Blog

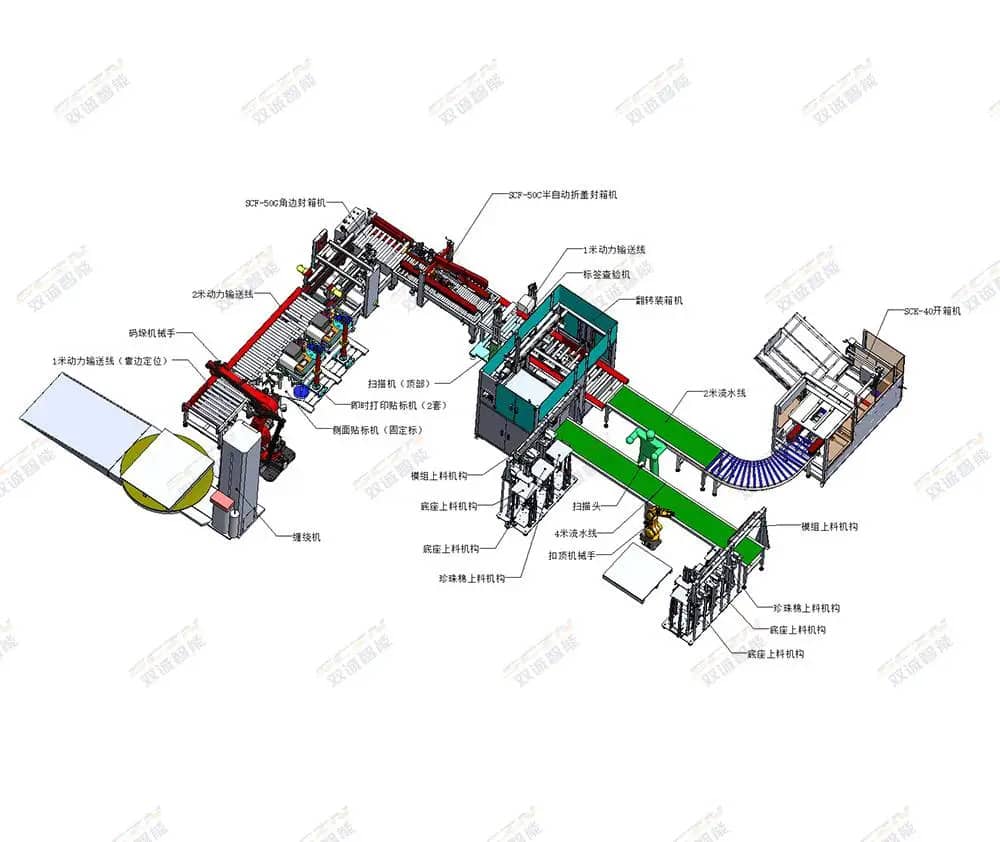

Automatic Chalk Production Line

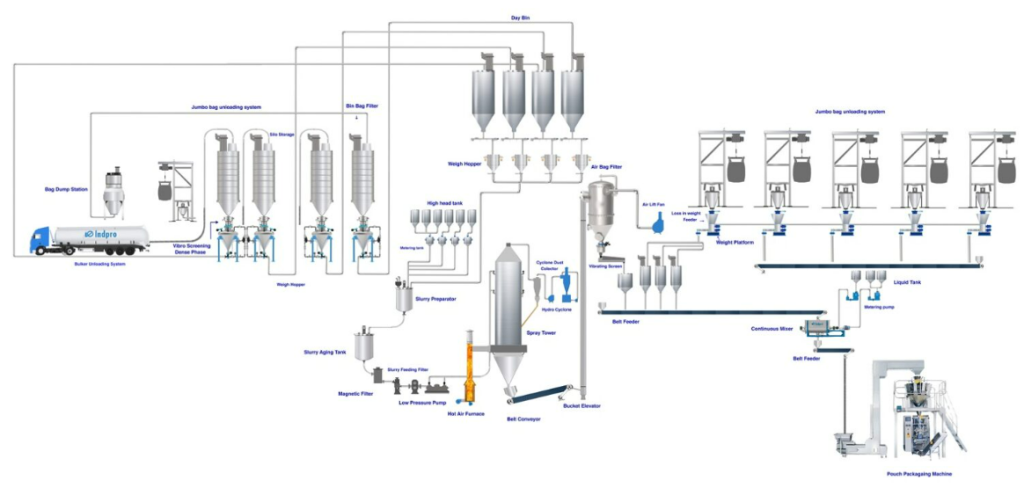

Automatic Laudry Detergent Production Line

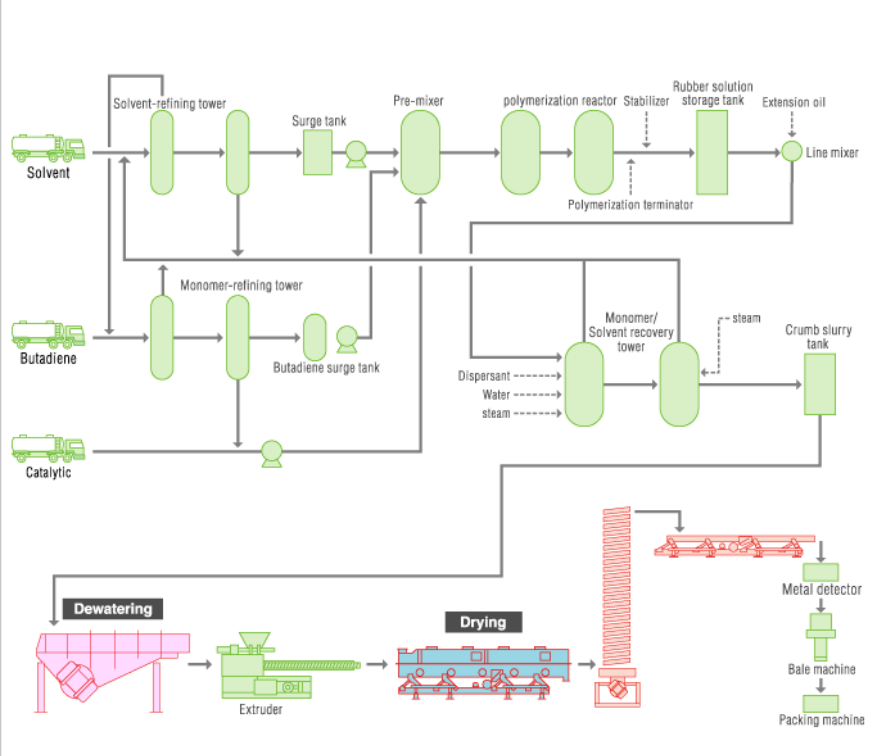

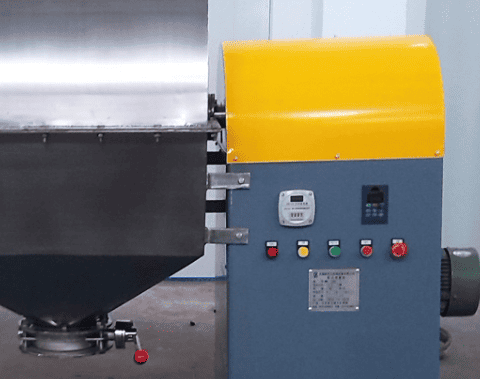

Automatic Crumb Rubber Powder Production Line

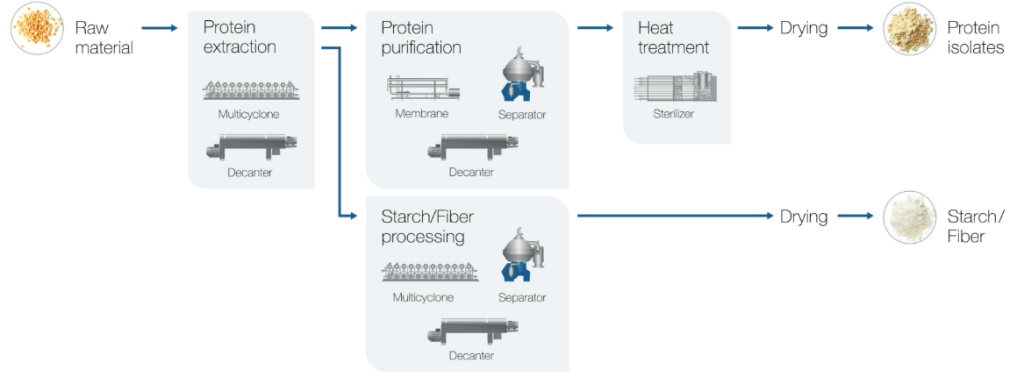

Automatic Protein Powder Production Line

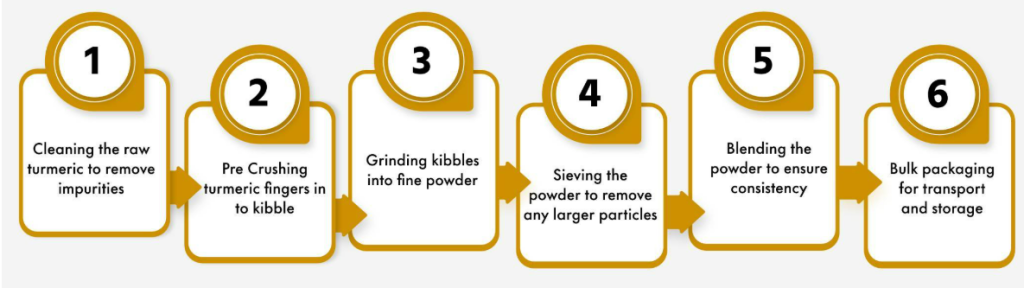

Automatic Turmeric Powder Production Line

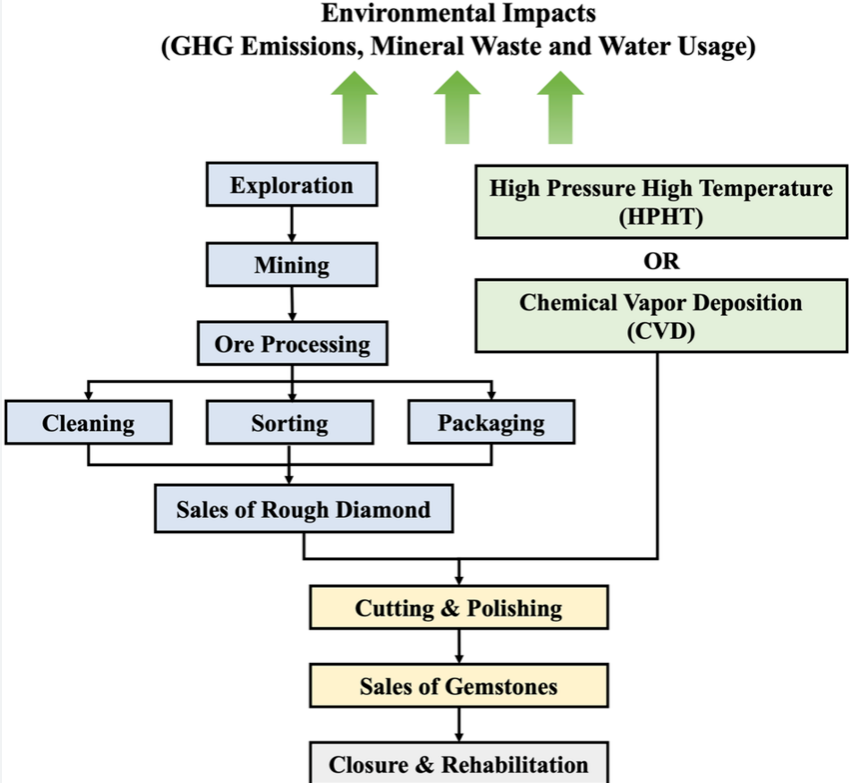

Automatic Diamond Powder Production Line

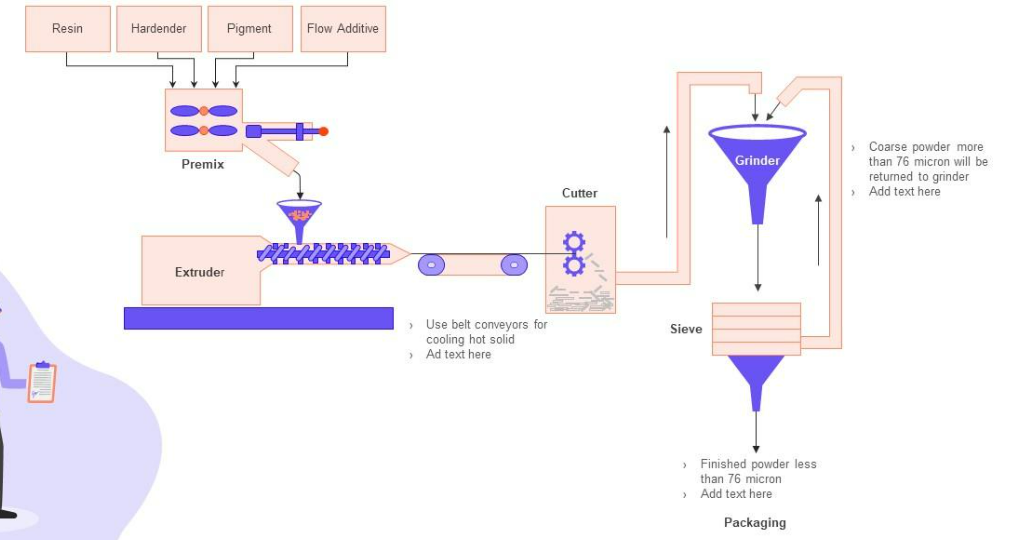

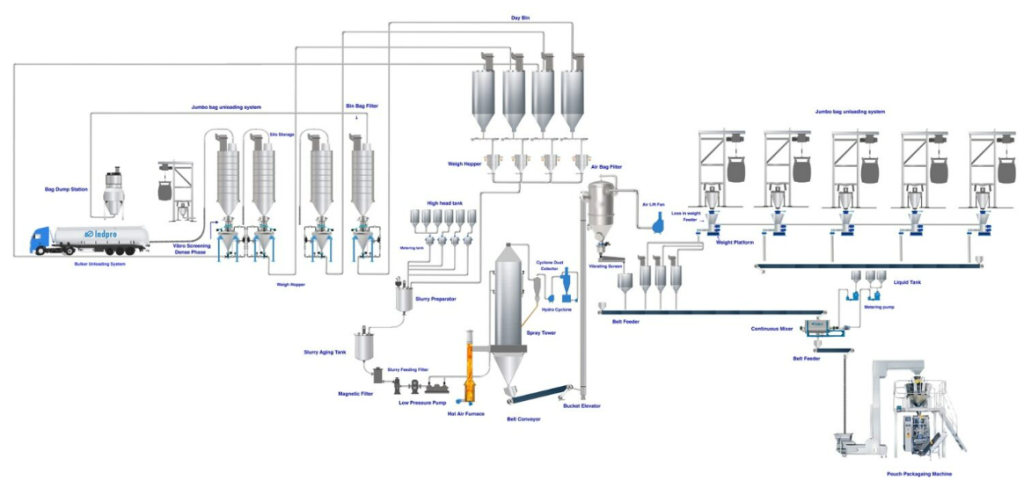

Automatic Laundry Powder Production Line

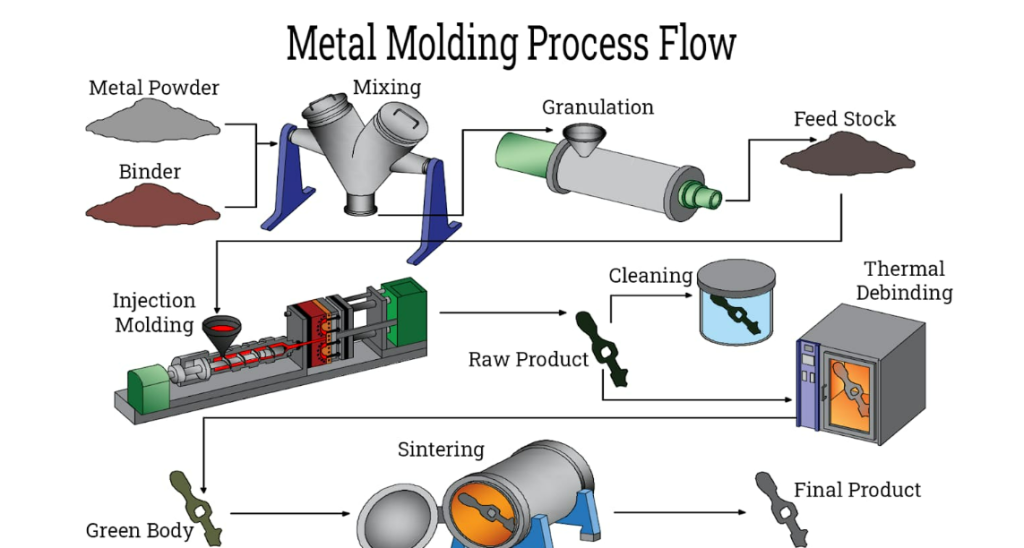

Automatic Metal Powder Production Line

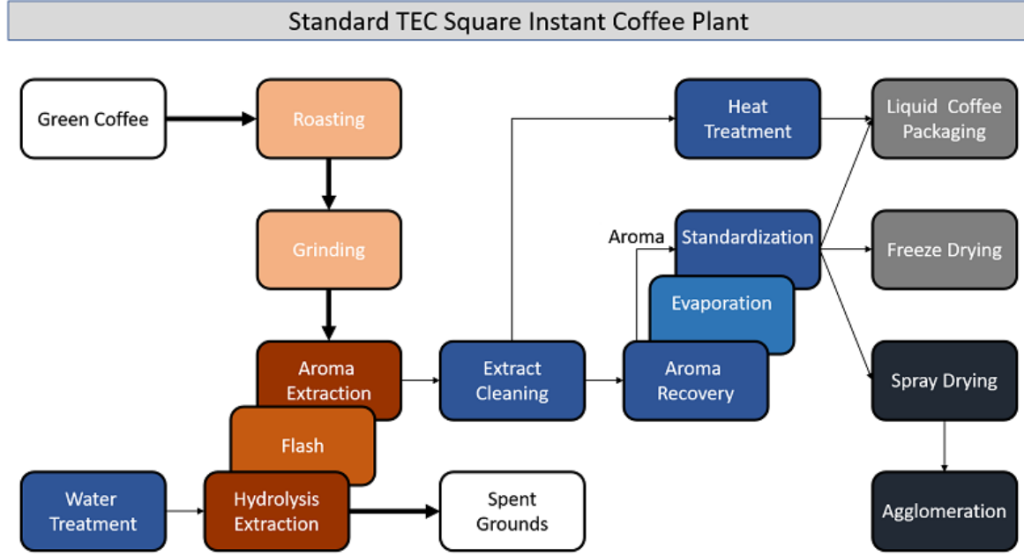

Automatic Coffee Powder Production Line

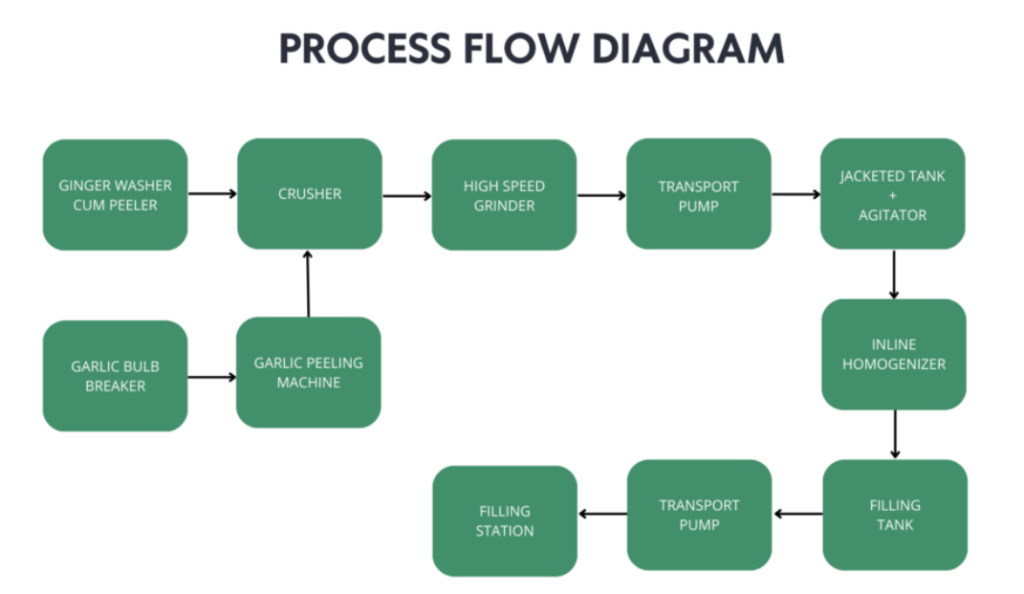

Automatic Ginger Powder Production Line

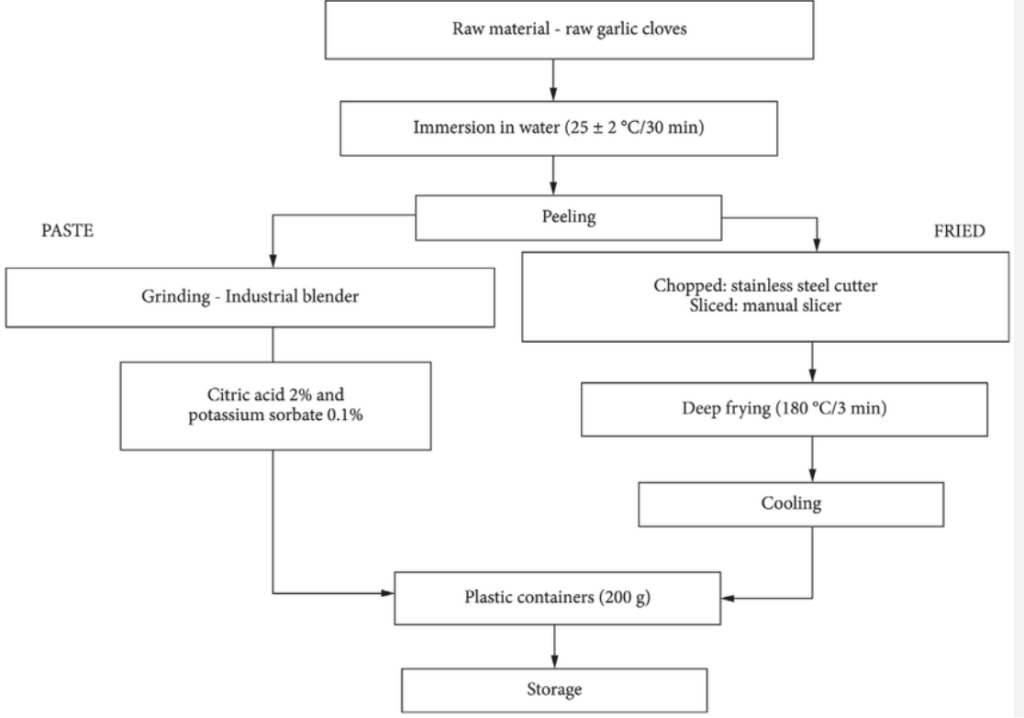

Automatic Garlic Powder Production Line

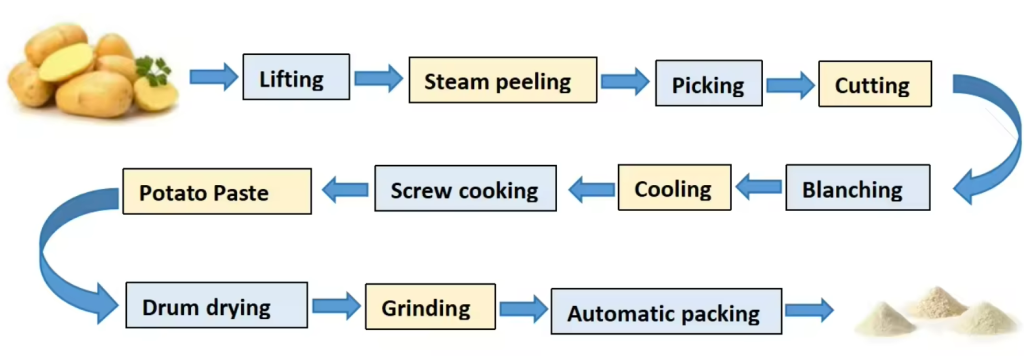

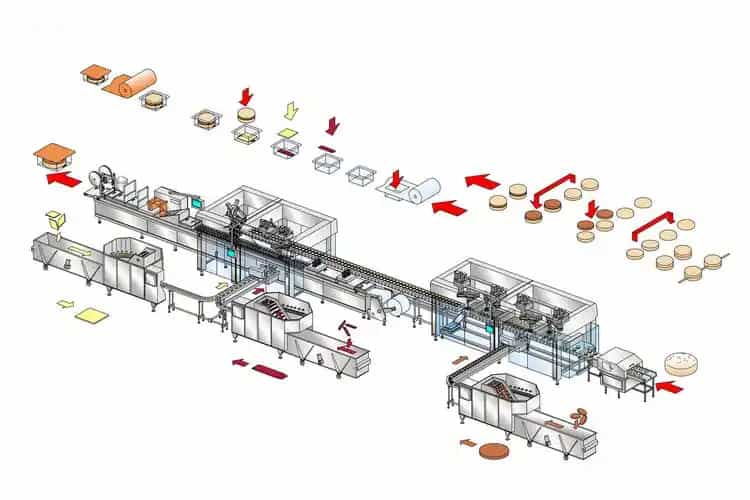

Automatic Potato Flakes Production Line

Automatic Banana Powder Production Line

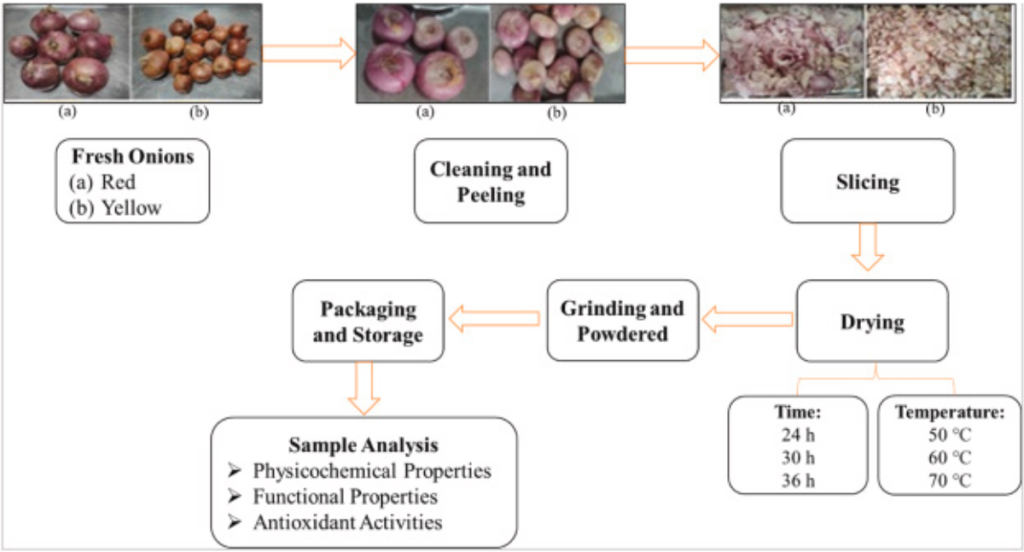

Automatic Yellow Onion Powder Production Line

What Are the Benefits of Using Robotics in Food Processing?

What Are the 4 Types of Food Production Systems?

What are the main types of food production?

What Are the Types of Food Production?

How is AI and machine learning being used in food production lines?

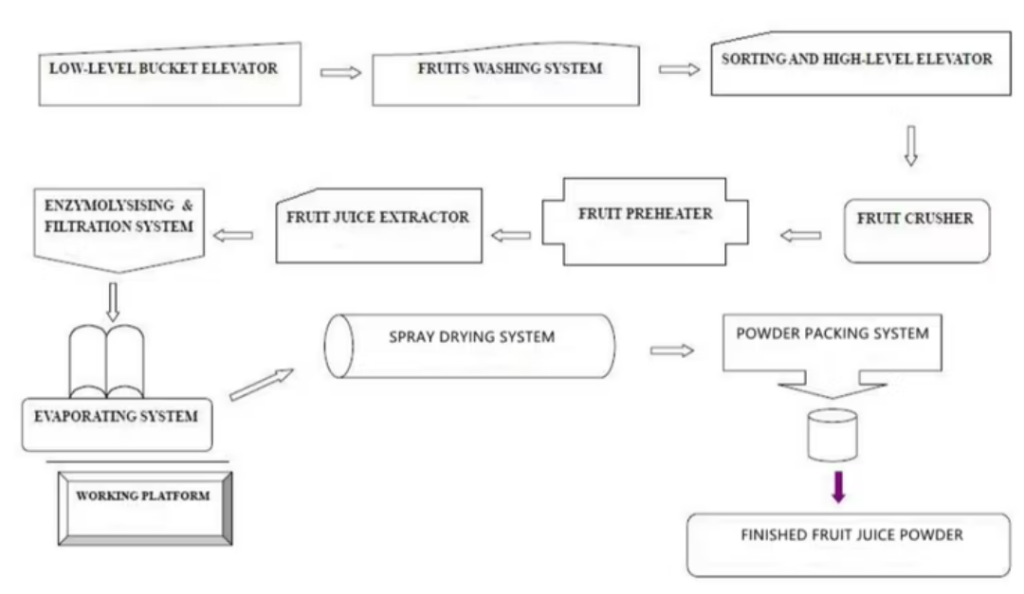

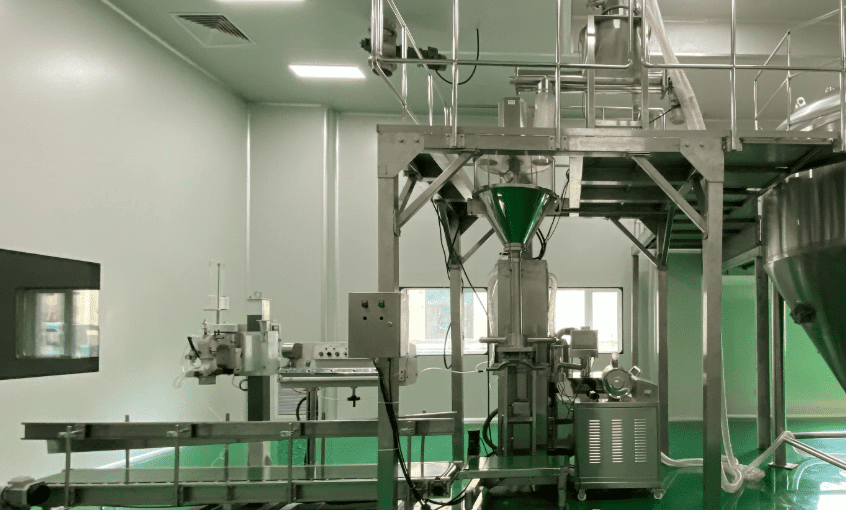

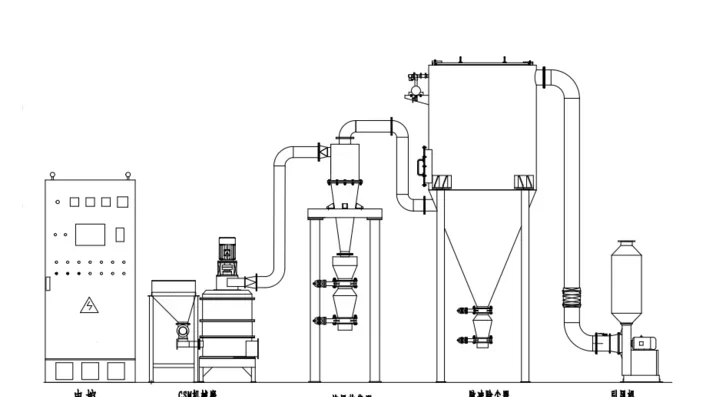

Automatic Powder Production Line

What are the essential pieces of equipment for a [specific product] line? (e.g., bakery, sauces, beverages, snacks)

How to Start a Food Product Line?

What else can you grind in a salt grinder?

What are the equipment needed for cassava processing?

How to dry grated cassava?

Can l use a food processor to grate cassava?

How to mill cassava powder?

How to Use a Dry Herb Grinder: A Comprehensive Guide

Can you use a coffee grinder for dried herbs?

What does a dry grinder do?

Should l wash my salt grinder?

What is the best way to grind dried herbs?

Is there any benefit to grinding salt?

What is ground dry mushroom?

What is the best way to grind salt?

Which salt is best for grinding?

What are the several steps that must be undertaken before beginning grinding operations?

What is the grinding procedure?

Can l use a food processor instead of a food mill?

Is a food mill better than a blender?

Can l use my blender as a grain mill?

ls grinding business profitable?

Can l use a food processor to mill grain?

Do and don’ts of grinding machine?

What is the cheapest way to mill grain?

What is the price of super steel grinding machine?

Can l use a blender as a grain mill?

What is a cassava mill?

Can you crush grains without a mill?

Does grind size affect coffee flavor?

About LKMixer

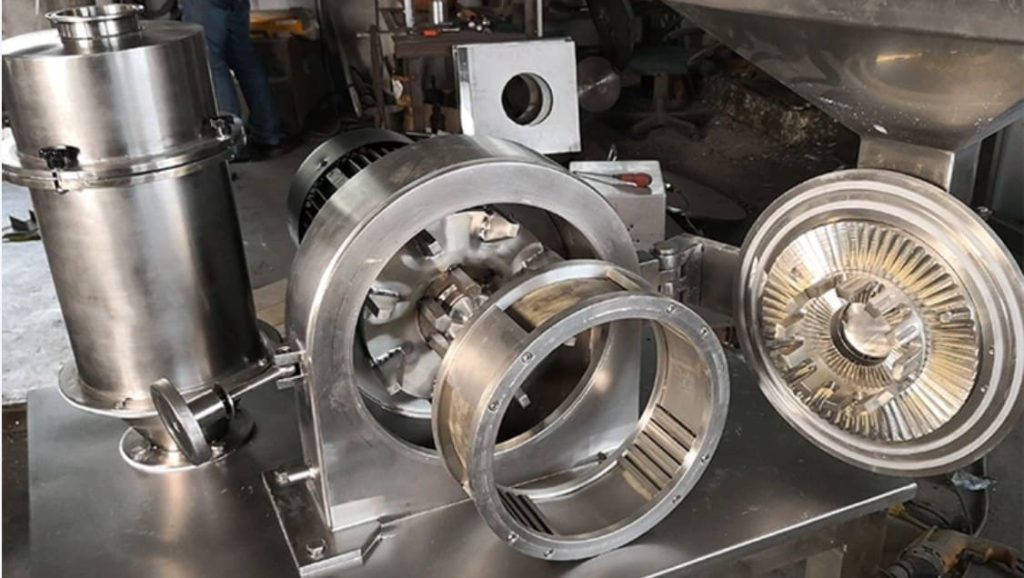

LK Mixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details.