Stainless Steel Grinder

A Stainless Steel Grinder is a type of industrial equipment that is used to grind, crush, and pulverize materials into fine particles. It is commonly used in the food, pharmaceutical, and chemical industries for the preparation of powders and granules. The equipment is typically made of high-quality stainless steel to ensure its durability and resistance to corrosion.

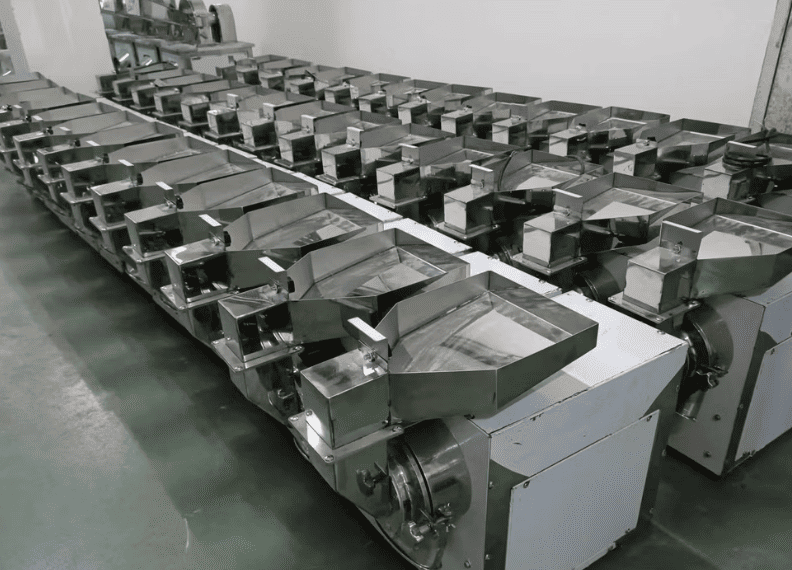

We have a technical engineering team well control the quality. The main task is to check the quality of each process, then to ensure the final quality according to international standard. With the solid ensure of raw materials, good price also enable us to own customer all over world.

With our technology, industrial experience and advanced mechanical support, we can provide design and high quality machine for our customer. The advanced infrastructure is the basic tool of enhancing our productivity. The active support provided by our experienced staff and advanced manufacturing units greatly helps us to meet our customers’ requirements. Our products are equipped with all the latest equipment and quality checks are carried out throughout the production process until the final delivery of the product.

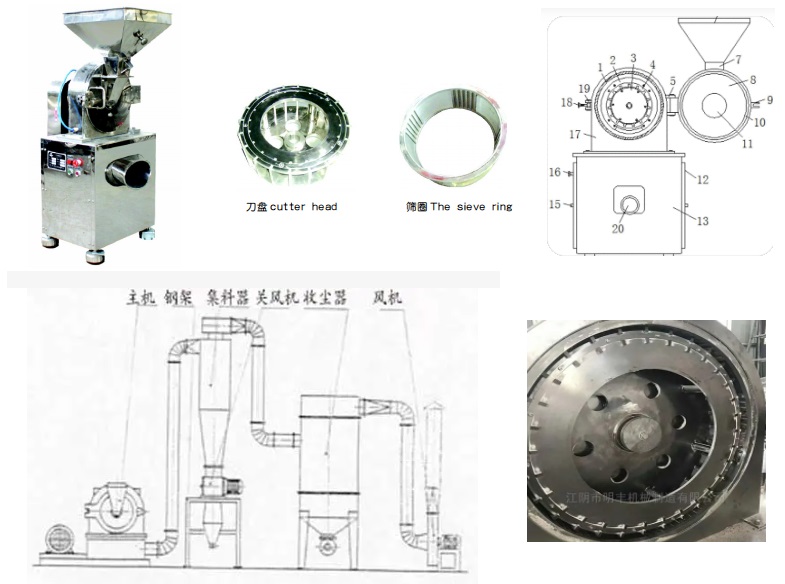

Super Grinder

- Feeding Granularity: <10mm;

- Powder Size: 80-320mesh

- Capacity: 10~2000kg/h according to different material

- Motor Power (KW): 13.37~119kw;

- Axis Rotating Speed(r/min):2000~6200;

- Dimension(mm):4200*1250*2700~8500*2800*4830.

- Price: $ 50-1,179. Video (To see more videos)

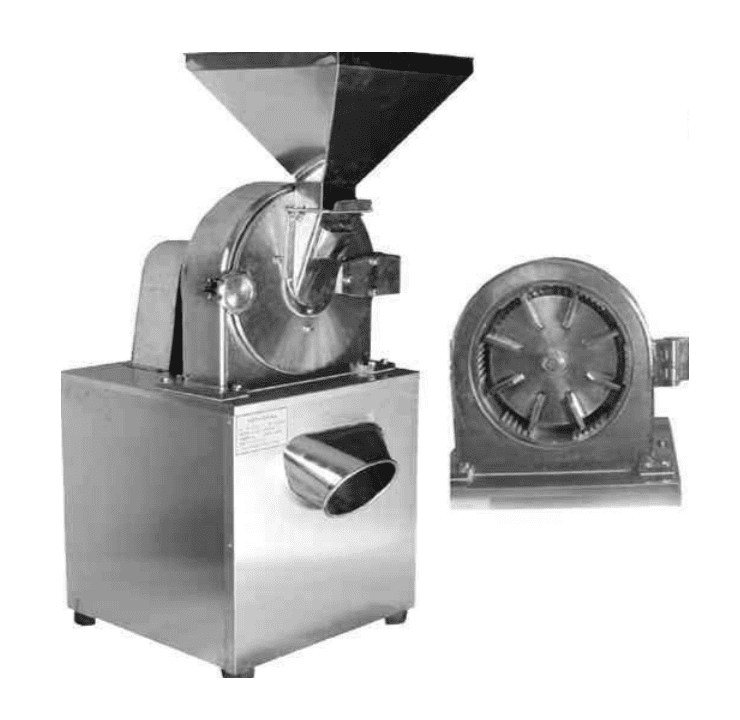

WF Universal Grinder – Hammer Mill

WF Dust Collector Grinder

- Feeding Granularity: <10mm~<20mm;

- Powder Size: 12~120 mesh;

- Capacity:100~2000kg/h(according different modes and raw materials);

- Motor Power (KW): 11.25~64.25kw;

- Axis Rotating Speed(r/min):1400~3800;

- Price: $ 50-1,179. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

WFJ Medicine Grinder – Hammer Mill

B Vacuum Mill

- Feeding Granularity: 10~15mm;

- Powder Size: 20~150 mesh;

- Capacity: 60-2000kg/h (according to mode and different raw material);

- Motor Power (KW): 4~30kw;

- Axis Rotating Speed(r/min):2200~5300;

- Dimension(mm):550*500*1200~1800*1200*2500.

- Price: $ 50-1,179. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

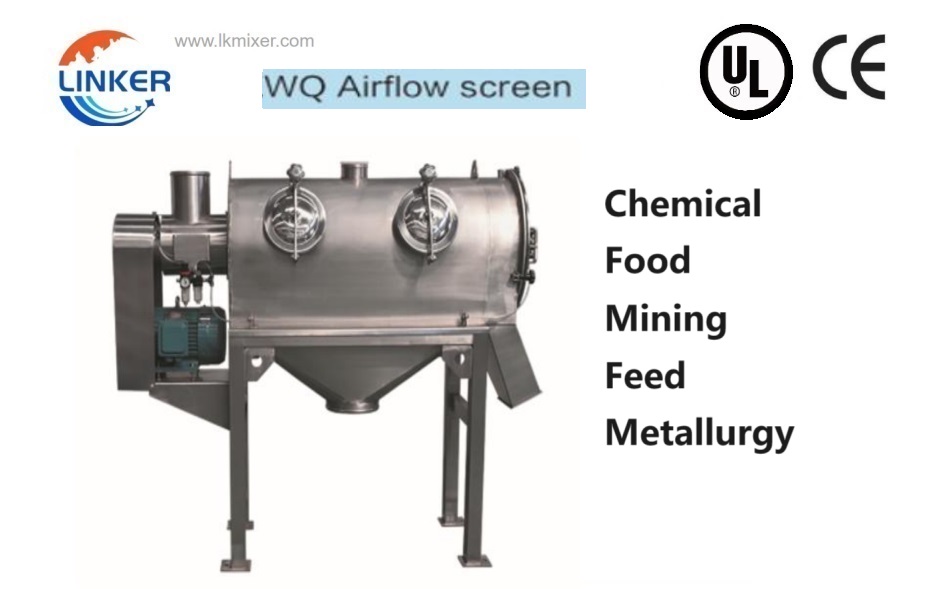

FL Airflow Pulverizer Supplier

- Feeding Granularity: <5mm, <10mm;

- Powder Size: 30~120 mesh;

- Capacity: 30~2200kg/h (according to mode and different raw material);

- Motor Power (KW): 4~22kw;

- Axis Rotating Speed(r/min):2200~4200;

- Dimension(mm):550*420*1400~1250*1100*2500.

- Price: $ 50-1,179. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

What is Stainless Steel Grinder?

A Stainless Steel Grinder is a type of industrial equipment that is used to grind, crush, and pulverize materials into fine particles. It is commonly used in the food, pharmaceutical, and chemical industries for the preparation of powders and granules. The equipment is typically made of high-quality stainless steel to ensure its durability and resistance to corrosion.

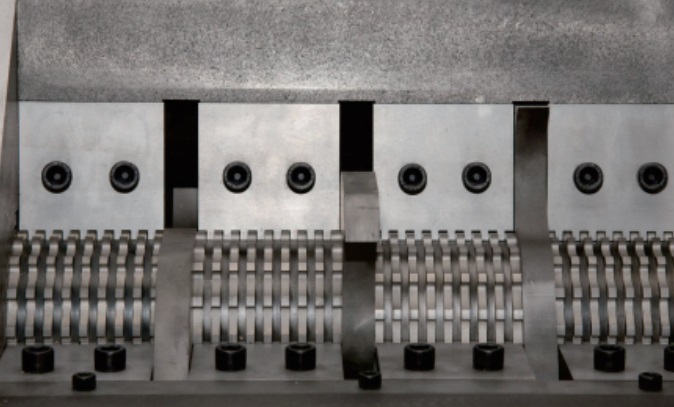

The Stainless Steel Grinder is designed to achieve high performance and efficiency while maintaining product quality. It is constructed with high-quality materials and precision engineering to ensure its longevity. The equipment is typically made up of several components, including a grinding chamber, a rotor, and a series of hammers or blades that rotate at high speed to crush and grind the materials.

The grinding chamber is the central part of the Stainless Steel Grinder, and it is where the materials are loaded for pulverization. The chamber is typically lined with wear-resistant materials to prevent damage from the abrasive nature of the particles being ground. The rotor is the rotating component of the grinder and is located inside the grinding chamber. It is usually made of high-strength steel or other durable materials and is designed to withstand the stresses and forces generated during the grinding process.

The hammers or blades of the Stainless Steel Grinder are attached to the rotor and are responsible for breaking up the materials into smaller particles. The blades can be fixed or swinging, depending on the design of the grinder. The swinging blades are typically more effective at grinding and pulverizing, as they generate more force and impact.

One of the key advantages of the Stainless Steel Grinder is its ability to produce consistent and uniform particles. This is essential in many industries where product quality and performance are critical. The equipment can also be used to reduce the particle size of materials that are difficult to process using other methods. This can lead to improved product performance and increased efficiency in downstream processing.

In addition to its durability and resistance to corrosion, stainless steel is also a hygienic material, which is important in industries such as food and pharmaceuticals. Stainless steel is easy to clean and sanitize, making it a popular choice for equipment that comes into contact with food or other sensitive materials.

Stainless Steel Grinders are typically available in a range of sizes and capacities to meet the specific needs of different industries and applications. Some models may feature additional components, such as screens or filters, to help ensure product quality and consistency.

In conclusion, the Stainless Steel Grinder is a versatile and essential piece of equipment in the food, pharmaceutical, and chemical industries. Its ability to produce consistent and uniform particles makes it a valuable tool for achieving high product quality and performance. The equipment is designed to be durable and long-lasting, making it a reliable investment for businesses that require high-performance grinding and pulverization.

Feature:

Stainless steel grinders have a number of features that make them a popular choice for grinding coffee, spices, and other ingredients. Some of the key features of stainless steel grinders include:

- Durable: Stainless steel is a sturdy and durable material that can withstand heavy use, making it ideal for use in grinders.

- Corrosion-resistant: Stainless steel is resistant to rust and corrosion, making it ideal for use in grinders that are frequently exposed to moisture and liquids.

- Easy to clean: Stainless steel grinders are easy to clean and maintain, and they can be washed with soap and water or placed in a dishwasher.

- Non-reactive: Stainless steel is non-reactive, which means that it does not react with acidic ingredients such as lemon juice or vinegar, making it ideal for use in grinders that are used to grind these types of ingredients.

- Stylish: Stainless steel has a modern and sleek appearance that looks great in any kitchen or coffee shop or large industrial factory.

- Consistent Grinding: Stainless steel grinders can provide a consistent grind size which is important for coffee enthusiasts or for recipes that require a specific grind size.

- High-quality material: Stainless steel grinders are often viewed as a higher quality alternative to plastic grinders due to the robustness and durability of the material.

Parameters:

Model Name | SG-600 | SG-800 | |

| Crushing Capacity(kg/h) | 1000~2000 | 2000~4000 | |

| Power(kw) | 11 | 15 | |

| Feeding Size(mm) | <5mm | <5mm | |

| Fineness(mesh) | 20~40 | 20~40 |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

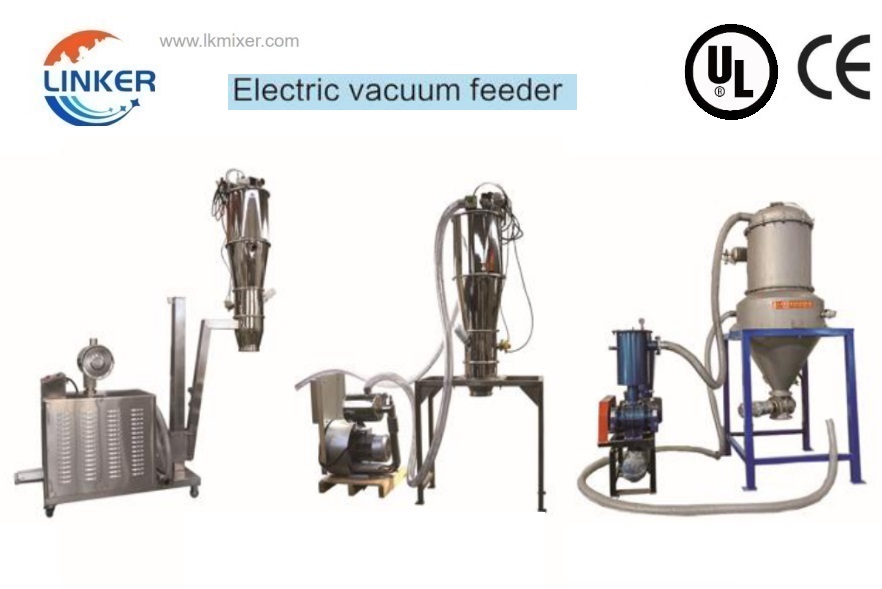

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

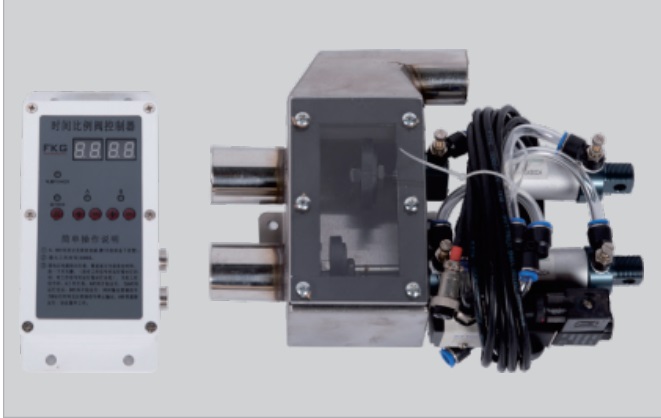

Electric Cabinet with UL Certification

Cyclone Processor and Motors:

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small machines for sea shipment, it is important to take measures to ensure that the machines are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small machines for sea shipment:

- Clean and dry the machine: Before packing, the machine should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the machine in protective material: The machine should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the machine in a sturdy box: The wrapped machine should then be placed in a sturdy box that is appropriate for the size and weight of the machine. The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the machine from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the machine’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small machine in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large Machine Packing:

Packing a large machine for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large machine for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large machine for sea shipment:

- Clean and prepare the machine: Before packing, the machine should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the machine to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the machine from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the machine from moving or shifting during transit.

- Securely fasten the machine: The machine should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the machine’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large machine for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the machine arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the machine is properly packed and prepared for sea shipment.

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

Operation Instruction

General Provisions

The operation instructions for a commercial grinder may vary depending on the specific model and manufacturer. However, here are some general guidelines that may apply to many high speed grinders:

- Safety precautions: Before operating the high speed grinder, it is important to review all safety precautions and warnings provided in the user manual. Safety precautions may include wearing appropriate personal protective equipment, such as eye protection and hearing protection, and avoiding loose clothing or jewelry that could become caught in the grinder.

- Preparation: The high speed grinder should be placed on a stable and level surface, and all necessary components should be assembled according to the manufacturer’s instructions. The grinder should also be connected to a power source that is appropriate for its voltage and wattage.

- Loading the grinder: The material to be ground should be loaded into the grinder according to the manufacturer’s instructions. Overloading the grinder may cause damage to the machine and result in poor grinding performance.

- Starting the grinder: The grinder should be started according to the manufacturer’s instructions. This may involve pressing a button, turning a dial, or flipping a switch. The user should ensure that their hands are clear of the grinder and that the material to be ground is positioned properly.

- Adjusting the speed and settings: The speed and other settings of the high speed grinder may be adjusted according to the material being ground and the desired outcome. The user should follow the manufacturer’s instructions for making adjustments to the grinder.

- Monitoring the grinding process: The user should monitor the grinding process to ensure that it is progressing smoothly and that the material is being ground to the desired size and consistency. Any issues or abnormalities should be addressed promptly to prevent damage to the machine.

- Shutting down the grinder: When the grinding process is complete, the grinder should be shut down according to the manufacturer’s instructions. The user should ensure that the machine is completely stopped and that all moving parts have come to a complete stop before attempting to clean or service the grinder.

Overall, the operation instructions for a commercial grinder may involve a number of steps and safety precautions. It is important to carefully review the manufacturer’s instructions and follow proper operating procedures to ensure safe and effective use of the machine.

Preparation Work

Before running a commercial grinder, there are several important preparation steps that should be taken to ensure safe and effective operation of the machine. Here are some general guidelines for preparing to run a high speed grinder:

- Read the user manual: The first step in preparing to run a high speed grinder is to carefully read the user manual provided by the manufacturer. The user manual will provide important information about the specific model of grinder being used, including its features, specifications, and safety precautions.

- Select the appropriate grinding wheel: The grinding wheel used in a high speed grinder should be selected based on the material being ground and the desired outcome. It is important to use the correct type of grinding wheel to prevent damage to the machine and ensure optimal grinding performance.

- Inspect the grinder: Before running the grinder, it is important to inspect it for any signs of damage or wear. The user should check for loose or missing components, cracks or other signs of damage to the machine’s housing or other parts, and any other issues that could affect the grinder’s operation.

- Install the grinding wheel: The grinding wheel should be installed according to the manufacturer’s instructions, making sure that it is securely fastened and aligned properly. The user should also check the wheel for any cracks or other signs of damage before installation.

- Secure the workpiece: The workpiece to be ground should be securely clamped or held in place before starting the grinder. This will help to ensure safe and effective operation and prevent the workpiece from becoming dislodged or damaged during grinding.

- Connect the power source: The high speed grinder should be connected to a power source that is appropriate for its voltage and wattage. It is important to use a properly grounded power source to ensure safe and reliable operation of the machine.

- Test run: Before beginning actual grinding operations, it may be useful to perform a test run to ensure that the grinder is functioning properly and that the grinding wheel is aligned and balanced properly. The user should follow the manufacturer’s instructions for performing a test run.

By following these preparation steps, users can ensure safe and effective operation of a high speed grinder and achieve optimal grinding results.

Treatment of inspection

Inspection of a commercial grinder is an important maintenance procedure that helps ensure safe and effective operation of the machine. Here are some general guidelines for inspecting a high speed grinder:

- Disconnect power source: Before performing any inspection or maintenance on a high speed grinder, the power source should be disconnected to prevent accidental startup.

- Check for wear and damage: The user should inspect the grinder for any signs of wear or damage, such as cracks in the housing, worn or damaged grinding wheels, or loose or missing parts. Any issues should be addressed promptly to prevent further damage to the machine.

- Check alignment and balance of grinding wheel: The grinding wheel should be inspected for proper alignment and balance, as these factors can affect the quality of the grinding operation. If the grinding wheel is not properly aligned or balanced, it should be adjusted or replaced as necessary.

- Check for proper lubrication: The high speed grinder should be inspected for proper lubrication, as inadequate lubrication can cause excessive wear and damage to the machine’s moving parts. The user should follow the manufacturer’s instructions for lubrication, and add lubricant as necessary.

- Inspect electrical components: The electrical components of the high speed grinder, including the wiring, switches, and control panel, should be inspected for any signs of wear, damage, or loose connections. Any issues should be addressed promptly to prevent electrical problems.

- Test run: After completing the inspection, it may be useful to perform a test run of the high speed grinder to ensure that it is functioning properly and that any issues have been addressed.

By following these inspection guidelines, users can help ensure safe and effective operation of a high speed grinder and minimize the risk of damage or injury during grinding operations.

Operation Attention

Running a commercial grinder can be a dangerous operation if proper precautions are not taken. Here are some general guidelines for safe operation of a high speed grinder:

- Personal protective equipment: The user should wear appropriate personal protective equipment, such as safety glasses, hearing protection, and gloves, to prevent injury from flying debris, noise, and contact with the grinding wheel.

- Secure workpiece: The workpiece being ground should be securely clamped or held in place to prevent it from becoming dislodged during grinding.

- Use proper grinding wheel: The user should select the appropriate grinding wheel for the material being ground and ensure that it is installed correctly and securely. The grinding wheel should be inspected for cracks or other damage before use.

- Adjust grinding wheel speed: The speed of the grinding wheel should be adjusted according to the manufacturer’s instructions to ensure optimal grinding performance and prevent damage to the machine or workpiece.

- Avoid excessive pressure: The user should avoid applying excessive pressure to the grinding wheel, as this can cause the wheel to overheat and wear out more quickly.

- Avoid overheating: The high speed grinder should not be operated continuously for extended periods of time, as this can cause overheating and damage to the machine.

- Monitor grinding operation: The user should closely monitor the grinding operation to ensure that the workpiece is being ground properly and that the grinding wheel is functioning correctly.

- Disconnect power source: After completing grinding operations, the power source should be disconnected to prevent accidental startup.

By following these guidelines, users can operate a high speed grinder safely and effectively, and achieve optimal grinding results. It is important to follow the manufacturer’s instructions and all applicable safety regulations when operating any type of machinery.

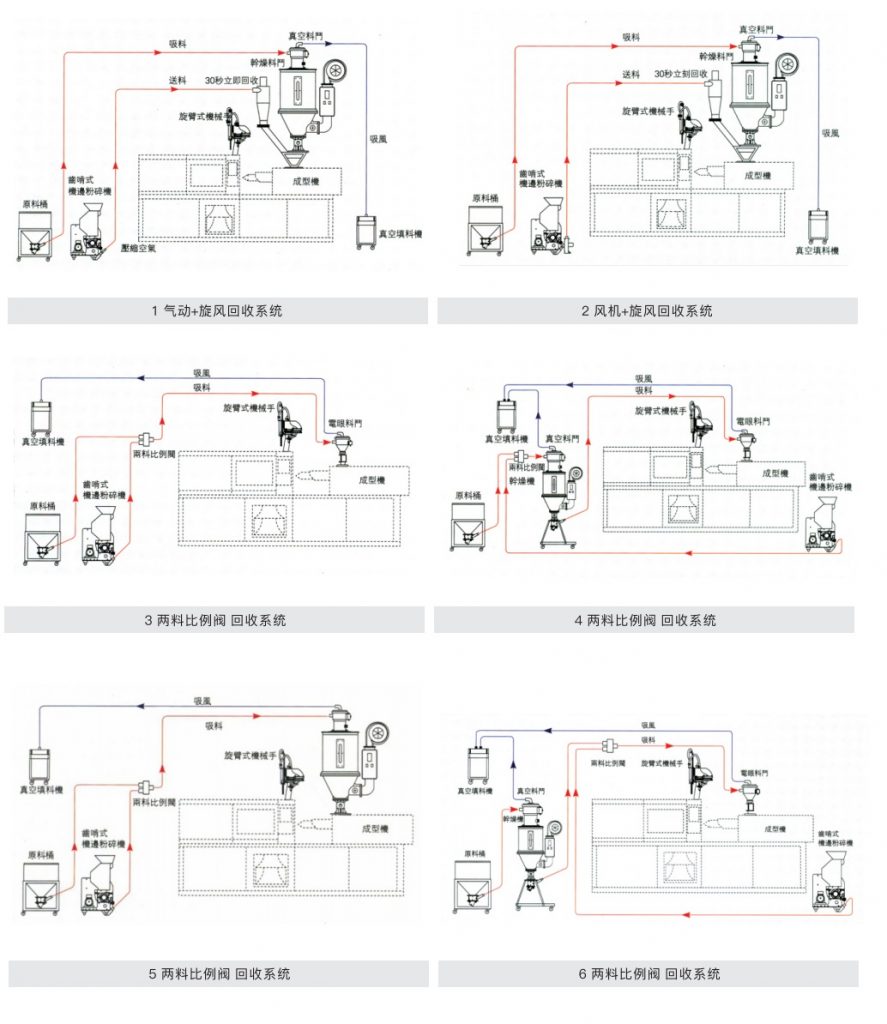

Installation Layout:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Ampere of Motors Customization for Pepper Mill:

| KW | HP | Ampere |

| 75kw | 100HP | 135A |

| 55kw | 75HP | 99A |

| 30kw | 40HP | 54A |

| 22kw | 30HP | 39A |

| 2.2kw | 3HP | 3.9A |

| 1.5kw | 2HP | 2.7A |

Stainless Steel Grinder Youtube Video

FAQ(Click and See More)

What metal is best for grinder?

Stainless steel is generally considered to be the best metal for grinders. This is because stainless steel is a durable and corrosion-resistant material that can withstand the stresses and forces generated during the grinding process. Additionally, stainless steel is a hygienic material that is easy to clean and sanitize, making it a popular choice for equipment that comes into contact with food or other sensitive materials. Other metals such as aluminum, brass, and zinc are also used in the manufacture of grinders, but they may not offer the same level of durability and resistance to corrosion as stainless steel.

How do you clean a stainless steel grinder?

Cleaning a stainless steel grinder is a simple process that involves the following steps:

Disassemble the grinder: Start by disassembling the grinder, separating the various parts, and removing any remaining materials or debris.

Wash with soap and water: Use a mild soap and warm water to wash each part of the grinder thoroughly. Use a soft-bristled brush or cloth to scrub any stubborn stains or debris. Be sure to rinse each part well with water to remove any soap residue.

Dry the parts: Use a clean towel or cloth to dry each part of the grinder thoroughly. Make sure that all parts are completely dry before reassembling the grinder.

Reassemble the grinder: Once all the parts are dry, reassemble the grinder carefully, ensuring that each component is properly aligned and tightened.

Optional: Disinfect: If desired, you can use a disinfectant solution to sanitize the grinder. This is particularly important if the grinder is used in the food or pharmaceutical industries. Simply apply the disinfectant to the parts of the grinder and allow it to sit for the recommended time before rinsing it off with water.

It’s important to note that abrasive materials such as steel wool should not be used to clean stainless steel grinders, as they can scratch the surface and damage the equipment. Additionally, acidic or alkaline cleaners should be avoided, as they can damage the stainless steel and corrode the metal. By following these simple steps, you can ensure that your stainless steel grinder is clean and well-maintained, providing reliable and high-quality performance for years to come.

Is an aluminum grinder good?

Aluminum grinders can be good, but their quality and durability can vary depending on the manufacturing process and the quality of the materials used. Some aluminum grinders may be lightweight and affordable, but they may not be as durable as stainless steel grinders, which can affect their longevity and performance over time.

One advantage of aluminum grinders is that they are lightweight and easy to carry around, making them a popular choice among people who use them for travel or on-the-go. Additionally, aluminum grinders can be affordable and come in a range of sizes and designs, making them accessible to a wide range of consumers.

However, it’s important to note that aluminum grinders may not be as resistant to wear and tear as other materials, and the teeth of the grinder may dull or break more easily over time. Additionally, aluminum grinders may be more prone to corrosion, which can affect their performance and lifespan.

Overall, whether an aluminum grinder is good or not depends on your personal preferences and the specific application you have in mind. If you’re looking for a lightweight and affordable option for occasional use, an aluminum grinder may be a suitable choice. However, if you need a durable and long-lasting grinder for frequent use or in a professional setting, a stainless steel grinder may be a better investment.

Is Brilliant cut grinder worth it?

The Brilliant Cut Grinder has gained a lot of popularity in the cannabis community due to its high-quality materials, customizable grind settings, and durable design. However, whether or not it is worth the investment depends on your personal preferences and needs.

If you are someone who frequently grinds cannabis and values the quality and consistency of your grind, then the Brilliant Cut Grinder may be worth the investment. Its diamond-cut teeth are designed to shred your herb evenly and effectively, resulting in a fluffy and even grind. Additionally, its customizable grind settings allow you to choose the perfect consistency for your needs.

On the other hand, if you do not grind cannabis often or do not require a high-quality and consistent grind, then the Brilliant Cut Grinder may not be worth the investment for you. Other less expensive grinders may be more suitable for your needs.

Overall, the Brilliant Cut Grinder is a high-quality and durable product that can provide an excellent grind for cannabis enthusiasts. However, it may not be the best choice for everyone, depending on their individual needs and preferences.