What is a Ribbon Blender?

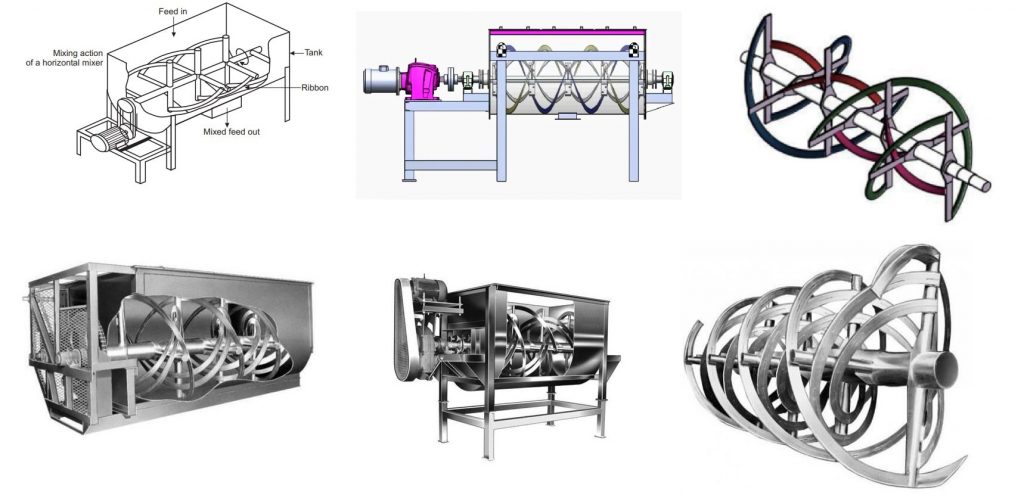

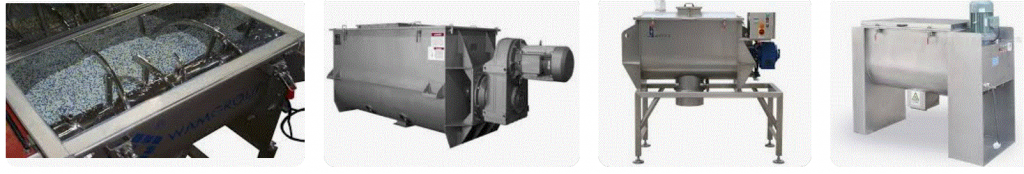

What is a RIBBON BLENDER? The RIBBON BLENDER is suitable for mixing solid, granule, dry powder and semi-liquid materials. Both interior and exterior ribbons offer efficient and economical mixing. In addition, RIBBON BLENDERS are a cost-effective and versatile choice for every industry.

In the pharmaceutical industry, there are many types of mixers, such as V-cone mixers, double-cone mixers, drum mixers, ribbon mixers and so on.

If you are looking to buy a RIBBON BLENDER, we have provided you with a complete guide to the pros and cons of ribbon mixers, how they work, and why the pharmaceutical industry needs them.

However, before diving into the details, let’s first know some basics about belt mixers. What are ribbon mixers and mixers? Horizontal ribbon mixer is a new type of mixing equipment with high efficiency, high uniformity, high loading coefficient, low energy consumption, low pollution and low crushing. The product is widely used, can be used for powder and powder, powder and liquid mixing, especially suitable for paste, viscous or high gravity materials (such as putty, real stone paint, metal powder, etc.) mixing. The equipment is widely used in medicine, food, pesticides, dyes, chemicals, plastics, ceramics, coatings, putty, mortar and other fields.

Operating conditions of ribbon blender

In order to ensure the normal operation of the ribbon blender, it is necessary to install it in a clean, dry, lighting and ventilated room. In addition, the surface of the installation machine must be flat and stable. Before starting the machine, you must carefully check that the power supply is working properly and ensure that the machine is properly grounded.

Before use, please conduct a thorough inspection of the equipment to ensure that it was not damaged during transportation. Be sure to clean the seals on the mixing tank and paddle. At the same time, ensure that the belt can move freely, check the state of the electrical components and the mixing paddle.

Next, when the machine is started, make sure that the mixing paddle does not collide with the cabinet wall. In addition, even after the machine has been running for a period of time, it is necessary to ensure that the temperature of the bearing is kept below 60 degrees Celsius. These steps help ensure the safe and efficient operation of the ribbon blender.

Working principle of Ribbon Blender

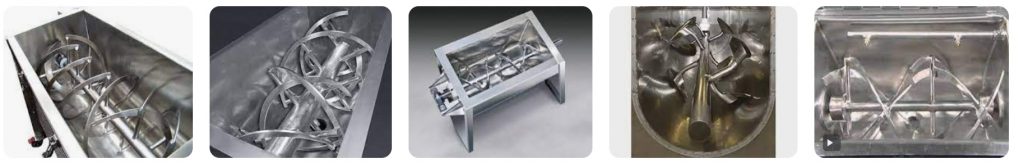

The ribbon blender is a special type of powder mixer consisting of two parts mounted on a central shaft. Mixed media typically include an inner spiral band and an outer spiral band, designed to move the material inward and outward. The outer spiral band pulls the product from the sides of the mixer to the middle, while the inner spiral band pushes the product back to the sides. This folding back and forth creates a convective mixing pattern.

The strip is designed to allow for precise clearance tolerances between the mixer walls. In some cases, they are even designed with soft material wipes to help prevent product buildup on the sides. The drive mechanism usually consists of a belt drive, which is used to transfer powder between the motor and the gearbox. This layout uses a flexible belt and pulley system to generate the speed and torque required for specific hybrid applications. However, more and more manufacturers are starting to adopt gear motor direct drive, utilizing the low inertia rotor of the motor to specifically match the transmission unit. The advantage of this configuration is that it requires less maintenance throughout its lifetime.

Make sure you know the capacity of the blender you need. Knowing the bulk density of the ingredients to be mixed is critical to determining the capacity required for the blender, especially knowing the motor power required to mix batches correctly. Most standard design mixers work well at a product pack density of 35 pounds per cubic foot. However, when starting to mix more dense batches, more powerful motor and gear ratio adjustments may be required.

How does the ribbon blender work? It consists of two components mounted on a central shaft to prompt the material to mix appropriately inward and outward. The overall back-and-forth motion of the material being mixed creates a convective mixing pattern.

In addition, the tape has a clearance tolerance between the mixer walls. In some cases, these strips are even designed with soft material wipes to ensure that the product is constantly piling up on both sides.

The drive mechanism mainly consists of a belt drive for transferring powder between the gearbox and the motor. This design utilizes a flexible belt or pulley system to achieve the required speed and torque. It helps meet the requirements of specific hybrid applications. Today, many manufacturers are adopting direct drive through geared motors, using motor low inertia rotors specifically matched to transmission units.

How does the ribbon blender work? A ribbon blender is a powder mixer with two moving parts on a central shaft. The mixed medium includes an inner and outer spiral band, which can move inward and outward. The outer spiral band pulls the product from the sides of the mixer to the middle, while the inner spiral band pushes the product back to the sides. This back-and-forth folding motion forms a hybrid pattern of connections.

The spiral belt of the machine has a certain clearance tolerance between its walls. Manufacturers sometimes use soft material wiper designs to ensure that the product is constantly piling up on both sides. The transmission mechanism uses a belt drive to achieve power transmission between the motor and the gearbox. This design generates the required speed through a system of flexible belts and pulleys.

Some manufacturers have begun to use direct drive through gears that use motors to match transmission units. Therefore, machine owners do not have to worry about long-term maintenance costs. However, understanding the capacity required for a ribbon blender is crucial for the operator.

Parts of Ribbon Blender:

The following are the main components of the Ribbon Blender:

- seal

- bearing

- gearbox

- engine

- tectum

- Ribbon stirrer

- Axis of rotation

- Spray pipe

- Discharge chute

- Control panel

Ribbon blender mixing and mixing applications

ribbon blenders are one of the most versatile, cost-effective and commonly used dry solids mixers in all processing industries such as general chemicals, food, pharmaceutical, agrochemicals and polymers.

ribbon blenders are ideal for mixing most solids and light pastes. The synergy of the inner and outer bands provides efficient and economical mixing.

Ribbon blenders are widely used in a variety of processing industries, including:

- Animal feed

- Baking mixture

- catalyst

- ceramic

- cosmetics

- Chemical fertilizer

- food

- Instant mixed drink

- Nutrition and health care products

- restoratives

- pigment

- Plastic powder

- Perrier

- Egg white powder

- Resin

- spice

- Mixed sugar

- vitamin

The application advantages of ribbon blender in different industries are as follows:

- ribbon blender in the fertilizer industry: its main advantages are high power and excellent mixing performance, especially suitable for the mass production of natural fertilizers.

- ribbon blenders in the chemical and dye industries: ideal for the manufacture of pellets, dry powder, talc, low viscosity, seasonings, etc., useful for particle mixing in the chemical industry.

- ribbon blenders in the pesticide/insecticide industry: the combination is perfect, especially for handling large amounts of dry and wet powders.

- The ribbon blender in the mineral industry: suitable for the uniform mixing of dry powder, the mixing effect of different packing densities in the mineral industry is significant.

- ribbon blenders in the pigment industry: specially designed to provide powerful mixing capabilities, suitable for mixing dry products.

Ribbon blenders are widely used in manufacturing plants and industry to mix items with many particles, ensuring a uniform mixture of particles. For example, LKmixer’s horizontal ribbon blenders are compact in size and user-friendly for limited head space areas. It has the ability to run smoothly and produce a uniform product in a short time, suitable for a variety of particle sizes and densities of powder materials.

The affordability and versatility of ribbon blenders make them ideal for industries such as pharmaceuticals, food, agriculture, cosmetics, fragrances and chemicals.

The main advantages and disadvantages of ribbon blender

The ribbon blender is not only an affordable device, but also has a range of advantages and disadvantages, which we will explain in detail.

In the powder mixing equipment sold on the market, the ribbon blender is a common accessory. They are commonly used in industrial applications where solid and liquid components need to be mixed. In the maximum mixing mode of the ribbon blender, short and fast mixing cycles can be run, ranging from a few minutes to 15 minutes. These rapid mixing periods give the impression that the tape is spinning at high speed. In reality, however, the tip speed of the ribbon stirrer is up to 300 ft/min.

If the machine is equipped with a central discharge port, it can take full advantage of its full discharge function. By running the machine at a lower speed, one can easily push the material back until the mixing container becomes empty. In addition, the manufacturer can use multiple powder valves on the discharge port of the mixer. Many plug valves are flush with the inner surface of the mixer body in the closed position, allowing accumulation of the mixture to be retained during the mixing cycle.

The working volume capacity of the ribbon blender is relatively low, only 30%. If the capacity is small, the ribbon is not allowed to contact the material. The mixer can work at 100% capacity in a variety of applications, but the ideal mixing capacity remains between 50-70.

ribbon blender is one of the most widely used and widely used powder mixers on the market. They are commonly used for solid-to-solid mixing and can also be used for applications including coating dry particles with liquid components and particle absorption of liquid additives. Because ribbon blenders use a convective mixing mode, short and fast mixing cycles can be achieved, usually between a few minutes and 20 minutes (depending on the volume and complexity of the formulation). Despite the fast mixing cycle, ribbon blenders typically operate at speeds of no more than 300 ft/min, a low speed that is very favorable for handling brittle and fragile materials while maintaining particle integrity.

Advantages of ribbon blender:

- Versatility: ribbon blenders can be used in multiple industries, including food, cosmetics, agriculture, and pharmaceuticals. It is easy to operate, allowing workers to easily mix important ingredients, saving time and ensuring high-quality results.

- Fast response: High shear speed ensures fast mixing of ingredients and a smooth output. The robust construction ensures that no component leaks during mixing, enabling tasks to be completed within the required time frame.

- Durable and hygienic: The design of the ribbon blender avoids cross-contamination of the product and maintains good hygiene. The stainless steel construction enables it to last for many years.

- Suitable for wet and dry users: with exquisite technology, it is equally effective for wet and dry users. The mixer is designed to be sealed at both ends.

- Easy fit for limited areas: The size saves space and easily fits into limited areas, making it ideal for mixing industry ingredients.

- Produce a uniform mixture: The twin-band stirrer transports the material from one place to another in counter-current motion, ensuring a uniform mixture.

Disadvantages of ribbon blender:

- Not suitable for all laboratories: The mixer will not perform well in all laboratories, so it needs to be considered according to actual needs when choosing.

- Clogging: When the bulk density of power is used in high concentrations, the problem of clogging may occur.

- Mixing takes time: If the mixing can is too full, it may take longer than normal to mix the ingredients.

- Particle leakage: Lack of proper care can cause seals to break, which can lead to particle leakage.

How to use a belt mixer to achieve good uniformity?

The key to achieving good uniformity is the correct operation and maintenance of the ribbon blender. Here are some tips to help you achieve good uniformity when using a belt mixer:

- Mixing time: ribbon blenders usually require a longer mixing time, generally between 3-5 minutes. Long mixing times are not always better, so it is best to determine the appropriate mixing time according to actual needs and production requirements. Too long mixing time may indicate that the mixer performance is poor.

- Mixing lot size: Maintaining 70-80% of the total volume of the mixer is key. Make sure the top of the blade is slightly above cargo level and that the top cover always has some headroom. Avoid overloading the mixer as it can significantly degrade performance.

- Mixing speed: The mixing speed of medium-sized ribbon blenders is usually between 500-2000 liters, about 50 rpm. Please follow the supplier’s recommended parameters. Too high or too low a mixing speed may affect uniformity.

- Order of addition of ingredients: Small ingredients and minor ingredients should be added after the main ingredient, or during the mixing process. It is best to add them to the center of the blender to ensure even mixing.

- Seal maintenance: Check and maintain the seals of mixers and mixers regularly. Broken seals can lead to material leaks and shaft alignment problems.

- Lubrication: Check the lubricant level of the mixer regularly and make sure the moving parts are properly lubricated. Good lubrication helps to extend the service life of the mixer.

- Protect the mixing tank: Make sure the mixer is properly spaced from the surrounding walls to avoid damage to the fuselage. Proper alignment ensures that the mixture is well mixed.

The above suggestions can help you get the most out of your ribbon blender and achieve the desired uniformity when using a ribbon blender. Regular maintenance and proper operation will help ensure the performance and longevity of the equipment.

7 consideration points for customizing and selecting a belt mixer:

- Firstly, you need to consider the size and volume: The size and shape of the ribbon blender are key considerations when choosing. Depending on the amount of material to be mixed and the mixing speed, choose the appropriate blender size. In some cases, a large mixer may be appropriate, while in other cases, multiple smaller mixers can optimize the process, avoid downtime issues, and reduce mixing time.

- Secondly, Ribbon or mixer type need to be considered: Different types of mixers are suitable for different mixing needs. Understand the type of ribbon and stirrer and choose the right type according to the characteristics of the ingredients and mixing time. Factors such as shear force, brittleness and mixing speed are considered.

- Structural materials and surface treatment of the mixer: It is important to choose the construction material of the mixer. Depending on the composition of the mixture, choose mild steel or stainless steel, and ensure that the surface treatment is suitable for the purpose, such as food grade raw materials require stainless steel. The external and internal surfaces of the mixer are customized to suit different materials and processes.

- Horsepower: Choose the appropriate horsepower according to the type and size of the mixer. Different mixers may require different amounts of power, especially for mixers with two mixers or wider spiral bands. Make sure the size and type of motor matches the mixer to avoid too much or too little power.

- Discharge gate: The choice of discharge gate depends on cycle time and downstream process requirements. Full-length drop bottom discharge doors are suitable for situations where immediate complete discharge is required, while pneumatic sliding doors are suitable for situations where gradual discharge or sealing is required. Select the appropriate discharge door type according to the specific needs.

- Composition characteristics: Understanding the composition characteristics of the mixture is the key to customizing the ribbon blender. It includes the type of composition, packing density, adhesion, particle size, flammability, etc. This information helps ensure that the mixer is designed to meet mixing requirements while protecting the mixer from damage.

- Finally, facility requirements and limitations: Record information about the facility’s space, peripherals, weighing equipment, etc., to ensure that the mixer selected is suitable for the facility and can work with existing equipment. Understand the production needs and determine the mixing time and speed so that the mixer can be customized to meet the production requirements.

These are the 7 key things to pay attention to when selecting and customizing belt mixers. By taking these factors into account, you can ensure that the mixer you choose meets your production needs and provides an efficient and reliable mixing result. If you are interested in ribbon blenders, LKMixer is a trusted supplier of high quality mixing equipment for pharmaceutical and other manufacturing applications.

You may also interest in:

Feel free to contact us for more information. Proposal, catalog, quotation.

- Working Time: Mon~Fri 8:00~17:00

- Mobile/WhatsApp: +86 18019763531

- Tel: +86 21 66037855

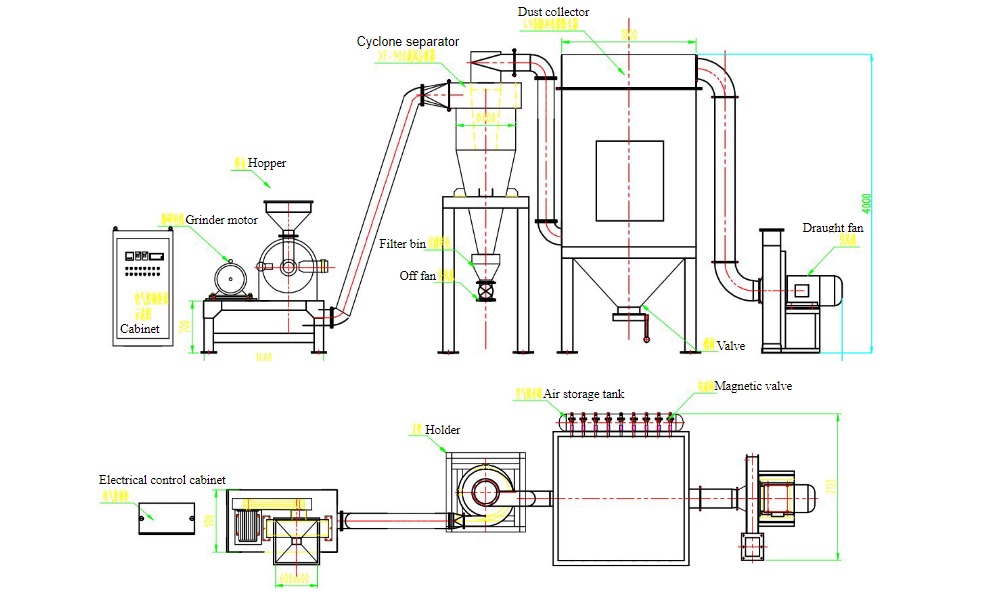

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details.