Pulverizer Grinder Safety

Grinder Safety Rules

Grinding machines are commonly used in various industries to shape and finish metals, wood, plastics, and other materials. Despite being a necessary tool for many tasks, grinders can be extremely dangerous if not operated with caution. The high-speed rotation of abrasive wheels can cause flying debris, electrical hazards, and noise exposure, making it crucial to follow proper safety measures when using a grinder. In this article, we will outline some essential grinder safety rules that should be followed to prevent accidents and injuries in the workplace.

Wear Appropriate Personal Protective Equipment (PPE)

Personal protective equipment (PPE) is essential when using a grinder. The following equipment should be worn at all times when operating a grinder:

- Eye protection: Debris and sparks can easily fly into your eyes, causing serious injuries. Safety glasses or a full-face shield should be worn to protect your eyes from harm.

- Hearing protection: Grinders can be very loud, and prolonged exposure to noise can cause hearing damage. Earplugs or earmuffs can reduce the risk of hearing loss.

- Gloves: They protect your hands from cuts, burns, and abrasions caused by flying debris or accidental contact with the abrasive wheel.

- Face shield or respirator: When grinding certain materials, such as metals or plastics, a respirator can protect you from inhaling harmful dust or fumes, while a face shield protects your face from flying debris.

Inspect and Maintain the Grinder

Before using a grinder, inspect it for any damage or defects. Check the power cord for cracks or frayed wires, and make sure the plug is in good condition. Inspect the abrasive wheel for cracks, chips, or other damage. If the wheel is damaged, replace it before using the grinder. A damaged wheel can break during use, causing serious injury or death. Make sure the guards and shields are in place and functioning properly. The guards and shields are designed to protect you from flying debris and sparks, so it’s crucial that they are in good condition.

Keep the work area clean and free of debris, and make sure the grinder is stored in a safe location when not in use.

Use the Grinder Correctly

When using a grinder, it’s crucial to follow proper procedures to prevent accidents and injuries. Always start the grinder with the wheel facing away from you and stand to the side of the grinder as you turn it on. Use both hands to hold the grinder and maintain a firm grip. Do not use excessive force when grinding, as this can cause the abrasive wheel to break. Never grind with the side of the wheel. The grinding surface should be flat against the workpiece at all times. Do not stand directly in front of the grinder while it is in use. Stand to the side, and make sure there are no bystanders nearby. When finished using the grinder, turn it off and allow the wheel to come to a complete stop before setting it down.

Never Alter or Modify the Grinder

Modifying a grinder in any way is dangerous and can lead to serious injury or death. Never alter or modify the guards, shields, or any other safety features on the grinder. Do not use a grinder for any purpose other than its intended use. Using a grinder for tasks it was not designed for can lead to damage, injury, or death.

Train Employees on Grinder Safety

Proper training is essential for safe grinder operation. All employees who use grinders should receive training on proper use, maintenance, and safety procedures. Training should cover the hazards associated with grinder use, as well as the correct PPE to wear, how to inspect and maintain the grinder, and the proper techniques for using the grinder.

Do Not Overuse the Grinder

Grinders are designed for intermittent use, not continuous operation.

Grinder Safety Guard

Grinder safety guards are an essential component of any grinding machine. These guards are designed to protect the operator from flying debris and the abrasive wheel from damage. Grinding machines use abrasive wheels to remove material from a workpiece and can cause serious injury or death if the operator is not wearing proper PPE or the machine is not properly guarded. In this article, we will discuss the importance of grinder safety guards and how to use them correctly.

Importance of Grinder Safety Guards

Grinder safety guards are required by OSHA (Occupational Safety and Health Administration) and are essential for protecting the operator from flying debris and the abrasive wheel from damage. The abrasive wheel on a grinder rotates at high speeds and can shatter if it comes in contact with an object, causing debris to fly in all directions. Grinder safety guards are designed to contain the debris and protect the operator from injury.

Grinder safety guards also prevent accidental contact with the abrasive wheel. When the abrasive wheel is rotating, it can cause serious injury or death if the operator’s hand or other body parts come into contact with it. The safety guard prevents accidental contact and keeps the operator safe.

Types of Grinder Safety Guards

There are several types of grinder safety guards available, each designed for a specific type of grinding machine and task. The most common types of grinder safety guards include:

- Eye Shield: This type of safety guard is designed to protect the operator’s eyes from flying debris. It is made of clear plastic and is mounted on the grinder’s tool rest. The eye shield can be adjusted to suit the operator’s height and angle of view.

- Wheel Guard: The wheel guard is designed to protect the abrasive wheel from damage and prevent debris from flying out of the grinding machine. It is mounted on the grinder’s housing and covers the entire wheel.

- Adjustable Guard: An adjustable guard can be adjusted to suit the operator’s height and angle of view. It is typically used for precision grinding, where the operator needs a clear view of the workpiece.

Using Grinder Safety Guards

When using a grinder, it is crucial to follow proper safety procedures to prevent accidents and injuries. The following steps should be taken when using grinder safety guards:

- Inspect the grinder safety guards before use to ensure they are in good condition and functioning properly.

- Use the appropriate type of grinder safety guard for the grinding machine and task.

- Position the grinder safety guard correctly to protect the operator and prevent debris from flying out of the grinding machine.

- Adjust the grinder safety guard to suit the operator’s height and angle of view.

- Wear the appropriate PPE, including eye protection, gloves, and hearing protection.

- Use the grinder safety guard during operation and do not remove it until the abrasive wheel has come to a complete stop.

- Turn off the grinder before making any adjustments to the safety guard.

- Replace damaged grinder safety guards immediately.

Grinder for sale

Conclusion

Grinder safety guards are an essential component of any grinding machine. They are designed to protect the operator from flying debris and the abrasive wheel from damage. When using a grinder, it is crucial to follow proper safety procedures to prevent accidents and injuries. Always inspect the grinder safety guards before use, use the appropriate type of grinder safety guard for the grinding machine and task, and wear the appropriate PPE. By following these guidelines, you can help ensure the safe operation of your grinding machine and prevent accidents and injuries.

Grinder Safety Training:

Grinder safety training is essential for anyone who works with or around grinding machines, whether it be in a factory, workshop, or construction site. Grinding machines are powerful tools that can be dangerous if not used properly. Therefore, it is crucial to ensure that individuals operating or maintaining grinders have the necessary knowledge and skills to do so safely.

Purpose:

The purpose of grinder safety training is to educate workers on the proper use, maintenance, and safety practices when working with grinders. This training includes both theoretical and practical components, covering topics such as:

- Understanding the hazards associated with grinding machines, including the potential for physical injury, fire, and explosion.

- Identifying the different types of grinding machines and their uses.

- Proper use of Personal Protective Equipment (PPE), such as safety glasses, face shields, gloves, and hearing protection.

- Safe work practices when operating a grinder, such as properly securing the workpiece, adjusting the grinder settings, and maintaining a safe distance from the grinding wheel.

- Proper maintenance and inspection of grinding machines to ensure they are in good working condition.

- Correct handling of grinding wheels, including selecting the appropriate wheel for the job, checking for damage or defects, and ensuring proper mounting and balancing.

- Emergency procedures in case of accidents or malfunctions.

Grinder safety training should be conducted by a qualified trainer or instructor who has experience working with grinders and understands the potential hazards associated with them. The trainer should also be familiar with the specific type of grinder being used and the safety procedures required for that machine.

It is important that employees attend grinder safety training regularly to ensure they are up-to-date with any changes in safety regulations or operating procedures. By providing regular training, employers can reduce the risk of accidents, injuries, and downtime caused by improperly maintained or operated grinders.

In summary, grinder safety training is crucial for ensuring the safety of workers who operate or maintain grinding machines. It is essential that employees receive comprehensive training that covers all aspects of grinder safety, including hazard identification, PPE, safe work practices, maintenance, and emergency procedures. Regular training can help prevent accidents and injuries, protect workers’ health, and ensure the efficient operation of grinding machines.

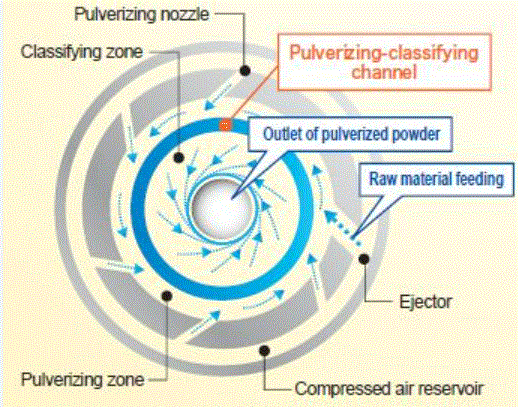

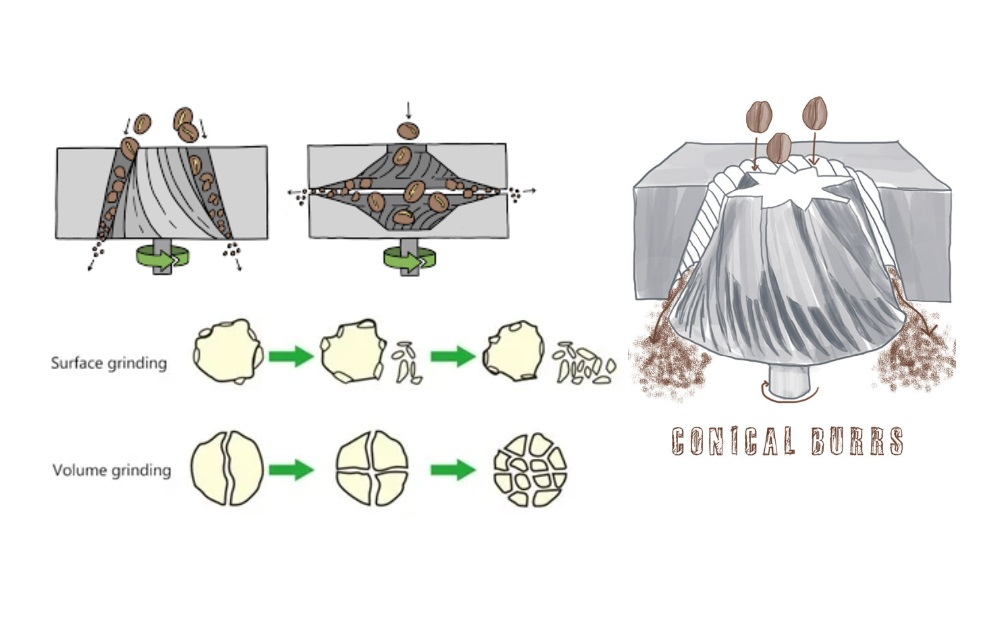

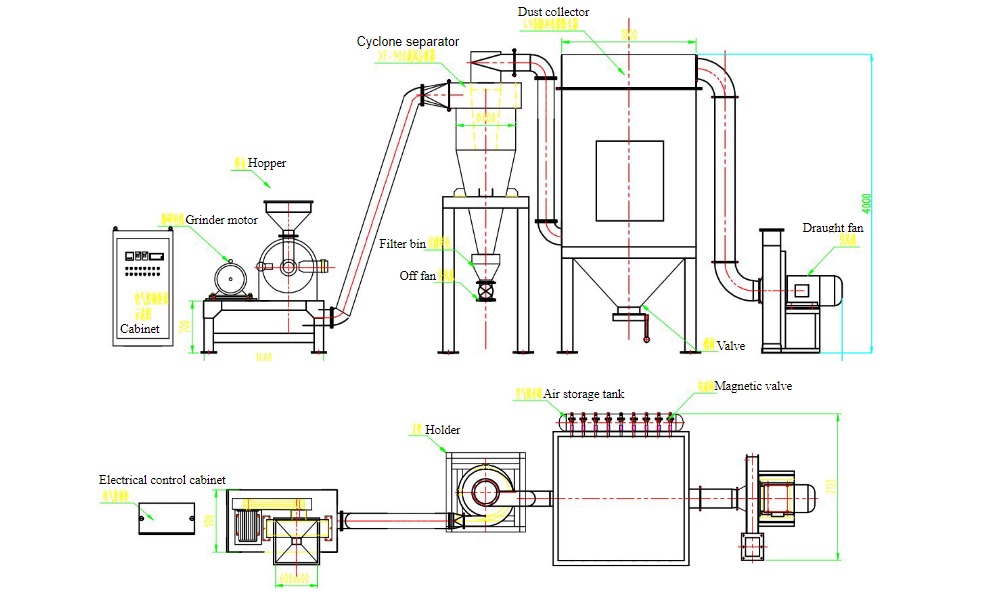

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com