What is the difference between a ball mill and a pulverizer?

What is the Difference Between a Ball Mill and a Crusher?

I. Core Differences in Working Principles

- Ball Mill:

- Uses grinding media (steel balls, ceramic balls, etc.) inside a rotating cylinder to impact, frictionally grind, and compress materials, achieving progressive pulverization.

- Typical rotation speed: 15-30 RPM (referencing Mining Machinery Design Manual), classified as low-speed grinding equipment.

- Suitable for prolonged continuous operation, with output particle sizes ranging from 1-100 microns. Ideal for high-precision fine grinding, such as in cement or ceramic raw material processing.

- Crusher:

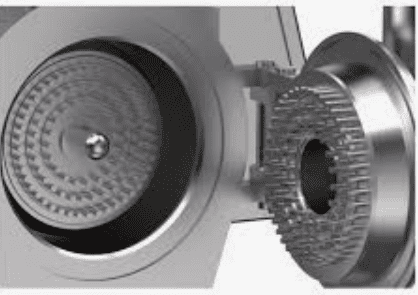

- Relies on high-speed rotating blades, hammers, or toothed discs to directly impact and shear materials, achieving instant fragmentation.

- Rotation speed typically ranges from 1000-3000 RPM (e.g., hammer crushers), offering high efficiency but coarser particle sizes (0.1-10 mm).

- Suitable for brittle materials (e.g., grains, primary ore crushing) and commonly used in food and chemical industries.

II. Structural and Performance Comparison

- Design Features:

- Ball mills feature a horizontal cylinder structure and require auxiliary grading equipment to control particle size. Crushers often have a vertical or compact design with integrated screens for particle size adjustment.

- Ball mills have higher maintenance costs (requiring periodic replacement of grinding media), while crushers allow easier replacement of wear parts (e.g., blades).

- Energy Consumption and Efficiency:

- Ball mills consume 30%-50% of a plant’s total energy (IEA data), with lower efficiency but more uniform output. Crushers consume 30% less energy but generate more heat and dust.

III. Application Scenario Recommendations

- Prefer a ball mill: For ultra-fine powder requirements (e.g., lithium battery materials) or applications demanding high uniformity.

- Prefer a crusher: For high-volume processing, lenient particle size requirements (e.g., feed processing), or heat-sensitive materials (requiring low-temperature crusher models).

What is the Difference Between a Ball Mill and a Crusher?

The main differences between a ball mill and a crusher are as follows:

- Working Principle:

- Crusher: Primarily uses compression, impact, or shearing to break large ore chunks into smaller pieces. The crushing process is mechanical, utilizing components like moving jaws, hammers, or cones to apply external force and fracture the ore.

- Ball Mill: Relies on the rotation and tumbling of steel balls or rods inside a cylinder to impact and grind the ore, achieving pulverization. The grinding process involves both mechanical and chemical actions.

- Processing Stage and Particle Size:

- Crusher: Mainly used for coarse, medium, and fine crushing stages, progressively reducing large ore chunks to smaller sizes. Output particle sizes are relatively larger, typically ranging from several millimeters to hundreds of millimeters.

- Ball Mill: Primarily used for the grinding stage, further pulverizing crushed ore into finer particles. Output particle sizes are smaller, usually between 0.1 mm and a few millimeters.

- Auxiliary Equipment:

- Crusher: Often paired with screening equipment to control particle size and separate qualified material early.

- Ball Mill: Typically paired with classification equipment to regulate particle size and separate qualified slurry for subsequent processing.

- Application Scenarios:

- Crusher: Widely used in mining, construction, metallurgy, and chemical industries for crushing ores and rocks of varying hardness.

- Ball Mill: Also widely used in these industries but mainly for the grinding stage, further refining crushed ore to meet downstream process requirements.

In summary, ball mills and crushers differ significantly in working principles, processing stages, particle sizes, auxiliary equipment, and application scenarios.

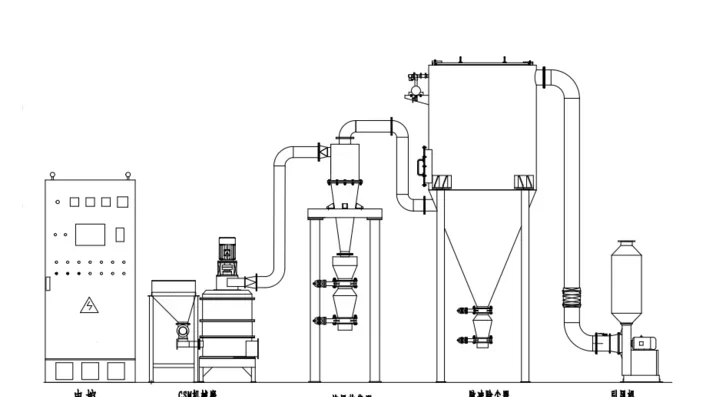

Food Producing Process Flow:

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Click and Read More about Pulverizer:

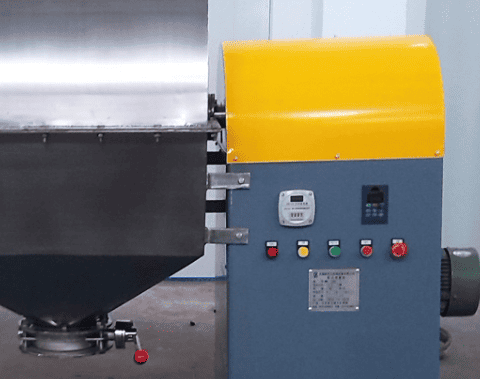

About LKMixer

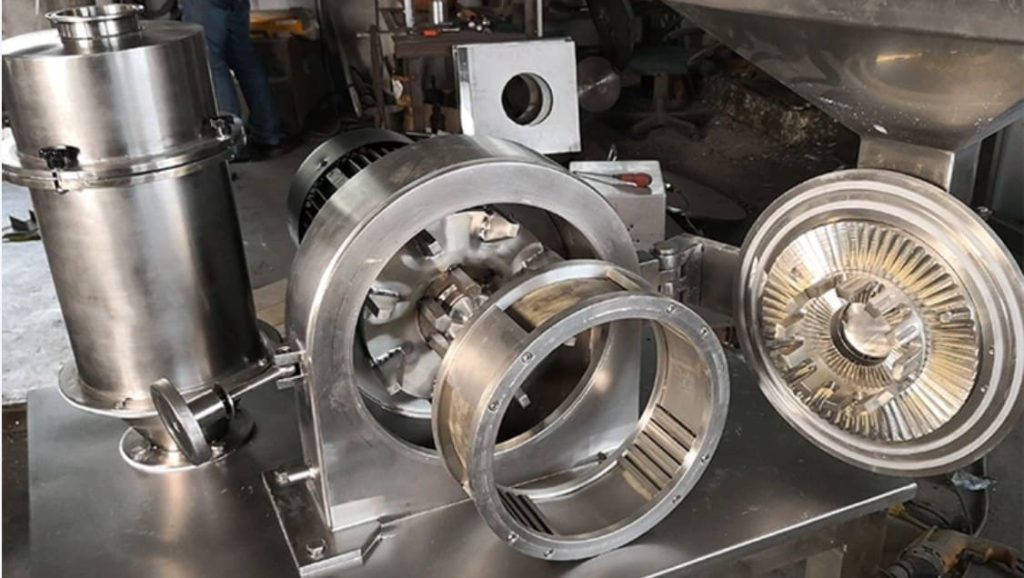

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Grinder for Sale:

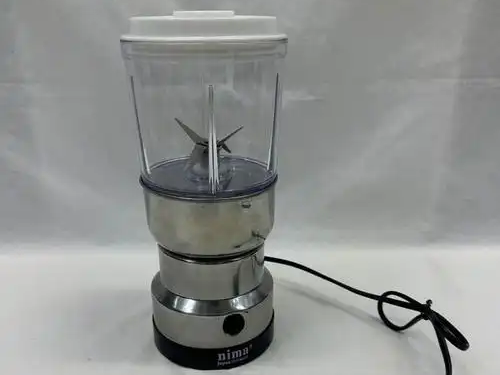

Blenders for Sale:

FAQ(Click and See More)

Why Choose Us?

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

What’s your main maket?

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

Can you support OEM?

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

What after-sale services?

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

WHAT kind of MACHINE YOUR COMPANY HAVE?

CAN YOU GIVE ME GUIDE ON OTHER MACHINE ? TO FULL MY PRODUCTION LINE

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

HOW TO VISIT YOUR COMPANY?

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

WHAT’S YOUR BEFORE & AFTER SERVICE ?

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

HOW ABOUT YOUR PAYMENT TERM?

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.