How to use a grinder step by step?

How to use a grinder step by step? Effective use of a grinder necessitates careful planning, accurate operation, and conscientious maintenance—a six-stage process that emphasizes longevity and safety while adapting to commercial, residential, and industrial settings. These procedures guarantee the best results whether using a home unit powered by a USB charger or a cryogenic industrial grinding machine. We break down the workflow with practical applications and technical detail below.

Universal Workflow: Six Stages for All Grinders

Stage 1: Pre-Operation Preparation

Before activating any grinding machine, conduct these critical checks:

- Equipment Inspection: Verify structural integrity—tighten loose screws on home grinders (e.g., Fang Shifu’s blade assembly), test sieve mesh integrity on industrial units, and ensure belt tension aligns with manufacturer specs (typically 10–15N force deflection). For cryogenic models, pressure-test liquid nitrogen lines using soap solution to detect leaks—a single undetected leak can cause severe frostbite at -196°C.

- Material Preparation: Optimize feedstock by drying high-moisture items (>10% humidity) like vanilla pods to <5% using dehydrators (40–50°C for 4 hours). Remove metal/stone contaminants via magnetic separators or sieving—essential for peppercorns often containing gravel. Pre-crush extremely hard materials (cassia bark, nutmeg) with a mallet to 2–3cm fragments; this reduces grinding stress by 70%, extending blade life.

Stage 2: Parameter Configuration

Calibrate settings based on material properties:

- Particle Size Control: Industrial jet mills adjust fineness via classifier wheel speed (e.g., 2,000 RPM for 25μm powder; 3,500 RPM for 10μm). Home devices like the Fang Shifu 3000W use dial settings—”Coarse” (250μm) for chili flakes, “Fine” (75μm) for spice blends.

- Thermal Management: Activate cooling systems for heat-sensitive herbs (mint, basil). Cryogenic units pre-chill chambers to -196°C for 5 minutes; lab grinders engage water-jacketed cooling to cap temperatures at 40°C. Neglecting this loses 30%+ volatile oils.

Stage 3: Startup & Operation

Initiate grinding systematically:

- No-Load Test: Power on without material—listen for abnormal vibrations indicating imbalance (e.g., blade misalignment in branch chippers). Industrial systems sequence auxiliary equipment first: dust collectors before main engines in airflow grinders.

- Feeding Protocol: Load materials gradually—never exceed 50% chamber capacity in home units. For sticky substances (honey-infused herbs), reduce screw feeder speeds to ≤10 RPM to prevent clogging. Industrial cryo-grinders maintain 0.1–0.15MPa pressure via regulated nitrogen flow.

Stage 4: In-Process Monitoring

Track performance metrics actively:

- Critical Gauges: Monitor industrial ammeters—shut down if current exceeds rated load by 30%. Home grinders auto-halt at 60°C surface temperature; cool for 15 minutes before restarting.

- Output Quality Checks: Inspect particle uniformity. For coffee grinding, inconsistent granules signal blade wear—replace if gaps exceed 0.5mm in burr grinders like HexMill.

- Troubleshooting: For jams, cut power immediately and clear blockages with nylon rods (never hands!). Burning smells indicate seized bearings—apply high-temp grease (e.g., molybdenum disulfide).

Stage 5: Shutdown & Unloading

Deactivate safely:

- Sequential Power-Down: Stop feeding first; run empty for 30–60 seconds to purge residue. Cryo-grinders close nitrogen valves before main engines. Industrial jet mills reverse-startup order: main engine off before classifiers/dust collectors.

- Material Recovery: After full stop, collect powder—rotate HexMill’s base knob to release trapped granules. Remove oil-rich residues (sesame, cocoa) with isopropyl alcohol to prevent rancidity.

Stage 6: Cleaning & Maintenance

Preserve equipment integrity:

- Daily Cleaning: Rinse stainless steel blades (home units) and air-dry thoroughly. For toxic materials (e.g., medicinal herbs), soak metal parts in 5% nitric acid for 30 minutes, followed by deionized water rinse.

- Scheduled Upkeep: Lubricate bearings every 50 operating hours with heat-resistant grease. Replace blades with >2mm nicks or worn burrs—HexMill’s lifetime warranty covers gear replacements.

Specialized Protocols by Grinder Type

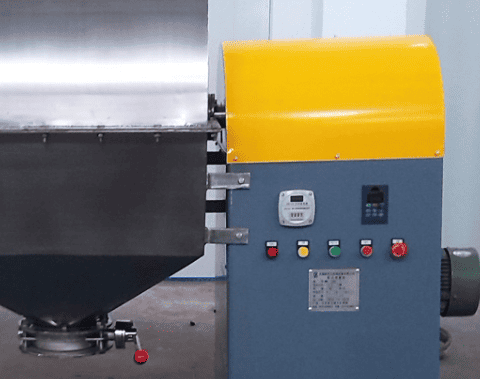

Industrial Cryogenic Grinders (e.g., Hongchuan LN₂ Systems)

- Pre-Chilling Ritual: Inject liquid nitrogen until -196°C stabilizes for 5 minutes—thermal sensors must confirm uniformity before loading.

- Safety Gear: Operators wear cryogenic aprons, face shields, and insulated gloves (ASTM F1891 standard). Install oxygen monitors to detect displacement risks.

- Pressure Calibration: Regulate tank valves to sustain 0.12±0.03MPa—exceeding 0.15MPa risks pipe bursts.

Commercial Burr Grinders (e.g., HexMill Pro)

- Precision Tuning: Rotate the top dial to select among 10 settings—position 8 (0.8mm) for sauce-grade pepper powder. Feed whole spices vertically to prevent uneven crushing.

- Cleaning Rules: Brush burrs with stiff-bristle tools; wipe exteriors with damp cloths. After acidic items (citrus zest), neutralize surfaces using baking soda solution.

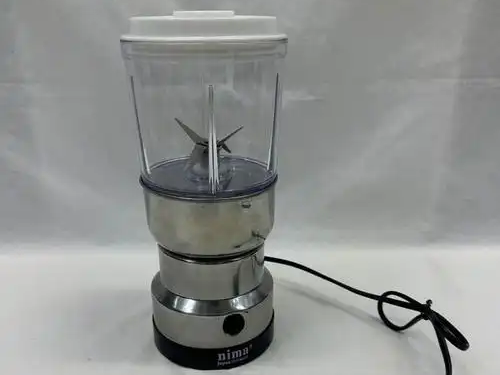

Home Electric Grinders (e.g., Fang Shifu 3000W)

- Efficiency Tactics: Grind hard spices (star anise) in 20-second bursts. Exploit auto-shutdown—prevents motor burnout during 30+ minute sessions.

- Multi-Material Handling: For herbs like ginseng, limit batches to 200g to avoid overheating. Deodorize between spices by grinding 30g rice—absorbs residual oils.

Safety Framework: Non-Negotiable Rules

- Protective Equipment:

- Industrial: Noise-canceling earmuffs (>85dB zones), N95 masks for ultrafine powders.

- Home: ANSI-rated goggles against projectile fragments.

- Operation Bans:

- Never open covers during operation, hand-clear jams, or overload beyond 115% rated capacity.

- Store home units away from children—lockout USB charger ports when idle.

- Emergency Response:

- Liquid nitrogen leaks: Evacuate, absorb spills with vermiculite, NEVER use water.

- Electrocution: Cut mains power, use fiberglass hooks to separate victims from equipment.

Maintenance Schedule

| Task | Industrial | Commercial | Home |

|---|---|---|---|

| Blade/Burr Check | Per shift | Weekly | Monthly |

| Bearing Lubrication | 50 operating hours | 20 hours | 50 uses |

| Sieve Calibration | Monthly | Quarterly | Biannually |

| Electrical Test | Quarterly | Biannually | Annually |

| Deep Cleaning | Acid wash monthly | Sanitize weekly | Quarterly |

Troubleshooting Common Failures

| Issue | Root Cause | Fix |

|---|---|---|

| Uneven particles | Worn blades, torn screens | Replace parts; adjust feed rate |

| Motor failure | Loose wiring, tripped thermal protector | Check plugs; cool & reset protector |

| Metal-contaminated output | Component wear, uncleaned feedstock | Swap damaged parts; pre-sift materials |

| Abnormal noise | Dry bearings, loose fasteners | Lubricate; tighten screws |

| Material sticking | High moisture, insufficient cooling | Dry inputs; enable chiller |

Industry Best Practices

- Michelin Restaurant Pepper Grinding:

- Set HexMill to position 9 (0.8mm).

- Vertically load Tellicherry peppercorns.

- Monitor through viewport—halt at 75μm granulation.

- Factory-Scale Chili Powder Production:

- Pre-cool cryo-grinder to -196°C.

- Process dried chilies via 150μm airflow classifier.

- Output: 500kg/hour with 92% aroma retention.

Conclusion: Precision Through Protocol

Mastering grinder operation hinges on standardization and hazard mitigation:

- Factories demand logged batch data (temperature/pressure) for traceability.

- Kitchens prioritize speed—grind immediately before use to lock in flavors.

- Homes leverage smart safeguards (auto-shutdown, USB charger indicators) for hassle-free use.

Adhere to the triad of training → inspection → progressive loading to slash failure rates by 80%. Remember: A $10,000 cryo-grinder and $30 USB-charger model share one truth—disciplined process transforms raw ingredients into perfected powder.

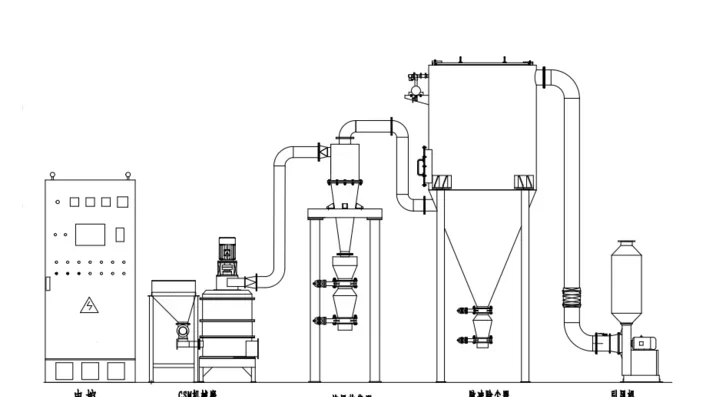

Food Producing Process Flow:

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

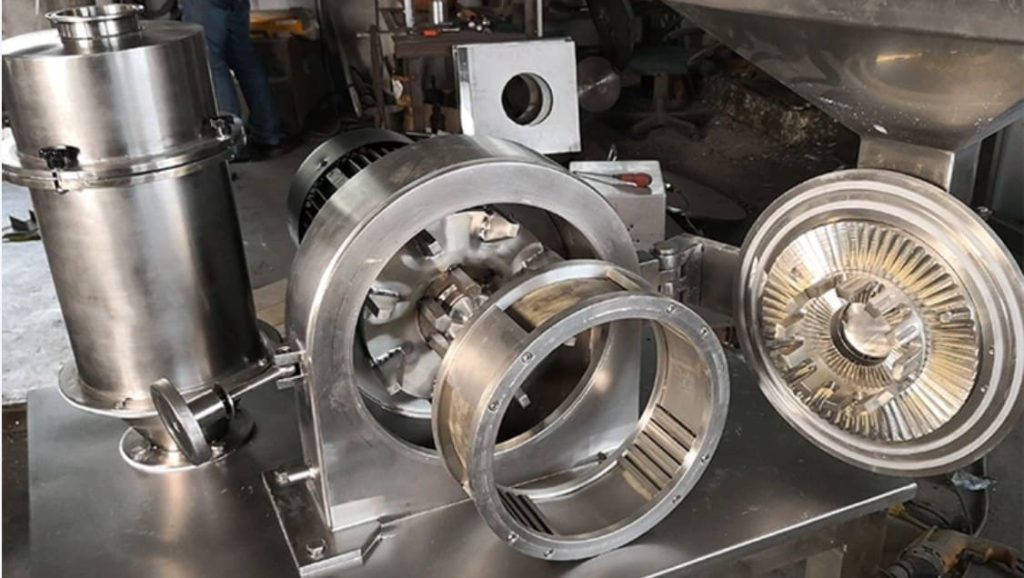

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Grinder for Sale:

Blenders for Sale:

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.