Do and don’ts of grinding machine?

Do and don’ts of grinding machine? The basic dos and don’ts of operating grinding machines revolve around safety procedures, material compatibility, and maintenance discipline. If you break even one rule, it could lead to catastrophic failure, ranging from $15 herb grinders breaking from wet spices to $500K industrial grinders exploding due to metal contamination. These universal principles apply to all grinding applications, whether you’re using a 500KG cassava grinder or a small electric coffee grinder.

Pre-Operation: The Make-or-Break Preparation

DO:

- Verify power compatibility like a CE Certificate grinder requires 380V±10% industrial voltage, while small grinder machines need stable 110V/220V. Use multimeter checks to prevent $8,000 motor burnout.

- Conduct blade integrity inspections: For stainless steel cutters in universal grinders, measure edge thickness with calipers – wear beyond 2mm (per JB/T 9824.1-2018) demands immediate replacement.

- Implement material triage: Remove metal fragments from cassava roots using magnetic separators, and pre-dry mushroom batches to ≤12% humidity to prevent dust grinder clogging.

DON’T:

- Neglect PPE protocols: Operating hammer mills without OSHA-approved face shields risks permanent eye damage from 200mph particle ejections.

- Bypass empty-run tests: Skipping 30-second no-load rotation checks for turbo grinders hides bearing defects that escalate to $20,000 breakdowns.

- Ignore capacity limits: Overfilling a 200KG cannabis grinder beyond 80% volume causes motor overload tripping.

Operational Phase: Precision Control Saves Lives

DO:

- Gradual feeding: Introduce corn kernels at 15% hopper capacity increments to coarse crushers, monitoring amperage to stay under rated load.

- Environment management: Run dust collector grinders at ≤85dB with N95 masks in chemical processing zones to meet NIOSH 4mg/m³ particulate limits.

- Thermal vigilance: Use infrared thermometers to ensure air cooled crusher bearings never exceed 70°C – the failure threshold for food-grade lubricants.

DON’T:

- Allow human intervention: Reaching into running cutting-type mills to unclog meat causes 400+ amputations yearly (OSHA 2023 data).

- Disregard material properties: Grinding bone in dry fruit powder grinder machines instead of dedicated bone crushers fractures titanium blades.

- Override safety systems: Disabling vacuum mill pressure sensors risks explosive decompression at 30PSI operating levels.

Post-Processing: Where Neglect Breeds Disaster

DO:

- Sequential shutdowns: For industrial weed grinders, always: 1) Stop feeding 2) Run empty 45 seconds 3) Cut power 4) Engage rotor lock.

- Post-operation sanitation: Disassemble licorice grinding machine chambers weekly with food-safe detergents to prevent cross-contamination in medicine production.

- Residual energy control: Install physical lockout tags on high speed dry grinders during maintenance – 37% of accidents occur during “inactive” servicing.

DON’T:

- Delay cleaning: Leaving sugar residues in ultrafine grinders attracts corrosion-causing moisture that pits stainless steel surfaces.

- Ignore wear documentation: Failing to log vibrating pulverizer screen replacements voids warranty on $50,000 units.

- Skip grounding checks: Omitting monthly earth resistance tests on electric grinders risks lethal shocks in wet environments.

Material-Specific Protocols

Food & Pharma Applications

DO:

- Sanitize dry ginger grinding machines with NSF-certified solutions after each batch

- Validate tea particle distribution through 100-mesh sieves pre-packaging

DON’T: - Process peanut batches without allergen cross-contamination buffers

- Operate cryogenic grinding machines below -150°C for heat-sensitive medicine

Industrial Materials

DO:

- Pre-crush metal scrap with coarse crushers before hammer mill processing

- Use inert gas purging in airflow pulverizers for flammable chemical powders

DON’T: - Feed uncut tobacco stalks directly into 200KG grinders

- Exceed 40% density limits when milling wheat in universal grinders

Maintenance Matrix: From Home to Heavy Industry

| Equipment | Critical Do’s | Forbidden Don’ts |

|---|---|---|

| Herb Grinder ($15-50) | Hand-wash blades weekly Store in silica-gel containers | Never submerge motor base Don’t grind frozen spices |

| Black Pepper Grinder (Commercial) | Replace ceramic burrs biannually Calibrate coarseness monthly | Avoid salt without corrosion-proofing Never run empty >2 minutes |

| 500KG Grinder (Industrial) | Laser-align rotors quarterly Rebuild hydraulics at 10,000hrs | Skip vibration analysis Use non-OEM bearings |

Emergency Response Protocol

- Mechanical Failure: Immediately hit emergency stop, disconnect power, lock out – then inspect for:

- Hammer mill blade fragmentation

- Turbo grinder smoke indicating winding burnout

- Material Hazards: For toxic chemical releases:

- Evacuate 50m radius

- Activate dust collector containment

- Notify HAZMAT teams

- Medical Emergencies:

- Amputation: Apply tourniquet, preserve limb on ice

- Electric shock: Never touch victim until power verified off

Core Principles for Every Grinder

- Precision Beats Power: A properly calibrated small grinder machine outperforms abused industrial weed grinders.

- Contamination is Cumulative: One rice batch in a coffee grinder requires 3 sterilizations to remove starch residues.

- Heat is the Silent Killer: Every 10°C above 70°C halves universal grinder bearing lifespan.

Final Verdict: Treat every grinder – from $20 flour mills to $500K cassava grinding machines – like precision surgical tools. The 30 seconds saved skipping lockout-tagout could cost $500,000 in equipment and lives. When in doubt: Stop. Lock. Verify.**

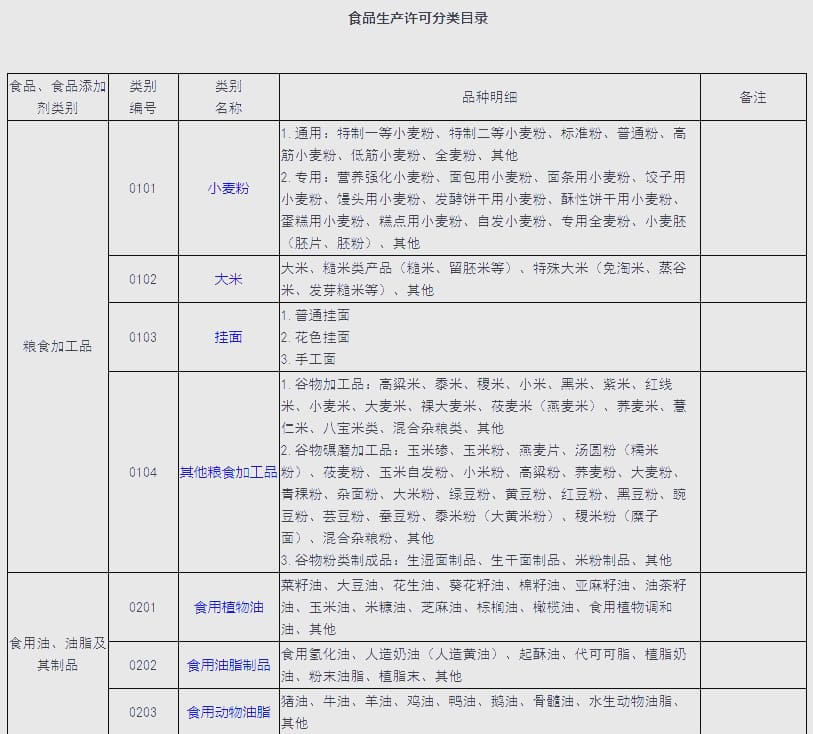

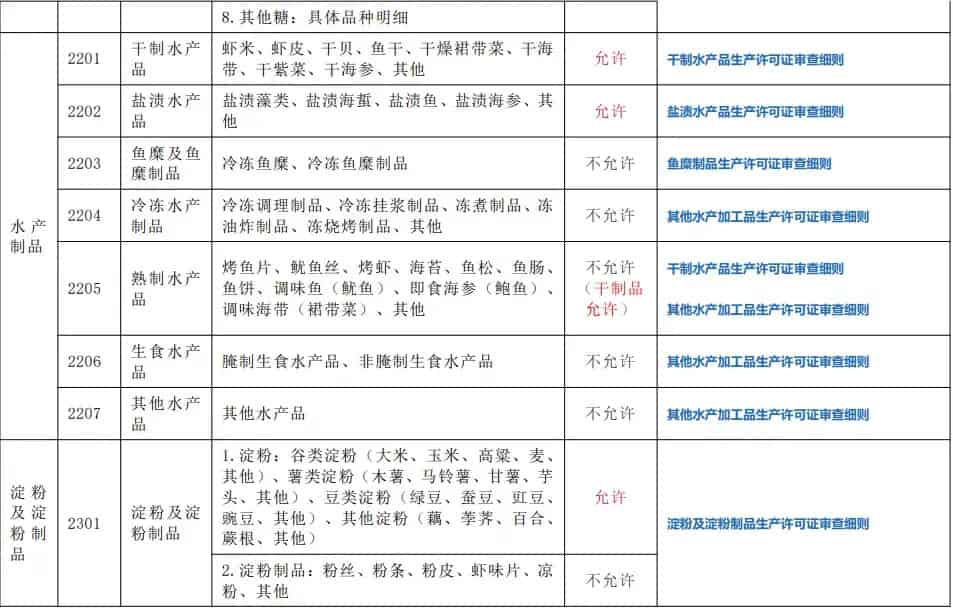

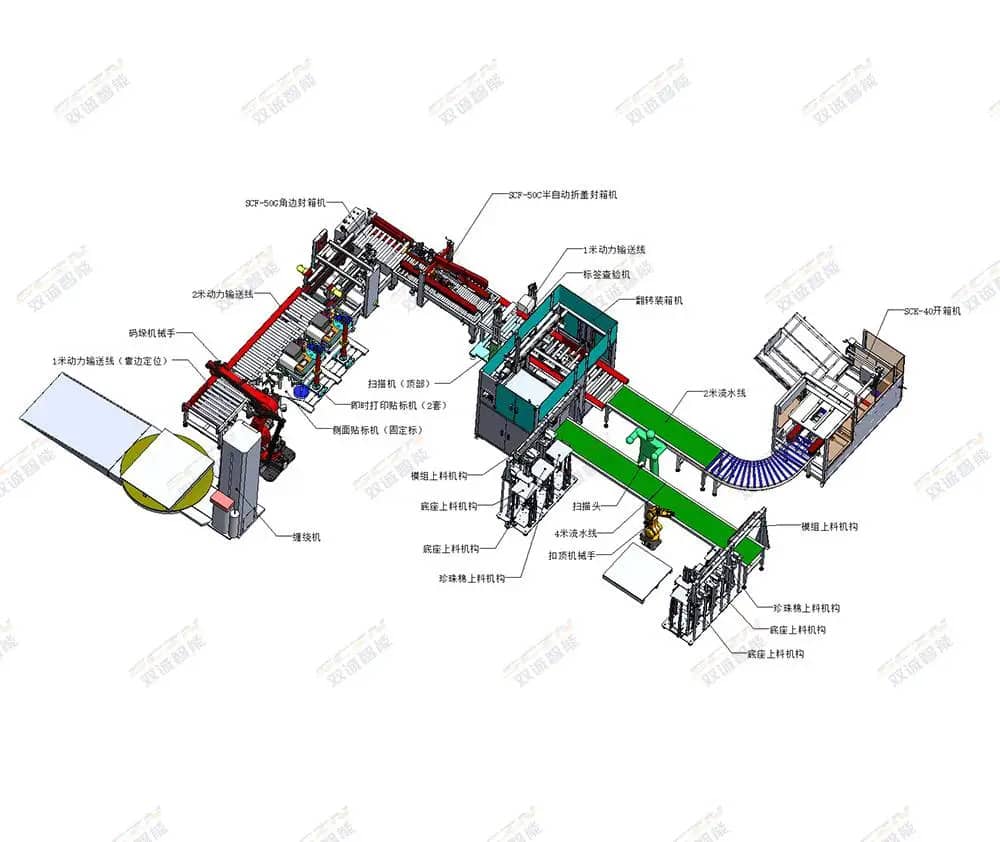

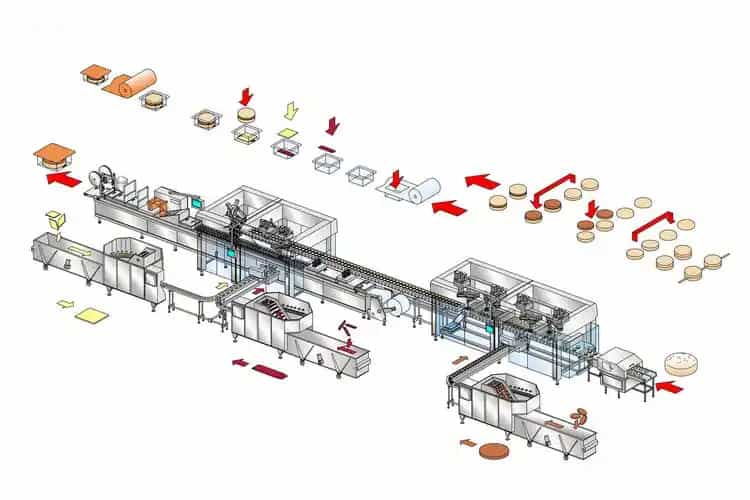

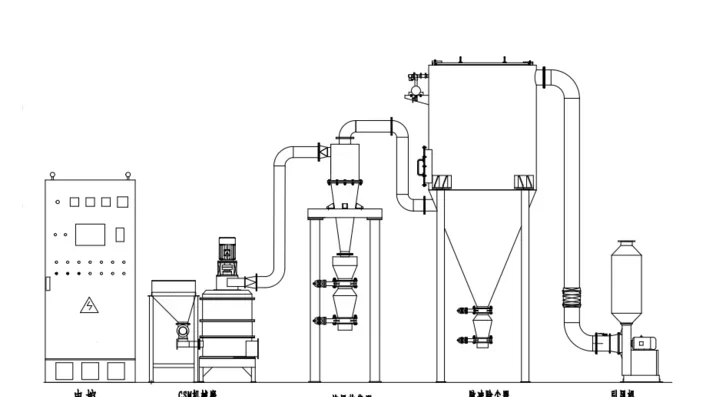

Food Producing Process Flow:

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

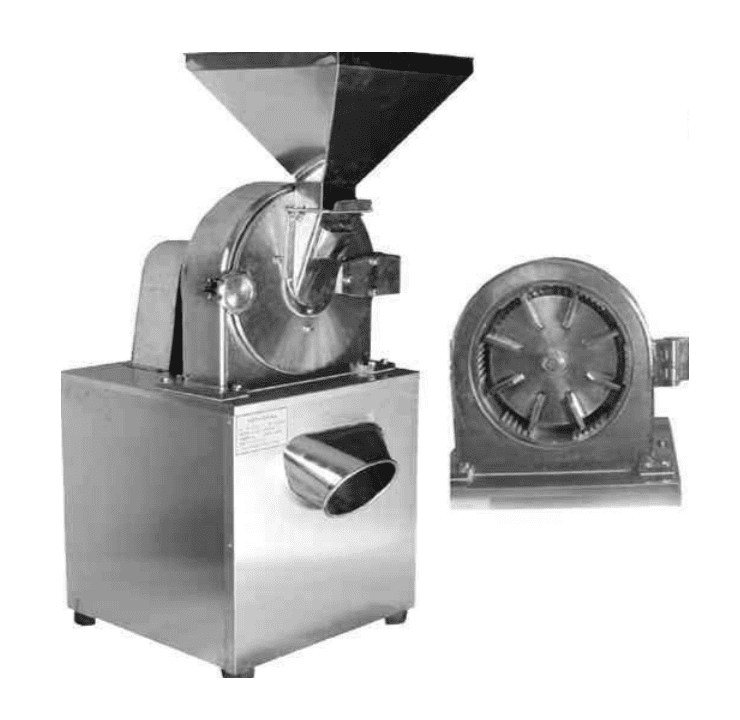

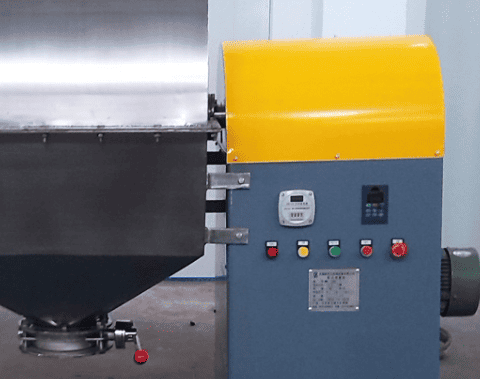

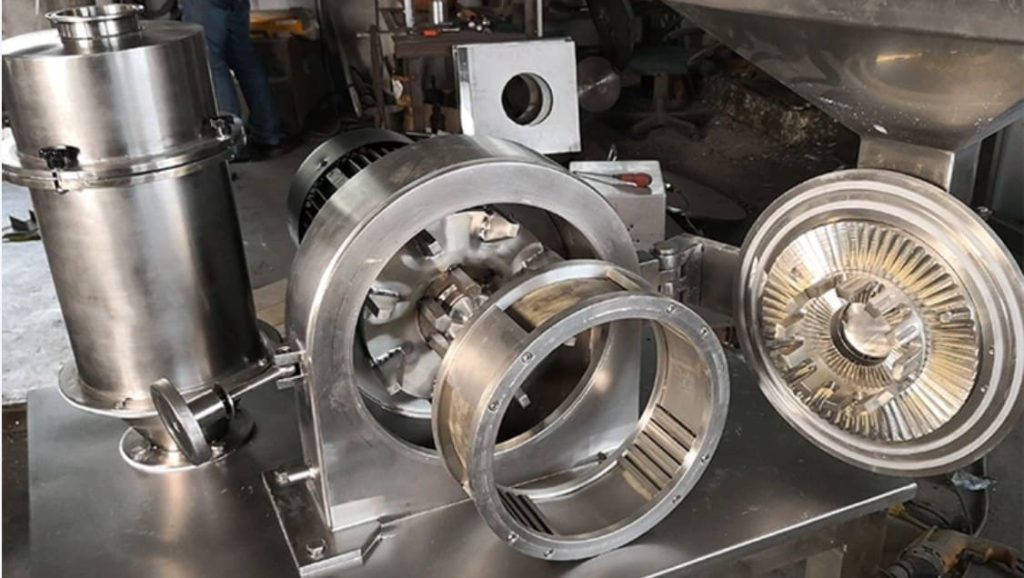

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Grinder for Sale:

Blenders for Sale:

FAQ(Click and See More)

Why Choose Us?

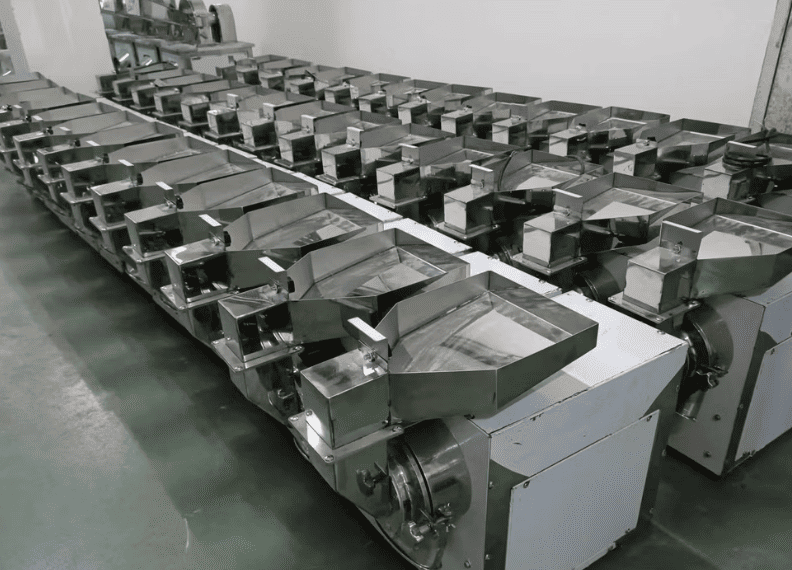

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.