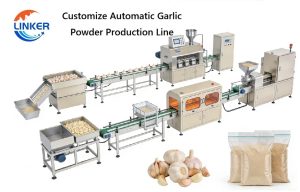

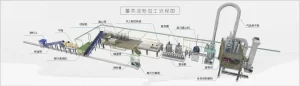

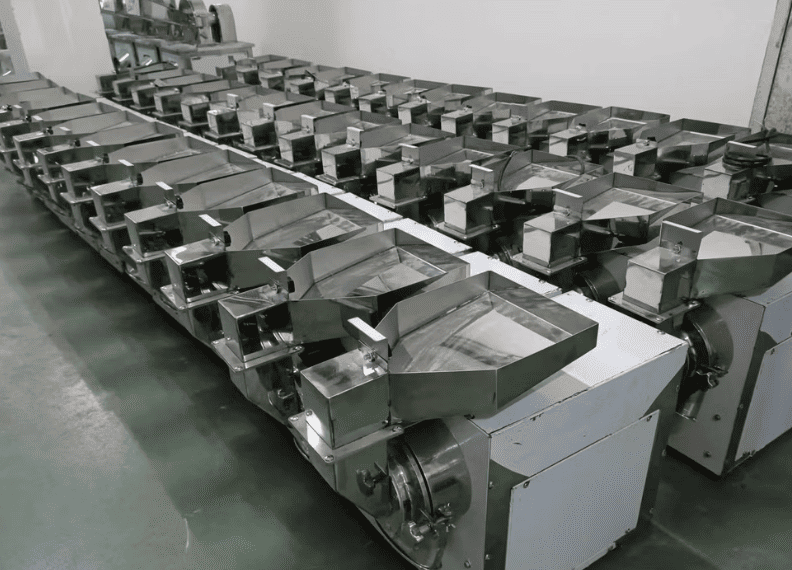

LK can customize fully automatic or semi automatic production line.

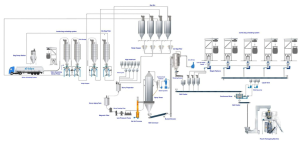

Custom Automatic Food Production Line is designed to meet diverse processing needs, supporting sauce, powder, paste, and other food products. Built with food-grade stainless steel, it ensures safety, hygiene, and long service life. It integrates washing, grinding, mixing, cooking, filling, and packaging in one fully automatic system. With customizable layout, capacity, and functions, it improves efficiency, reduces labor, and ensures stable product quality. Ideal for factories seeking flexible, reliable, and high-performance food processing solutions.

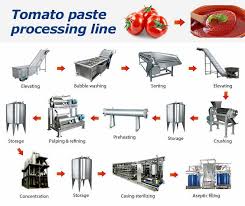

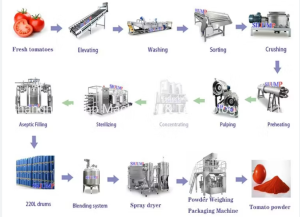

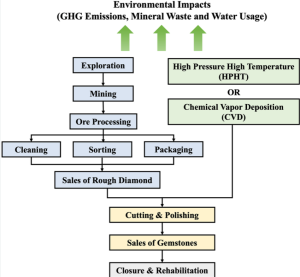

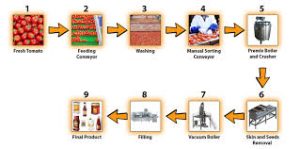

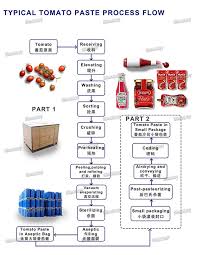

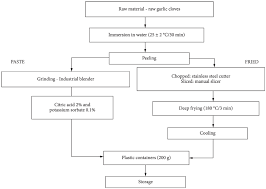

Tomato Sauce Paste Process Flow Tomato Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

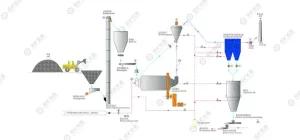

Vegetable Powder Process Flow Vegetable Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

baby Powder Process Flow purple sweet potato Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

purple sweet potato Powder Process Flow purple sweet potato Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine…

Baobab Powder Process Flow Baobab Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

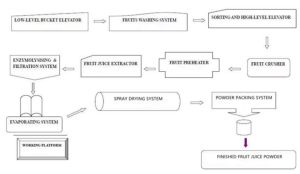

Fruit Powder Process Flow Fruit Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

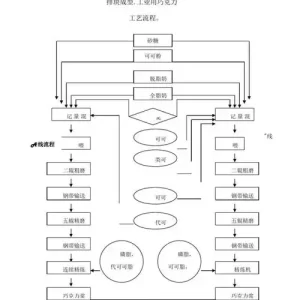

Coca Powder Process Flow Coca Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Chilli Powder Process Flow Chilli Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Potato Chip Process Flow Potato Chip Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

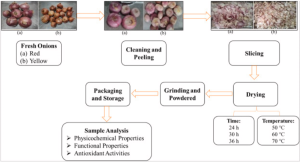

Red Onion Powder Process Flow Red Onion Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Milk Powder Process Flow Milk Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

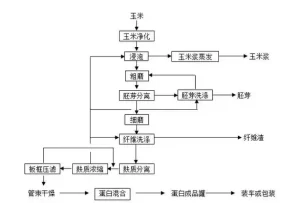

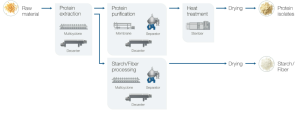

Protein Powder Process Flow Protein Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Egg Shell Powder Process Flow Egg Shell Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Tomato Powder Process Flow Tomato Powder Automatic Productino Line Design: While not requiring the extreme precision of an Ultrafine Grinder used…

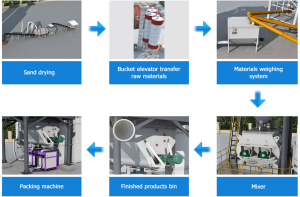

Putty Powder Process Flow Putty Powder Automatic Productino Line Design: For the continuous, large-scale production of premium dry-mix building…

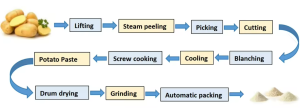

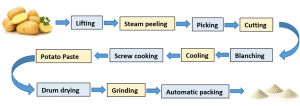

Potato Powder Process Flow Potato Powder Automatic Productino Line Design: An Automatic Potato Powder Production Line is a fully…

Green Onion Powder Process Flow Green Onion Powder Automatic Productino Line Design: Through a smooth, automated process of cleaning,…

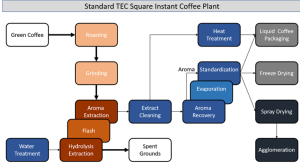

Coffee Powder Process Flow Coffee Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Ginger Powder Process Flow Ginger Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

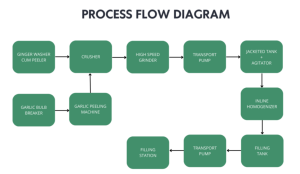

Garlic Powder Process Flow Garlic Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Potato Flakes Process Flow Potato Flakes Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Banana Powder Process Flow Banana Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Yellow Onion Process Flow Yellow Onion Automatic Productino Line Design:x` Food Producing Process Flow: Ultrafine grinding is one of…

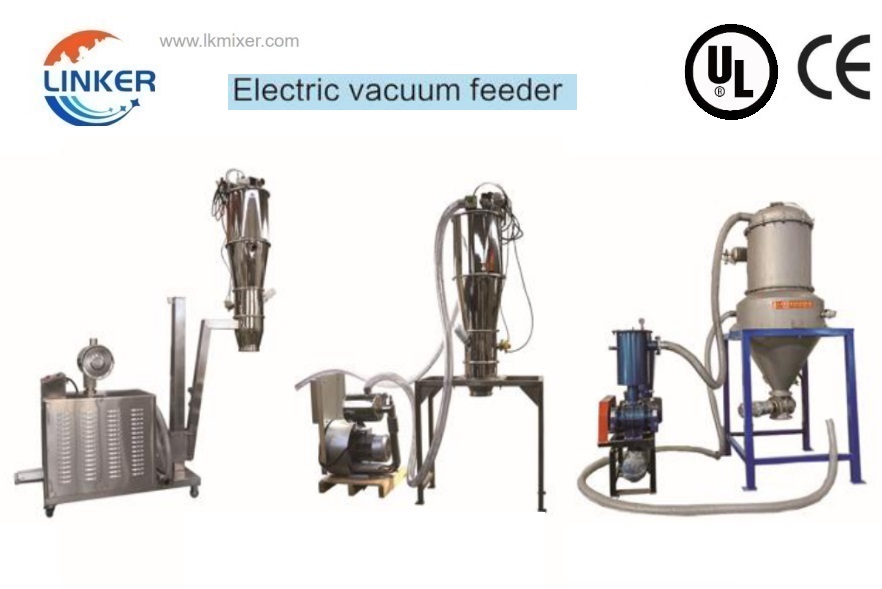

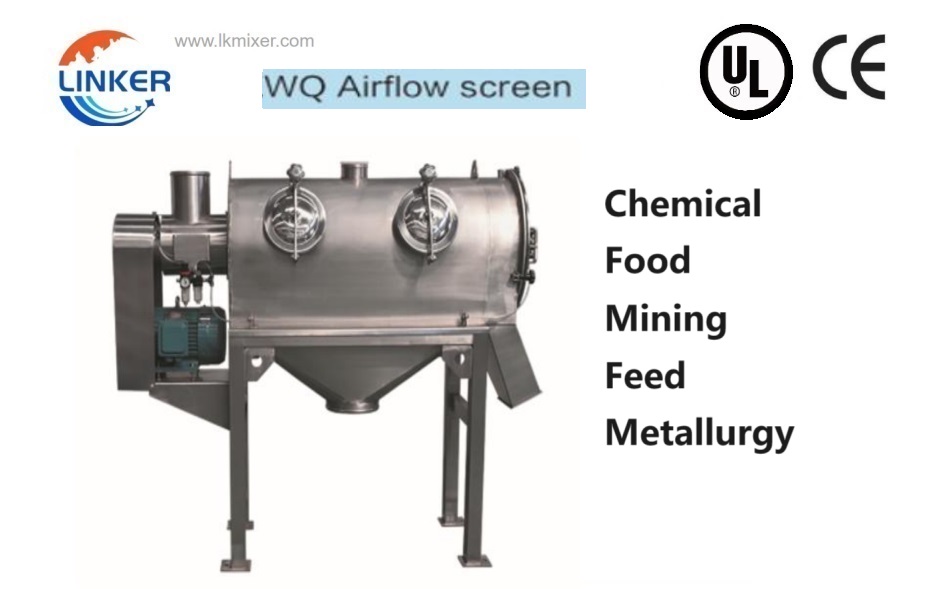

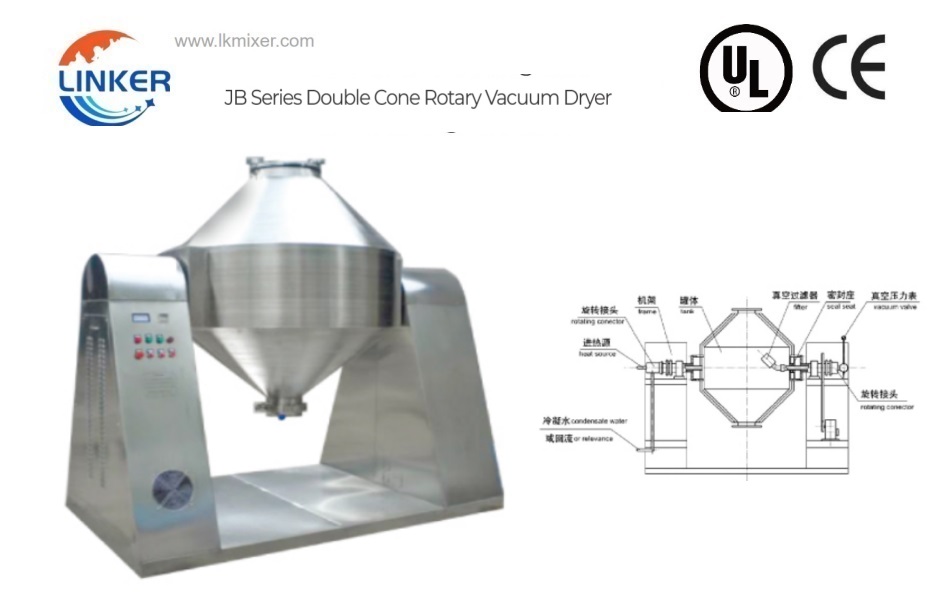

Customize Automatic Powder Production Line is designed for flexible, high‑efficiency dry material processing. It integrates crushing, grinding, mixing, sieving, conveying, metering, and packaging, fully customizable to capacity, particle size, and material properties. Made of food‑grade stainless steel, it meets hygiene standards and ensures stable, uniform powder quality. With intelligent control, it reduces labor and improves consistency, widely used for spices, herbal powder, flour, and food additives.

Vegetable Powder Process Flow Vegetable Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

baby Powder Process Flow purple sweet potato Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

purple sweet potato Powder Process Flow purple sweet potato Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine…

Baobab Powder Process Flow Baobab Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

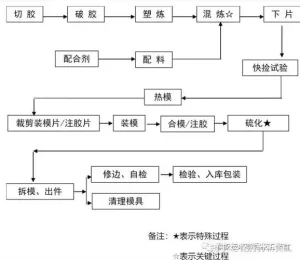

Epdm Rubber Powder Process Flow Epdm Rubber Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Moringa Leaf Powder Process Flow Moringa Leaf Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

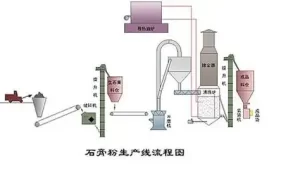

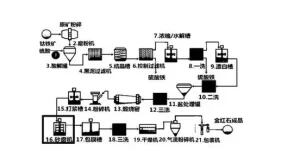

Gypsum Powder Process Flow Washing Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

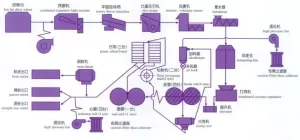

Washing Powder Process Flow Washing Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Fruit Powder Process Flow Fruit Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Aluminum Powder Process Flow Aluminum Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Coca Powder Process Flow Coca Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Chilli Powder Process Flow Chilli Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Hair Line Powder Process Flow Hair Line Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Red Onion Powder Process Flow Red Onion Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

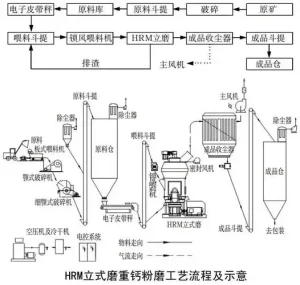

Calcium Carbonate Process Flow Calcium Carbonate Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Elf Powder Process Flow Elf Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Zenith Industrial Powder Process Flow Zenith Industrial Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Butyl Rubber Powder Process Flow Butyl Rubber Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Quartz Powder Process Flow Quartz Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Milk Powder Process Flow Milk Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Protein Powder Process Flow Protein Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Egg Shell Powder Process Flow Egg Shell Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Tomato Powder Process Flow Tomato Powder Automatic Productino Line Design: While not requiring the extreme precision of an Ultrafine Grinder used…

Putty Powder Process Flow Putty Powder Automatic Productino Line Design: For the continuous, large-scale production of premium dry-mix building…

Talc Powder Process Flow Talc Powder Automatic Productino Line Design: An Automatic Talc Powder Production Line is a fully…

Potato Powder Process Flow Potato Powder Automatic Productino Line Design: An Automatic Potato Powder Production Line is a fully…

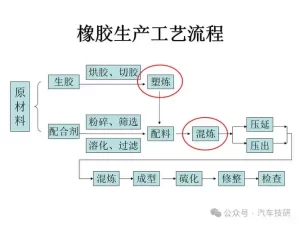

Rubber Powder Process Flow Rubber Powder Automatic Productino Line Design: Waste tires can be continuously converted into fine rubber…

Green Onion Powder Process Flow Green Onion Powder Automatic Productino Line Design: Through a smooth, automated process of cleaning,…

Ceramic Powder Process Flow Ceramic Powder Automatic Productino Line Design: An Automatic Ceramic Powder Production Line is a cutting-edge,…

Chalk Powder Process Flow Chalk Powder Automatic Productino Line Design: In order to achieve high output, consistent quality, and…

Crumb Rubber Powder Process Flow Crumb Rubber Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Protein Powder Process Flow Protein Powder Automatic Productino Line Design:x` Food Producing Process Flow: Ultrafine grinding is one of…

Turmeric Powder Process Flow Turmeric Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Diamond Powder Process Flow Diamond Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Laundry Powder Process Flow Laundry Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

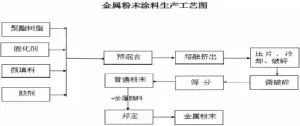

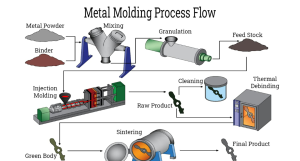

Metal Powder Process Flow Metal Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Coffee Powder Process Flow Coffee Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Ginger Powder Process Flow Ginger Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Garlic Powder Process Flow Garlic Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Banana Powder Process Flow Banana Powder Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Yellow Onion Process Flow Yellow Onion Automatic Productino Line Design:x` Food Producing Process Flow: Ultrafine grinding is one of…

Custom Automatic Sauce Paste Production Line is fully customized for different sauces, pastes, and condiments. It integrates material washing, crushing, cooking, mixing, homogenizing, pasteurizing, filling, capping, and labeling. Made of food‑grade stainless steel, it ensures high hygiene and stable product quality. With intelligent control, high automation, and flexible capacity design, it greatly improves efficiency and reduces labor costs. Suitable for chili sauce, tomato paste, bean paste, garlic sauce, and other viscous food products.

Pouch Sauce Paste Process Flow Pouch Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

secret Sauce Paste Process Flow secret Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Sriracha Sauce Paste Process Flow Sriracha Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Chili Sauce Paste Process Flow Red Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Red Sauce Paste Process Flow Red Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

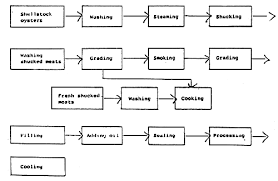

Oyster Sauce Paste Process Flow Oyster Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Cranberry Sauce Paste Process Flow Cranberry Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

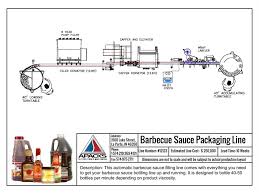

BBQ Sauce Paste Process Flow BBQ Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

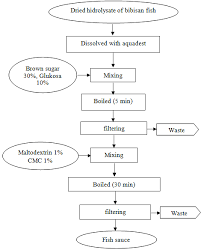

Fish Sauce Paste Process Flow Fish Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Garlic Sauce Paste Process Flow Garlic Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

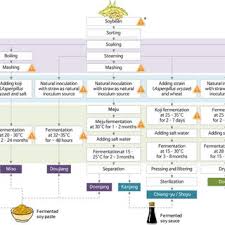

Soya Sauce Paste Process Flow Soya Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Soy Sauce Paste Process Flow Soy Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Hot Sauce Paste Process Flow Hot Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Sauce Paste Process Flow Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is one of…

Tomato Sauce Paste Process Flow Tomato Sauce Paste Automatic Productino Line Design: Food Producing Process Flow: Ultrafine grinding is…

Custom Automatic Liquid Production Line provides a fully integrated solution for processing and packaging various liquid products. It includes automatic filling, capping, labeling, stirring, filtering, and pasteurization. Made of food‑grade stainless steel, it ensures hygiene, stability, and easy cleaning. The line supports customizable flow, capacity, and control systems, with PLC touch screen operation. It is widely used for beverages, oils, sauces, dairy, and other liquid food products, improving efficiency and ensuring consistent product quality.

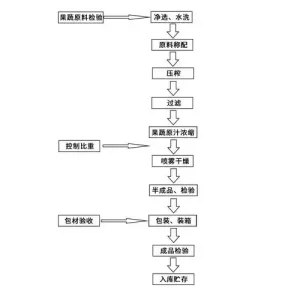

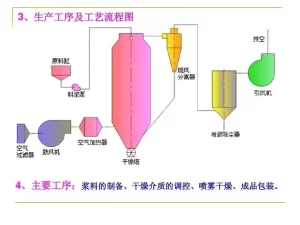

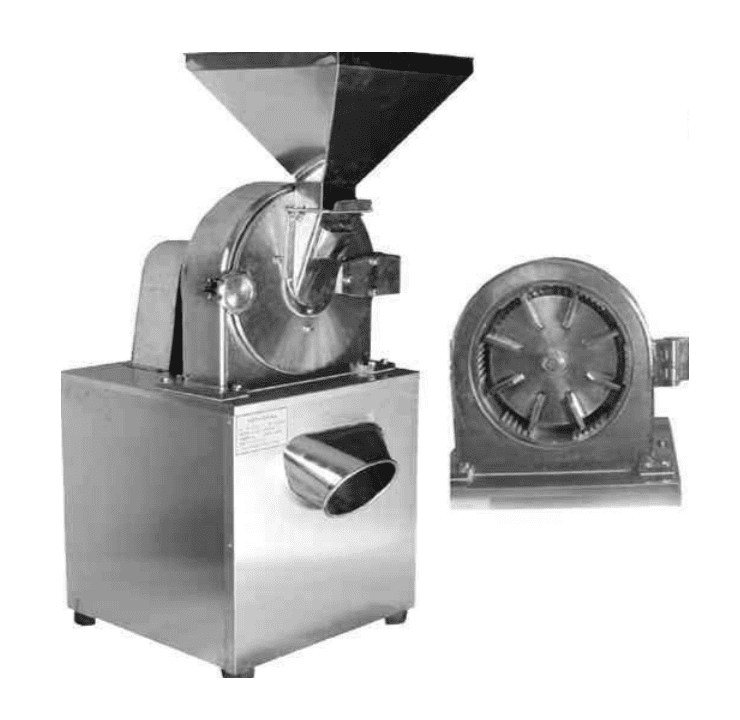

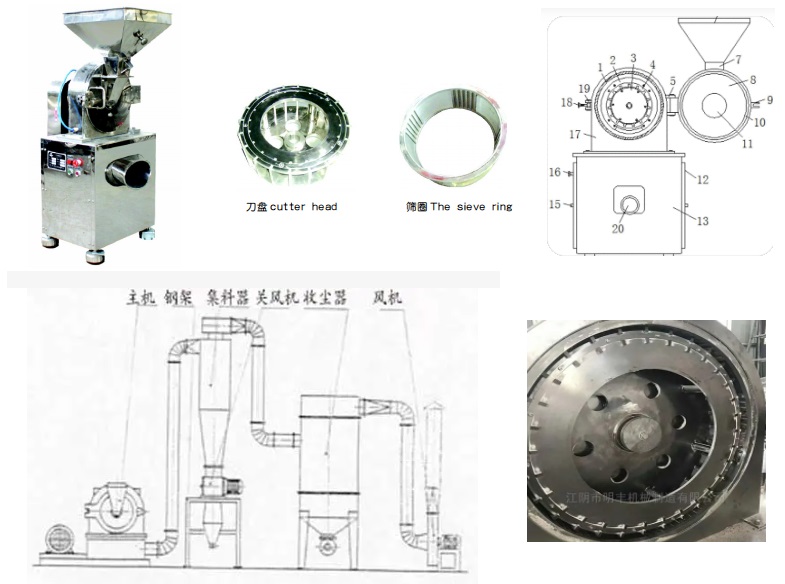

Ultrafine grinding is one of the very key procedure in whole production line . It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

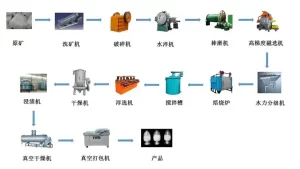

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling , sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Contact Whatsapp: +86 13641968560

industrial-food-processor-products

VIDEO

Seeds Grinder According to your Capacity:We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Seeds Grinder Many model of Seeds Grinder seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example: