What is the main advantage of using a vertical roller mill over a ball mill?

What is the main advantage of using a vertical roller mill over a ball mill? The dominant advantage of vertical roller mills (VRMs) over ball mills is their significantly lower energy consumption—typically 20-40% less per ton of processed material—achieved through efficient interparticle crushing mechanics, integrated drying capabilities, and reduced auxiliary power requirements. This fundamental efficiency advantage cascades into operational cost savings, compact plant layouts, and superior process control, revolutionizing industrial grinding for materials like cement, coal, and slag.

1. Energy Efficiency: The Physics of Interparticle Crushing

Vertical roller mills leverage interparticle crushing—a force-efficient grinding mechanism where material particles fracture each other under pressure in a compacted bed. Here’s how it outperforms ball mills:

- VRM Mechanism: Material is fed by a precision charger onto a rotating grinding table. Hydraulically loaded rollers exert 50–150 MPa pressure on a stabilized material bed. Particles crush adjacent particles with minimal metal-to-metal contact. Only 5–10% of energy dissipates as friction or heat.

- Ball Mill Mechanism: Steel balls (occupying 25–35% of the drum) cascade and impact material randomly. Studies show 60–70% of energy is wasted on ball collisions, liner abrasion, and heat generation. Merely 30% actually fractures particles.

- Real-World Impact:

- Cement raw meal grinding: VRMs consume 15–25 kWh/t vs. ball mills’ 30–45 kWh/t.

- Coal pulverization: VRMs use 8–12 kWh/t; ball mills require 20–30 kWh/t.

A single 300-tph VRM saves ~3,000 MWh annually—enough to power 250 homes.

2. Integrated Drying: Eliminating Pre-Processing Steps

VRMs inherently handle moisture-rich feeds, bypassing standalone drying systems:

- Hot Gas Integration: Preheater exhaust gases (200–350°C) enter below the grinding table. As material centrifuges outward, hot gases fluidize and dry particles during grinding. This handles 15–20% moisture in clays or slag.

- Ball Mill Limitation: Moisture >7% causes slurry formation (“slip”). External rotary dryers add 15–30 kWh/t energy and double equipment footprint.

- Case Study: A Brazilian cement plant reduced fuel costs by 18% using VRM’s waste-heat drying instead of natural gas-fired dryers for limestone slurry.

3. Space Optimization: Vertical Integration vs. Horizontal Sprawl

VRMs consolidate processes into a single tower, slashing plant footprint:

- VRM Layout: Grinding, classification, and drying occur in a 20–40m vertical column. Auxiliary systems (e.g., the material charger) attach directly. A 200-tph unit occupies ~150 m².

- Ball Mill Circuit: Requires horizontal ball mill (e.g., Ø4.2m × 13m), separate elevator, dynamic separator, and baghouse. Total area: 400–600 m².

- Footprint Ratio: VRM plants use 50–60% less space—critical for urban sites or brownfield expansions.

4. Particle Size Distribution & Product Quality

Precise classification mechanics yield superior product consistency:

- VRM Classification: Ground material enters an integrated rotor-type separator. Centrifugal forces eject coarse particles (>45 µm) back to the table; fines (<45 µm) exit with airflow. Resulting PSD has a steep slope (narrow size range)—e.g., 95% under 75 µm.

- Ball Mill Classification: Material exits the mill before classification, causing “overgrinding” of fines and coarse tailings. Typical PSD spreads widely (e.g., 70–130 µm for cement).

- Performance Impact:

- Cement: VRM-produced cement achieves 5–10% higher 28-day strength due to optimized particle shapes (angular fragments hydrate faster than ball mills’ rounded grains).

- Coal: VRM’s uniform 45–75 µm coal powder burns with 99.5% combustion efficiency vs. 92–95% for ball mill output.

5. Operational Flexibility & Process Control

Automation compatibility makes VRMs responsive to real-time demands:

- Adjustability:

- Roller pressure: Hydraulic charger systems modulate force ±10% in seconds to handle material hardness fluctuations.

- Airflow: Gas volume adjusts to alter drying speed or fineness.

- Separator speed: Particle cut size shifts without stopping the mill.

- Ball Mill Rigidity: Changes require physical interventions—adjusting feed rate, ball charge, or separator settings—taking hours.

- Example: A German plant switches VRM from cement (45 µm) to slag (32 µm) in 15 minutes. Ball mills need 4–6 hours for similar transitions.

6. Maintenance & Lifetime Economics

Reduced wear part exposure lowers operating costs:

- VRM Wear Profile:

- Rollers and table liners endure 8,000–12,000 hours before replacement.

- Wear occurs only during bed compression—no impact abrasion.

- Segmented wear parts allow partial replacement during 8-hour shutdowns.

- Ball Mill Wear Profile:

- Balls and liners last 3,000–5,000 hours.

- High-impact collisions accelerate metal fatigue.

- Full mill entry required for relining (24–48 hours downtime).

- Cost Comparison:

Cost Component VRM (per ton) Ball Mill (per ton)

Energy $1.80 $3.20

Wear Parts $0.35 $0.85

Maintenance Labor $0.20 $0.50

Total OPEX $2.35 $4.55 7. Environmental & Safety Advantages VRMs inherently support sustainability goals:- Noise: VRMs operate at 75–80 dB(A) due to enclosed grinding—ball mills exceed 100 dB(A) from cascading balls.

- Dust Control: Negative pressure systems capture 99.9% of dust at the source.

- Heat Recovery: Utilizing waste gases cuts CO₂ by 15–25 kg/ton of cement vs. standalone dryers.

- Safety: No high-risk confined-space entries for grinding media replacement.

- Ultra-Fine Grinding: For particles <10 µm (e.g., pigments), ball mills’ extended residence time wins.

- High-Abrasives: VRM wear costs spike for silica >15% or Mohs 9+ minerals.

- Small-Scale Operations: Sub-50 tph plants may favor ball mills’ lower CAPEX.

Other questions about roller mill:

what are the disadvantages of roller mills?

What is the main purpose of a roller?

What is the difference between a roller mill and a ball mill?

What does a roller mill do?

What’s the difference between a mill and a grinder?

How efficient is a vertical roller mill?

Which is better,roller mill or hammer mill?

What is a roller flour mill?

What is the purpose of a two roll mill?

What is a roller mill also known as?

How does a 3 roller mill work?

What is the job description of a mill roller?

What is the working principle of a roller mill?

What is a mill and how does it work?

What is the basic principle of a milling machine?

What is the two roll mill mixing process?

How to adjust a roller mill?

What is a hammer mill not suitable for?

What is the main advantage of using a vertical roller mill over a ball mill?

What is the difference between a roller mill and a hammer mill?

What are the disadvantages of a hammer mill?

What is the difference between a roller mill and a disc mill?

Which mill is preferred for weight grinding?

What are the disadvantages of a cutter mill?

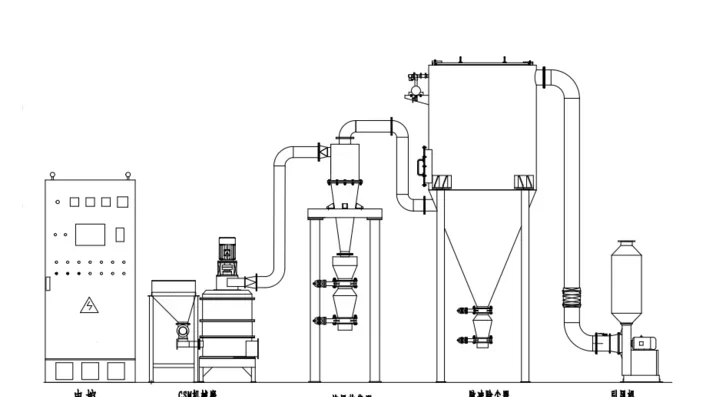

Food Producing Process Flow:

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

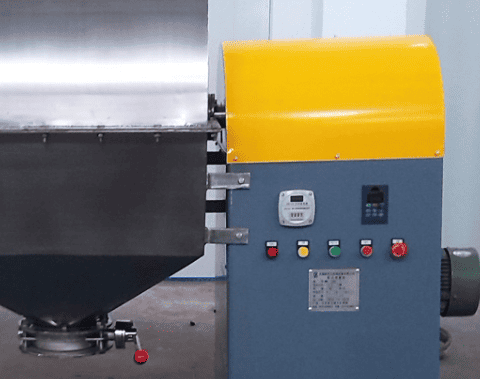

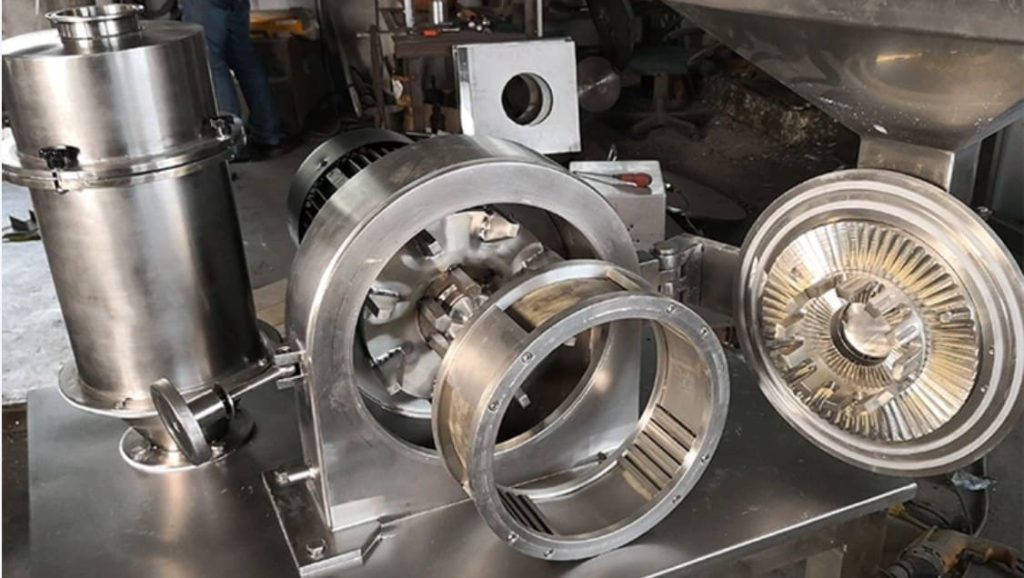

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Grinder for Sale:

Blenders for Sale:

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.