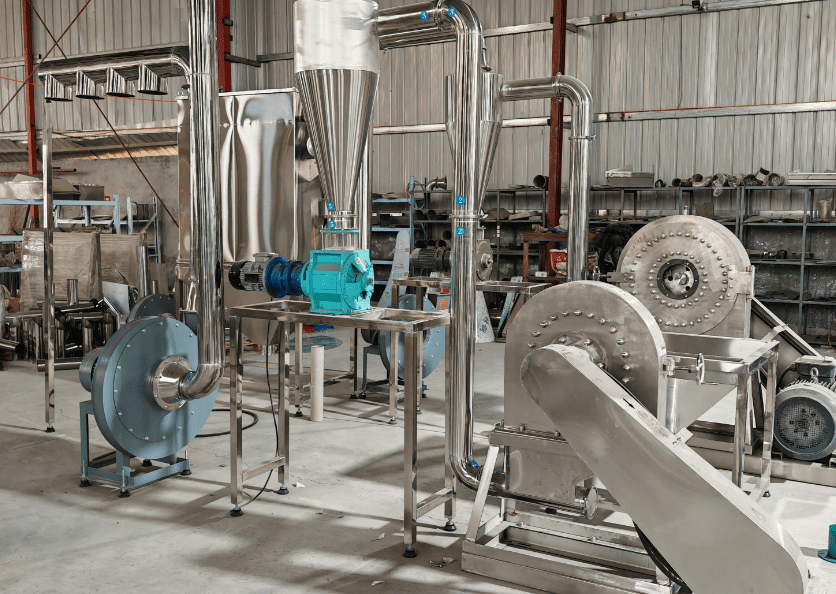

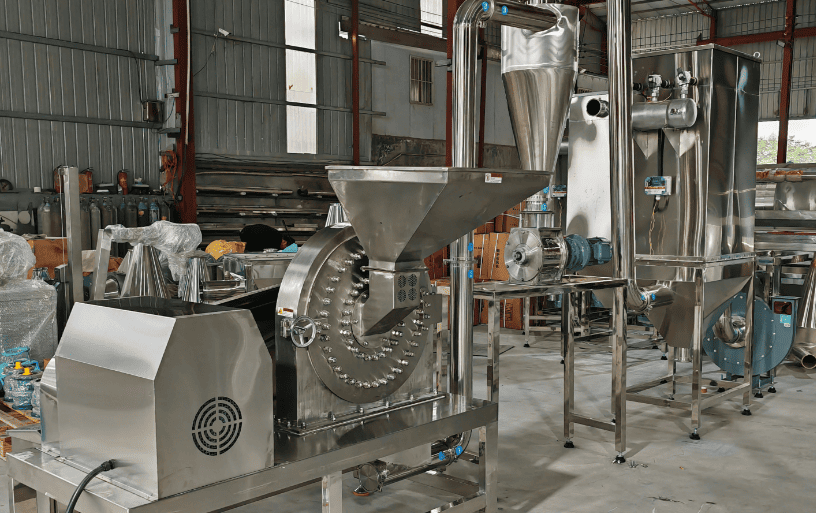

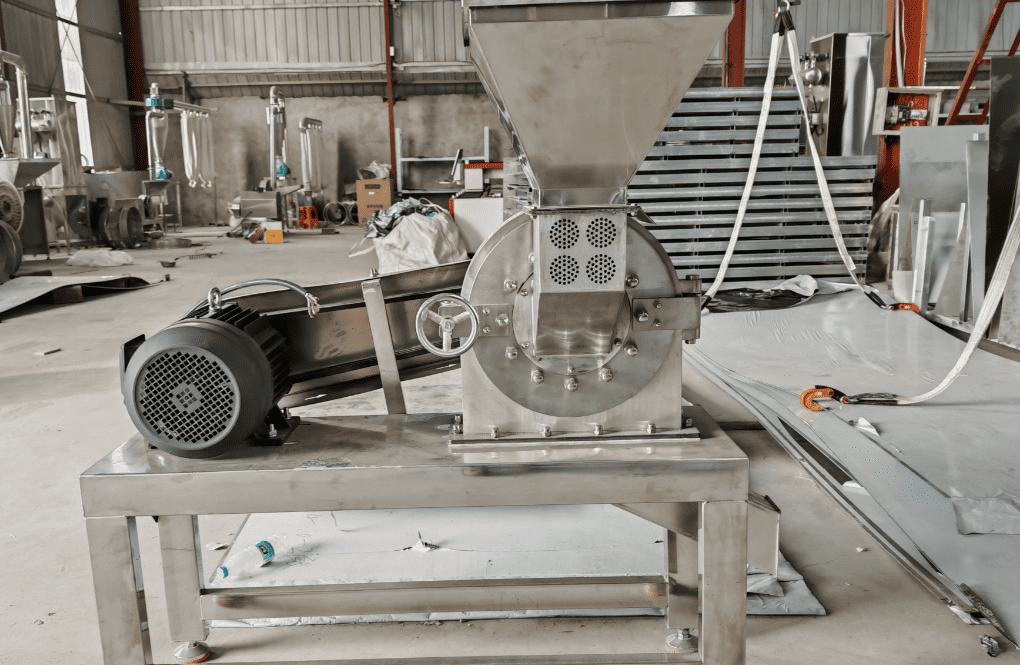

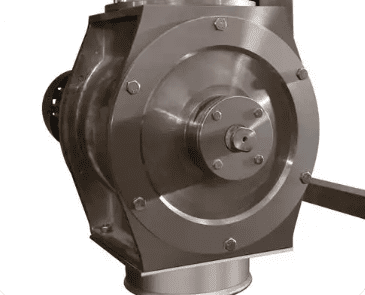

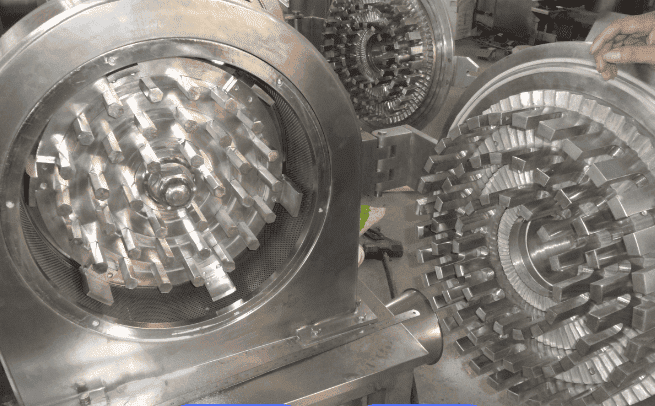

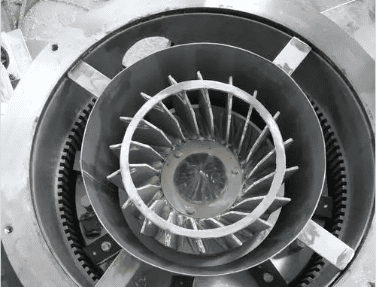

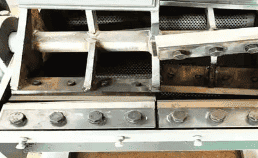

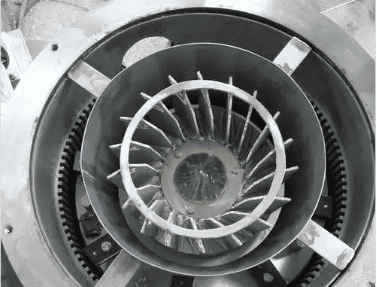

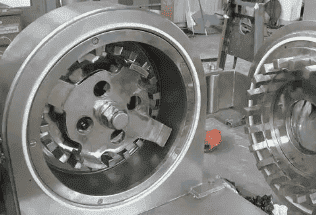

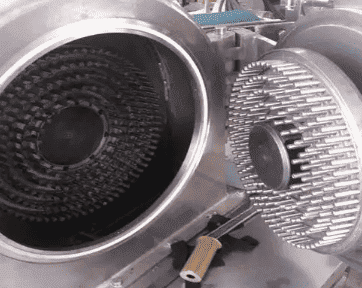

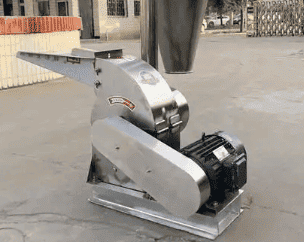

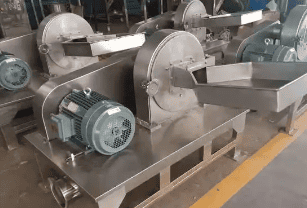

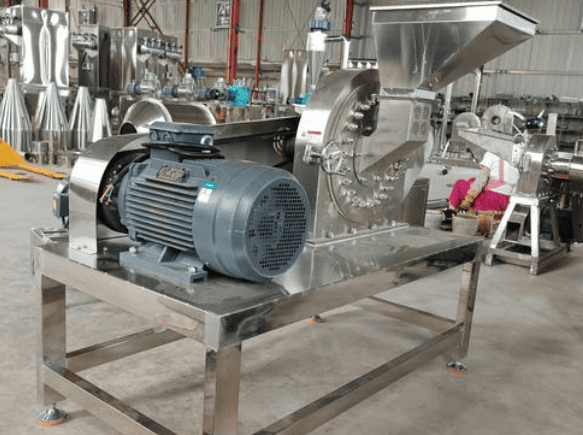

LK Mixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details.