Automatic Fruit Powder Production Line

Completely different from the aluminum powder and cocoa powder you inquired about earlier, there is currently no “universal standard complete line” for the “automatic fruit powder production line” at all—which is the most fundamental fact revealed by the current search results. The problem you are facing is not “which equipment manufacturer to choose”, but the decision-making dilemma of first determining the technological route and then deducing the equipment combination. Fruits vary greatly in water content (80%-95%), acid content and heat sensitivity (vitamin C is easily destroyed by light), so their processing routes are completely different. The following will thoroughly clarify the real cost, equipment list and industrial maturity of the four major technical schools for you, and point out which are mature industrialized schemes and which are still in the laboratory patent stage.

Industry Truth: Why Is There No “One Line” That Can Process All Fruits?

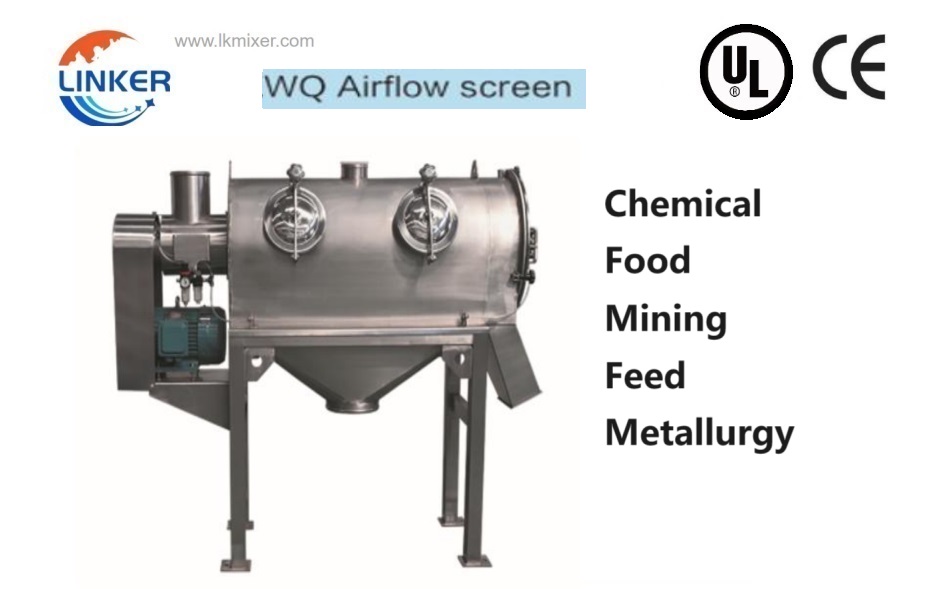

The fundamental contradiction is that fruit powder essentially falls into two major camps with completely opposite processing logics. These two camps have different requirements for equipment, raw material handling and process control, and the core equipment used is also quite different. Most of the equipment used in the automatic fruit powder production line is made of stainless steel, which is corrosion-resistant, easy to clean and meets the strict hygiene standards of the food industry. At the same time, most key equipment is equipped with a stable charger to ensure continuous and stable operation, and some export-oriented equipment is CE Certificate grinder to meet international quality and safety requirements.

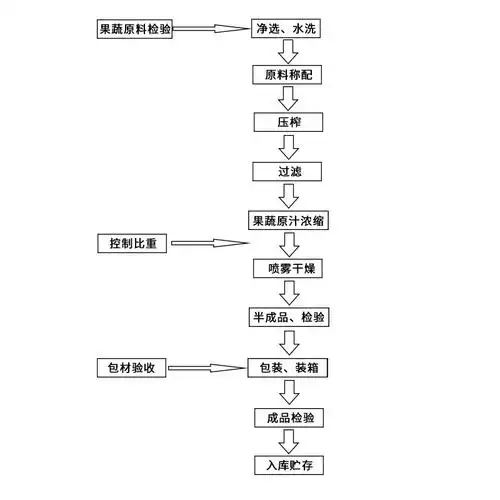

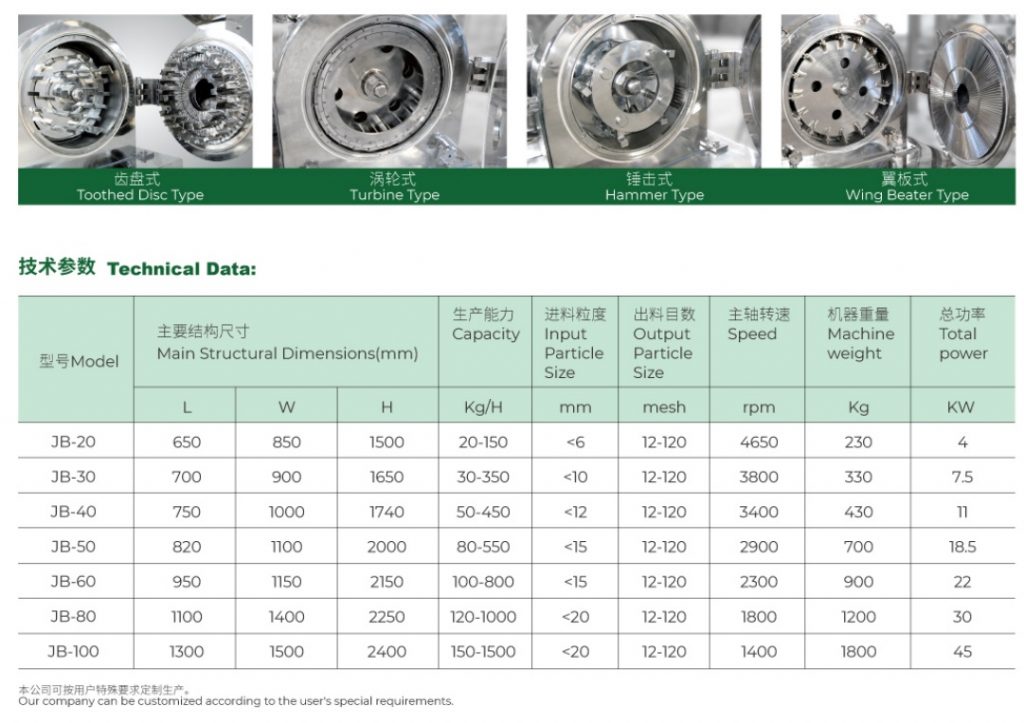

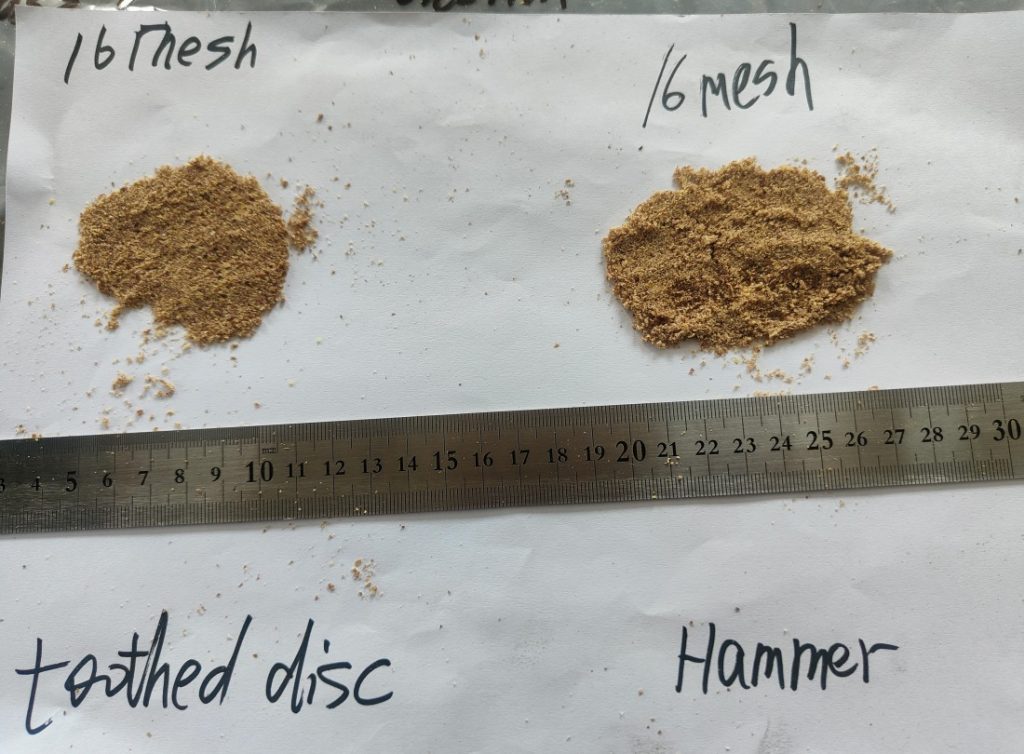

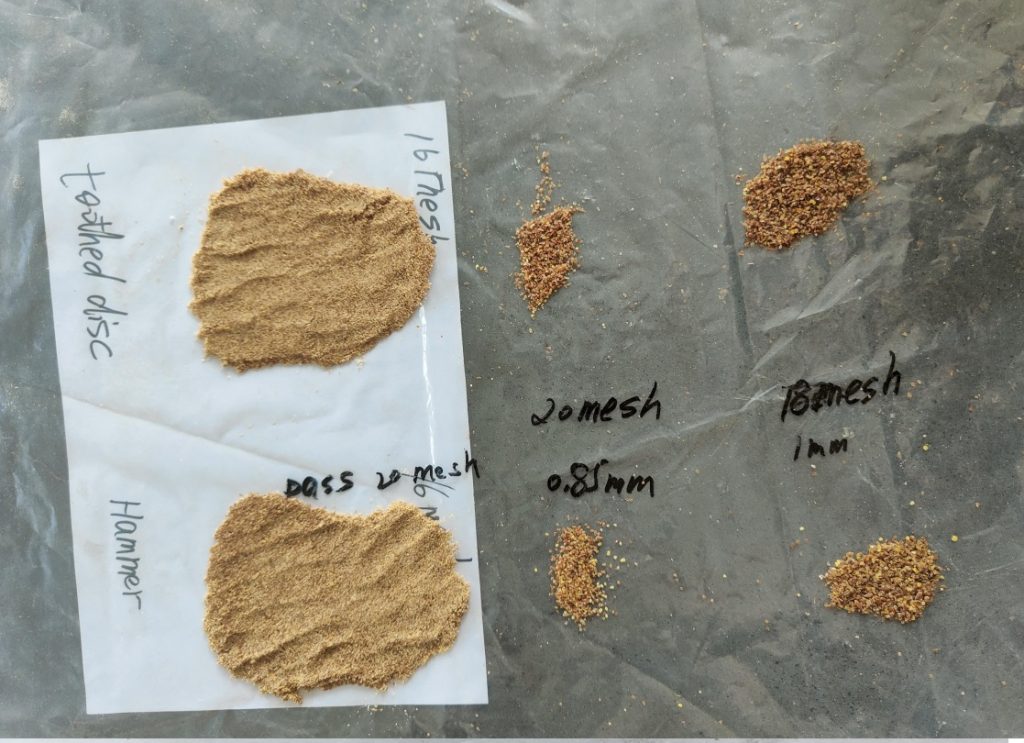

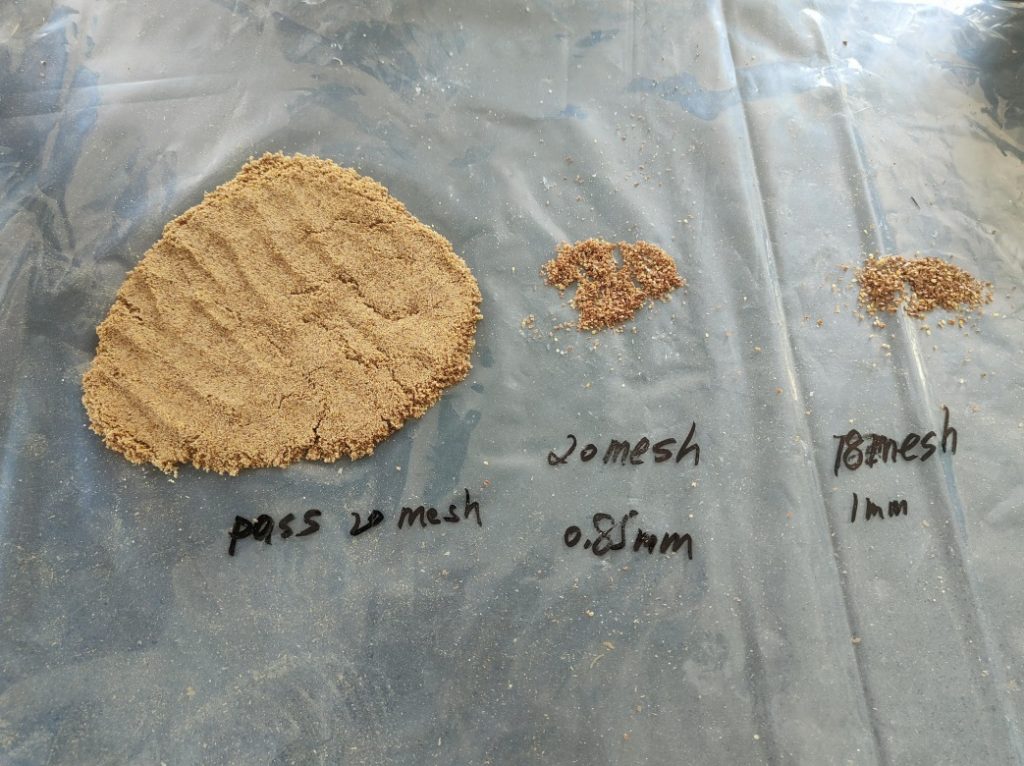

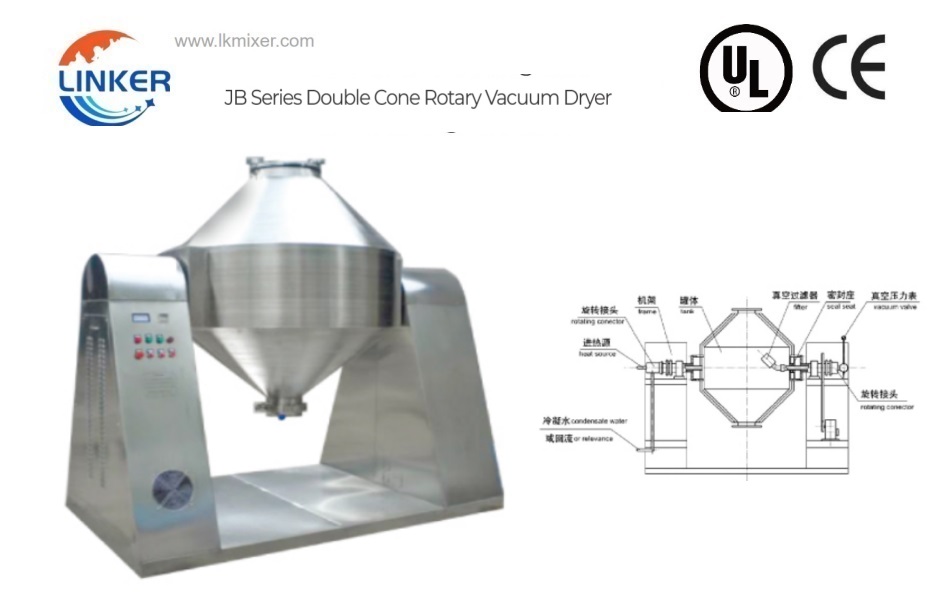

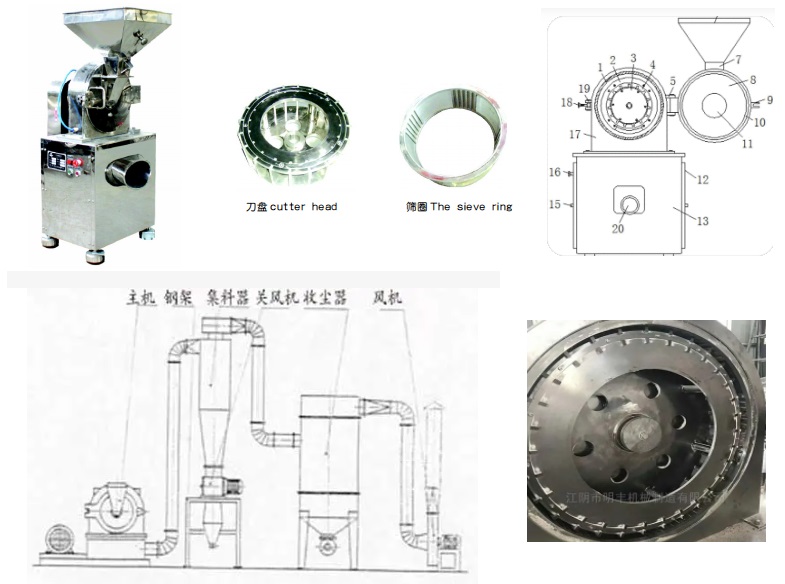

The first camp is fruit juice powder, represented by oranges, strawberries, mangoes and papayas. Its processing logic is to first squeeze juice and remove residues, then spray dry. The core challenges are heat sensitivity, wall sticking and the addition of drying aids. The automation difficulty lies in that the front-end juice extraction and back-end spray drying are mature, but manual blending is required in the middle. The equipment used in this camp mainly includes juicers, filters, spray drying towers, airflow pulverizer and Dust Grinder. The second camp is fruit pulp powder, represented by red dates, hawthorns, blueberries and bananas. Its processing logic is to first dehydrate and dry, then crush and sieve. The core challenges are drying energy consumption, crushing fineness and browning. The automation difficulty lies in that cleaning and drying are mature, ultra-fine crushing is at the patent level, but continuous connection is not mature. The equipment used in this camp mainly includes dryers, grinding machine, Hammer Mill, Ultrafine Grinder and vibrating pulverizer.

The cruel reality is that you cannot buy a universal line that “puts fresh fruits in and automatically produces fruit powder”. At present, the mature automatic lines are all customized lines bound to specific fruit categories and specific processes. It should be emphasized that the automatic fruit powder production line is quite different from the production lines of chili powder, cocoa powder and aluminum powder you inquired about earlier. Chili powder is a low-moisture dry product that can be directly crushed; fruit must be dehydrated first, otherwise it will become mud, so the equipment is completely not universal. Cocoa powder needs to extract cocoa butter, while fruit powder retains all solids (or all soluble substances), and their process logics are opposite. Aluminum powder is produced by physical crushing/atomization, while the core of fruit powder production is dehydration, so there is no reference value across industries.

Full Dismantling of Four Technological Routes (The Choice You Must Make)

Route 1: Spray Drying Method——The Absolute Mainstream of Fruit Juice Powder (Industrial Maturity: ★★★★★)

If you produce strawberry powder, mango powder, papaya powder, banana powder, etc., this is the only large-scale industrialized route. However, it should be noted that it produces “fruit juice powder”, not “fruit pulp powder”—you must first squeeze juice, filter, only dry the soluble solids, and the fiber residues are discarded. This route is currently the most mature and widely used technological route in the fruit powder industry, with a large number of actual production cases and mature equipment supply channels.

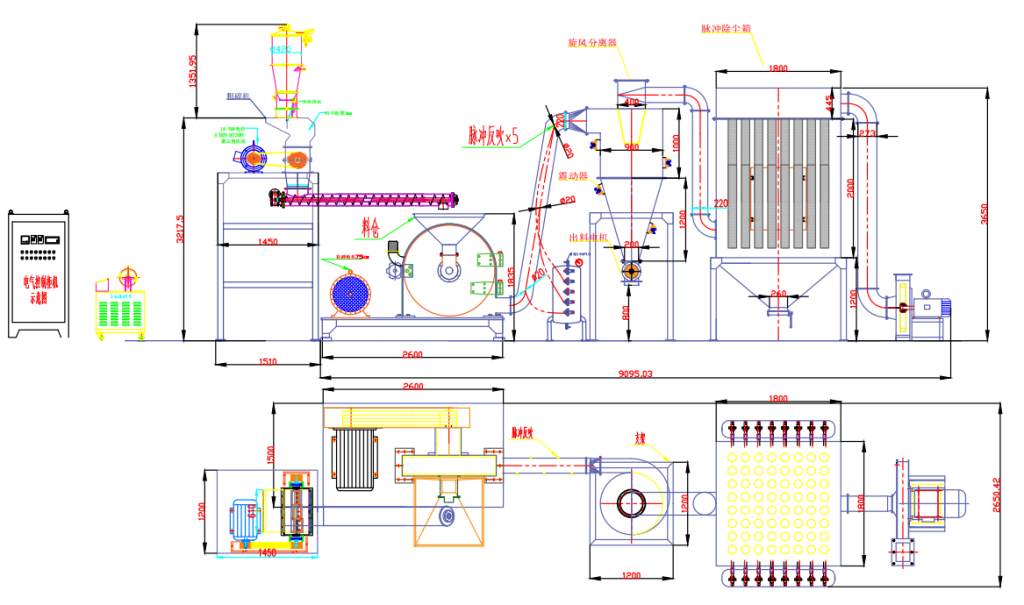

A real production line case is the papaya/green papaya fruit juice powder spray drying unit, whose equipment manufacturer is Changzhou Xinma Drying (industrial grade, not laboratory equipment). Its core configuration includes three sections: pretreatment section, drying section and control system. The pretreatment section includes a cleaning machine, peeling and seeding