What are the different types of grinding?

Grinding, a fundamental precision machining process, can be classified into various types based on several key perspectives: lubrication method, operation mode, workpiece surface geometry, and precision requirements. Understanding these classifications is crucial for selecting the optimal grinding method for a specific application, balancing factors like material removal rate, surface finish, dimensional accuracy, and cost.

1. Classification by Lubrication/Cooling Method (How the abrasive interacts with the workpiece)

- Dry Grinding: This method involves grinding without any liquid coolant or lubricant. Instead, fine abrasive grains (typically ranging from W3.5 down to W0.5 in size) are uniformly embedded or “charged” directly into the surface of the grinding tool (lap or plate). As the workpiece moves against this charged surface under pressure, the exposed abrasive grains perform the cutting action. The absence of fluid means no messy cleanup and avoids potential fluid contamination issues. Its primary advantage is achieving exceptionally high precision and a very fine surface finish. This is because the rigidly held abrasives produce minimal elastic deformation during cutting, leading to extremely controlled material removal, often in the sub-micron range. Consequently, dry grinding is the preferred choice for the final finishing stages of precision components like gauge blocks, optical flats, and high-precision bearing surfaces where achieving nanometer-level flatness or surface roughness is paramount. The main drawback is the significant heat generation at the contact point, which requires careful control to prevent thermal damage (like burning or tempering) to the workpiece and accelerated abrasive wear. It’s also generally slower than wet grinding for stock removal.

- Wet Grinding: In wet grinding, a liquid grinding fluid (often called a slurry or coolant) is continuously applied or flooded over the grinding zone. This fluid contains coarser abrasive particles (usually W14 to W5) suspended within it. As the grinding tool moves relative to the workpiece, the fluid carries the abrasive grains into the interface. Here, the grains roll, slide, and sometimes fracture, performing a combined cutting, ploughing, and rolling action that removes material. The fluid serves multiple critical functions: it efficiently flushes away swarf (removed material chips) preventing them from scratching the surface, provides cooling to dissipate the intense heat generated, reduces friction between the workpiece and the tool, and can even provide some lubrication. This cooling action allows for much higher material removal rates without damaging the workpiece due to heat, making wet grinding the dominant method for rough grinding operations, initial stock removal, and applications where high productivity is key. It’s widely used for grinding castings, welded components, and preparing surfaces for subsequent finishing operations. The downside is the mess associated with handling the fluid, the need for filtration systems to clean and recirculate the coolant, and the potential for fluid residue that requires cleaning post-operation.

- Semi-Dry Grinding: As the name suggests, semi-dry grinding strikes a middle ground between wet and dry methods. It utilizes a paste-like grinding compound (grinding paste or grease-mixed compound) applied to the grinding tool. This compound consists of abrasive grains mixed with a viscous lubricant base (like grease or heavy oil), often including additives like stearic acid. The paste holds the abrasives effectively and provides lubrication and some cooling, but without the free-flowing nature of wet grinding fluid. This method offers greater flexibility. By adjusting the consistency of the paste (more or less viscous) and the abrasive grain size, operators can tailor the process to achieve results ranging from relatively aggressive stock removal (approaching wet grinding speeds) to finer finishing (closer to dry grinding precision). It’s particularly useful for applications where continuous fluid application is impractical, for portable grinding tools, or when a balance between speed and finish is needed without the full setup of a wet grinding system. Cleaning up the paste residue is generally easier than dealing with large volumes of wet coolant.

2. Classification by Operation Mode (How the grinding action is applied)

- Manual Grinding: This is the traditional method where the grinding action relies entirely on the skill and physical effort of an operator. The operator holds either the workpiece or the grinding tool (like a hand stone, file, or charged lap) and applies controlled pressure while moving them relative to each other in specific patterns. Manual grinding excels in situations involving very low production volumes, one-off custom parts, intricate shapes or contours that are difficult or expensive to fixture for a machine, delicate components requiring sensitive touch, or localized repair work. The operator’s experience is critical for achieving the desired shape, size, and finish. While highly flexible, manual grinding is labor-intensive, relatively slow, and the consistency and precision achieved are highly dependent on the operator’s skill level and fatigue. It’s often used for tool and die maintenance, mold finishing, and precision fitting of small components.

- Mechanical Grinding: This method employs dedicated grinding machines where the relative motion between the workpiece and the grinding tool (wheel, belt, or lap) is powered and precisely controlled by the machine. The workpiece is typically fixtured securely, and the machine controls parameters like rotational speed, feed rate, depth of cut, and oscillation patterns. Mechanical grinding is the backbone of high-volume manufacturing due to its high productivity, repeatability, and consistency. Once the machine is set up and programmed correctly, it can produce identical parts with minimal operator intervention beyond loading/unloading and monitoring. It allows for precise control over grinding parameters, enabling the achievement of tight tolerances and specific surface finishes consistently. Types of mechanical grinding machines include surface grinders (for flat surfaces), cylindrical grinders (for external and internal diameters), centerless grinders (for high-volume cylindrical parts without centers), tool and cutter grinders (for sharpening cutting tools), and specialized machines for complex geometries. Mechanical grinding is essential for producing automotive parts, aerospace components, bearing races, shafts, and countless other mass-produced items.

3. Classification by Workpiece Surface Geometry (What shape is being ground)

- Surface Grinding: This process is dedicated to creating or finishing flat surfaces. The workpiece is typically held on a magnetic chuck or fixtured to a reciprocating or rotary table. The grinding wheel rotates on a horizontal or vertical spindle and moves linearly (or the table moves) to traverse the wheel across the workpiece surface. Precision surface grinding achieves very high levels of flatness and parallelism. It’s used for machining precision machine tool ways, die sets, mold bases, gauge surfaces, and any component requiring a critical flat reference surface. Different wheel types and dressing techniques can produce various surface finishes.

- External Cylindrical Grinding: This method grinds the external diameters and shoulders of cylindrical or conical workpieces (like shafts, pins, rollers, spindles). The workpiece rotates between centers or is supported in a chuck, while a rotating grinding wheel traverses along its length and/or radially in-feed to remove material. Variations include plunge grinding (wheel feeds radially without traverse for shoulders or short lengths) and traverse grinding (wheel moves along the length). Centerless grinding is a highly productive sub-type where the workpiece is supported not by centers but by a work rest blade and controlled by a regulating wheel, grinding the entire outer diameter in a single pass. External grinding is vital for achieving precise diameters, roundness, and surface finish on rotating components found in engines, transmissions, pumps, and machinery.

- Internal Cylindrical Grinding: This process grinds the internal diameters of holes, bores, or cylindrical cavities. The grinding wheel, mounted on a spindle, is smaller than the hole diameter and rotates at high speed. The wheel spindle oscillates or traverses within the bore while the workpiece rotates. Achieving precision internal grinding requires careful wheel selection and balancing due to the smaller, often long and thin, wheel spindles which can deflect. It’s used to finish precision bearing bores, hydraulic cylinder tubes, gun barrels, and any internal diameter requiring tight size, roundness, straightness, and surface finish tolerances.

4. Classification by Precision Requirements (The level of accuracy achieved)

- Conventional Grinding: This represents standard grinding practices aimed at achieving typical engineering tolerances, typically in the range of a few micrometers (microns) to tens of microns (e.g., 0.01 mm to 0.05 mm or 10-50 microns). Surface roughness values (Ra) are usually above 0.1 micrometers. This level of precision is sufficient for many functional parts, roughing operations before finishing, and components where very tight fits or optical finishes are not required. Most standard mechanical grinding operations fall into this category.

- Precision Grinding: This denotes grinding processes specifically controlled and executed to achieve sub-micron level tolerances, often in the range of tenths of a micron (0.1 µm to 1 µm) and surface roughness (Ra) values typically between 0.01 µm and 0.1 µm. Achieving this requires high-precision machines with exceptional rigidity and thermal stability, carefully selected and dressed grinding wheels, controlled environments to minimize temperature fluctuations and vibration, and often sophisticated measurement and feedback systems. Precision grinding is essential for components like precision bearings, fuel injection parts, optical lens mounts, and critical sealing surfaces.

- Ultra-Precision Grinding: This is the pinnacle of grinding technology, pushing tolerances into the nanometer range (below 0.1 µm) and surface roughness values down to a few nanometers (Ra). It often involves specialized single-point diamond turning combined with grinding principles, or advanced processes like ductile mode grinding of brittle materials. Ultra-precision grinding demands state-of-the-art machines operating in highly controlled environments (cleanrooms with temperature control within fractions of a degree), extremely fine grit diamond or CBN wheels, and atomic-level metrology. Applications include critical components for semiconductor manufacturing equipment (wafer chucks, stages), advanced optics (telescope mirrors, laser components), infrared lenses, and medical implants requiring ultimate smoothness and dimensional perfection.

Fundamental Principle of Grinding as Precision Machining

Grinding is fundamentally an abrasive machining process used for precision finishing. It operates on the principle of removing minute amounts of material from a workpiece’s surface using a grinding tool (called a lap, wheel, or plate) that has been embedded or coated with hard abrasive particles. This occurs through controlled relative motion between the tool and the workpiece under applied pressure. The abrasive grains act as countless microscopic cutting tools, each shearing off tiny chips of material. Grinding is typically performed after other machining operations (like turning or milling) to achieve final dimensions, superior geometric accuracy (flatness, roundness, etc.), and an exceptionally fine surface finish that is difficult or impossible to attain with conventional cutting tools. Its versatility allows it to be applied to a vast array of materials, including hardened steels, ceramics, glass, carbides, and composites, and to a wide range of surface geometries (flat, cylindrical, conical, spherical, complex contours).

Key Advantages of Grinding

- Micro-Scale Material Removal: Grinding excels at removing material in extremely thin layers, typically ranging from 0.01 micrometers (10 nanometers) to 0.1 micrometers (100 nanometers) per pass. This capability is essential for achieving the ultra-fine finishes and tight tolerances required in precision engineering and optics.

- Randomized Error Correction (“Randomness”): Unlike deterministic machining with a fixed cutting edge, grinding involves numerous randomly oriented abrasive grains contacting the workpiece surface. This random contact is actually beneficial for precision. High points (peaks) on the workpiece surface are statistically more likely to be struck and removed by the abrasives than low points (valleys). Over successive passes, this probabilistic removal action gradually reduces surface errors and improves overall form accuracy (like flatness or roundness) simultaneously with improving surface roughness.

- Targeted Processing (“Targetedness”): Skilled operators (or sophisticated CNC systems in mechanical grinding) can inspect the workpiece during or between grinding stages. Based on measurements indicating where material needs to be removed or where errors exist, they can intentionally focus the grinding action on specific areas or adjust the grinding time for different sections. This allows for highly controlled correction of localized errors in size and geometric form (e.g., correcting a slight taper on a shaft or a dip on a surface).

Essential Materials in Grinding

- Grinding Tool (Lap/Plate) Materials:

- Cast Iron: The most common material for precision grinding laps, especially for ferrous metals. Its porous microstructure readily holds abrasive grains, and it wears relatively evenly, maintaining geometric accuracy. Used for grinding hardened and unhardened steel, cast iron, and often ceramics.

- Copper / Brass: Softer than cast iron, these metals are primarily used for grinding softer workpiece materials like aluminum, brass, bronze, and plastics. They prevent excessive embedding of hard workpiece particles into the lap which could scratch the surface.

- Other Materials: Glass, hardened steel, ceramics, and even soft woods or leather are used for specialized applications or specific workpiece materials.

- Grinding Media (Grinding Compound/Paste/Slurry):

- Abrasives: The hard particles that perform the cutting. Common types include:

- Aluminum Oxide (Al2O3): General-purpose, economical, used for ferrous metals.

- Silicon Carbide (SiC): Harder and sharper than Al2O3, used for non-ferrous metals, ceramics, glass, cast iron, but more brittle.

- Diamond: The hardest abrasive, essential for grinding carbides, ceramics, glass, and achieving ultra-precision finishes. Synthetic diamond is widely used.

- Cubic Boron Nitride (CBN): Second hardest to diamond, excellent for grinding hardened ferrous metals (steels >50 HRC) due to its high thermal stability and chemical inertness to iron.

- Cerium Oxide (CeO2): A “soft” abrasive used extensively in final polishing stages for optics and glass due to its chemical-mechanical polishing action.

- Iron Oxide (Fe2O3 – Rouge): Traditionally used for fine polishing of soft metals and precious stones.

- Carrier Fluid/Lubricant (for Compounds/Slurries): Provides cooling, lubrication, carries abrasives, and removes swarf. Common types include:

- Mineral Oils: Light machine oil, spindle oil.

- Kerosene / Paraffin: Often used for fine grinding, evaporates cleanly.

- Water-based Fluids: Emulsions or solutions for cooling and rust prevention.

- Fatty Acids: Stearic acid, oleic acid – act as lubricants and can chemically assist in material removal (chem-mech polishing).

- Greases: Used as the base for semi-dry grinding pastes.

- Animal/Vegetable Oils: Historically used (e.g., lard oil), less common now but still used in some pastes for specific properties.

- Abrasives: The hard particles that perform the cutting. Common types include:

Expanded Overview of Major Grinding Process Categories

- Mechanical Grinding: This is the broadest and most common category, encompassing all processes where material removal is primarily achieved through the direct mechanical interaction (cutting, ploughing, fracturing) between hard abrasive particles and the workpiece surface. The force driving this interaction can be applied manually or via machinery. As discussed earlier, it includes all classifications by lubrication, operation mode, surface geometry, and precision. Examples range from manually honing a cylinder bore with an oilstone to a fully automated CNC creep-feed grinder machining turbine blade roots. Its universality makes it indispensable across virtually all manufacturing sectors.

- Chemical Grinding / Chemo-Mechanical Polishing (CMP): This category relies on a combination of chemical reaction and mechanical abrasion. A chemically reactive slurry or paste is applied to the workpiece surface. The chemicals react with the surface material, forming a softened or altered layer that is significantly easier to remove mechanically by the abrasive particles suspended within the slurry than the underlying bulk material. This synergistic action allows for extremely uniform material removal over large areas and the achievement of exceptional surface flatness and low roughness with minimal subsurface damage. Chemical Mechanical Polishing (CMP) is the dominant process in this category, absolutely critical in semiconductor manufacturing for planarizing silicon wafers between lithography steps and polishing intricate metal/dielectric layers. Other examples include using cerium oxide slurry for polishing optical glass lenses and specific slurries for polishing hard disk substrates.

- Electrochemical Grinding (ECG): ECG is a hybrid process combining electrochemical dissolution (like ECM – Electrochemical Machining) with conventional mechanical grinding. The workpiece is made the anode (positive terminal) in an electrolytic cell. A conductive grinding wheel (metal-bonded with abrasives, typically diamond) acts as the cathode (negative terminal). An electrolyte solution (usually sodium nitrate) is flushed through the gap between the wheel and the workpiece. As DC current is applied, the electrochemical reaction dissolves the workpiece material (anode reaction: Metal -> Metal ions + electrons). The abrasive grains in the wheel serve two key functions: they mechanically remove the passivating oxide layer formed by the electrochemical reaction, exposing fresh metal for further dissolution, and they also provide a small amount of conventional grinding action to improve precision and surface finish. ECG offers major advantages: very low grinding forces (reducing distortion), minimal heat generation (avoiding thermal damage), no wheel loading (since most material is dissolved), and the ability to machine very hard or tough materials (like carbides, Inconel, titanium) that are difficult for conventional grinding. It’s widely used for sharpening carbide cutting tools, machining aerospace alloys, and producing intricate forms in hard materials.

- Other Specialized Grinding Types:

- Ultrasonic Grinding / Ultrasonic Machining (USM): This process uses high-frequency (ultrasonic, >20 kHz) vibrations applied to a tool (shaped to the desired form) that is pressed against the workpiece with an abrasive slurry in between. The ultrasonic vibration causes the abrasive grains in the slurry to hammer the workpiece surface at high speed, fracturing and removing tiny particles. It’s primarily used for machining hard, brittle materials like ceramics, glass, quartz, and semiconductors, especially for intricate cavities, holes, and profiles that are difficult with conventional methods.

- Ion Beam Milling (IBM): While not grinding in the traditional mechanical sense, IBM is an ultra-precision material removal technique. A focused beam of high-energy ions (like argon) bombards the workpiece surface. The kinetic energy of the ions causes atoms on the surface to be sputtered (ejected). It allows for atomic-level control of material removal, creating extremely smooth surfaces and precise features without mechanical stress or heat-affected zones. It’s crucial in semiconductor fabrication for device trimming, TEM sample preparation, and creating ultra-precision optics.

- Laser Ablation / Laser Machining: A high-energy laser beam is focused on the workpiece surface, rapidly heating, melting, and vaporizing the material. While often used for cutting or drilling, controlled ablation can be used for surface structuring, micro-machining, and precision material removal. It’s a non-contact process suitable for very hard or delicate materials, but thermal effects (heat-affected zones) can be a concern.

Conclusion

Grinding is an exceptionally diverse and vital family of manufacturing processes, indispensable for achieving the levels of precision, surface quality, and complex geometries demanded by modern technology. From the brute force of heavy stock removal via wet grinding to the atomic-level finesse of ultra-precision grinding or ion beam milling, the techniques available cover an enormous spectrum. The classifications based on lubrication, operation, geometry, and precision provide a practical framework for understanding the options. The fundamental principles of micro-scale abrasive cutting, coupled with the unique advantages of random error correction and targeted processing, underpin its effectiveness. Furthermore, the distinct categories – mechanical, chemical (CMP), electrochemical (ECG), and specialized methods – highlight the adaptability of grinding principles to leverage different physical phenomena (mechanics, chemistry, electrochemistry) to solve diverse manufacturing challenges. Selecting the optimal grinding process requires careful consideration of the workpiece material, required precision and surface finish, production volume, geometric complexity, and cost constraints. Mastering these diverse grinding technologies is key to advancing manufacturing capabilities across industries like aerospace, automotive, medical devices, energy, optics, and semiconductors.

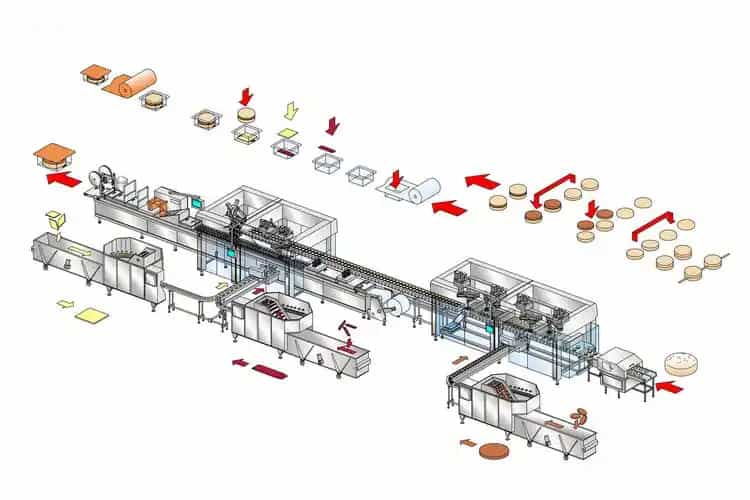

Food Producing Process Flow:

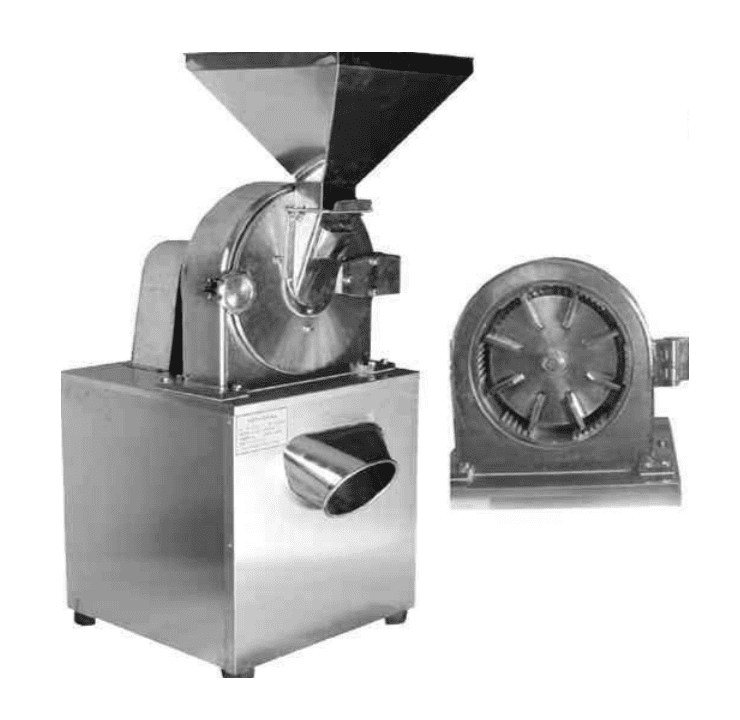

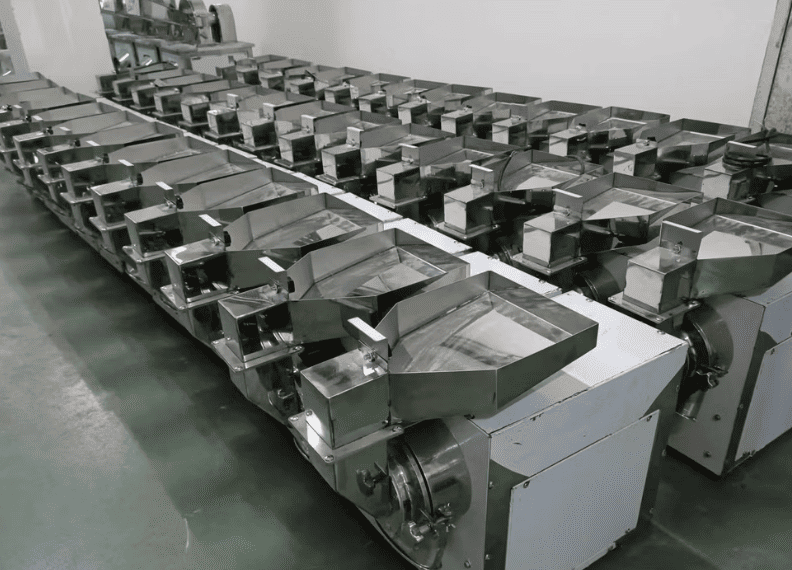

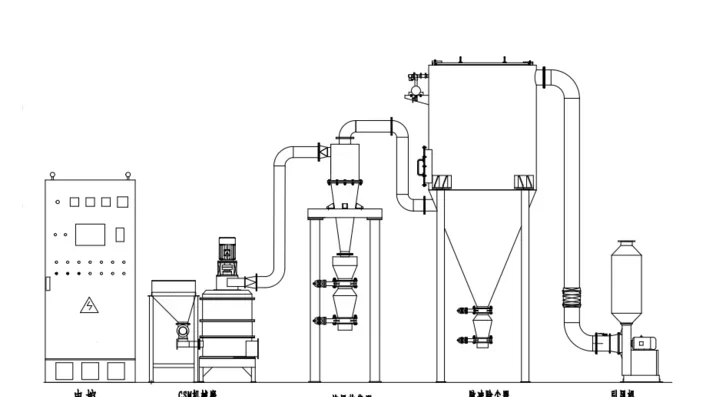

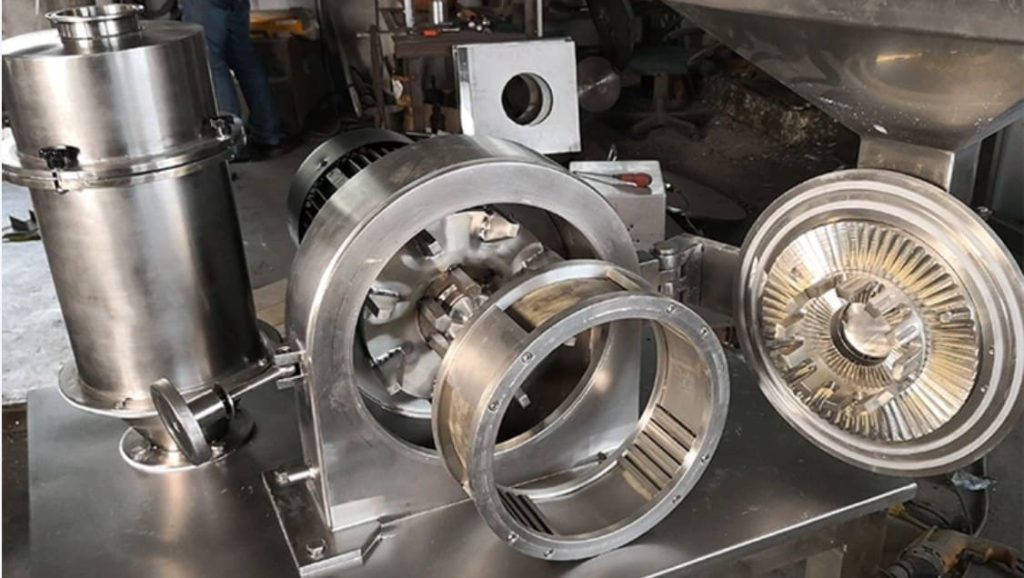

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

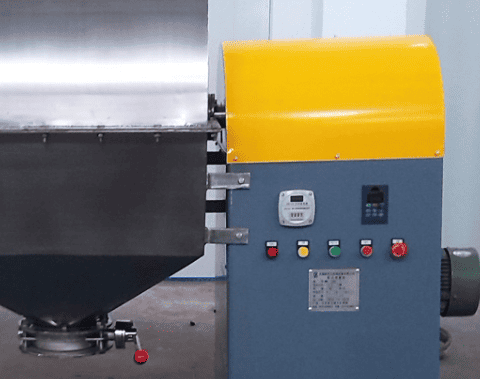

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Grinder for Sale:

Blenders for Sale:

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

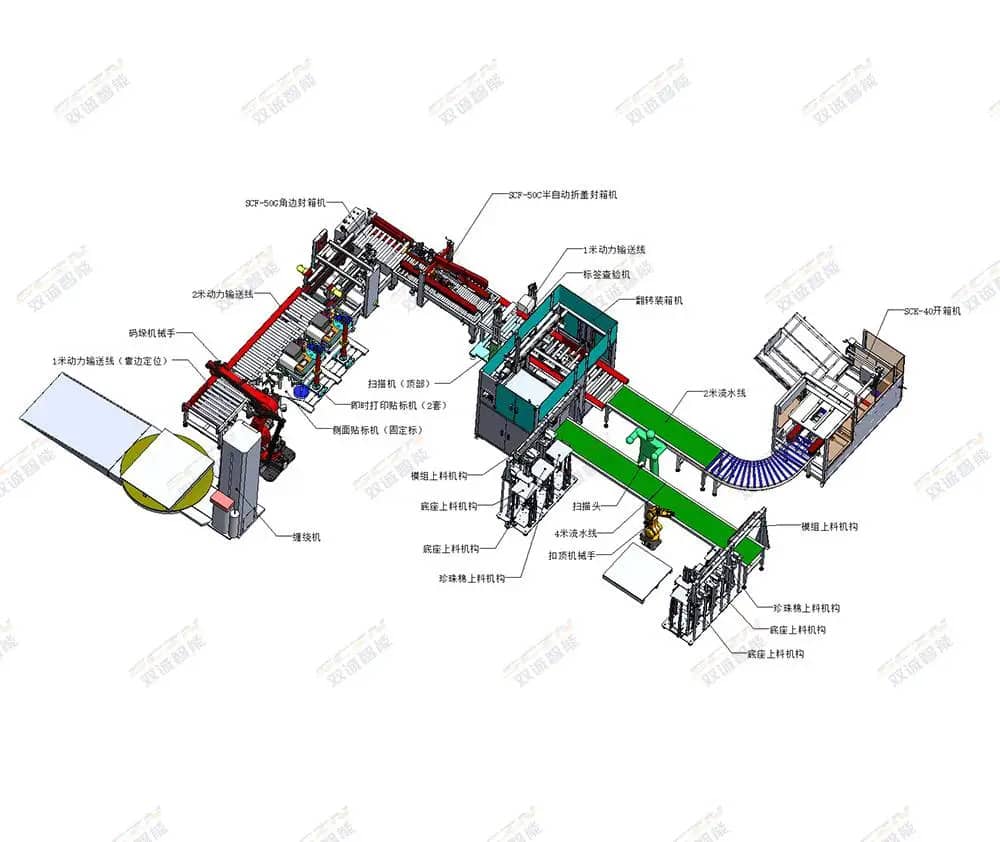

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.