Is it necessary to clean a coffee grinder?

Is it necessary to clean a coffee grinder? Yes, cleaning your coffee grinder is essential for maintaining the flavor of real coffee, stopping the growth of bacteria, and prolonging the life of your device. Within hours, leftover coffee particles and oils oxidize, contaminating fresh beans with rancid, stale flavors and providing a moist environment for mold growth. A precision tool becomes a source of tainted brews when this ritual is neglected, sacrificing both taste and hygiene.

Why Cleaning Isn’t Optional: Flavor, Health, and Machine Integrity

- Flavor Sabotage: Coffee beans contain volatile aromatic compounds (like aldehydes and esters) that create nuanced fruity or floral notes in light roasts. When residual oils oxidize, they generate “off” flavors—mustiness, bitterness, or cardboard-like notes—that overpower these delicate profiles. A blade grinder or universal grinder left unwashed for a month can taint new batches, masking the terroir of Ethiopian Yirgacheffe or Colombian beans.

- Bacterial Risks: Coffee oils attract moisture, creating a biofilm ideal for mold (like Aspergillus) and bacteria. In humid climates (e.g., Southern China’s “wet cold magic”), this risk intensifies. Deep-roasted, oily beans accelerate this process, turning your grinder into a microbial incubator.

- Mechanical Damage: Caked-on fines jam burrs or blades, forcing motors to overwork. In electric grinders, this strains bearings and motors; in manual models, it corrodes stainless steel axles. Unchecked, this reduces grinding uniformity—converting a precision ultrafine grinder into a coarse crusher.

Optimal Cleaning Frequency: From Daily Rituals to Deep Cleans

- Daily (After Every Use): Brush out residual grounds with a soft bristle brush. Target burr crevices, hoppers, and discharge chutes. This prevents particle buildup that alters grind size consistency.

- Weekly/Biweekly: For blade grinders or those processing oily dark roasts, use dry methods like grinding rice or oats to absorb rancid oils. Avoid water—it promotes rust in stainless steel components.

- Monthly Deep Clean: Disassemble burrs/chambers. Wipe with dry microfiber cloths or alcohol-dipped cotton swabs. Never submerge electric bases—this voids warranties and risks electrocution.

- 3–6 Months: Replace burrs if grinding feels sluggish or consistency declines (e.g., excess fines in espresso). Hardened steel burrs last ~200kg; titanium-coated variants endure 500–1,000kg.

Step-by-Step Cleaning Methods by Grinder Type

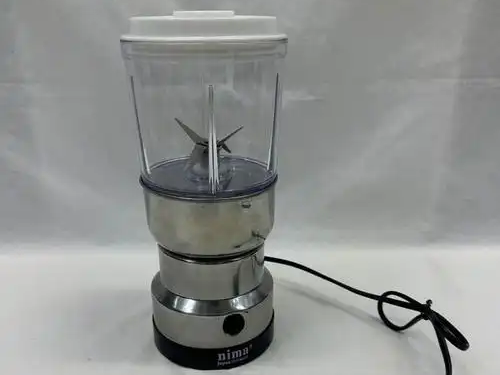

1. Blade Grinders (Entry-Level Electric Models)

- Dry Brushing: Unplug, invert, and tap to dislodge loose grounds. Use a narrow brush (toothbrush-sized) to scour blade edges and seams.

- Oil Absorption: Grind ¼ cup of white rice or rolled oats—their abrasiveness scrubs residues without moisture. Follow with corn starch to absorb lingering oils.

- Caution: Never rinse blades—water seeps into motors, causing shorts. These units lack the sealed design of CE-certificate grinders.

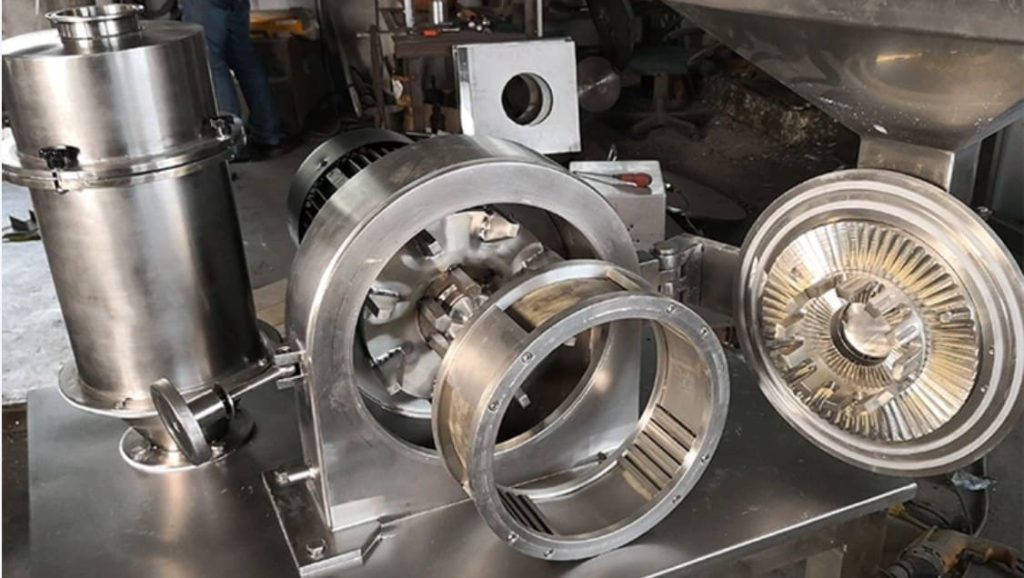

2. Burr Grinders (Conical/Flat, Manual or Electric)

- Disassembly: Remove hoppers and top burrs. Brush burr grooves radially (follow cutting angles) using soft brushes. For ghost tooth burrs, use toothpicks to dislodge impacted fines.

- Non-Washable Parts: Wipe with 70% food-grade alcohol; evaporates quickly, leaving no residue. Avoid citrus cleaners—they leave perfumed traces that corrupt tea or spice grinding.

- Calibration Check: Reassemble carefully. Misaligned burrs ruin grind uniformity—test with coarse crusher settings for French press consistency.

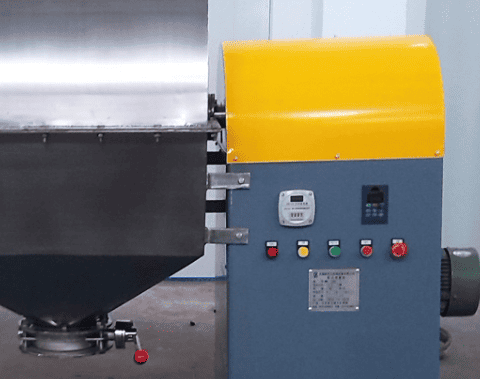

3. Specialty Grinders (Commercial/High-Volume)

- Industrial Protocols: Machines like 500KG grinders use dust collector systems and air-cooled crushers to manage heat. Clean with compressed air and vacuum mill attachments daily.

- Chemical-Free Purging: Grind dedicated grinder cleaning pellets (made of compressed wheat) monthly. Unlike chemical solvents, these won’t taint food-grade surfaces.

Critical Mistakes to Avoid

- Water Exposure: Electric bases and bearings corrode when wet. Even manual axles seize if moisture invades. Blot spills immediately—never emulate cassava grinding machine hose-downs.

- Harsh Cleaners: Soap residues cling to oils, creating soapy off-notes. Vinegar or chemical degreasers corrode metal burrs. Stick to grain/alcohol-based methods.

- Overcleaning: Daily disassembly wears down screws and calibration. Treat your grinder like a dry fruit powder grinder machine—gentle maintenance preserves alignment.

Advanced Tactics for Flavor Guardians

- Bean-Specific Cleaning: After grinding pungent cannabis or spices (e.g., black pepper, licorice), run neutral grains (e.g., instant rice) to purge cross-contamination. Dedicate separate grinders for non-coffee items.

- Humidity Control: In tropical zones, store grinders with silica gel packs. Oily residues attract moisture, clumping grinds like flour.

- Seasoning Post-Cleaning: After deep cleans, grind 10g of discard beans to “recoat” burrs. This restores friction stability for uniform particles—critical for espresso or turbo grinder workflows.

Conclusion: Clean = Pristine Flavor + Machine Longevity

Your grinder, which is a universal bean grinder without a blender or hammer mill, is the guardian of coffee’s soul. Treat it like a precision tool by replacing the burrs at 80% of their rated lifespan (e.g., 160kg for 200kg-hardened steel), performing thorough deep cleanings every three months, and gently dry cleaning after every use. The outcome? Every cup captures the authentic voice of the bean, free from mechanical deterioration or leftovers from the previous day. According to baristas, 70% of the potential of your coffee is determined by your grinder. Honor it.

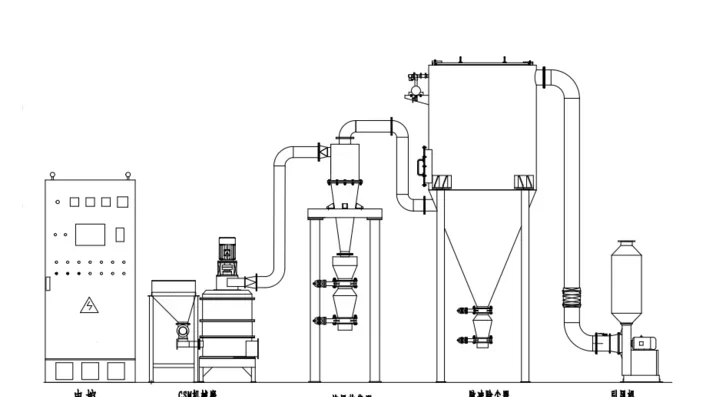

Food Producing Process Flow:

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Grinder for Sale:

Blenders for Sale:

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.