Automatic Putty Powder Production Line

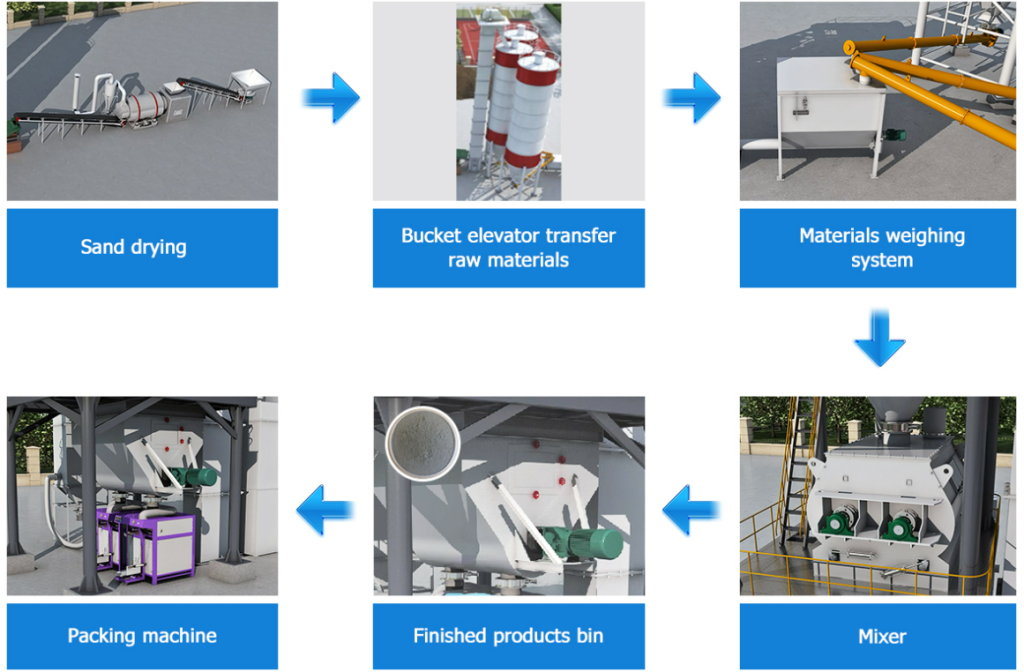

Putty Powder Automatic Productino Line Design:

For the continuous, large-scale production of premium dry-mix building materials like putty, an Automatic Putty Powder Production Line is an integrated, computer-controlled industrial system that smoothly completes the entire process of raw material handling, accurate batching, high-intensity mixing, automated packaging, and palletizing.

Storage of Raw Materials and Initial Processing

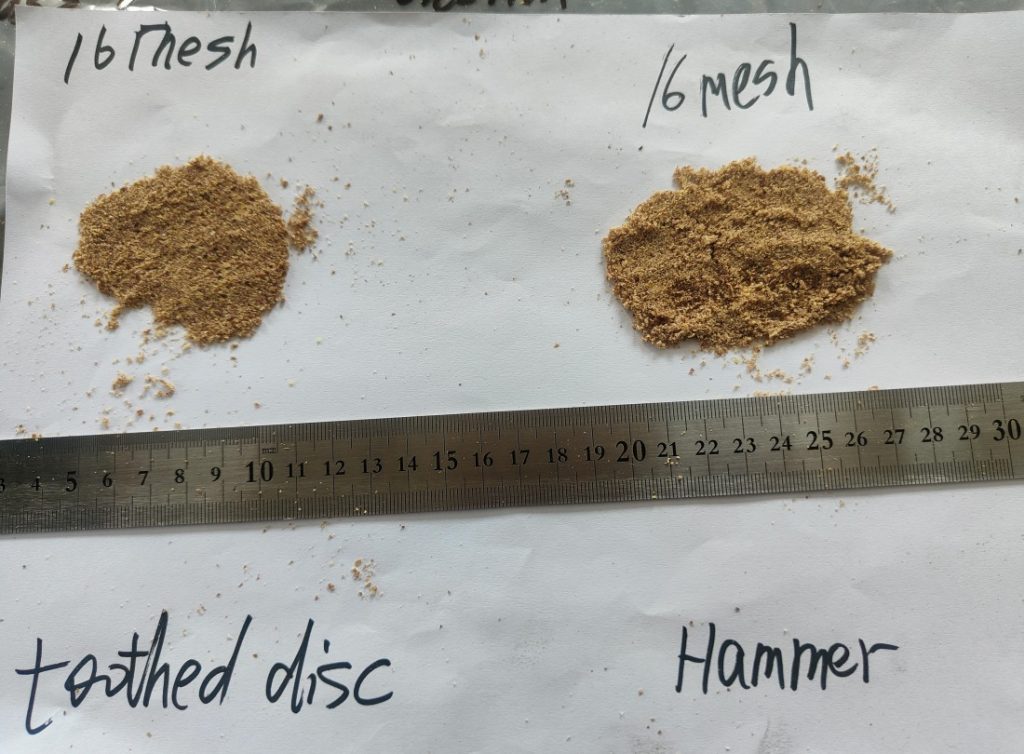

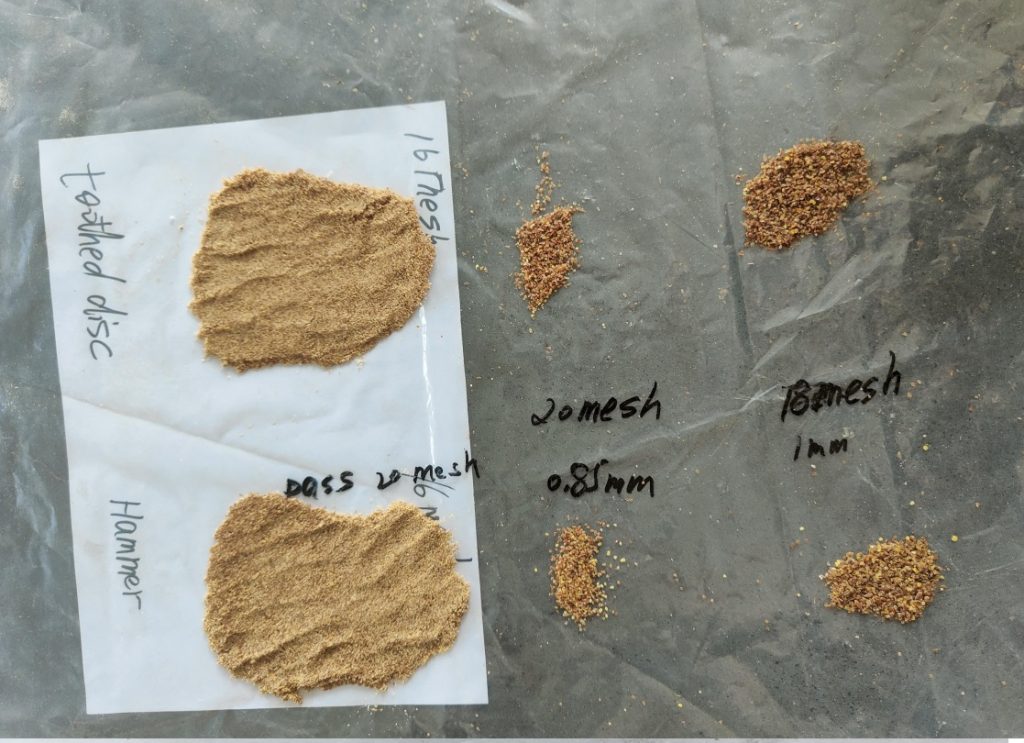

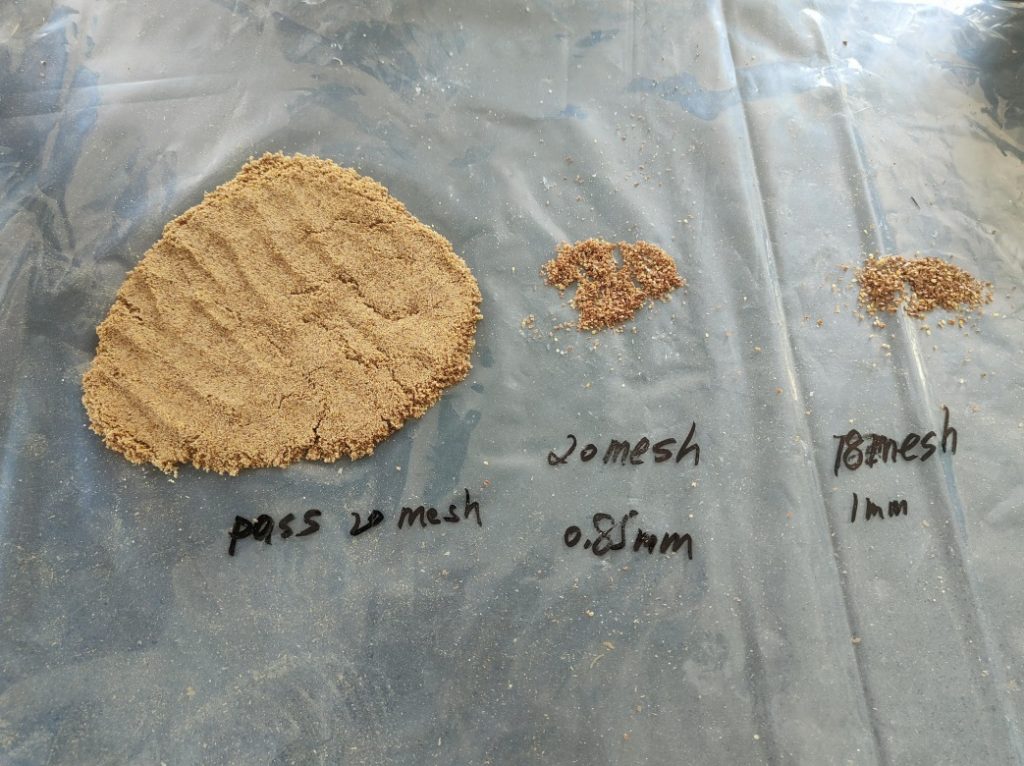

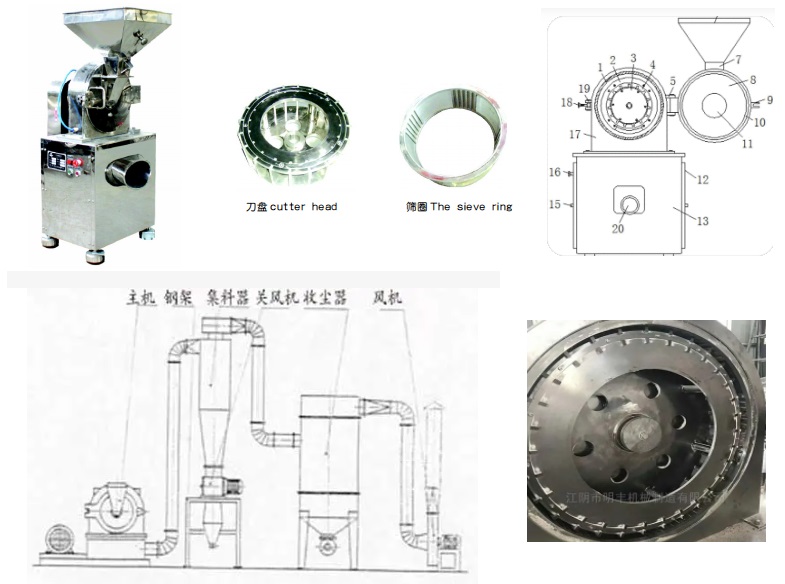

The methodical intake and storage of raw materials marks the start of the production process. Important components like hydrated lime, heavy calcium carbonate powder, white cement, and different chemical additives are kept apart in big, sealed storage bins or silos.Level sensors installed in these silos offer constant inventory data, guaranteeing a steady supply. The storage system serves as the production line’s main source of bulk charging. Before being stored, some pre-processing may be necessary for some mineral-based raw materials, such as talc or limestone. A coarse crusher, which resembles machinery used in mining or the processing of materials like bone or cassava, may be used to initially reduce the size of large pieces. It may then be necessary to grind the material to a certain fineness. A grinding device like a Hammer Mill or a Dry Grinder could be used to obtain the required particle size distribution, guaranteeing uniformity in the final product, without needing the extreme precision of an Ultrafine Grinder used for chemicals or medicine.Similar to obtaining uniform flour from wheat, a grinding machine like a Hammer Mill or a Dry Grinder could be used to achieve the desired particle size distribution, ensuring consistency in the final mix, without requiring the extreme precision of an Ultrafine Grinder used for chemicals or medicine.

Precision Batching and Automated Weighing

Every raw ingredient is carefully measured from the storage silos using a computer-stored recipe. The consistency and quality of the final output depend on this step. Each component is dispensed using sophisticated weighing systems that use load cells, controlled screw feeders, or pneumatic valves. These systems may handle enormous quantities of fillers like calcium carbonate (similar to handling bulk salt or sugar) or small, crucial amounts of organic polymers like cellulose ether.To expedite the batching cycle, multiple scales frequently operate concurrently. With errors usually kept at 0.1%, the accuracy is outstanding. This accuracy is just as important in the chemical sector as it is in the food production process for mixing spices or creating nutritional powders. Before being transferred to the mixer, the battered ingredients are gathered in a makeshift holding bin, often known as a premix or weigh hopper. By ensuring a smooth and rapid transition between batching cycles, this step maximizes line efficiency.

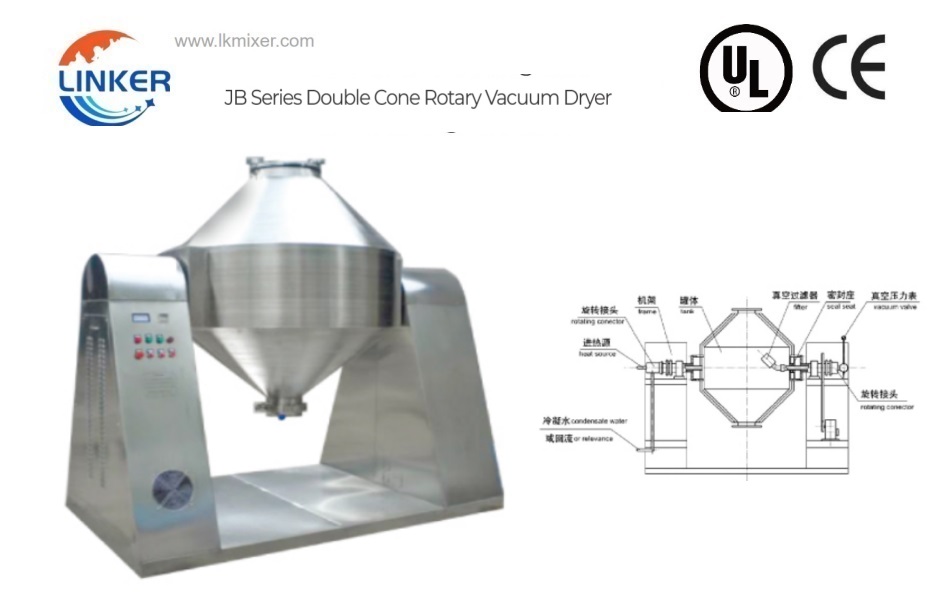

Mixing and homogenization at high intensities

The industrial mixer, which is the center of the production line, receives the pre-batched dry ingredients.Horizontal ribbon mixers or twin-shaft paddle mixers are common for high-volume, high-uniformity applications such as putty powder. These are big, strong machines that are usually lined with stainless steel plates that are resistant to wear. The powder moves vigorously and three-dimensionally as a result of the mixer’s activity, whether it is through revolving ribbons or intermeshing paddles. This guarantees that each additive, polymer, or pigment particle is evenly dispersed throughout the bulk filler material. High-speed chopper blades (commonly referred to as “fly knives”) are incorporated into the mixer to break up any potential agglomerates, particularly with fibrous additions. They ensure a flawlessly smooth, lump-free mixture by acting as an internal, high-intensity grinding machine or cutter.The procedure in a universal grinder or blender used for tea, coffee, or spice mixes is essentially the same as the mixing technology used to create a homogenous dry blend, but it is carried out on a large industrial scale. To guarantee consistent results with each batch, the central computer carefully regulates the mixing duration and speed.

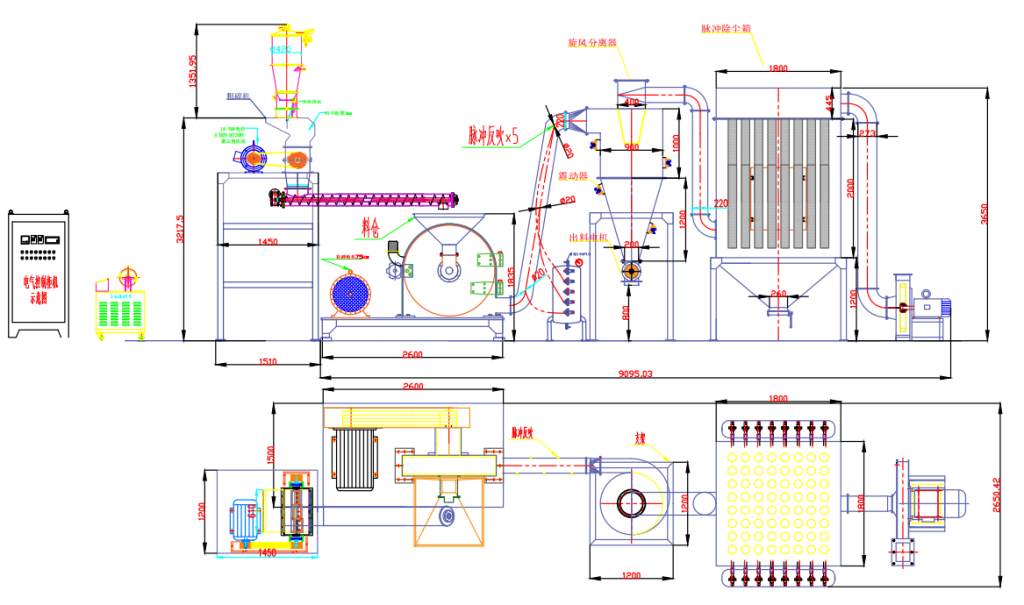

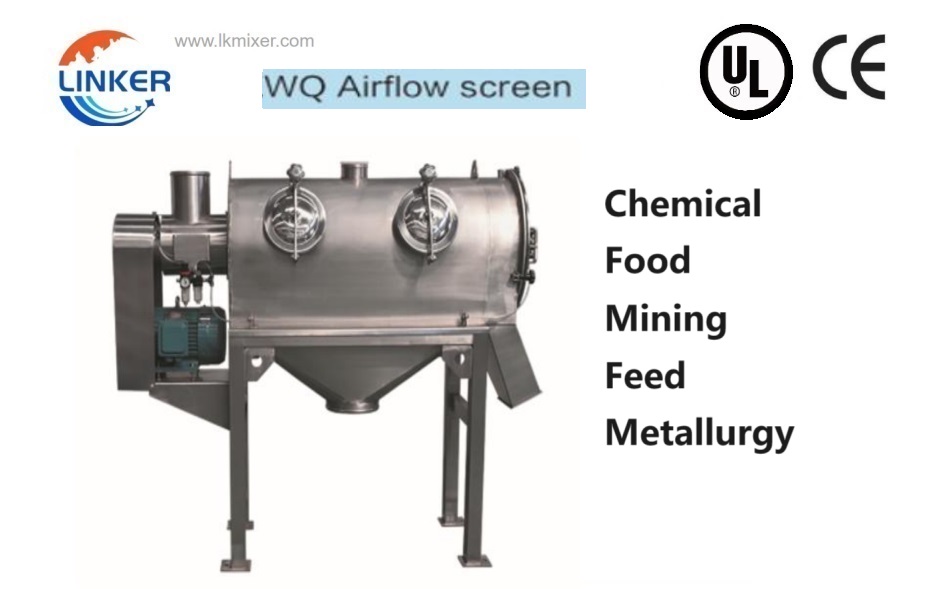

Complete Material Handling and Dust Control

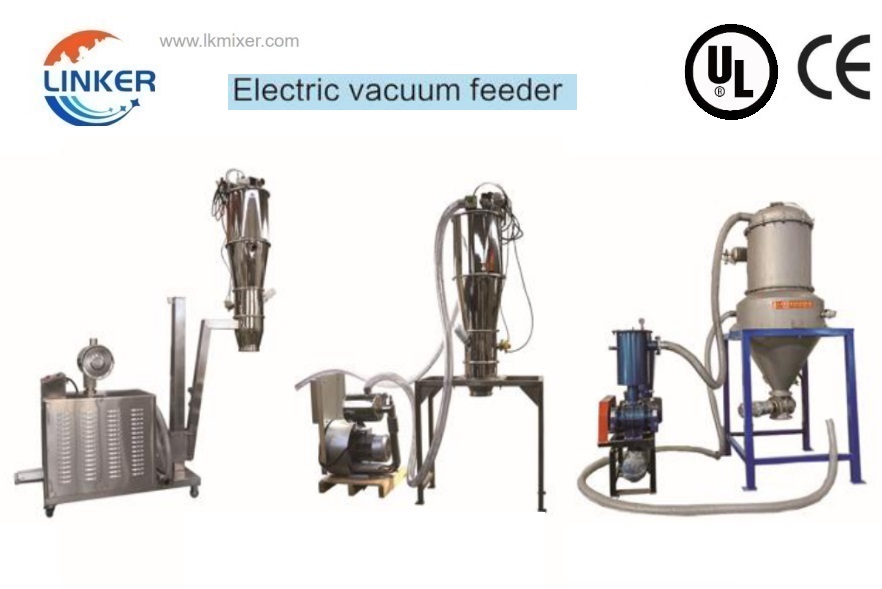

Because all of the materials involved are fine and powdery, dust management is essential for product output, safety, and environmental compliance. Every effort is made to design the entire production line as a closed system.A centralized dust collector grinder or industrial vacuum mill system is connected to each transfer point, including silo discharge, weighing, the mixer, and packaging. By capturing airborne particles, this network preserves a clean plant environment, safeguards the health of employees, and—above all—reclaims valuable raw materials that would otherwise be lost. This system is just as important as those found in chemical facilities that handle fine powders or in food powder factories that process rice flour or milk powder.

Palletizing, Automated Packaging, and System Intelligence

A buffer hopper that feeds the automated packaging machinery receives the properly blended putty powder. Valve bags (e.g., 25 kg) are the most widely used packaging. A high-speed, precisely regulated auger filling method is used by an automatic valve bag packer, which operates with the accuracyValve bags (e.g., 25 kg) are the most widely used packaging. To fill each bag to the correct target weight, an automatic valve bag packer uses a high speed, carefully regulated auger filling mechanism that works with the precision of a metered dispensing from an electric grinder. After being filled, the bags are sealed, occasionally given a date code, and transported. The bags are automatically sent to a robotic palletizer for large-scale operations. In accordance with a preprogrammed pattern, this robot selects and arranges the bags onto a pallet to create a sturdy, interlocking load. In order to secure the palletized cargo for storage and transportation, an automatic wrapper frequently wraps it in stretch film.A central Distributed Control System (DCS) or an advanced PLC controls the entire line, from the first charger system to the last pallet. The intelligent command center is this system. It keeps track of all recipes, manages the exact order and timing of each operation, keeps an eye out for equipment malfunctions, gathers production data, and optimizes settings for efficiency. It guarantees that, batch after batch, the line generates a reliable, superior product. The machinery is constructed in accordance with industrial standards, and essential parts are frequently certified (such as a CE Certificate grinder for pertinent machinery), guaranteeing dependability and safety. The Automatic Putty Powder Production Line is the epitome of clean, intelligent, and efficient manufacturing in the building materials sector, handling everything from raw minerals to delivering a pallet of completed goods.

Food Producing Process Flow:

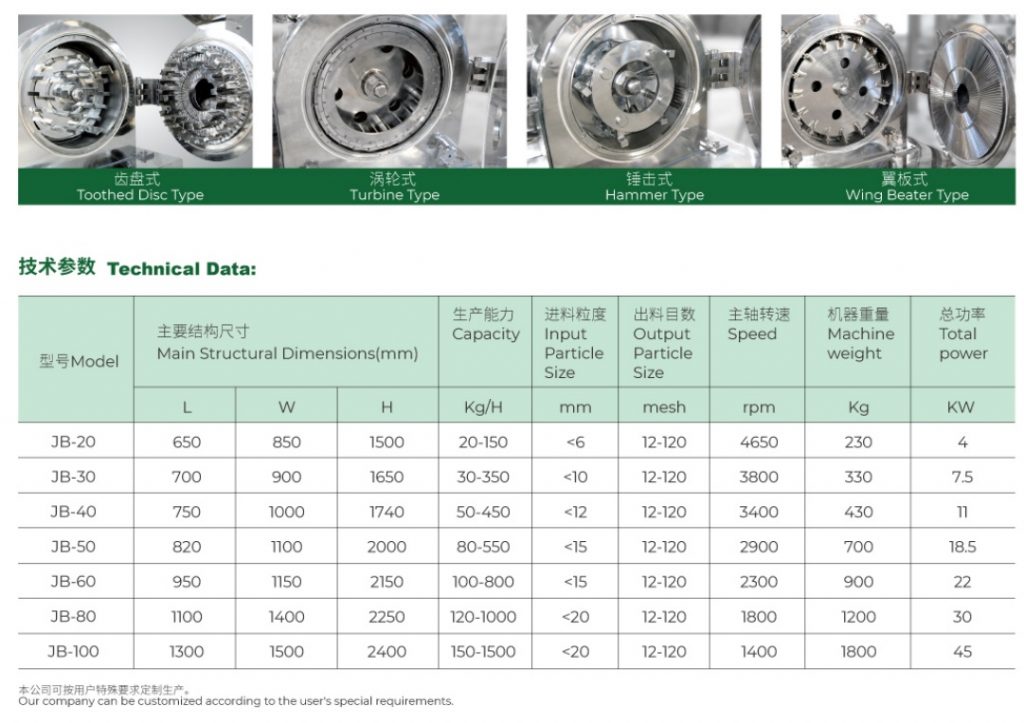

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Automatic Banana Powder Production Line Youtube Video

Customization Seeds Grinder According to your Capacity:

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?