What is the process of grinding called?

The process of material removal using abrasive tools is broadly called Grinding, but within this overarching term, specific techniques exist with distinct names depending on the application area and the workpiece being processed. These specialized grinding processes vary significantly in their tools, motion patterns, and intended outcomes. Here’s a detailed exploration of the common types and their characteristics:

1. Surface Grinding

Surface grinding is a fundamental process primarily employed to achieve exceptionally smooth and flat surfaces on workpieces. Its core function is machining flat planes, cylindrical surfaces, and other regular geometric profiles. This is accomplished through the precise relative motion between a rotating abrasive grinding wheel and the workpiece. The wheel, composed of hard abrasive grains bonded together, acts like countless tiny cutting tools, shearing away microscopic amounts of material. This high-precision polishing action makes surface grinding the go-to method for achieving mirror-like finishes, especially on hard materials like metals (steel, cast iron, aluminum alloys) and glass. Key components of surface grinding machines include a reciprocating or rotating table that holds the workpiece and a spindle that drives the grinding wheel at high speeds. Precision is paramount, with machines capable of controlling movement down to micrometers. The process is vital in manufacturing parts requiring tight tolerances and low surface roughness, such as machine tool ways, precision gauges, bearing surfaces, and optical components. Coolants are almost always used to control the significant heat generated at the grinding interface, prevent workpiece thermal distortion, and flush away grinding debris (swarf).

2. Honing

Honing is a specialized abrasive finishing process designed almost exclusively for the final machining of internal cylindrical surfaces, particularly bores like engine cylinders, hydraulic cylinders, gun barrels, and bearing housings. Unlike surface grinding which uses a solid wheel, honing employs a tool called a honing head or hone. This tool holds several abrasive stones (often made of aluminum oxide, silicon carbide, or diamond/cubic boron nitride for hard materials) under controlled, adjustable spring or hydraulic pressure. The honing head rotates within the bore while simultaneously oscillating or stroking back and forth along the bore’s axis. This unique combination of motions creates the characteristic cross-hatch pattern on the finished surface, known as the “honing pattern.” This pattern is not merely aesthetic; it serves the critical function of retaining lubricating oil, significantly improving the friction and wear characteristics of the mating surfaces. Honing achieves two primary goals: exceptional dimensional accuracy and geometric form (correcting minor out-of-roundness or taper) and the creation of a specific, optimal surface texture for lubrication. It removes only a very small amount of material, typically the final few thousandths of an inch, following processes like boring or internal grinding. Its importance in engine manufacturing cannot be overstated, as it directly impacts piston ring sealing, oil consumption, and engine longevity.

3. Gear Grinding

Gear grinding is the precision finishing process used to produce the highly accurate tooth profiles and smooth surfaces required for high-performance gears, especially after heat treatment which hardens the gear teeth but can cause distortion. There are two dominant methods:

* Continuous Generation Grinding (Generating): This highly efficient method uses a rotating, profiled grinding wheel shaped similarly to a rack (a straight gear). The gear blank and the grinding wheel rotate in precise synchrony, mimicking the meshing action of gears. As the gear rotates, the grinding wheel also traverses along the face width of the gear. This synchronized motion gradually generates the precise involute tooth form across the entire gear. It’s exceptionally fast and well-suited for high-volume production of small to medium-sized gears, commonly found in automotive transmissions, industrial gearboxes, and aerospace applications. The accuracy and surface finish achieved are critical for minimizing noise, vibration, and wear in power transmission systems.

* Profile Grinding (Form Grinding): This method uses a grinding wheel whose profile is precisely dressed (shaped) to exactly match the desired shape of the space between two gear teeth (the tooth flank form). The wheel grinds one tooth space at a time. After finishing one space, the gear indexes (rotates precisely) to bring the next tooth space into position for grinding. While generally slower than continuous generation grinding, profile grinding offers greater flexibility. It can handle gears with unusual tooth profiles, very large gears where generation wheels become impractical, internal gears, cluster gears where adjacent gear teeth limit access, and gears requiring modifications like tip relief or root fillets. It’s often the choice for large, high-precision gears in wind turbines, heavy machinery, and specialized applications.

4. Leather Grinding (Buffing or Snuffing)

Leather grinding, often termed buffing or snuffing in the leather industry, is a distinct process focused on processing leather hides or “crust” leather (tanned but not yet finished). Unlike metal grinding, it uses abrasive belts or sheets (like sandpaper) with coated abrasives. The primary purposes are twofold: adjusting the thickness of the leather uniformly across the hide (“levelling”) and modifying the surface texture or appearance. This process is subdivided based on which side of the leather is worked on:

* Grain Buffing (Corrected Grain): This involves lightly sanding the top, grain side of the leather. It removes the very top natural layer to eliminate surface imperfections like scars, insect bites, or wrinkles. The result is a more uniform, smoother, but less natural-looking surface, often embossed later with an artificial grain pattern. This is common for making durable leathers used in furniture, car seats, and some footwear.

* Flesh Buffing (Sueding or Nubuck): This process sands the flesh side (the rough, inner side) of the leather. It creates a soft, velvety nap, characteristic of suede. Alternatively, sanding the grain side more aggressively can also produce a napped surface while retaining more strength than suede, known as nubuck. Buffing the flesh side also helps achieve uniform thickness. Leather grinding is essential in shoe and bag manufacturing, allowing tanneries to utilize hides with imperfections by correcting them, achieving desired textures (suede, nubuck, smooth corrected grain), and ensuring consistent thickness for manufacturing. It directly impacts the leather’s aesthetics, feel, and cost-effectiveness.

Core Differences: Tools and Motion

The fundamental distinctions between these grinding processes lie in the specific tools employed and the nature of the relative motion between the tool and the workpiece. Surface grinding utilizes rigid, high-speed rotating wheels with a specific abrasive composition and bond. Honing uses a tool with expanding abrasive stones performing a combined rotating and reciprocating motion within a bore. Gear grinding employs specialized profiled wheels in either a synchronized generating motion or a precise indexing and profiling motion. Leather grinding uses flexible abrasive belts or sheets moving against the leather surface. Choosing the correct process hinges critically on understanding the workpiece material properties (hardness, brittleness, thermal sensitivity), the geometric features to be machined (flat, cylindrical, internal, complex tooth form), the required surface finish and texture (mirror polish, cross-hatch, velvety nap), and the dimensional accuracy and production volume needed. Matching the process to these requirements ensures efficiency, quality, and cost-effectiveness.

Grinding Methods: Peripheral vs. Face Grinding

Within surface grinding itself, the method is further categorized based on which part of the grinding wheel contacts the workpiece:

* Peripheral Grinding (Cylindrical Grinding with the Wheel’s Circumference): This is the most common method for precision surface grinding. The outer circumference (periphery) of a relatively narrow grinding wheel contacts the workpiece. It offers superior precision, finer surface finishes, and better heat dissipation compared to face grinding. There are two main feed techniques within peripheral grinding:

* Traverse Grinding (Plunge Grinding): The grinding wheel is fed directly perpendicularly (radially) into the workpiece surface to the full desired depth. It’s highly efficient for grinding specific grooves, shoulders, or when the width of the area to be ground is less than the wheel’s width.

* Longitudinal Grinding (Creep Feed Grinding – though traditionally slower): The grinding wheel is fed slowly along the workpiece surface (axially) while simultaneously making a relatively deep radial cut. While traditionally associated with slower table feeds and high precision (achieving IT6~IT7 tolerance grades and surface roughness Ra 0.4~0.2 μm), the modern evolution is Creep Feed Grinding. Here, the table feed rate is drastically reduced (creeping speed), but the depth of cut is significantly increased (often the entire finishing allowance in one pass). Combined with specialized wheels and high-pressure coolant, creep feed grinding achieves high material removal rates with excellent surface integrity and precision, especially for complex profiles.

* Face Grinding (Grinding with the Wheel’s End Face): This method utilizes the flat end face of a larger diameter grinding wheel, often shaped like a cup or disc, to contact the workpiece surface. The primary advantage is a much larger contact area, leading to significantly higher material removal rates, making it ideal for rapid stock removal and rough grinding operations. However, the large contact area also generates significantly more heat, and heat dissipation is poorer compared to peripheral grinding. This increased heat, coupled with potentially higher grinding forces, makes face grinding more prone to causing thermal damage (like burns or cracks) and workpiece distortion. Consequently, while efficient, it typically achieves lower precision and coarser surface finishes than peripheral grinding and is best suited for applications where high precision is not the primary concern, or as a preliminary step before finer grinding.

Fundamentals of Grinding

At its core, grinding is a mechanical material removal process classified as a finishing operation. It employs abrasive particles (the “grits”) bonded together to form a tool (grinding wheel, honing stone, abrasive belt) to cut away microscopic chips from a workpiece surface. The abrasive grits act like numerous hard, sharp, but microscopically small cutting tools. Key characteristics define grinding:

* High Cutting Speeds: Grinding wheels rotate at very high peripheral speeds, typically 30-50 meters per second (m/s). Speeds exceeding 45 m/s are termed High-Speed Grinding (HSG), demanding specialized equipment and wheels.

* High Precision and Surface Finish: Grinding is renowned for achieving very tight dimensional tolerances (commonly IT8 to IT5 or better on the International Tolerance grade scale) and extremely low surface roughness values. Standard grinding achieves Ra 1.25 to 0.16 micrometers (µm), precision grinding Ra 0.16 to 0.04 µm, ultra-precision grinding Ra 0.04 to 0.01 µm, and mirror grinding can go below Ra 0.01 µm.

* Material Versatility: Due to the extreme hardness of common abrasives (aluminum oxide, silicon carbide, cubic boron nitride – CBN, diamond), grinding can effectively machine very hard materials that are difficult or impossible to cut with conventional tools, such as hardened steels, tool steels, high-temperature alloys, cemented carbides (carbide tips), ceramics, glass, and stone.

* High Specific Energy and Temperature: The process of shearing material with small, often negative-rake-angle grits consumes significantly more energy per unit volume of material removed (specific energy) compared to turning or milling. Much of this energy converts into heat, leading to very high localized temperatures at the grinding zone, often reaching 1000°C to 1500°C. This necessitates effective cooling strategies.

* Small Material Removal Rates (Typically): Due to the small size of the individual chips formed, the overall material removal rate in conventional grinding is lower than in rough turning or milling. Consequently, grinding is usually applied as a finishing process, removing only a small amount of pre-machined stock (0.1-1 mm or less). However, developments like Creep Feed Grinding and High-Efficiency Deep Grinding (HEDG) have significantly increased achievable removal rates, sometimes even enabling grinding from near-net-shape blanks (“grind-hardening” or “grind-finishing”).

* Grinding Wheel Selection: Choosing the right wheel is critical and depends on the abrasive type (Al2O3, SiC, CBN, Diamond), grit size (coarse for stock removal, fine for finish), bond type (vitrified – ceramic, resin, metal, rubber), bond hardness (soft wheels wear faster but stay sharp, hard wheels hold form longer), and structure (density of grits and bond). The wheel must be periodically dressed (truing and sharpening) using a diamond tool to restore its shape and expose fresh, sharp abrasive grains.

Historical Development

Grinding technology has evolved significantly over centuries. Its origins trace back to the sharpening of tools using natural stones. A pivotal moment came in the 18th century (circa 1730s) when grinding was first applied more systematically for manufacturing precision components in clockmaking and armaments. The birth of the modern grinding machine is attributed to Joseph Brown and Lucian Sharpe in 1876 with their universal cylindrical grinder. The early 20th century saw revolutionary breakthroughs: the development of synthetic abrasives (silicon carbide in 1891, aluminum oxide in 1901) provided consistent, high-performance alternatives to unpredictable natural stones, and the introduction of hydraulic drives enabled smoother, more precise machine tool movements. This spurred the development of diverse specialized grinding machines. Post-World War II, particularly from the 1960s onwards, grinding technology advanced rapidly with the adoption of computer numerical control (CNC), allowing complex automated grinding cycles. Developments in abrasives (superabrasives CBN and synthetic diamond), grinding wheel bonds, high-speed spindle technology, precision machine tool design, and advanced coolant delivery systems (like high-pressure through-wheel coolant) have continually pushed the boundaries of grinding speed, precision, efficiency, and the range of applications. Modern grinding is a highly sophisticated, often automated, key process in advanced manufacturing.

Grinding in Manufacturing Context

Within the sequence of machining operations, grinding is predominantly classified as a finishing process. Manufacturing typically involves stages: Rough machining (turning, milling, drilling) removes the bulk of material quickly but leaves a relatively rough surface and moderate dimensional accuracy. Heat treatment (quenching, tempering, case hardening) often follows to enhance material properties like hardness and strength. However, heat treatment frequently causes distortion and dimensional changes. This is where grinding excels. As a finishing operation, grinding removes only a small, controlled amount of material (“grinding allowance”) left after roughing and heat treatment. Its primary role is to achieve the final, precise dimensions, geometric accuracy (flatness, roundness, cylindricity), and the required smooth surface finish on hardened components. It’s indispensable across the manufacturing industry for critical parts like bearings, shafts, gears, cutting tools, dies, molds, and precision mechanical components. A significant challenge associated with grinding hardened steel, particularly high-carbon tool steels or case-hardened steels, is the potential for grinding cracks. These are fine, often network-like cracks appearing on the ground surface, typically perpendicular to the grinding direction. They arise primarily from excessive localized heat generation during grinding, causing rapid thermal expansion and contraction stresses that exceed the material’s fracture strength, especially in hardened, brittle structures. Grinding cracks are detrimental, compromising the part’s appearance, reducing its fatigue strength, accelerating wear, and potentially leading to catastrophic failure in service. Preventing them requires careful control of grinding parameters (wheel speed, workpiece speed, feed rate, depth of cut), selection of the correct wheel (softer grades can help), and most critically, the effective application of grinding fluid (coolant) to minimize thermal shock and control grinding zone temperatures.

Detailed Process Principles and Variations

Grinding fundamentally relies on the interaction between countless hard, sharp abrasive grains bonded into a tool (wheel, stone, belt) and the workpiece surface, moving at high relative speeds. This interaction plows, cuts, and fractures material away as microscopic chips. The self-sharpening nature of many grinding wheels – where dull grains fracture or are pulled out, exposing fresh sharp grains – is crucial for sustained cutting action. Grinding encompasses several key variations beyond the previously mentioned categories:

* Cylindrical Grinding: Performed on cylindrical grinders (or universal grinders), this process is dedicated to machining the external surfaces of rotating, axisymmetric workpieces like shafts, spindles, and rollers. The workpiece rotates between centers or in a chuck, while the rotating grinding wheel contacts its periphery. As described earlier, the two main methods are:

* Traverse Grinding: Wheel moves radially into the workpiece to depth and may traverse along its length.

* Plunge Grinding: Wheel width exceeds the workpiece feature length; wheel feeds radially without axial traverse. Ideal for shoulders, grooves, and profiles. High precision and fine finishes are hallmarks.

* Internal Grinding: This process machines internal cylindrical surfaces (holes) and their end faces. It’s performed on internal grinders, universal grinders, or dedicated machines like jig grinders or coordinate grinders. Key challenges include the restricted space within the hole, limiting the grinding wheel diameter and thus the achievable cutting speed (often below 30 m/s), and the need for high spindle rigidity on long overhangs. The workpiece usually rotates, and the smaller grinding wheel rotates at high speed on its own spindle. Common methods are longitudinal grinding (wheel traverses along the bore) and plunge grinding for short holes or grooves. Achieving roundness, straightness, and surface finish inside a hole demands high precision. Coordinate grinding uses precise X-Y positioning (like a jig borer) combined with high-speed spindle rotation and sometimes planetary spindle motion to grind holes and contours with exceptional accuracy.

* Centerless Grinding: This is a highly productive method for grinding the external diameters of cylindrical workpieces without using centers or chucks for fixation. The workpiece rests unsupported (“centerless”) on a work rest blade, positioned between two wheels: a large, fast-rotating grinding wheel and a smaller, slower-rotating regulating wheel (usually rubber-bonded). The regulating wheel controls the workpiece rotation and axial feed. The two primary modes are:

* Through-Feed Grinding: The axes of the grinding and regulating wheels are tilted slightly relative to each other (typically 0.5°-6°). This tilt imparts an axial force component, automatically feeding the workpiece longitudinally through the gap between the wheels. Ideal for long, straight cylindrical parts like pins, rods, and tubes.

* In-Feed Grinding (Plunge Centerless): The wheel axes are parallel. The grinding wheel is fed radially into the workpiece, which is held against the end stop. No axial feed occurs during grinding. Used for parts with shoulders or multiple diameters, or for form grinding where the grinding wheel is dressed to the desired profile. Centerless grinding offers high throughput, excellent roundness, and eliminates centering errors, but setup is more complex.

* Surface Grinding (Expanded on Methods): As detailed earlier, this involves grinding flat surfaces and is categorized by the wheel contact area (Peripheral vs. Face) and feed method (Traverse vs. Plunge/Creep Feed). Modern surface grinders often feature CNC controls for complex profiles and automation.

In conclusion, while “Grinding” is the overarching term for abrasive material removal, the specific process name and technique—Surface Grinding, Honing, Gear Grinding (Generating/Profile), Leather Grinding (Buffing/Snuffing), Cylindrical, Internal, Centerless—are determined by the workpiece geometry, required outcome, tooling, and motion strategy. Each process has been developed to meet specific manufacturing challenges, particularly the need for high precision, fine finishes, and the ability to machine extremely hard materials, solidifying grinding’s indispensable role in modern industry.

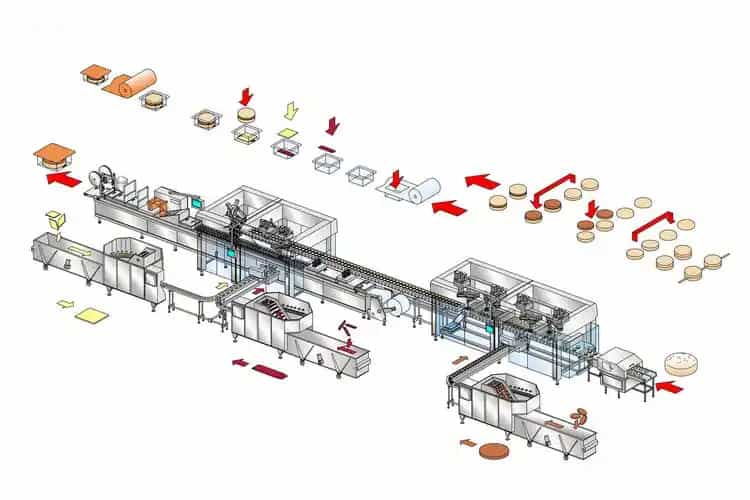

Food Producing Process Flow:

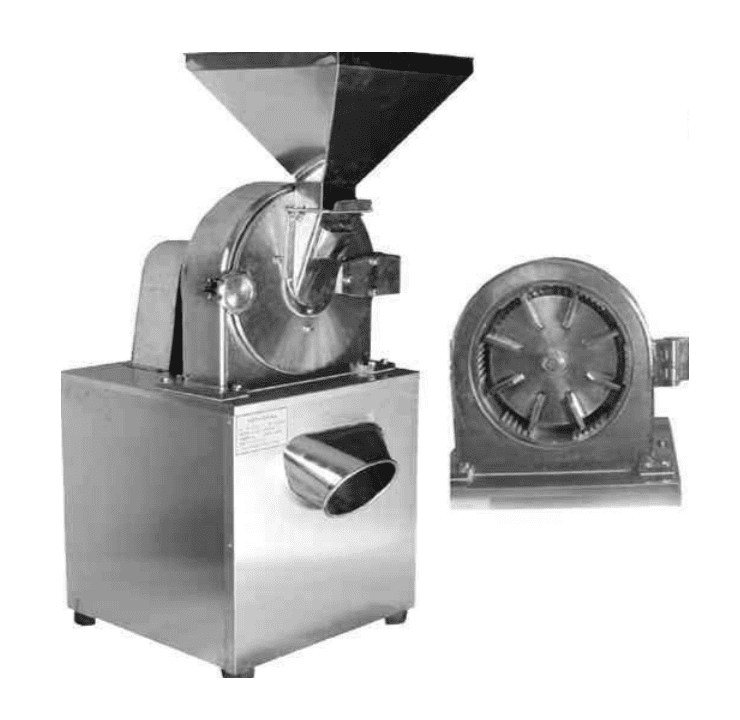

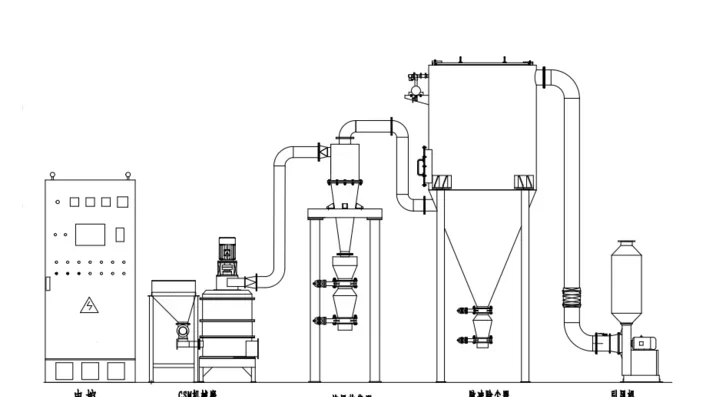

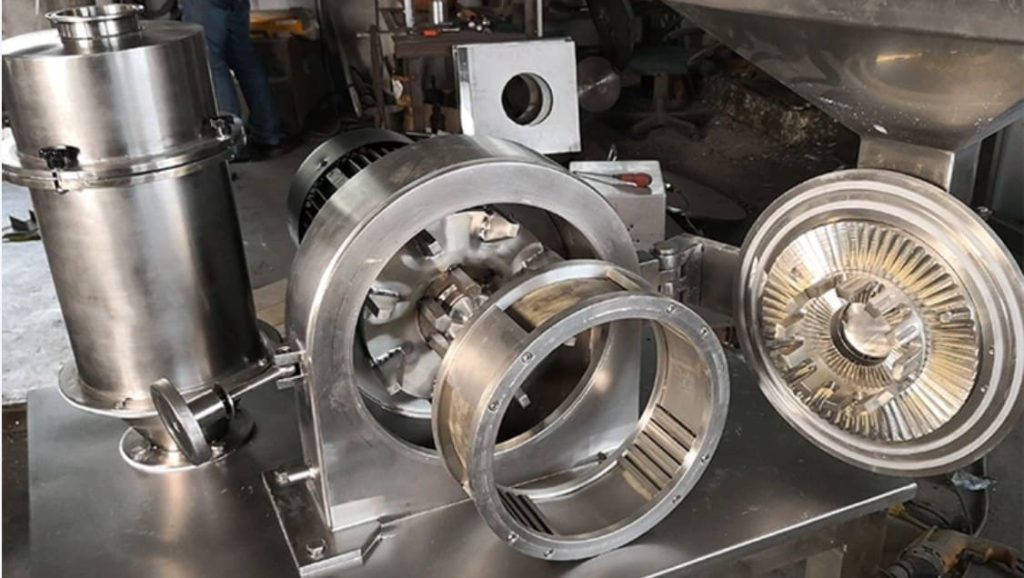

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

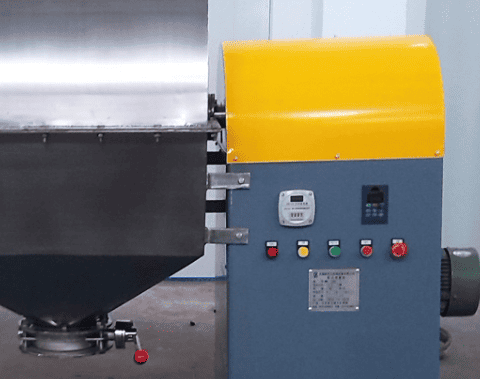

About LKMixer

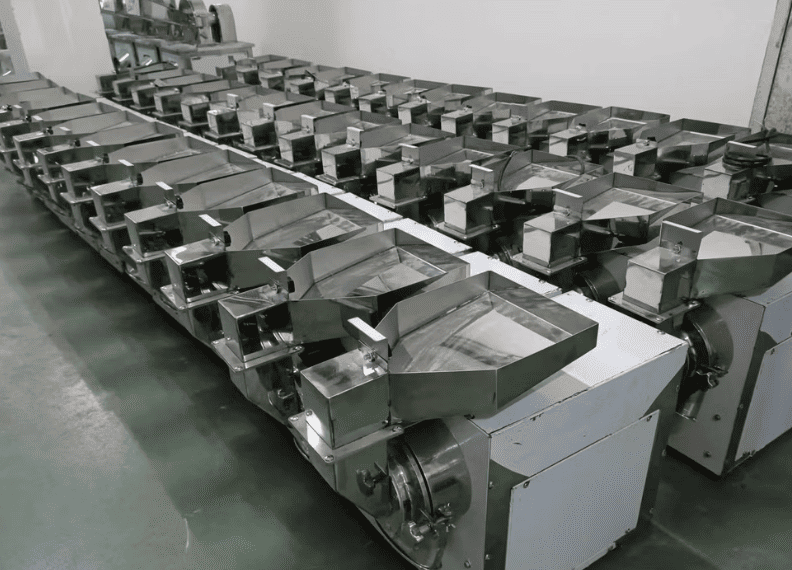

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Grinder for Sale:

Blenders for Sale:

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

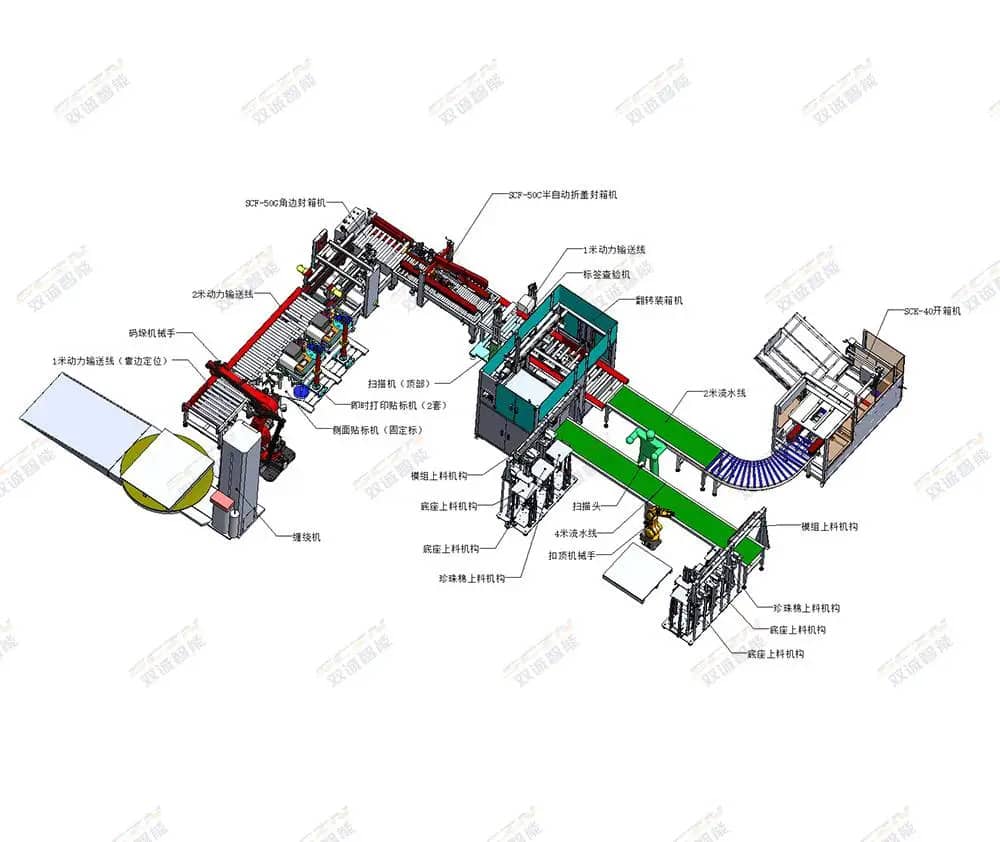

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.