V Blender vs Double Cone Blender

A double cone blender is an ideal choice for blending 2 to 5 ingredients effectively. On the other hand, V blenders, characterized by their V-shaped design, offer efficient mixing with short blending times. These blenders consist of two connected cylinders that continuously divide and intermesh particles, resulting in blend variations as low as 1 to 2 percent.

Let’s explore the advantages of V cone blenders:

V cone blenders are highly beneficial in various processing industries. They are particularly suitable for handling fragile materials and excel at eliminating product contamination. The V-shaped design itself provides advantages such as particle size reduction and easy discharge of the blended product.

Now, let’s consider the applications of V cone blenders:

V cone blenders find extensive use in producing homogeneous solid-solid mixtures. Mixing is a vital step in the manufacturing processes of industries including healthcare, food, chemical, cosmetics, detergents, fertilizers, and plastics.

Moving on to the advantages of double cone blenders:

Using a double cone blender offers several advantages. Its visually appealing design enhances the aesthetics of the factory environment. Moreover, it reduces noise levels in the workplace. The double cone shape enables easy and uniform mixing, while facilitating the uniform discharge of the blended material. This feature is particularly crucial for pharmaceutical products that require high uniformity.

However, it’s important to consider the disadvantages of double cone blenders:

Double cone blenders are not suitable for fine particulate systems with very small-sized ingredients or ingredients with significant differences in particle size distribution. These blenders do not apply sufficient shear for effective blending in such cases. For free-flowing powders, serial dilution may be necessary.

When it comes to efficiency, double cone blenders excel due to their exceptional three-dimensional motion, resulting in constant and reproducible mixing results. The rhythmic pulsing motion ensures thorough blending of the substances.

The principle of a double cone blender is straightforward. Dry ingredients, such as powders and granules, are loaded manually or through a vacuum system into the double cone vessel for blending.

During the motion of the double cone blender, the contact points with the rails gradually move toward the apex of each cone. This movement decreases the distance of the center of gravity from the horizontal plane, ensuring effective blending.

In summary, both V cone blenders and double cone blenders offer unique advantages for specific blending needs in various industries. Understanding their capabilities and limitations helps in selecting the most suitable blender for specific applications.

Feel free to contact us for more information. Proposal, catalog, quotation.

- Working Time: Mon~Fri 8:00~17:00

- Mobile/WhatsApp: +86 18019763531

- Tel: +86 21 66037855

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details.

Contact Us

Here we shows frequent asked questions about Pulverizer Grinder and Mixer:

Yes, our factory produced grinder, mixer, pulverizer for over 20 years.

Yes, we have video and word file lessons to teach customer how to operate the machine.

Yes, water cooling system can customize according to customer request. Many of the machine we producing is with water cooling system.

Yes, we provide the suitable screen and knife and other spare parts all the life time with nice price for our customer.

We can provide 0.5mm, 1mm thickness screens.

Material type of screen: SUS304 stainless steel.

You can choose another type of screen, also stainless steel, like the follow video shows, the screen have 2 layers, one layer large hole, another layer 40mesh as you request. This two layers are welded together. this kind of screen is more cheap to save the cost.

Yes, we have CCC, GB, EN, IEC, UL certification for motors.

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

– We offer full services covers whole process of your new project. Including your factory feasibility assessment, process flow chart, preliminary factory machines layout and factory building planning, project budget estimation, project time schedule arrangements, etc.

– We supply sample processing tests as to your detail product. To estimate the capacity of machine, this helps you controls better to the capacity and get to know more accuracy of quantity of machine you need to book. In our test station where are equipped with our various machine products,this is also help you compare performances of different types of machines or process.

– For large machine. If neccessary, we can assign engineers to the your project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

– Warranty period is 12 months after installation.

– We offer lifetime service for our machine products after the delivery, and will follow up the machine status with our clients after the successful machine installation in our clients’ factories.

For details, please contact our project consultants, thank you.

– Choose small or large ? Calculate your current customer capacity request, this is to get a estimate capacity needs. To think about you only for small quantity use or large quantity. Do you want to expand your customer base so that need to expand your capacity in near future? If yes, you can order larger machine instead of small machine. If not, smaller one is more suitable for you.

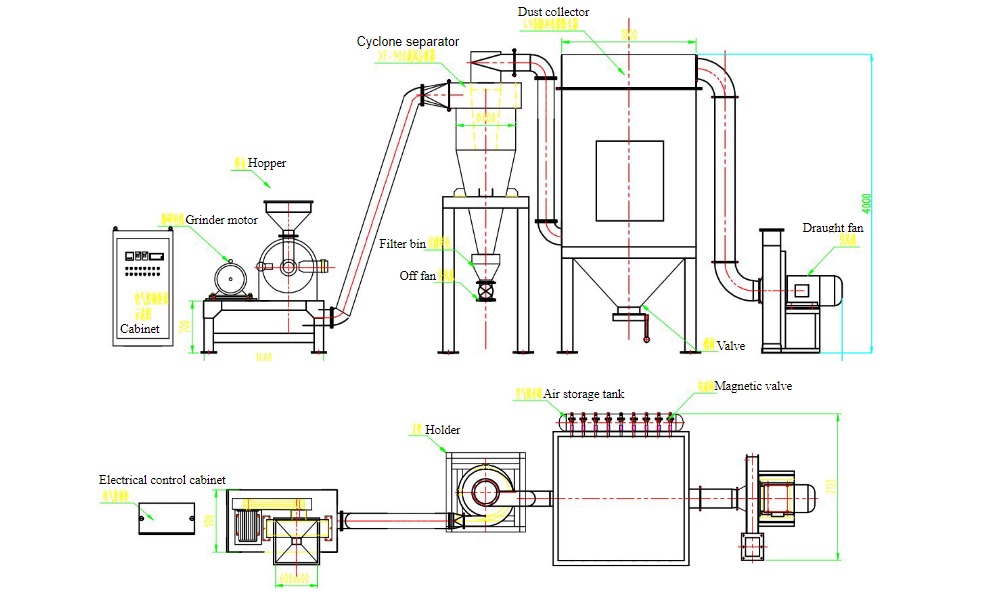

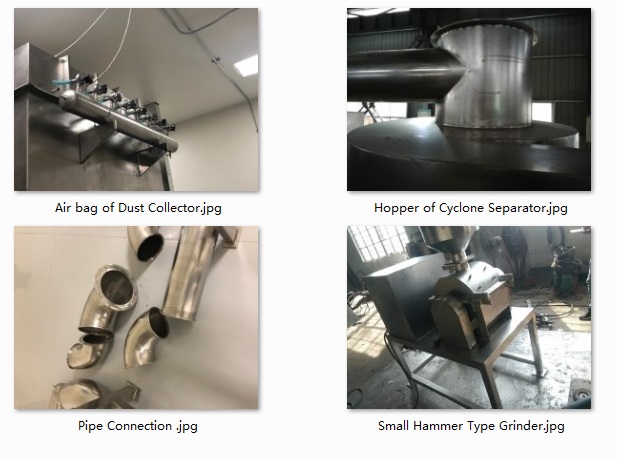

– Choose single or whole group? Single machine is cheaper and easy to move from here to there, space location are also easy. Whole group machine including material feeder, main machine, cyclone sperator and rotary valve. Whole group machine not easy to move cause of link of each portions. But whole group also advantages such as easy to dust collect, save manpower. Think about clearly what you want, we would know which is right to choose.

– If you think about your customers and volume, you’ll be off to a good start in knowing what you need from your grinder.

If you are a large factory request several machine. You may think the question of quantity that you need to purchase. This question actually we have already talked when we previously discussed how much the grinder can produce in an hour.

Based on the capacity of how much kg/hour that we can get, it’s very each to calculate the quantity of machine that you may need finally.

One of the questions that may pay attention here is, how many hour you plan to work per day? If you plan to work 24 hours non-stop, you need to have cooling water system definitely to cool down the machine. And the working hour also need to be calculated into your capacity calculation.

Automatically material feeder helps to feed the raw material automatically, so that no need to stop and refill the hopper frequently. Cyclone Seperator helps output material quickly, vibrating table screener helps screen out the qualified fineness material. All these portion run automatically will significantly help improve the efficiency and capacity.

A good rule of thumb to remember is that a larger capacity usually also means a higher level of speed.

Quality is of paramount importance to just about everyone, and it should be to you, too.

Customers always want the quality in their purchasing, and they will keep long term business with high quality supplier.

Always offering high-quality grinder machine to our customers will earn us a solid reputation with them.

Keeps in mind about quality, we ensure our quality through following items:

– Material: we use 304 or 316 stainless steel body, 316 stainless steel for raw material contact portion.

The material of body always decide by customer, we will confirm the material type with you before you load order.

– Cooling Water System: jaket design allow ooler temperatures while grinding, preventing the burning of the raw material.

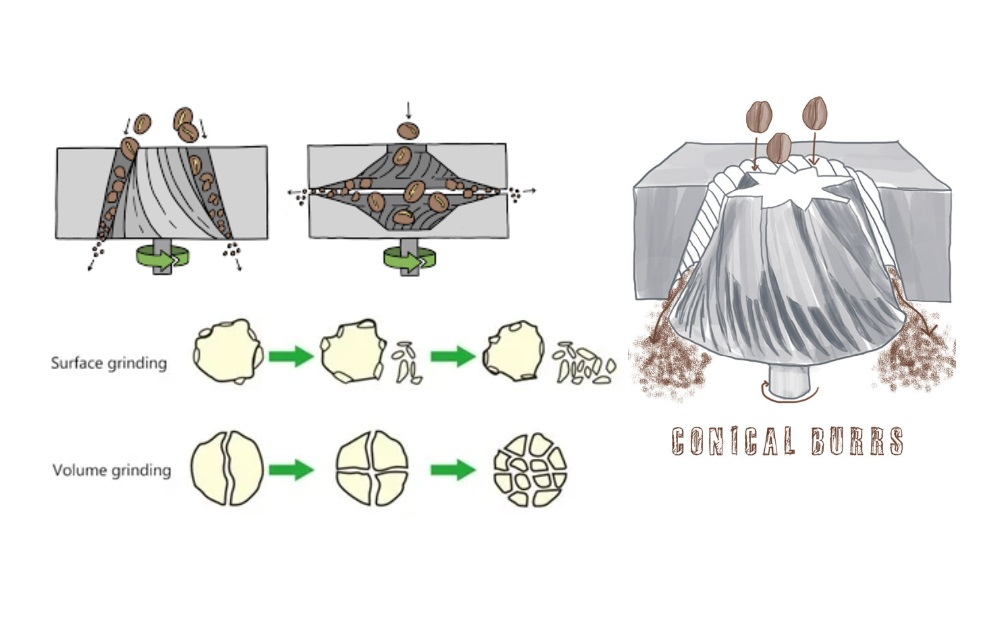

– Grinding Disc and Knife Cutter Design: The industry standard in material for grinding discs is steel, but there are different types of steel to choose from, such as die-cast and tungsten carbide. Good disc and knife design helps cut the material efficienctly. This also ensure the high quality of result mesh fineness.

Convenience to operate for your employees and yourself is also very important.

Your operator may need to carry the material back and forth in batches. Your operator may need to stop machine to clear and clean machine frequently. Your operator may also need to do screens the size of fineness after grinding and then put the inqualified powder back to machine to do grinding second time.

Yes, these are all the problems. But LINKER Pulverizer helps you reduce or solve these probems. You only need to buy the whole set group, which including automatically feeding system, grinding main machine, cyclone separator system, screen system after grinding and even an back material system back to grinder.

Save the manpower also helps to save the cost.

Yes. 100% of inspection for each step of products will be carried out by QC department until shipping.

A mill and a crusher are both types of grinding equipment used to process materials, but there are some key differences between the two:

- Purpose: Mills are typically used to grind and refine materials into a more uniform size and shape, while crushers are used to crush large materials into smaller pieces.

- Types of materials: Mills are often used to process materials that are dry or have a low moisture content, while crushers are used to process materials that are moist or sticky.

- Method of operation: Mills typically use a rotating wheel or drum to grind materials, while crushers use pressure to crush materials.

- Size of output: Mills can produce very fine particles, while crushers typically produce larger pieces of material that may require additional processing.

- Applications: Mills are commonly used in industries such as agriculture, food processing, and metalworking, while crushers are used in industries such as mining, construction, and recycling.

Overall, the main difference between mills and crushers is that mills are used to refine materials into a more uniform size and shape, while crushers are used to crush large materials into smaller pieces. The choice of equipment used will depend on the specific needs of the application and the type of materials being processed.

An industrial grinder is a machine designed to reduce the size of materials by grinding or crushing them. Here are some of the common tasks performed by industrial grinders:

Grinding: Industrial grinders are commonly used for grinding materials to a desired particle size. This can be done using various types of grinders, such as angle grinders, bench grinders, and surface grinders, depending on the specific application.

Crushing: Industrial grinders are also used for crushing materials into smaller pieces. This can be useful in various industries such as mining and construction, where materials need to be crushed for further processing.

Polishing: Industrial grinders can be used for polishing surfaces of materials to achieve a desired finish. This is commonly done using angle grinders and other handheld grinders.

Sharpening: Bench grinders are commonly used for sharpening tools, such as knives and scissors, by grinding them against a rotating abrasive wheel.

Overall, industrial grinders are versatile machines that can perform a wide range of tasks, depending on the specific application and type of grinder used.

Choosing the right crusher for your application involves considering a variety of factors. Here are some key factors to consider when choosing a crusher:

Type of material: The type of material that needs to be crushed is an important factor to consider. Different crushers are better suited for crushing different types of materials. For example, jaw crushers are well-suited for crushing hard, abrasive materials like granite, while impact crushers are better for softer materials like limestone.

Size of material: The size of the material to be crushed is also an important consideration. Larger materials may require a larger crusher or a crusher with more power.

Capacity: The amount of material that needs to be processed per hour or per day is another important consideration. Different crushers have different capacities, so it’s important to choose a crusher that can handle the volume of material you need to process.

Desired final product size: The final product size you need will also impact your crusher choice. Some crushers produce a more uniform product size than others, while others are better for creating coarse or fine materials.

Maintenance requirements: The maintenance requirements of the crusher you choose can also be an important consideration. Some crushers require more maintenance than others, and the cost and frequency of maintenance should be factored into your decision.

Budget: Finally, your budget is an important consideration when choosing a crusher. Different crushers have different price points, so it’s important to choose a crusher that fits within your budget.

Overall, choosing the right crusher requires careful consideration of your specific application and requirements, and weighing the pros and cons of each option. Consulting with a knowledgeable equipment supplier or manufacturer can also be helpful in making an informed decision.

An industrial grinder is a machine used to reduce the size of materials through grinding or crushing. These machines are commonly used in various industries such as mining, construction, manufacturing, and food processing.

Industrial grinders come in different types and sizes, depending on the specific application and the material being processed. Some of the common types of industrial grinders include:

Angle grinders: These are handheld grinders used for cutting, grinding, and polishing various materials.

Bench grinders: These are stationary grinders mounted on a bench or pedestal and used for grinding and sharpening tools.

Surface grinders: These are machines used to grind flat surfaces of materials to a high degree of precision.

Cylindrical grinders: These are machines used for grinding cylindrical surfaces of materials.

Centerless grinders: These are machines used to grind cylindrical and other types of workpieces without using a centering device.

Industrial grinders are essential machines in many industries, as they help reduce the size of materials, improve efficiency, and increase productivity.

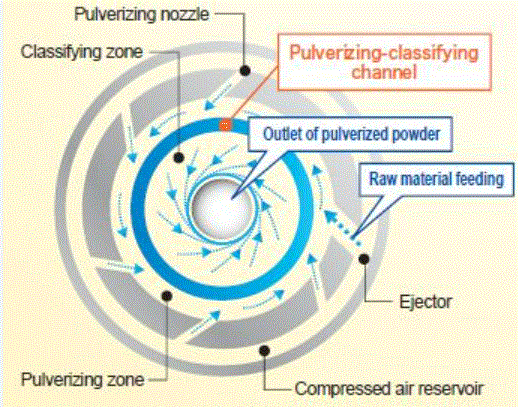

Jet mills, pin mills, and ball mills can all be categorized as ultrafine grinders. These mills are capable of producing very fine particles and powders, and are commonly used in industries such as pharmaceuticals, food processing, and cosmetics, where ultrafine particles are required for various applications. The specific type of mill used as an ultrafine grinder will depend on the material being processed and the desired end product.

Ultrafine grinders use mechanical grinding and air pressure to achieve size reduction. In these machines, the material to be ground is fed into a grinding chamber, where it is subjected to mechanical forces such as impact, compression, and attrition. As the material is ground, it is also exposed to a stream of high-pressure air or gas, which helps to break down the particles and create a fine powder.

The combination of mechanical grinding and air pressure allows ultrafine grinders to achieve a very fine particle size, often in the sub-micron or nanometer range. This makes them particularly useful for applications that require very small particle sizes, such as in the pharmaceutical, cosmetics, and food industries.

The best type of ultrafine grinder to use will depend on the specific application and the material being processed. Some factors to consider when choosing an ultrafine grinder include:

- Particle size requirement: The desired particle size of the final product will help determine the type of ultrafine grinder to use. Different types of grinders are better suited for producing specific particle sizes.

- Material hardness: The hardness of the material being ground will affect the choice of ultrafine grinder. Some materials require more aggressive grinding methods to break them down into fine particles.

- Production volume: The required production volume will also influence the choice of ultrafine grinder. Some types of grinders are better suited for high-volume production than others.

- Maintenance and operating costs: The cost of maintaining and operating the grinder should also be considered when choosing an ultrafine grinder.

Some popular types of ultrafine grinders include jet mills, pin mills, and ball mills. Ultimately, the best choice of ultrafine grinder will depend on the specific needs of the application and the material being processed.

A turbo grinder is a type of angle grinder that is specifically designed for heavy-duty applications, such as grinding and cutting thick metal and concrete. It features a high-powered motor and a specialized blade or wheel that rotates at high speeds to remove material quickly and efficiently.

Turbo grinders are typically larger and heavier than standard angle grinders, and are often used in industrial settings such as construction sites and metalworking shops. They are capable of removing large amounts of material in a short amount of time, making them ideal for projects that require aggressive grinding or cutting.

Some turbo grinders may also come equipped with dust collection systems, which help to control the amount of debris and dust generated during use. This can be especially important when working with concrete or other materials that create a lot of dust when ground or cut.

In pharmacy, a hammer mill is a type of size reduction equipment that is used to reduce the particle size of various types of pharmaceutical ingredients.

Hammer mills are commonly used in the pharmaceutical industry for grinding and milling a wide range of materials, including:

- Active pharmaceutical ingredients (APIs): Hammer mills can be used to grind APIs into fine powders for use in tablet and capsule formulations.

- Excipients: Hammer mills can be used to grind excipients, such as lactose and magnesium stearate, into fine powders for use in tablet and capsule formulations.

- Raw materials: Hammer mills can be used to grind raw materials, such as herbs and spices, into fine powders for use in herbal medicines and supplements.

- Drug delivery systems: Hammer mills can be used to grind materials for drug delivery systems, such as nanoparticles and microparticles.

- Formulation development: Hammer mills can be used in formulation development to grind and blend various materials to achieve a desired particle size and consistency.

Overall, the use of a hammer mill in pharmacy allows for efficient and precise size reduction of a wide range of pharmaceutical ingredients, which is important for ensuring the quality and effectiveness of pharmaceutical products.

A pulverizer is a type of mechanical equipment that is used for grinding, crushing, or pulverizing different materials into smaller particles. Pulverizers are commonly used in a variety of industries, including mining, construction, agriculture, food processing, and pharmaceuticals.

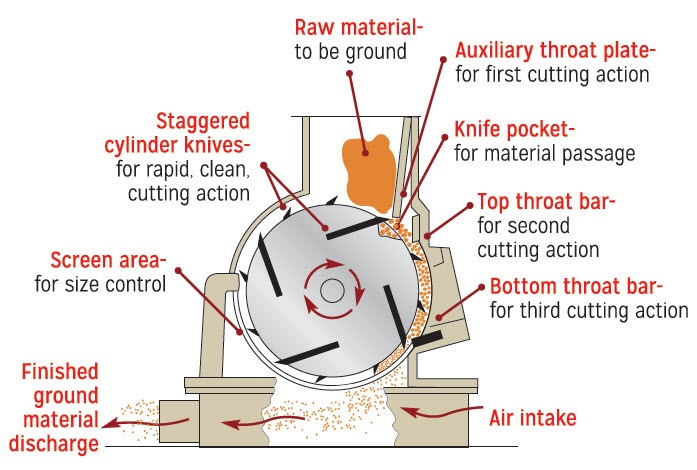

The main purpose of a pulverizer is to reduce the size of materials to a fine powder, which is required for various applications. Pulverizers use a variety of mechanisms to accomplish this, including:

- Impact: The pulverizer uses high-speed rotating hammers or blades to impact and crush the material.

- Shear: The pulverizer uses sharp blades to cut and shear the material.

- Compression: The pulverizer uses rollers or plates to compress and crush the material.

- Attrition: The pulverizer uses friction to break down the material.

Pulverizers can be used for a variety of materials, including coal, rock, clay, limestone, wood, and various types of ores. They are commonly used in the mining industry to crush and grind ore into fine particles for further processing.

In addition to mining, pulverizers are also used in the food industry to grind spices, sugar, and other food products into fine powders. They are also used in the pharmaceutical industry to pulverize tablets, capsules, and other forms of medication for further processing.

1. Please provide to us the product material you are use the machine to grinding for.

2. The capacity you request.

3. Consider the layout of your factory, the height width and length of the machine location.

4. If your product material is not normal type, we can arrange trail to estimate the capacity of output.

5. Our sales will recommend the right mode to you.

Yes, large machine is the major products we are producing. These machine exported to over 30 countries and regions, customer feedback quite good.

Because the medium or small size running speed is faster than larger machine. The noise is decided by the running speed. Also, if there is hole open on the machine, the noise will also larger.

It is totally ok to use. No leakage.

ok, it is no problem, we can add emergency shut off, if the main grinder door open, the machine can not start, and if the machine in running and the main grinder door open, the machine will stop, but the running of the machine can not stop immediately because of the iterance. The rotating of the spindle will stop slowly after the machine shut down because of inertia, so it is still dangerous to open the door in running of machine.

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

Our products includs powder grinding mills, classifiers, coating machines, mixing machines, etc.

Normally 60 to 90 days after receive the deposit payment.

– 50% by T/T deposit payment.

– 50% balance by T/T before shipment.

– For machines, we ship with export wooden box and pallet suitable for long time boat transportation in standard containers or Bulk by sea.

– For spare parts, wooden Case and pallet for delivery by air.

We send engineers to the clients’ project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

Right size is definitely important for grinder business.

If your business is small, you may not have the space to accommodate a large grinder. Read keep in mind, While, that a smaller grinder doesn’t have to mean that it’s not able output as much as a bigger one.

On the contrary, if you have a lot of space, you may require different things from your grinder.

For example, you may want to have dust collector and material feeder for your enviornment production and operation convenience.

-Industrial coffee grinders can grind very large quantities of coffee bean to powder, Coffee shop can buy from factory and sell to customer or buy small coffee grinder to grind the powder by themselves.

Speed is an easy to estimate: We have an estimate capacity for each grinder machine. To more accuracy test, you can have sample to do trail test for each model. This can helps us to get a more accurate capacity volume. We test and calculate how many KG/hour or pounds/hour that we can get for each model, then you can choose how many quantity for each model that you need.

LINKER grinder capacity range from 2.5kg/h to 3000kg/hour for your choose. You can always find the right model no matter you are laboratory want the small machine or a large factory want big machine.

a). The size of your products before grinding and after grinding, by mesh or mm or um.

b). The application for your products. This machine is used for food or chemical or pharmaceutical? The more detail the better.

c). If any special packing methods that you need.

d). Raw material is 304 or 316 that you request.

e). The motor if need any certification or not.

f). If need to customize voltage or not, how much voltage, 380V 440V? or any.

Yes, of course, we have stock for ordinary models. At the same time, we also offer OEM service. Please send us your drawing if you need to do OEM Services.

A coarse crusher is a type of grinding equipment that is used to crush large materials into smaller pieces. Coarse crushers are typically used in industries such as mining, construction, and recycling, where large rocks, debris, or other materials need to be broken down into smaller pieces for further processing or disposal.

Coarse crushers typically use mechanical force to break down materials, such as through the use of a jaw crusher or a cone crusher. These types of crushers rely on a fixed or moving jaw or cone to apply pressure to the material and break it down into smaller pieces.

Coarse crushers are designed to handle large, hard materials that may be difficult to process using other types of grinding equipment. They can be used for a variety of applications, including crushing concrete and asphalt, breaking down rocks and minerals, and reducing the size of construction debris.

Overall, coarse crushers are an important type of grinding equipment used in many industries to process large materials and prepare them for further processing or disposal.

Grinders and crushers are both types of grinding equipment used in various industries, but there are some key differences between the two:

- Purpose: Grinders are typically used to grind and refine materials into a more uniform size and shape, while crushers are used to crush large materials into smaller pieces.

- Types of materials: Grinders are often used to process materials that are dry or have a low moisture content, while crushers are used to process materials that are moist or sticky.

- Method of operation: Grinders typically use a rotating wheel or drum to grind materials, while crushers use pressure to crush materials.

- Size of output: Grinders can produce very fine particles, while crushers typically produce larger pieces of material that may require additional processing.

- Applications: Grinders are commonly used in industries such as agriculture, food processing, and metalworking, while crushers are used in industries such as mining, construction, and recycling.

Overall, the main difference between grinders and crushers is that grinders are used to refine materials into a more uniform size and shape, while crushers are used to crush large materials into smaller pieces. The choice of equipment used will depend on the specific needs of the application and the type of materials being processed.

Whether an industrial grinder is worth it depends on several factors, such as the specific needs and requirements of your industry or application, the frequency of use, and the cost-benefit analysis of investing in the machine.

Here are some potential benefits of using an industrial grinder:

Increased efficiency: Industrial grinders can help increase efficiency in various industries by reducing the time and effort required to grind, crush, or polish materials.

Improved accuracy: Industrial grinders can be designed to achieve a high degree of precision in grinding and polishing, which can be useful in industries such as manufacturing.

Cost-effective: In industries that require frequent grinding or crushing of materials, an industrial grinder can be a cost-effective investment over time, as it can reduce the need for manual labor and the associated costs.

Durability: Industrial grinders are designed to withstand heavy use and are typically more durable than consumer-grade grinders.

However, it’s important to note that industrial grinders can be expensive, and the initial investment cost may not be worth it for smaller businesses or applications that don’t require frequent use of the machine. It’s essential to do a cost-benefit analysis and consider factors such as maintenance costs, the lifespan of the machine, and the potential return on investment before investing in an industrial grinder.

An industrial grinder can be used to grind a wide variety of materials, depending on the specific type of grinder and the intended application. Here are some examples of materials that can be ground using an industrial grinder:

Metals: Industrial grinders are commonly used to grind metals such as steel, aluminum, and copper. This can be useful in industries such as metalworking and manufacturing.

Plastics: Industrial grinders can be used to grind plastic materials such as PVC, PET, and HDPE. This is commonly done in the recycling industry to reduce the size of plastic waste for further processing.

Wood: Industrial grinders can be used to grind wood materials such as lumber, logs, and pallets. This can be useful in industries such as woodworking and forestry.

Food: Industrial grinders can be used to grind food products such as grains, spices, and coffee beans. This is commonly done in the food processing industry to reduce the size of ingredients for further processing.

Minerals: Industrial grinders are also used in the mining industry to grind minerals such as coal, limestone, and quartz.

Overall, an industrial grinder can be used to grind a wide variety of materials, and the specific type of grinder used will depend on the material being processed and the intended application.

There are three primary types of crushers commonly used in various industries:

Jaw Crushers: Jaw crushers are commonly used in mining, construction, and recycling industries. They work by compressing the material between two plates, known as the “jaw plates.” The material is crushed as it moves down the chamber and exits through the bottom opening.

Cone Crushers: Cone crushers are commonly used in mining and aggregate industries. They work by crushing the material between a stationary mantle and a moving cone-shaped crushing surface. As the material is crushed, it falls down the chamber and exits through the bottom opening.

Impact Crushers: Impact crushers are commonly used in the construction and mining industries. They work by using high-speed impact to break down the material. The material is fed into a chamber where a rotating rotor with bars or hammers strikes the material, breaking it into smaller pieces.

Each type of crusher has its own unique advantages and disadvantages, and the specific type of crusher used will depend on the industry and application requirements.

An ultrafine grinder is a machine used to grind and crush solid materials, typically materials that are not easily processed by other grinding machines. This type of grinder can produce very fine powders from materials with a hardness of up to 10 on the Mohs scale, which is a measure of a material’s hardness.

Ultrafine grinders typically operate using a combination of mechanical grinding and air pressure, which helps to break down the materials and create a fine powder. They are commonly used in industries such as pharmaceuticals, cosmetics, and food processing, where very fine powders are required for various applications.

Ultrafine grinders can be designed in a variety of configurations, including jet mills, pin mills, and ball mills. Each type of ultrafine grinder has its own advantages and disadvantages, and the specific type used will depend on the material being processed and the desired end product.

Contact Us

Please feel free to contact with us for more information. Such as catalogue, price list and so on.

Working time: Mon~Fri 8:00~17:00

Mobile/WhatsApp: +86 18019763531

Email: sales@lkmixer.com

Related Products:

GHJ V Blender High Efficient

CH-VI Tumble Blender V Ribbon

Recommend Reading

Licorice root powder benefits

Licorice Flavored Spice Types

Difference between primary and secondary crusher

What is the purpose of fine grinding?

The principle of ultra-fine grinding technology and the purpose and significance of Chinese medicine processing

What is the difference between wet grinding and dry grinding?

What is ultrafine grinding?

What is Dry Sift?

How to disassemble flour sifter?

How to sift flour without a sifter?

How to clean flour sifter?

What Does a Granulator Do?

What are the advantages and disadvantages of dry granulation?

What is the difference between granulation and powder?

What are the stages of granulation?

What are the different types of granulation?

What is the advantage of granular?

What’s the meaning of Granulation?

How to Use Blender?

What is a ribbon blender used for?

What Is Blender?

Ribbon Blender vs Paddle Blender

Show Case

Different Types of Blenders

Ribbon Blender Advantages and Disadvantages

How does a pulverizer work?

What is a Ribbon Blender?

Commercial Grinder Price List

How to Grind Coffee Beans without a Grinder?

How does grinder work?

The advantages and disadvantages of Mixers?

What does the Pulverizer Mill Do?

What is a Granulator

My Grinder is Stuck

Grinder Not Working

How to use a grinder?

How to Clean a Grinder?

Pulverizer Grinder Safety

Grinder Videos Collection

How to Speed Up a Pulverizer

Table of Contents

Toggle