Ribbon Blender vs Paddle Blender

Many User want to know the difference of Ribbon Blender vs Paddle Blender. As we know that blending machine is important in usage in food, chemical and pharmaceutical industries. They are widely used in many final products. The blending machine have various shapes and dimensions, so that to meet the blending requirement of customer. And the most commonly used blending machine are paddle blenders and ribbon blenders. So it is of great importance to understand the difference between this two kinds of blenders when we choose the right model for our customer.

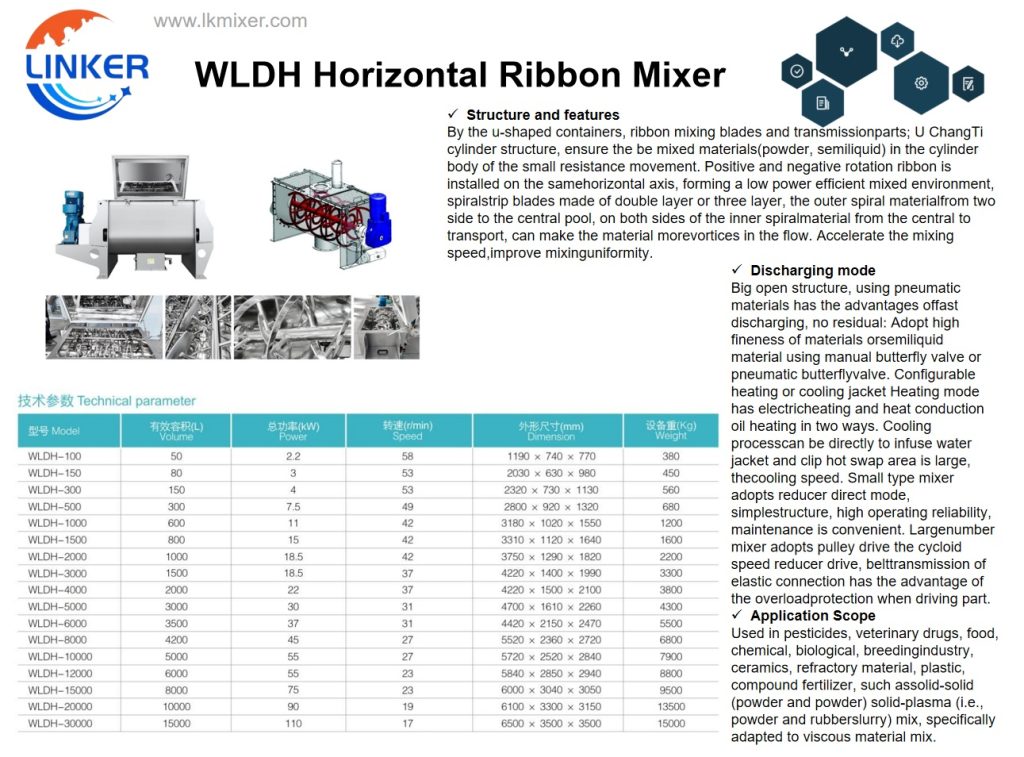

Ribbon Blender

Paddle Blender

The Major difference of Paddle Blender and Ribbon Blender:

The major difference between Paddle Blender and Ribbon Blender is that the Ribbon Blender is suitable for large batch of Bulk materials no need conveyor; but the paddle mixer is more suitable for small batch or large batch but normally need conveyor. In addition, both types of mixers can mix materials of different sizes, shapes and densities.

The Different Efficiency of Blending:

Ribbon Blender advantages and disadvantages:

Ribbon Blender always have “U shape” tank, and at the same time have two or more ribbon vertical or horizontal lay out in tank. These ribbons rotate in opposite direction, and this opposite strength can bring the raw materials to be blended sufficiently. Ribbon Blender always suitable for large batch of material blending. Because of the top of tank open and easy to load the material into the tank, so it can mixing large batch of materials.

The great feature and advantages of the ribbon blender is that it is capable to mix different shape, dimension, and density material in large batch. To make final power, granule, or liquid to be fully mixed. Another point is that ribbon mixer can mix in low speed, so to protect the product not to be destroyed elements in material, to keep the raw material in good condition.

Though the ribbon blenders have many advantages, but at the same time, it also have disadvantages, such as:

Firstly, it is not efficient enough when mixing small batch material. This is because the mixing machine tank always exists corner which is hard to mixed, this may result as when mixing small batch of material, some portion can not be mixed fully.

Secondly, If need to heat in mixing procedure, the heat transferring is also another problem. The open top side and the gap between the top make it is not so high efficient in heat transferring.

Paddle Mixer Advantages and Disadvantages:

As to the mixing time, the paddle mixer is most efficient. They can finish the mixing process within several minutes. The V shape and Cone Mixer usually need to finish in longer time. LINKER Paddle Mixer reduced the space in mixing tank, this upgraded the efficiency at most.

Paddle Mixer is also more easy in maintain when compared with other mixer. You can easily change and adjust the position of paddle, the material also protected as they are softly treated by paddle instead of in high rotating speed.

The structure of paddle mixer usually have two or more rows of paddle. If need, the paddle can also add the cutting function, softly and gently. So paddle mixer can be used in both small and large batch mixing.

One of the main advantages of using a paddle mixer is its ability to slowly, finely and efficiently mix materials with different sizes, shapes and densities. In addition, blade mixers are capable of mixing at high speeds, making them ideal for products that need to be mixed quickly.

Blade mixers also have better heat transfer because the closed top and cylindrical design has a larger surface area and is enclosed and improves efficiency.

However, one of the main disadvantages of using paddle mixers is that they are not as efficient at loading bulk material directly into the mixer as the cylinder type configuration usually requires conveying during loading.

When choosing a mixer, it is important to consider the size and type of material to be mixed. Ribbon mixers are ideal for mixing large volumes of bulk material when loaded without a conveyor, while paddle mixers are better for mixing small or large batches, but usually require a conveyor for loading. In addition, both types of mixers can mix materials of different sizes, shapes and densities. Ultimately, deciding which type of mixer is best for your needs will depend on the specific application. Finally, when you compare mixing time and batch time efficiency, paddle mixers are superior to ribbon mixers.

About LKMixer

LK Mixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details.