ls grinding business profitable?

ls grinding business profitable? Yes, the grinding industry can be very profitable, with some segments generating 20–50% net margins, but success depends on operational efficiency, value-chain integration, and strategic niche selection. Profitability varies greatly across sectors, from 500KG grinders pulverizing cassava for starch to industrial weed grinders processing cannabis, driven by market demand, equipment precision, and material value. Below, we analyse the economics, opportunities, and pitfalls shaping this fragmented industry.

Key Profit Drivers: Market Growth, Technology, and Value Addition

Three factors dominate grinding profitability:

- Explosive Demand in Critical Sectors:

- Construction & Infrastructure: Global cement grinding stations like Dangote’s 3-million-ton facility in Ivory Coast drive demand for industrial coarse crushers and dust collector grinders. With infrastructure investments surging, the surface grinding services market is projected to grow at 7.4% CAGR, reaching $12.4 billion by 2031 .

- Automotive & Aerospace: Precision grinding for engine components and turbine blades relies on ultrafine grinders and CNC cylindrical grinders. The non-woven abrasives market (used in auto finishing) will hit $4 billion by 2037, with transportation applications claiming 51.3% share .

- Food/Pharma: Cryogenic grinding machines for heat-sensitive medicine or licorice extract yield 30–40% margins due to low competition and high bioavailability premiums.

- Equipment Efficiency & Innovation:

- Automation: Robotic systems (e.g., 3M’s abrasive labs) reduce labor costs by 50% while boosting output consistency. CE-certificate grinders with IoT sensors cut downtime 30% via predictive maintenance .

- Energy Savings: Air-cooled crushers and vacuum mills lower power consumption by 15–25%, crucial for bulk operations like cassava grinding (500kg/hour models consume 70–100 kWh/ton) .

- Value-Added Processing:

- Raw cannabis sells for $1,000/kg, but industrial weed grinders convert it into extracts worth $5,000/kg.

- Waste wood chips ($50/ton) become premium biomass pellets ($180/ton) via hammer mill pulverization .

Profitability by Segment: From Scrap Metal to Spices

1. Metal Recycling: Scale-Dependent Margins

- Equipment: Turbo grinders (e.g., 6000HP shredders) process 80–100 tons/hour of scrap metal.

- Economics:

- Revenue: Shredded steel sells for $250–$320/ton.

- Costs: Electricity ($70/ton), labor ($45/ton), and hammer mill blade replacements ($20/ton).

- Profit: $50–$100/ton net. Large plants clear $5M+ annually, but require $200M+ initial investment .

2. Wood/Biomass: Low-Barrier Entry

- Equipment: Small grinder machines (e.g., portable chippers) handle 1–5 tons/day.

- Economics:

- Revenue: Decorative wood flour fetches $600/ton; biomass pellets sell for $180/ton.

- Costs: Raw timber ($100/ton), electric grinder operation ($15/ton).

- Profit: $100–$200/ton. Small operators net $50K/year with $50K equipment .

3. Food Processing: Premium Niches

- High-Value Examples:

- Dry ginger grinding machines produce powder selling for $8/kg (vs. $2/kg for raw ginger).

- Peanut butter made via universal grinders commands 50% margins in organic markets.

- Equipment Costs: Dry fruit powder grinder machines cost $10K–$50K but pay back in 12–18 months .

4. Minerals & Industrial Materials: Precision Pays

- Diamond Drills: China’s diamond drill market hit $1.9 billion in 2024, with industrial-grade tools (e.g., for aerospace) yielding 35% gross margins .

- Roll Grinders: Tenova’s CNC roll grinders sell for $1M+ but are essential for steel mills. Operators charge $500/hour for regrinding services .

Cost Structures & Hidden Risks

1. Capital and Operational Costs

- Equipment Investment:

- Entry-level: Herb grinders ($50–$500) for cannabis/spices.

- Industrial: Cassava grinding machines ($20K–$100K) or ultrafine grinders ($200K–$500K).

- Operating Expenses:

- Energy: 500KG grinders consume 70–100 kWh/ton; solar integration slashes costs 40%.

- Maintenance: Hammer mill screens/blades require monthly replacement ($2K–$8K).

- Labor: Semi-automated dust collector grinders need 1–3 operators ($30K/year each).

2. Profit-Killing Risks

- Material Contamination: Metal fragments in cassava jam cutting-type blades, causing $5K+ downtime.

- Regulatory Compliance: OSHA fines for dust grinder emissions exceed $50K/violation.

- Market Volatility: Scrap steel prices dropped 13.4% in 2025, eroding margins .

Winning Strategies for Maximum Profitability

1. Technology Upgrades

- Automate sorting with AI-powered optical systems: Separating copper from shredded cars adds $200/ton revenue.

- Use cryogenic grinding machines for premium medicine/spices—particles under 10μm sell at 300% markup.

2. Vertical Integration

- Coffee roasters using in-house electric grinders save $0.50/lb on outsourcing.

- Metal recyclers combine shredders and airflow pulverizers to produce ready-to-sell powder.

3. Niche Specialization

- Target underserved markets:

- Licorice root grinding for digestive supplements (40% margins).

- Bone meal production via high-speed dry grinders for pet food ($1,500/ton).

4. Sustainability Incentives

- Governments subsidize biomass grinding: U.S. USDA grants cover 30% of hammer mill costs for wood waste processing .

Conclusion: Grind Smarter, Not Harder

The grinding business thrives when operators align equipment, materials, and markets:

- Avoid low-margin commoditization: Pulverizing rice/flour yields 5–10% margins; instead, target cannabis extracts or aerospace alloys.

- Invest in precision: CE-certificate grinders with automation boost output 30% while cutting labor.

- Leverage waste streams: Cassava peels (worth $10/ton) become $500/ton gluten-free flour via dry fruit powder grinder machines.

Final verdict: Profits exist—but only for those who grind with strategy. From a $500 black pepper grinder to a $500K vacuum mill, the real money lies not in crushing harder, but in crushing wiser.

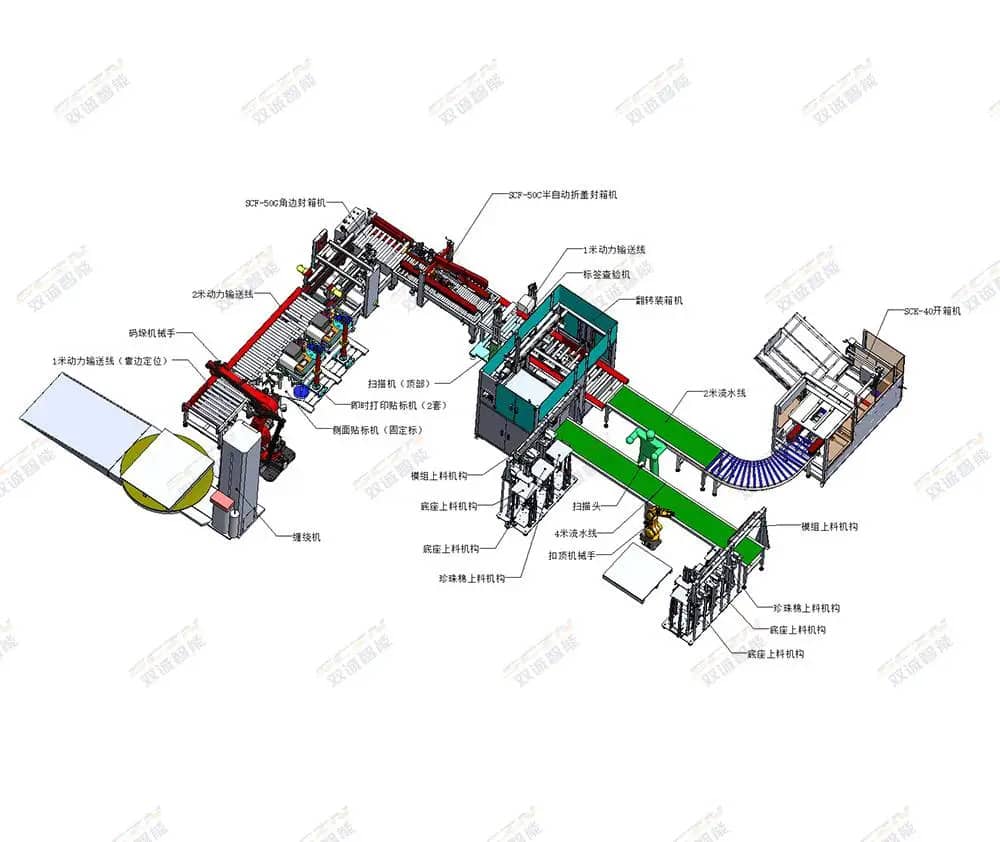

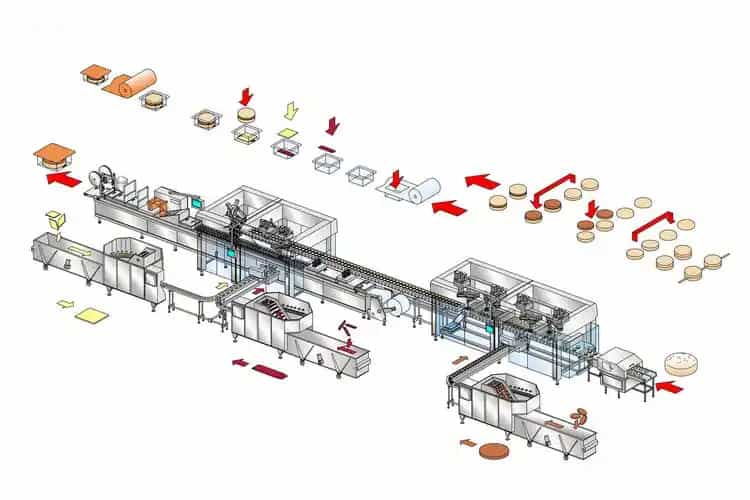

Food Producing Process Flow:

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

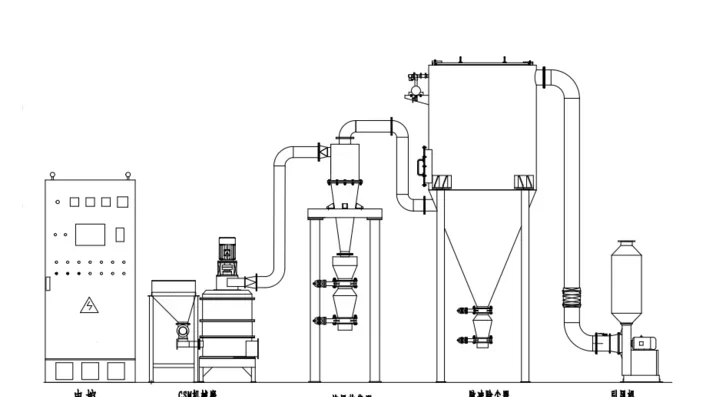

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

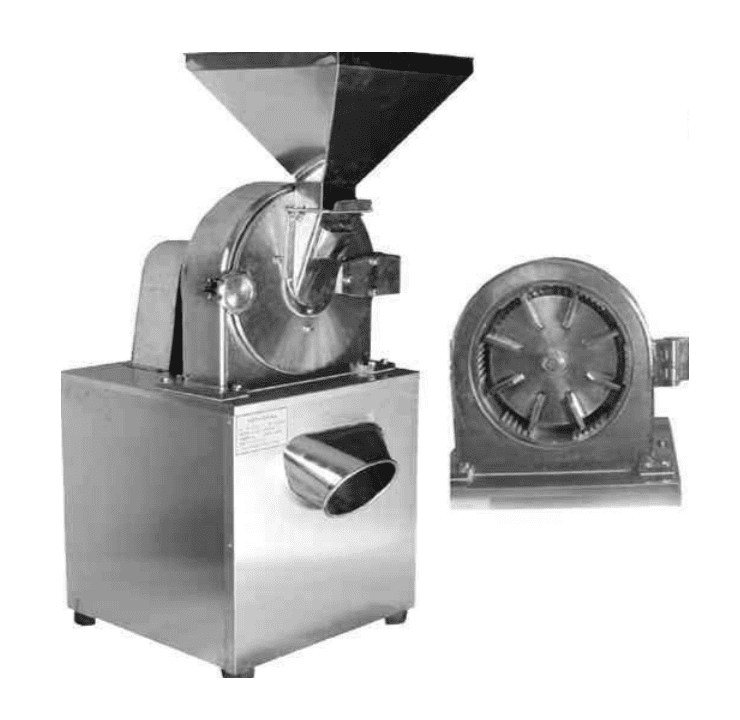

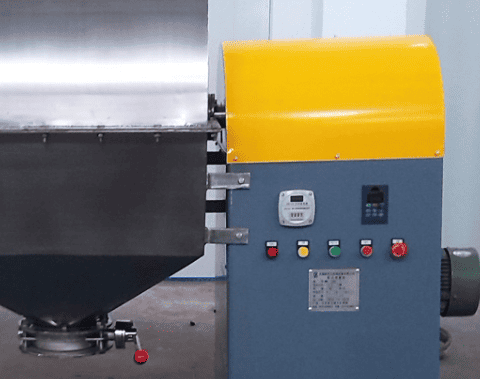

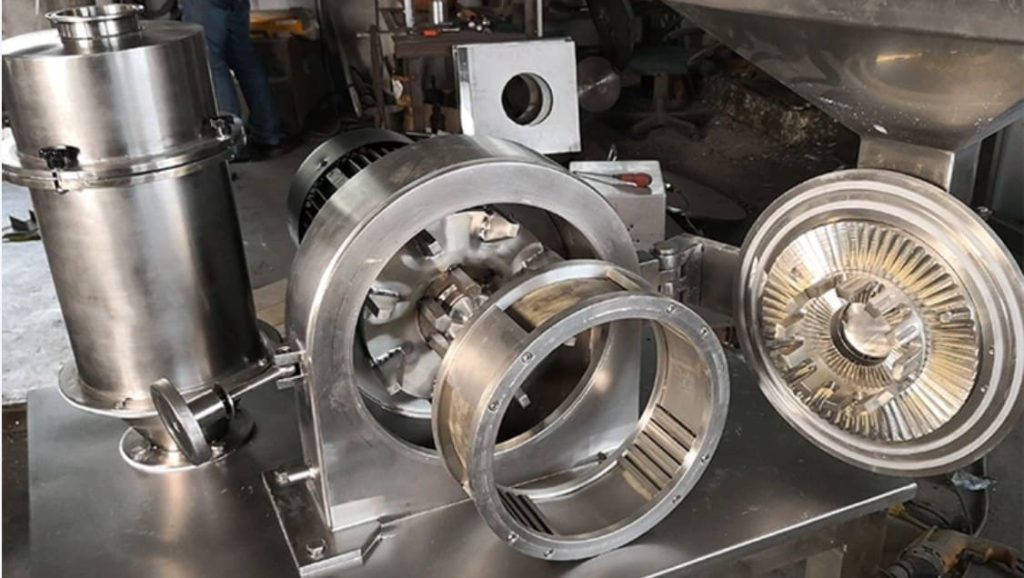

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Grinder for Sale:

Blenders for Sale:

FAQ(Click and See More)

Why Choose Us?

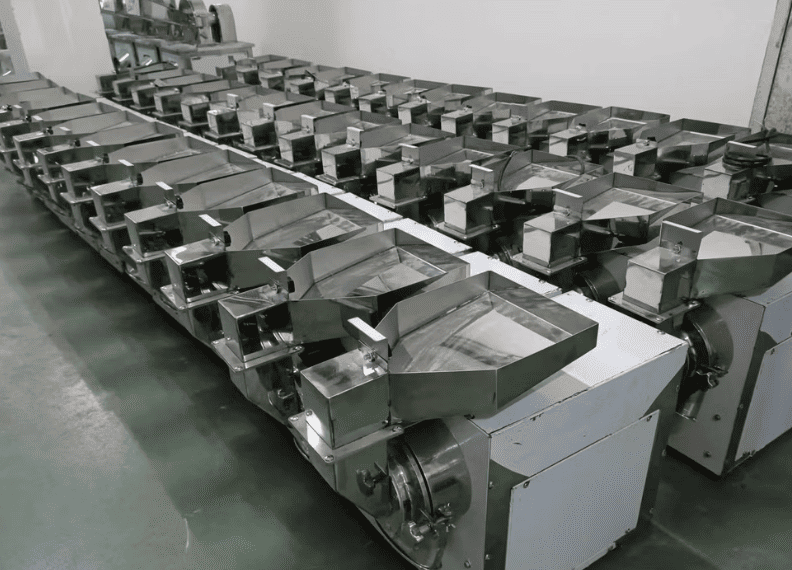

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.