What is the difference between a roller mill and a hammer mill?

What is the difference between a roller mill and a hammer mill? The core difference between a roller mill and a hammer mill lies in their fundamental grinding mechanics: roller mills crush and shear material through controlled compression between rotating cylinders, while hammer mills pulverize via high-speed impact from swinging hammers. This distinction drives divergent applications, energy efficiency, product characteristics, and operational costs across industries like agriculture, mining, and manufacturing.

1. Working Principles: Compression/Shear vs. Kinetic Impact

Roller Mill: Precision Force Application

Roller mills operate on interparticle crushing and shearing:

- Material enters via a regulated charger (screw feeder, vibratory tray) into the gap (nip) between counter-rotating rollers.

- Hydraulic or spring-loaded pressure systems exert 50–150 MPa, compressing the material bed. Particles fracture adjacent particles with minimal metal contact.

- A speed differential (e.g., 1.1:1 to 1.4:1) between rolls generates shearing forces, slicing fibrous or layered materials.

Example: Wheat grains are sheared open between corrugated rollers—bran separates from endosperm with minimal starch damage.

Hammer Mill: Violent Impact Dominance

Hammer mills rely on kinetic energy transfer:

- Rotors spin at 1,000–3,000 RPM, accelerating hammers to 50–120 m/s.

- Material fed by a gravity charger is struck by hammers, then flung against breaker plates/screens.

- Fragmentation occurs through collision, shattering brittle materials instantly.

Example: Coal chunks explode into fragments after direct hammer impact.

Physics Contrast:

- Roller mills use 60–70% of energy for actual particle fracture.

- Hammer mills waste 40–60% of energy as heat, noise, and vibration.

2. Structural Design: Stability vs. High-Velocity Chaos

| Component | Roller Mill | Hammer Mill |

|---|---|---|

| Core Parts | Heavy rolls, hydraulic pressure system | Rotor, hammers, screens, breaker plates |

| Speed | 10–100 RPM (low-inertia rotation) | 1,000–3,000 RPM (high centrifugal force) |

| Frame | Reinforced for static pressure | Vibration-dampened for impact shocks |

| Charger | Precision feeder for even distribution | Gravity hopper tolerates uneven feed |

| Wear Zones | Roll surfaces (replaceable liners) | Hammers, screens, interior linings |

Key Insight: Roller mills resemble a precision press; hammer mills function like a centrifugal grenade.

3. Material Suitability: Brittleness vs. Ductility

Roller Mills Excel With:

- Medium-hard, friable materials (Mohs 3–6): Cement clinker, limestone, dry clay.

- Moisture-tolerant substances (up to 20%): Slag, wet grains (integrated drying).

- Ductile/fibrous items: Oilseeds, rubber, plastics (shearing action).

Avoid: Quartz (Mohs 7), sticky mud, or metals—causing rapid wear or jams.

Hammer Mills Handle Best:

- Brittle, low-moisture materials (<15%): Coal, glass, dry biomass.

- Lightweight items: Straw, wood chips, electronic waste.

Failures: Tacky polymers (clog screens), tungsten carbide (shatters hammers).

4. Output Characteristics: Uniformity vs. Fractured Fragments

| Property | Roller Mill | Hammer Mill |

|---|---|---|

| Particle Size | 80% < 75 µm (adjustable via gap pressure) | 0.5–50 mm (screen-dependent) |

| Shape | Cubic/flaky (controlled fracture) | Angular/irregular (random impact) |

| Consistency | Narrow PSD (e.g., cement: ±2% tolerance) | Broad PSD (fines + coarse tails) |

| Heat Sensitivity | Low temp rise (<15°C) | High temp (60–90°C common) |

Application Example:

- Roller mill flour: Uniform 100 µm particles optimize baking.

- Hammer mill animal feed: Coarse 5 mm fragments aid digestion.

5. Energy & Maintenance: Efficiency vs. High-Uptkeep

Energy Consumption

- Roller Mills: 15–25 kWh/ton (e.g., cement raw meal).

- Hammer Mills: 30–45 kWh/ton for similar materials—40% higher due to aerodynamic losses.

Maintenance Reality

- Roller Mill Wear:

- Roller liners last 8,000–12,000 hours.

- Hydraulic seals replaced annually.

- Hammer Mill Wear:

- Hammers degrade in 200–1,000 hours (abrasives).

- Screens replaced weekly in mining apps.

- Rotor bearings fail from imbalance.

Cost Impact: Hammer mills incur 3x higher wear-part costs per ton.

6. Operational Applications: Specialized Roles

Roller Mill Dominates:

- Cement/Clinker Grinding: VRMs cover 90% of new installations.

- Food Processing: Flaking oats, grinding cocoa nibs.

- Pharmaceuticals: Precise API size reduction.

Hammer Mill Prevails:

- Recycling: Crushing e-waste, pallets.

- Biomass Prep: Chopping straw for pelletizing.

- Coarse Mineral Crushing: Primary size reduction in quarries.

When to Choose: Decision Factors

| Factor | Choose Roller Mill If | Choose Hammer Mill If |

|---|---|---|

| Particle Size Target | < 100 µm | > 500 µm |

| Material Moisture | > 10% | < 8% |

| Energy Budget | Prioritize efficiency | Accept higher kWh/ton |

| Abrasiveness | Low-to-medium (e.g., limestone) | Low (e.g., coal) |

| Noise Constraints | Critical (75 dB max) | Tolerable (110 dB+) |

Conclusion: Two Philosophies of Size Reduction

Roller mills and hammer mills solve grinding challenges through opposing physical principles. The roller mill—a controlled, energy-efficient grinding machine—excels in precision applications demanding fine powders and uniform morphology. Its hydraulic charger system and interparticle crushing mechanics make it ideal for cement, food, and pharmaceuticals. Conversely, the hammer mill’s brute-force impact suits coarse, high-volume fragmentation of brittle materials, despite higher energy and maintenance costs. They are not rivals but complementary tools: select roller mills for “refined grinding” and hammer mills for “rugged crushing.” Understanding this divide prevents costly misapplication—like using a hammer mill for cement (wasting $40/ton in energy) or a roller mill for e-waste (jamming with copper wires).

Other questions about roller mill:

what are the disadvantages of roller mills?

What is the main purpose of a roller?

What is the difference between a roller mill and a ball mill?

What does a roller mill do?

What’s the difference between a mill and a grinder?

How efficient is a vertical roller mill?

Which is better,roller mill or hammer mill?

What is a roller flour mill?

What is the purpose of a two roll mill?

What is a roller mill also known as?

How does a 3 roller mill work?

What is the job description of a mill roller?

What is the working principle of a roller mill?

What is a mill and how does it work?

What is the basic principle of a milling machine?

What is the two roll mill mixing process?

How to adjust a roller mill?

What is a hammer mill not suitable for?

What is the main advantage of using a vertical roller mill over a ball mill?

What is the difference between a roller mill and a hammer mill?

What are the disadvantages of a hammer mill?

What is the difference between a roller mill and a disc mill?

Which mill is preferred for weight grinding?

What are the disadvantages of a cutter mill?

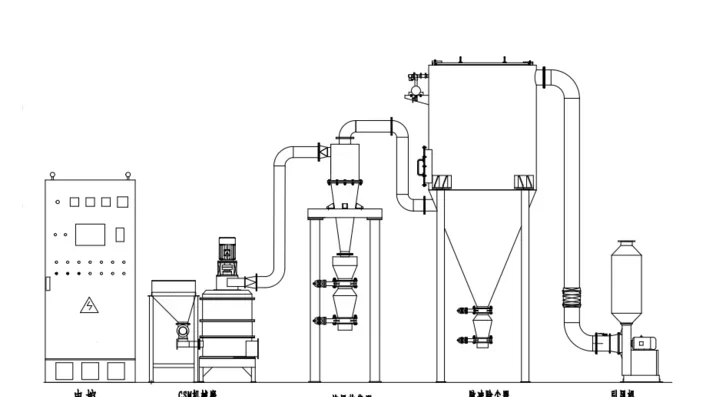

Food Producing Process Flow:

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

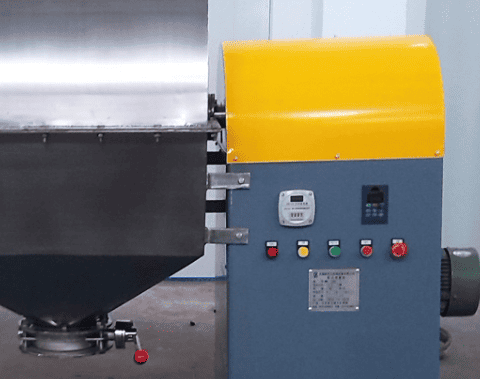

About LKMixer

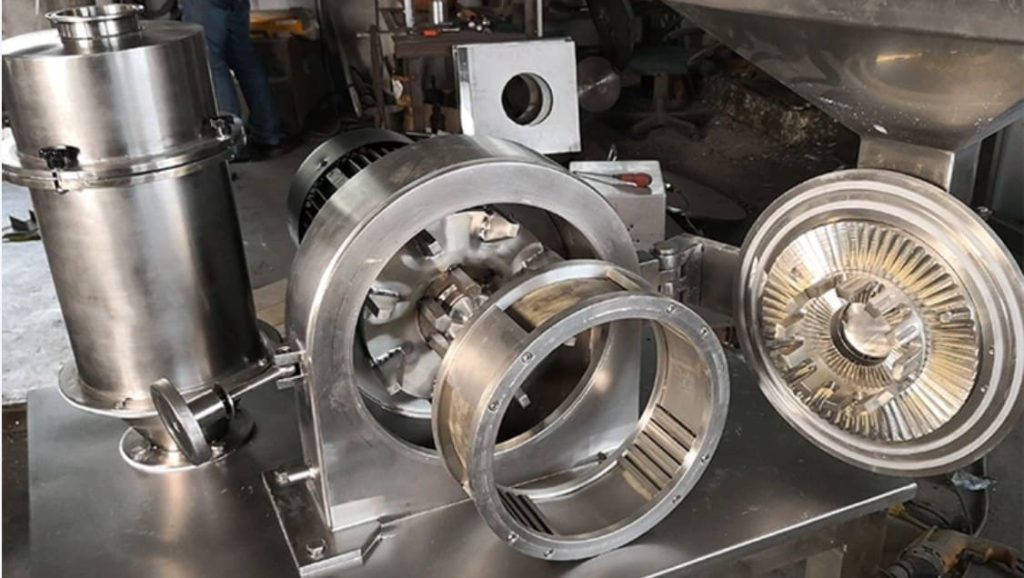

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Grinder for Sale:

Blenders for Sale:

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.