Automatic Talc Powder Production Line

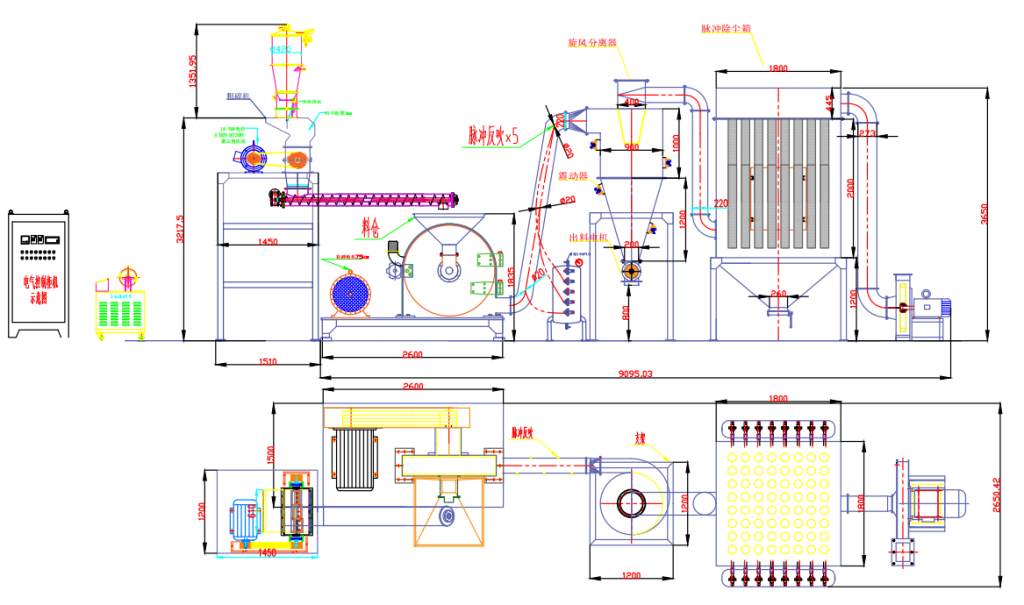

Talc Powder Automatic Productino Line Design:

An Automatic Talc Powder Production Line is a fully integrated industrial system that uses a smooth, automated process to effectively turn raw talc mineral into fine or ultra-fine powder. Four essential modules make up its core operation, which guarantees high productivity, constant quality, and little environmental impact: raw material processing, grinding and sorting, completed product collection, and intelligent control.

Crushing and pre-processing of raw materials

The processing of raw talc ore is the first step in the trip. A primary crusher receives large blocks of talc material as input.For this initial size reduction, the ore is usually broken down into particles no larger than 30 mm (occasionally 25 mm, depending on the process requirements) using a sturdy jaw crusher or a heavy-duty coarse crusher. Unlike a small herb grinder or a normal hammer mill used for cereals like corn or wheat, this main crushing stage is essential and functions on a much bigger scale. To remove any naturally fine particles, the material is frequently sent through a pre-screening apparatus, such as a vibrating pulverizer, after the initial crush. This saves energy by preventing already-suitable material from needless additional crushing—a concept that is also valued in food processing, such as screening rice or flour. The raw ore’s moisture content is a crucial component.The technology can automatically turn on built-in hot air dryers to lower moisture during handling if it beyond a certain threshold, such as 10%. A bucket elevator then raises the processed material, which is then kept in a buffer silo. From this point on, a controlled feeding device—typically an automated charger or an electromagnetic vibratory feeder—ensures a consistent and steady flow of material into the subsequent stage, simulating the precise feeding needed in operations like batching systems in chemical plants or cassava grinding machines.

System of Core Grinding and Classification

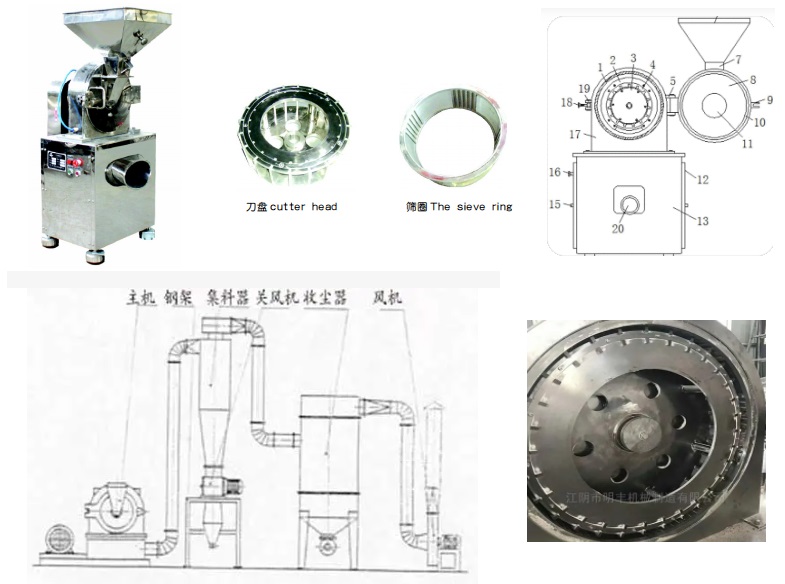

The talc is turned into the appropriate fineness of powder here, at the center of the production line.The target particle size is the only factor that influences the grinding machine selection, which is crucial. A Raymond mill, a kind of pendulum roller mill, is a popular and dependable option for generating conventional talc powder in the range of 80 to 600 mesh. In order to crush the material, this mill uses centrifugal force to press grinding rollers against a stationary ring. With capacities ranging from 1 to 40 tons per hour, it has significant capabilities. More sophisticated milling equipment is needed to produce ultra-fine talc powder (from 1000 mesh to an amazing 5000 mesh, where 97% of particles are 5 micrometers or smaller). Specialized ultrafine grinders, ring roller mills, or vertical roller mills are used for this.These are frequently energy-intensive, high-speed devices that combine classification and grinding into one unit. Technologies like turbo grinders or airflow pulverizers (jet mills) are used for the very best grades. These achieve remarkable fineness without producing a lot of heat or contaminating the grinding media by accelerating the particles with steam or compressed air, which causes them to collide and fracture. The pursuit of regulated, cool grinding to retain material qualities is a common goal in high-end powder processing, while a cryogenic grinding equipment is usually reserved for heat-sensitive materials like certain spices, medicine botanicals, or polymers.

The intelligent categorization system is immediately linked with the grinding process. Classifiers, such as dynamic air separators or turbine classifiers, are essential whether they are part of the mill or used independently. They use a combination of airflow and centrifugal force to continually separate the ground powder according to particle size. Too-coarse particles are automatically rejected and sent back to the grinding machine for additional processing. This results in a very effective closed-loop system that guarantees a narrow particle size distribution and maximizes yield. High-efficiency cyclone collectors are usually used to extract the “accepts”—the fine powder that satisfies requirements—from the air stream.In order to maintain a clean, safe, and effective working environment and to capture valuable product that might otherwise be wasted, the entire grinding and classifying section runs under negative pressure and is connected to a central dust collector grinder system (similar to a pulse-jet baghouse).

Completed Product Gathering and Packaging

The final talc powder needs to be handled carefully after classification to preserve its purity and avoid contamination. Systems for enclosed conveyance are used everywhere. Common options include dense-phase pneumatic conveying systems and tubular drag chain conveyors. They move the powder to big, specialized storage silos from the gathering locations.Large stainless steel is usually used to build these silos in order to maintain cleanliness and prevent corrosion, following regulations akin to those in the chemical, pharmaceutical, and food sectors (e.g., for sugar, salt). Completely automated packing is the last stage. Precision weighing and bagging equipment receive the powder delivered from the silo. These systems offer exceptional accuracy with weight inaccuracies typically limited within ±0.2% thanks to servo-controlled auger fillers or comparable devices. The packing line is highly automated: robotic palletizers automatically palletize the bags into stable, programmable stacks after robotic arms pick and place empty bags, fill them, and seal them using stitching, heat sealing, or other techniques.Options like vacuum packing can be incorporated for high-end products or to stop caking during long-term storage. Modern packaging lines for consumer items like coffee, tea, bean products, or pet food are equivalent to this degree of end-to-end automation.

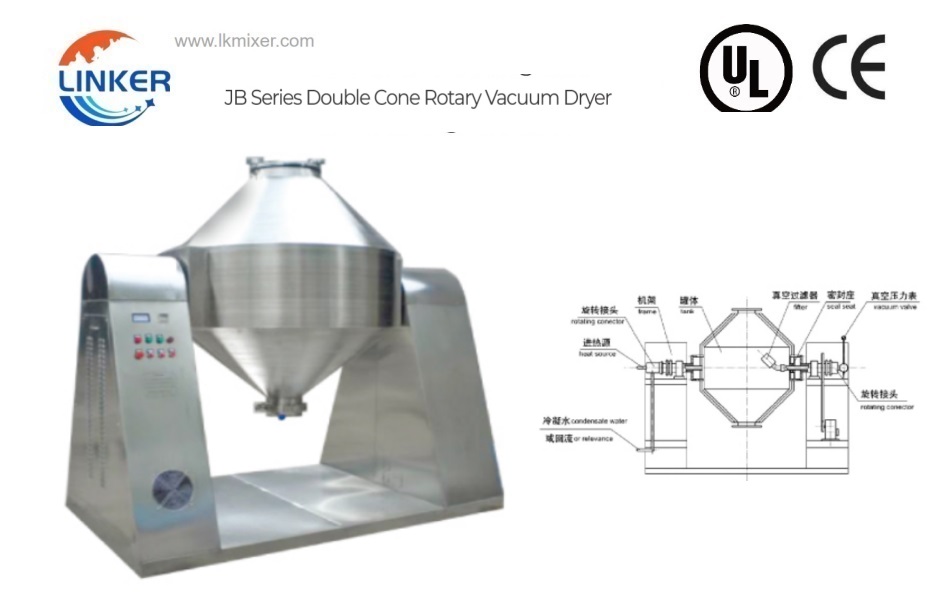

Intelligent Control and Environmental Protection

The design of a contemporary Automatic Talc Powder Production Line prioritizes intelligent operation and sustainability. The mechanism for controlling dust is extensive. Every possible source of dust generation—crusher discharge, conveyor transfers, mill inlets and outlets, and packaging stations—is equipped with pulse-jet bag filters, which achieve dust capture rates of 99.9%. This guarantees that emissions meet strict environmental laws and that the workshop environment is safe.The centralized intelligent control system is the operation’s brain. When paired with a supervisory computer (SCADA/HMI), a programmable logic controller (PLC) enables operators to oversee and manage the entire line from a single location. Real-time monitoring is done for variables including motor speed, temperature, pressure, feed rate, and energy usage. Remote diagnostics, production data tracking for traceability, and dynamic operational parameter change to optimize for varying product grades or shifting feed circumstances are all supported by the system. Important pieces of equipment in the line, particularly the electrical panels and central grinding machine, are frequently made to international safety and quality standards and may even have certifications such as the CE Certificate grinder, which guarantee dependability and security.

To sum up, an advanced example of automation in mineral processing is an Automatic Talc Powder Production Line. Despite being specific to talc, it incorporates ideas seen in many other powder manufacturing sectors. Similar physical rules govern the size reduction process in a pilot plant’s universal grinder and a 500KG peanut butter grinder. Its focus on cleanliness, accurate classification, and automated handling links it to a variety of industries, including food production, sophisticated materials manufacturing, and spice processing (using machinery like a dry ginger or licorice grinder). Such a line effectively manufactures an essential industrial mineral with consistency, quality, and environmental respect by utilizing sturdy machinery, intelligent controls, and enclosed design.

Food Producing Process Flow:

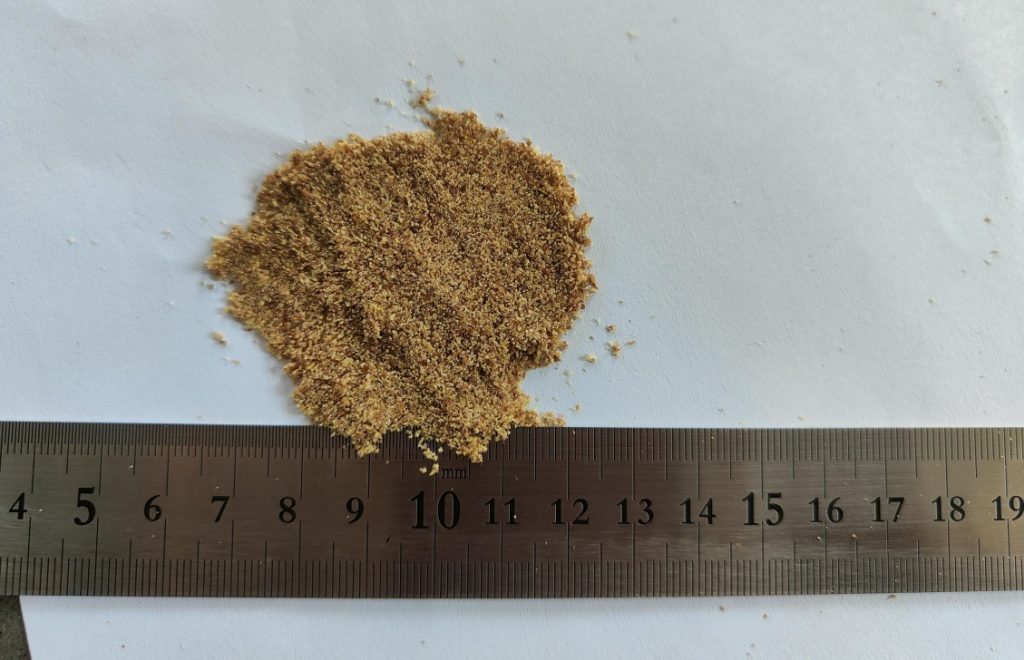

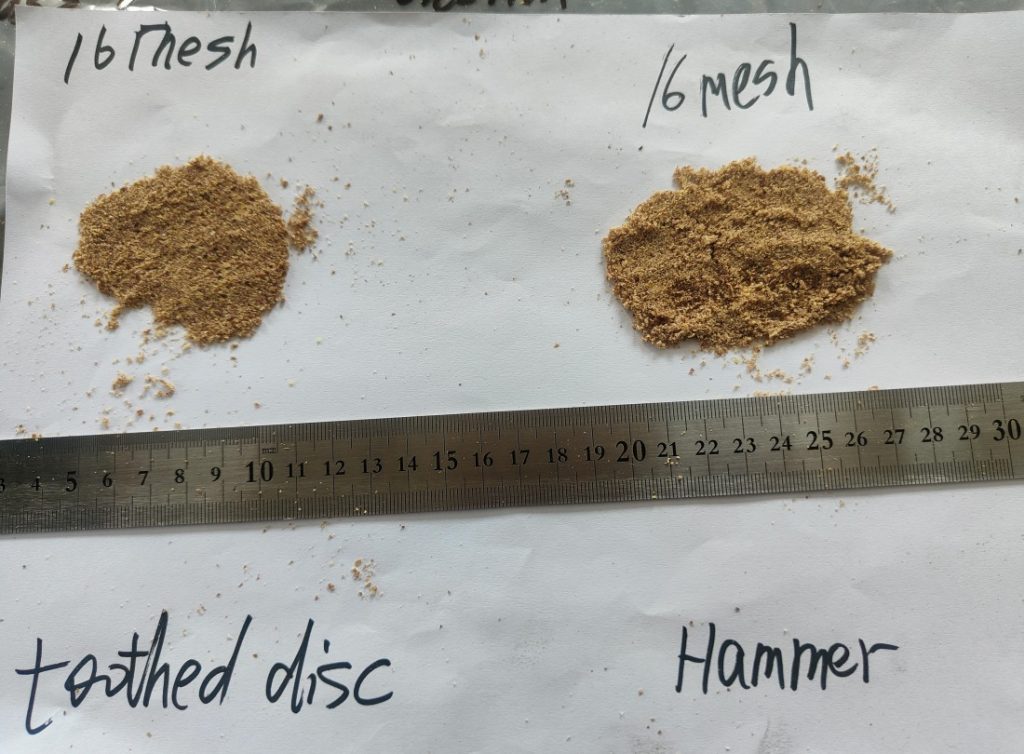

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Automatic Banana Powder Production Line Youtube Video

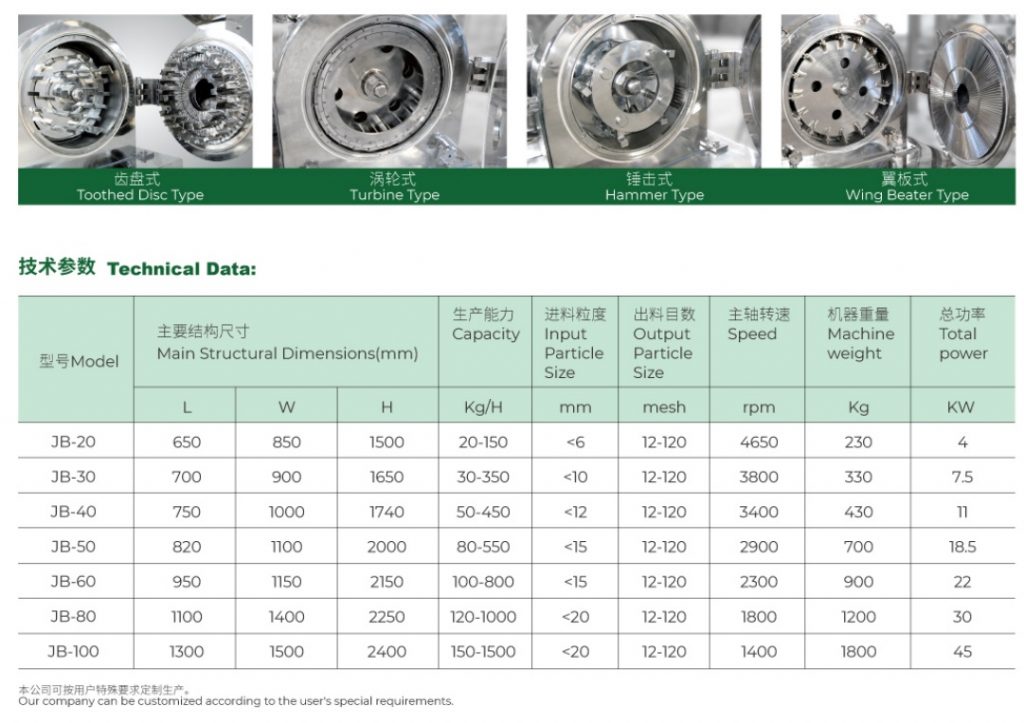

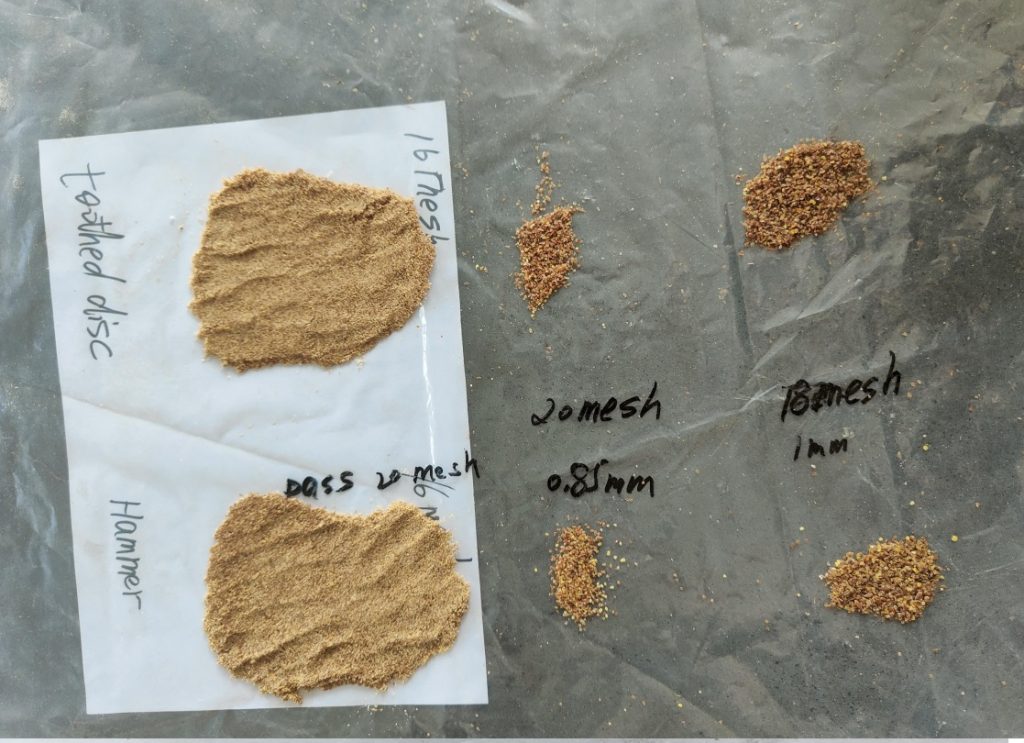

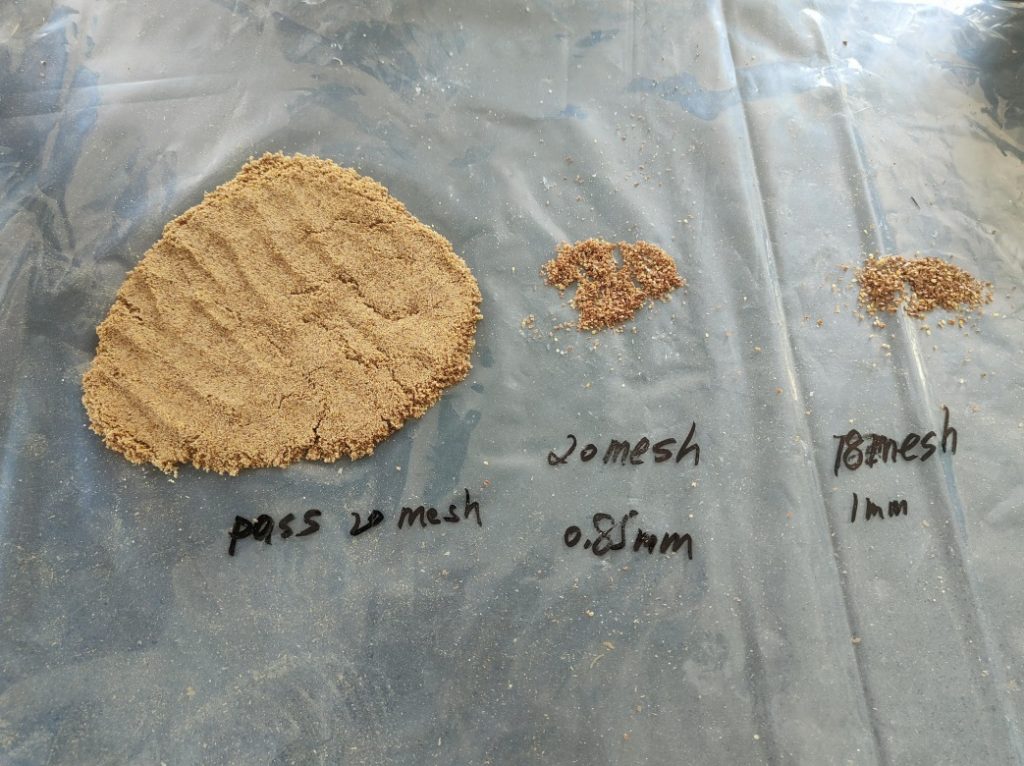

Customization Seeds Grinder According to your Capacity:

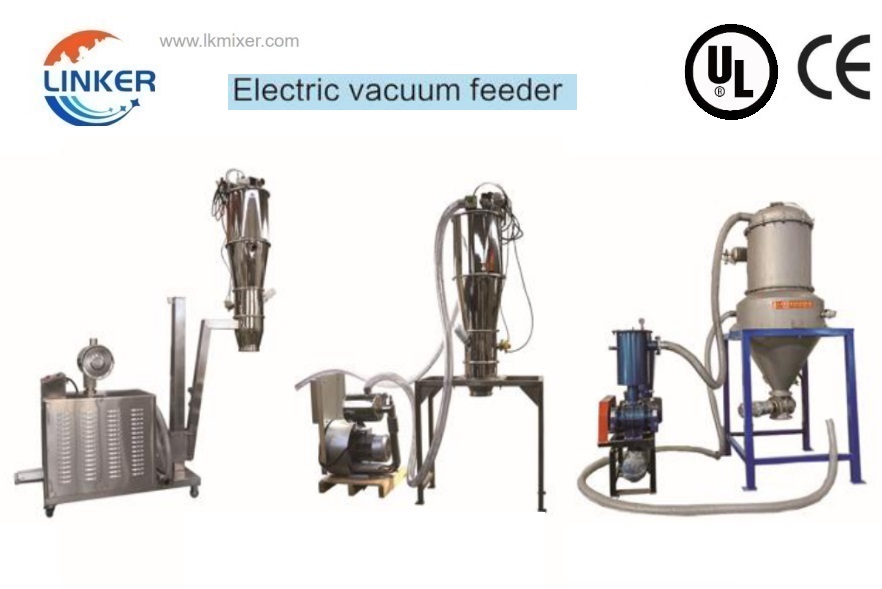

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?