How does grinder work?

How does grinder work? Simply speaking, a grinder typically consists of two or more interlocking, toothed metal or plastic components that rotate against each other to grind up material. The teeth and ridges on the grinder components break up the material as it is ground, and screens or mesh can be used to filter out larger particles.

I. Introduction

Explanation of what a grinder is and its common uses:

A grinder is a tool or machine used to grind and crush materials into smaller particles or a finer powder. The most common use of grinders is to grind coffee beans, spices, and herbs. However, grinders are also used in various industries for grinding materials such as grains, seeds, nuts, and even meat.

In the culinary industry, grinders are used to prepare ingredients such as spices, garlic, and herbs for cooking. Coffee shops also use grinders to grind coffee beans to make fresh coffee. In the cannabis industry, grinders are used to break down cannabis buds into smaller particles for smoking or baking.

In addition, grinders are also used in manufacturing industries for grinding materials into a finer powder for use in the production of various products. For example, grinders are used in the production of paint, cement, and pigments.

Overall, grinders are versatile tools that have many common uses, from culinary to industrial applications, and play an important role in the preparation and processing of various materials.

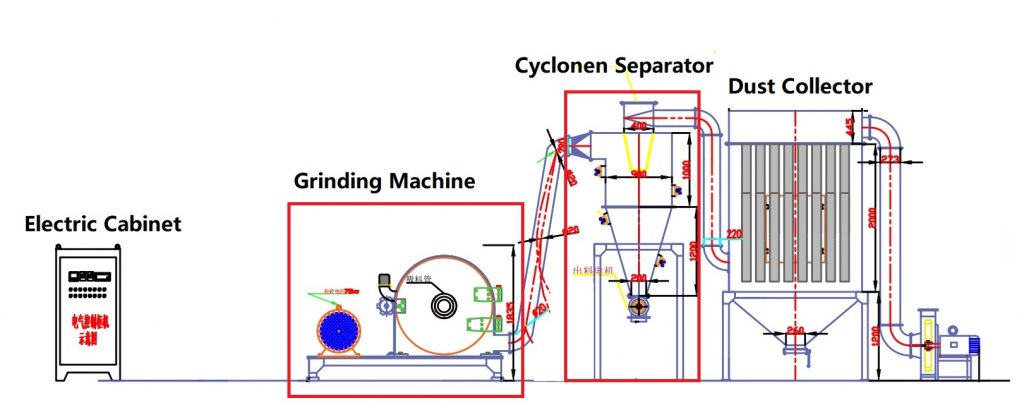

Construction of Grinder:

- Auto feeder – is to feed the material into coarse crusher by sucking the material ;

- Coarse Crusher is to pre-treatment the material, such as cinnamon, need to do pre-treatment before grinding, the coarse crusher will broke the material into small pieces firstly to improve the effectiveness of grinding machine;

- Grinding Machine: then the material drop from coarse crusher directly into grinding machine and broken into 80 mesh;

- Cyclone Separator: the material will output from cyclone separator under the negative pressure, at the same time the dust will enter into dust collector.

- Dust collector: the dust collector consists of several cloth bags, when dust enter into the box, it sedimentary and collected by the cloth bag. The cloth bad need to be cleared at regular intervals to make sure the dust collector is effective.

- The reason why for this construction is for dust-free working environment. The cyclone separator helps output of materials after grinding, the dust collector can collect the dust caused by grinding.

Importance of understanding how a grinder works

Understanding how a grinder works is important for several reasons:

- Efficiency: By understanding how a grinder works, users can operate it more efficiently, ensuring that materials are ground to the desired consistency without wasting time, energy, or materials. This is particularly important in industrial settings, where productivity and cost-effectiveness are critical.

- Consistency: Different types of grinders can produce different levels of consistency, depending on the materials being ground and the grinder’s settings. Understanding how a grinder works and how to adjust it to achieve the desired consistency is important to ensure consistent results every time.

- Quality: The quality of the ground material can affect the final product’s quality, whether it is coffee, spices, or other materials. By understanding how a grinder works, users can ensure that the materials are ground uniformly, resulting in a higher quality end product.

- Safety: Grinders can be dangerous if not used properly. Understanding how a grinder works and its safety features is important to avoid accidents and injuries.

- Innovation: Finally, understanding how a grinder works can lead to innovation in the design and use of grinders. Researchers and engineers can use this knowledge to develop more efficient, effective, and safer grinders for various applications.

Overview of the structure and functions of a grinder

II. Types of Grinders

Manual vs Electric grinders

When it comes to grinding coffee, there are two main types of grinders: manual and electric. Both have their advantages and disadvantages, and the right choice for you depends on your individual needs and preferences.

Manual grinders require you to physically turn a crank or handle in order to grind your coffee. They tend to be smaller and more portable than electric grinders, making them a great option for travel or for those who want to make coffee on the go. They are also often more affordable than electric grinders, which can be a consideration for some coffee drinkers.

However, manual grinders can be more time-consuming and labor-intensive to use, especially if you are grinding a large amount of coffee. They may also be less consistent in the grind size they produce, which can impact the quality of your coffee.

Electric grinders, on the other hand, are powered by electricity and can grind coffee quickly and efficiently. They often offer more options for grind size and tend to produce a more consistent grind, which can result in better-tasting coffee.

However, electric grinders are typically larger and less portable than manual grinders. They may also be more expensive and require access to an electrical outlet, which can be a consideration for those who want to make coffee while camping or traveling.

In summary, manual grinders are portable, affordable, and great for small amounts of coffee, but may be more time-consuming and less consistent. Electric grinders are efficient, consistent, and offer more options for grind size, but are typically larger and less portable, and can be more expensive.

Different materials used for grinders (e.g. wood, metal, plastic)

Grinders can be made from a variety of materials, including wood, metal, plastic, and even ceramic. The choice of material can affect the performance, durability, and aesthetic appeal of the grinder.

Wooden grinders are often prized for their natural beauty and can add a touch of elegance to any coffee preparation setup. They are also durable and can last a long time with proper care. However, wooden grinders may not be as easy to clean as metal or plastic grinders, and can be more susceptible to damage from moisture.

Metal grinders, such as those made from stainless steel, are durable and easy to clean. They can also be very sharp, which can result in a consistent grind. However, they can be heavy and may not be as aesthetically pleasing as wooden grinders.

Plastic grinders are often lightweight and affordable. They can be a good choice for those who want a simple and functional grinder without spending a lot of money. However, plastic grinders may not be as durable or long-lasting as other materials, and can be more prone to wear and tear over time.

Ceramic grinders are known for their consistency and precision in producing a uniform grind. They can also be very durable and long-lasting. However, ceramic grinders can be more fragile than other materials and may be more difficult to clean.

Ultimately, the choice of material for a grinder depends on individual preferences and priorities, such as durability, aesthetics, ease of use, and cost.

Comparison of different types of grinders and their advantages/disadvantages

There are several different types of coffee grinders available, each with their own advantages and disadvantages. Here’s a comparison of some of the most common types:

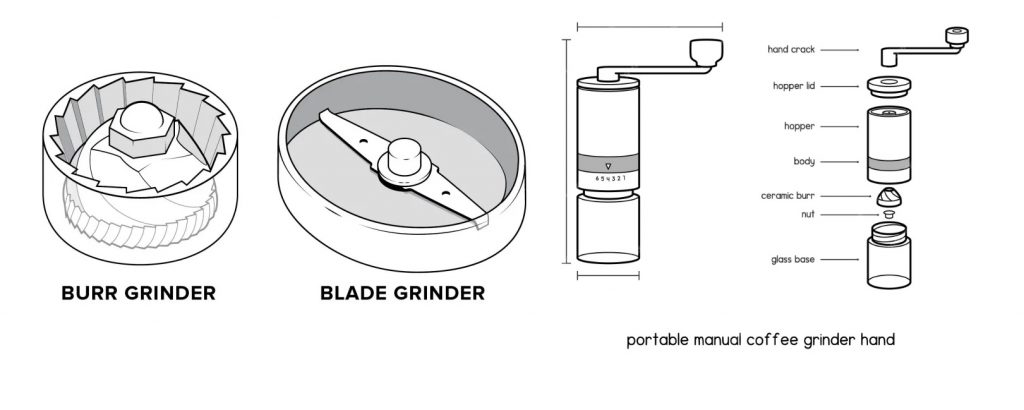

- Blade Grinders: Blade grinders use a spinning blade to chop the coffee beans into small pieces. They are generally the most affordable type of grinder, but they can be inconsistent in producing a uniform grind. They are also quite noisy and can generate heat that can affect the flavor of the coffee.

Advantages:

- Affordable

- Easy to use

Disadvantages:

- Inconsistent grind size

- Can generate heat that affects flavor

- Noisy

- Burr Grinders: Burr grinders use two revolving abrasive surfaces (burrs) to grind coffee beans. They are known for producing a consistent grind size and are available in both manual and electric models. Burr grinders tend to be more expensive than blade grinders but are a better choice for those who want to make high-quality coffee.

Advantages:

- Consistent grind size

- Available in manual and electric models

- Good for making high-quality coffee

Disadvantages:

- More expensive than blade grinders

- Can be noisy

- Can be difficult to clean

- Hand Grinders: Hand grinders, also known as manual grinders, require you to physically turn a crank or handle to grind coffee beans. They are generally small and portable, making them a good option for travel or camping. Hand grinders can produce a consistent grind size but may be more time-consuming to use than electric grinders.

Advantages:

- Portable

- Can produce a consistent grind size

- Quiet

Disadvantages:

- More time-consuming to use

- Can be difficult to grind for larger quantities

- May require more effort to turn the handle

- Bladeless Grinders: Bladeless grinders use a unique design that combines elements of both blade and burr grinders. They use a spinning cylinder with ridges on the surface to grind the beans, which can result in a more consistent grind size than blade grinders. They are typically more expensive than blade grinders but less expensive than burr grinders.

Advantages:

- More consistent grind size than blade grinders

- Generally less expensive than burr grinders

Disadvantages:

- Can generate heat that affects flavor

- Not as consistent as burr grinders

- More expensive than blade grinders

In summary, the choice of grinder depends on individual preferences and priorities, such as grind consistency, price, and ease of use. Burr grinders are generally the best option for making high-quality coffee, but they can be more expensive than other types of grinders. Blade grinders are the most affordable but can be inconsistent in producing a uniform grind. Hand grinders are portable and quiet but can be more time-consuming to use. Bladeless grinders offer a middle ground between blade and burr grinders but can still be affected by heat and may not be as consistent as burr grinders.

III. The Grinding Process

How the grinding process works in a grinder

The grinding process in a grinder involves breaking down whole coffee beans into smaller, more uniform pieces suitable for brewing. The process can vary depending on the type of grinder, but generally involves the following steps:

- The coffee beans are loaded into the grinder’s hopper.

- The beans are then fed into the grinding mechanism, which can vary depending on the type of grinder. In a blade grinder, a spinning blade chops the beans into small pieces. In a burr grinder, the beans are crushed between two burrs, which can be either flat or conical. In a manual grinder, the beans are ground by manually turning a crank or handle.

- As the beans are ground, they are forced through small holes or channels in the grinding mechanism, resulting in a more uniform grind size.

- The ground coffee is then collected in a container, ready to be used for brewing.

The consistency of the grind size can be adjusted in some grinders to suit the brewing method, such as coarse for French press or fine for espresso. The quality of the grind can also affect the flavor of the coffee, with a consistent and uniform grind being important for a high-quality cup of coffee.

The role of teeth and ridges in breaking up materials

Teeth and ridges play an important role in breaking up materials by providing a surface for the material to be sheared and crushed against. In general, teeth are pointed or sharp protrusions that are used to cut or slice through material, while ridges are raised, often linear features that are used to crush or grind material.

In the case of grinders, the teeth and ridges are specifically designed to break up coffee beans into smaller, more uniform pieces suitable for brewing. The teeth on a blade grinder, for example, are typically angled or curved to chop the beans into small pieces, while the ridges on a burr grinder are designed to crush and grind the beans between the burrs. In both cases, the teeth and ridges are arranged in a specific pattern to ensure a consistent and uniform grind size.

In other applications, teeth and ridges are used to break up a wide variety of materials, such as food, rocks, and wood. For example, a food processor typically uses sharp blades to chop and slice food, while a mortar and pestle uses ridges to crush and grind herbs and spices. In the case of rocks and minerals, specialized equipment like crushers and mills use teeth and ridges to break up and grind the material into smaller pieces.

Overall, teeth and ridges are an important design feature in many types of equipment and machinery used to break up materials, providing a surface for the material to be sheared, cut, crushed, or ground against to achieve the desired size and consistency.

The function of the different compartments in a grinder

The compartments in a grinder can vary depending on the type of grinder, but here are the most common compartments and their functions:

- Hopper: The hopper is the top compartment of the grinder where the whole coffee beans are stored before they are ground. The hopper can vary in size and can hold varying amounts of coffee beans, depending on the grinder model.

- Grinding Mechanism: The grinding mechanism is the part of the grinder that grinds the coffee beans into smaller, more uniform pieces. Depending on the type of grinder, the grinding mechanism can be a set of revolving blades, burrs, or a manual mechanism such as a hand crank.

- Grind Container: The grind container is the compartment that collects the ground coffee after it has been processed by the grinding mechanism. The grind container can be removable or built into the grinder, and its size can vary depending on the grinder model.

- Doser (Optional): Some coffee grinders have a doser, which is a compartment that holds a predetermined amount of ground coffee that can be dispensed into a portafilter or a coffee filter. The doser can be helpful in maintaining consistency in the amount of coffee used for each brew.

- Chute (Optional): Some grinders have a chute that directs the ground coffee from the grind container to the doser or directly into a portafilter or coffee filter. The chute can be adjustable to direct the ground coffee where it needs to go.

Overall, the compartments in a grinder are designed to hold and process the coffee beans into a consistent and uniform grind size suitable for brewing. The size and number of compartments can vary depending on the type of grinder and its intended use.

IV. Achieving the Desired Consistency

How to adjust a grinder to achieve the desired consistency of the ground material

Adjusting a grinder to achieve the desired consistency of the ground material can vary depending on the type of grinder. Here are some general steps that can be applied to different types of grinders:

- Determine the desired grind size: The first step in adjusting a grinder is to determine the desired grind size. The grind size can vary depending on the brewing method, with coarser grinds typically used for French press and drip coffee, and finer grinds used for espresso.

- Adjust the grinder setting: Many grinders have adjustable settings that allow you to change the distance between the burrs or blades, which can affect the grind size. For example, in a burr grinder, the distance between the burrs can be adjusted by turning a dial or knob. In a blade grinder, the grinding time can be adjusted to achieve a finer or coarser grind.

- Test the grind: Once you have adjusted the grinder setting, it’s important to test the grind size to ensure it’s the desired consistency. You can do this by grinding a small amount of coffee and visually inspecting the grind size. You can also feel the grind with your fingers to determine whether it’s too fine or too coarse.

- Fine-tune the grind: If the grind is too fine or too coarse, you can fine-tune the grind by making small adjustments to the grinder setting and testing the grind again. This process may require some trial and error to achieve the desired consistency.

- Record the setting: Once you have achieved the desired grind consistency, it’s a good idea to record the grinder setting for future use. This can be helpful in maintaining consistency in your coffee brewing.

Overall, adjusting a grinder to achieve the desired consistency of the ground material requires some experimentation and fine-tuning. By following these steps and making small adjustments, you can achieve a consistent and high-quality grind for your coffee.

The role of screens and mesh in filtering out larger particles:

Screens and mesh play an important role in filtering out larger particles from a mixture or solution. A screen or mesh is a woven material made of metal, plastic, or fabric that consists of evenly spaced openings or pores of a specific size.

In the case of coffee, screens or mesh are often used in the brewing process to filter out larger particles or sediments from the final cup of coffee. For example, in a French press, a metal mesh filter is used to separate the coffee grounds from the water as the plunger is pressed down. Similarly, in a pour-over coffee maker, a paper or metal mesh filter is used to separate the coffee grounds from the hot water as it passes through the filter into the carafe.

In other applications, screens and mesh can be used to filter out larger particles from a variety of mixtures or solutions. For example, screens can be used in industrial processes to separate solids from liquids, or in wastewater treatment plants to remove large debris from the water before it’s treated.

The size of the openings or pores in a screen or mesh is crucial to its effectiveness in filtering out larger particles. The size of the openings or pores is measured in microns, with smaller micron sizes indicating smaller openings and a higher level of filtration. In coffee brewing, the size of the filter is typically chosen based on the desired level of sediment in the final cup of coffee.

Overall, screens and mesh are an important tool in filtering out larger particles from a mixture or solution. Their effectiveness depends on the size of the openings or pores and their intended use, whether it be for coffee brewing, industrial processes, or wastewater treatment.

V. Applications of Grinders

Different industries and contexts where grinders are commonly used (e.g. coffee shops, spice shops, culinary industry)

Grinders are commonly used in a wide range of industries and contexts for various purposes. Some of the most common industries and contexts where grinders are used include:

- Coffee industry: Grinders are a critical tool in the coffee industry for grinding coffee beans to a specific size and consistency for different brewing methods.

- Food industry: Grinders are used in the food industry to grind meat, grains, spices, and other ingredients. They can be found in restaurants, grocery stores, and industrial food processing plants.

- Construction industry: Grinders are used in the construction industry to cut and grind concrete, stones, and other hard materials. They are often used for smoothing and shaping surfaces or for removing old coatings and adhesives.

- Metalworking industry: Grinders are used in the metalworking industry to shape and polish metal objects. They are commonly used for grinding, sanding, and polishing, and can be found in manufacturing plants and metalworking shops.

- Woodworking industry: Grinders are used in the woodworking industry for shaping and finishing wood surfaces. They are often used for sanding, grinding, and polishing wood, and can be found in woodworking shops and manufacturing plants.

- Automotive industry: Grinders are used in the automotive industry for various purposes, including cutting, grinding, and polishing metal parts. They are commonly used in auto body shops and manufacturing plants.

- DIY projects: Grinders are also commonly used in DIY projects and home improvement tasks. They can be used for cutting, grinding, and polishing a variety of materials, including wood, metal, and concrete.

Overall, grinders are a versatile tool that can be used in a wide range of industries and contexts for various purposes. They are available in different sizes and types, each designed for specific applications, and can be powered by electricity, battery, or manual operation.

The benefits of using a grinder for grinding materials

Using a grinder to grind materials offers several benefits, including:

- Consistent results: Grinders are designed to provide a consistent and even grind, ensuring that the ground material is uniform in size and texture. This can be especially important in industries such as coffee and food where consistent grinding is crucial for achieving the desired end product.

- Control over the grind: Grinders allow you to adjust the grind size to your specific needs, whether you need a fine, medium, or coarse grind. This level of control over the grind size can be important for achieving the desired flavor or texture in different materials.

- Efficiency: Grinders can grind materials quickly and efficiently, making them ideal for use in high-volume production environments. In industries such as construction and metalworking, the use of grinders can speed up the grinding process and improve productivity.

- Versatility: Grinders can be used to grind a wide range of materials, including coffee beans, meat, grains, spices, and more. This versatility makes them a useful tool in many different industries and contexts.

- Cost-effectiveness: Using a grinder can be more cost-effective than purchasing pre-ground materials. For example, in the coffee industry, purchasing whole bean coffee and grinding it in-house can be more cost-effective than purchasing pre-ground coffee.

Overall, using a grinder to grind materials can provide a range of benefits, including consistent results, control over the grind, efficiency, versatility, and cost-effectiveness. These benefits make grinders a useful tool in many different industries and contexts.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Grinder Videos

Grinder videos are instructional or review videos that provide information and guidance on using different types of grinders for various purposes. These videos can be found on platforms such as YouTube and Vimeo and may feature demonstrations of specific grinders, tips for achieving a desired grind size or texture, or reviews of different grinder models. Grinder videos can be useful for both professionals and hobbyists looking to improve their grinding techniques or to learn more about different grinder options. They can also provide insights into the features and capabilities of different grinder models, helping consumers make informed purchasing decisions.