Glass Powder Grinding Machine

Glass Powder Grinding Machine

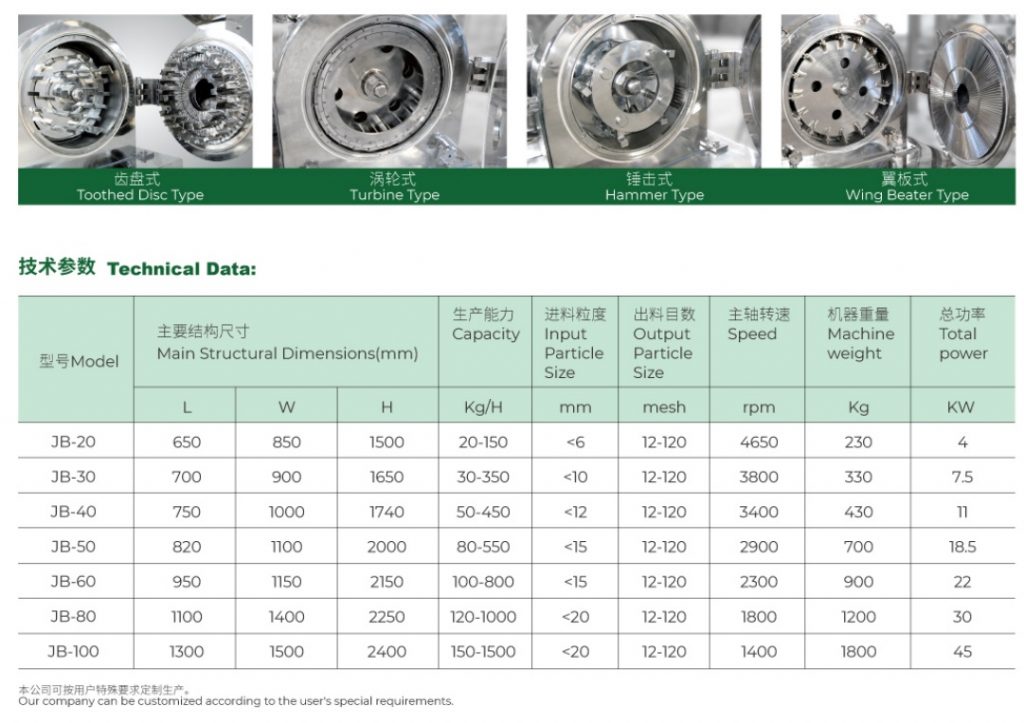

- Feeding granule size: <5mm;

- Powder Size: 20~40 mesh;

- Capacity: 1~4000kg/h(according to different modes and raw materials);

- Motor Power (KW): 11~15kw;

- FOB Unit Price: 1 unit $ 6,646~10,154. More than 5 units: $5,982~9,138. Video

- Application: Medicine, potato, bean, rice, herb, pepper, grain, food, corn, Sugar

Industrial Cumin Seeds Grinder Youtube Video

Glass Powder Grinding Machine

Because glass has three main characteristics—high hardness (Mohs hardness about 7-8), brittle texture, and sharp granular shape after grinding—which greatly wear down the equipment, a glass powder grinding machine is specialized equipment made for the highly technical field of glass grinding.

Consequently, wear resistance and fineness control are crucial factors when choosing a glass powder grinding machine. Glass powder grinding machines are designed to meet specific raw material forms and intended uses, such as recycling broken glass or creating fine glass powder fillers. This is in contrast to standard herb grinders, black pepper grinders, or dry fruit powder grinder machines. In order to maximize production efficiency and operational safety, these machines can be combined with accessories like a charger, dust collector grinder, and air-cooled crusher. They range in size from small laboratory or small-batch models to large industrial models like 500KG grinders. Key wear-resistant parts are made of high-hardness materials.

1. Coarse and Medium Crushing Equipment

In order to prepare for later fine grinding, the objective of this stage is to crush big waste glass pieces (such as beer bottles and flat glass) into small pieces or coarse particles. Although the equipment must be more resistant to wear, this stage is comparable to the coarse crushing of hard materials like metal and bone.

1.1 Jaw Crusher

This is the most commonly used equipment in the first process of glass grinding. It is more wear-resistant than ordinary coarse crusher and Hammer Mill, and is the “pioneer” of the glass powder production line.

Working Principle

Through the relative movement of the fixed jaw plate and the movable jaw plate, a strong extrusion and splitting effect is generated on the glass, crushing it. The jaw plates are driven by a powerful motor, and some large models are also equipped with a charger to ensure stable power supply during long-term continuous operation.

Applicable Scenarios

It is suitable for processing large glass raw materials, crushing them into blocks of tens of millimeters in size. It has a simple structure and a large crushing ratio, which can efficiently handle various large waste glass, and its performance is superior to that of a small Electric Grinder in processing large hard materials.

1.2 Impact Crusher/Hammer Mill

Secondary crushing, which may further break down the coarsely crushed glass into tiny pieces, frequently uses this kind of machinery. Like the use of a turbo grinder in the spice business, it is a typical piece of secondary crushing equipment in the glass recycling sector.

Working Principle

It uses high-speed rotating plate hammers or hammer heads to strongly impact the glass, making it hit the impact plate for secondary crushing. The high-speed rotation of the hammer heads is driven by a high-power motor, and the cooling effect is similar to that of an Air cooled crusher, which can reduce equipment wear caused by high temperature.

Core Advantages

Compared with the jaw crusher, the particles produced by it have a more regular shape, and the fine powder content is controllable, which is suitable for the production of primary glass sand with requirements on particle size. Similar multi-stage crushing systems are also adopted in common glass grinders, which can improve the crushing efficiency and product quality.

It has strong adaptability and can also process hard materials such as cassava and bone after simple adjustment, but it is mainly designed for glass crushing, with better wear resistance than ordinary universal grinder.

2. Fine Crushing and Fine Grinding Equipment

When it is necessary to process glass into finer powder (such as dozens to hundreds of meshes) for fiberglass products, building material fillers, or craft manufacturing, fine grinding equipment is required. These equipment are more precise than coarse crushing equipment, similar to the difference between an Ultrafine Grinder and a common Hammer Mill.

2.1 Vertical Shaft Grinder/Hammer Type Fine Crusher

This is a typical piece of fine crushing machinery that is frequently utilized in the glass recycling industry. It is an affordable option for producing medium-fine glass powder, and its output is comparable to that of a 200KG grinder for medium-scale manufacturing.

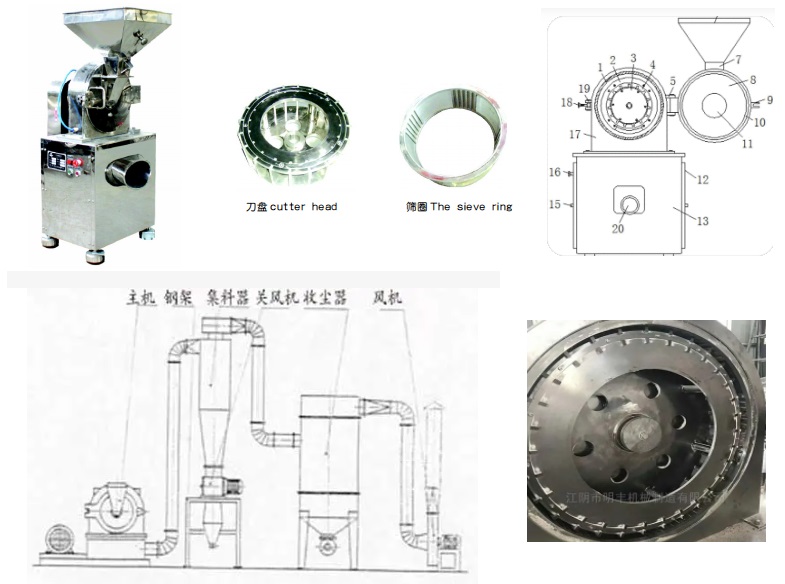

Working Principle

After the materials enter the crushing chamber, they are subjected to violent impact, shearing and grinding by high-speed rotating hammer heads or blades. The fineness of the discharged material can be controlled by adjusting the number of hammer heads, rotating speed, or the gap of the discharge grate.

This working principle is similar to that of a cutting type grinder, but with better wear resistance and finer fineness adjustment range, which can avoid the problem of equipment blockage that often occurs in a Dust Grinder when processing sharp glass particles.

Reference for Technical Parameters

According to the technical parameters of glass grinders, this type of equipment usually has a variety of models to choose from (such as 400 type, 600 type, 800 type, 1000 type). The motor power ranges from 22 kilowatts to 100 kilowatts, the output ranges from 125 kg to 2600 kg per hour, and the discharge fineness can be adjusted between 10 meshes and 320 meshes.

Large models such as 1000 type have an output close to that of a 500KG Grinder, which is suitable for large-scale industrial production, and most models have CE Certificate grinder qualification, meeting international industrial standards.

Core Advantages

Wear-Resistant Design: The wearing parts (such as hammer heads and liners) of this type of equipment are usually made of high-hardness, high-toughness multi-component alloy wear-resistant materials (such as high-chromium cast iron), and their service life is 2-3 times longer than that of ordinary steel. This is similar to the wear-resistant design of a meat grinder and Medicine grinder that need to handle hard materials.

Versatility: It can not only handle ordinary glass bottles, but also composite materials such as fiberglass and automotive glass. It is a kind of universal grinder that can also process hard materials such as Seasam and Peanut shells after simple adjustment.

2.2 Ball Mill

This is a classic fine grinding equipment, suitable for further grinding glass particles into finer powder. It is widely used in large-scale glass powder production, and its grinding effect is more stable than that of a vibrating pulverizer and airflow pulverizer.

Working Principle

In a rotating cylinder, grinding media (steel balls, ceramic balls) are lifted to a certain height with the rotation of the cylinder and then dropped, generating impact and grinding effects on the materials. The grinding media are made of high-wear-resistant materials to cope with the high hardness of glass.

Applicable Scenarios

It is often used for mass production of glass micro powder with stable fineness requirements. It can work in dry mode or wet mode (to obtain finer slurry). The wet grinding mode is similar to the working mode of a vertical sand mill used for processing Medicine and cosmetic raw materials.

It can also be used for grinding materials such as wheat, corn, and bean after replacing the grinding media, but it is mainly designed for glass grinding, with better wear resistance than ordinary Dry Grinder.

3. Ultrafine Crushing Equipment (Micron-Level Glass Powder)

Glass powder must be ground to the micron or even submicron level (below 10 microns, or over 1250 meshes) for high-end applications such electronic packaging materials, premium coating fillers, and cosmetic additives. Ultrafine crushing equipment has to be used right now.

3.1 Airflow Pulverizer

This is the mainstream equipment for preparing ultrafine and high-purity glass powder. It is more precise than a Vacuum Mill and turbo grinder in processing ultrafine glass powder, and can ensure the purity and particle shape of the product.

Working Principle

Instead of impacting mechanical parts directly, it employs high-speed airflow (compressed air or superheated steam) to accelerate glass particles to supersonic speed. This causes the particles to collide with one another in the crushing chamber to smash. By using this “self-grinding” technique, metal impurity contamination from mechanical wear is prevented.

Core Advantages

High Purity and No Pollution: Since it is material self-grinding, it avoids metal impurity pollution caused by mechanical wear, ensuring the purity of the product. This is very important for high-end applications such as electronic materials, which is the same as the high-purity requirement of Medicine grinding equipment.

Low-Temperature Crushing: The gas expansion is an endothermic process, and the temperature of the crushing chamber is low, which is suitable for heat-sensitive materials, and can also maintain the physical properties of the glass. This cooling effect is similar to that of a cryogenic grinding machine, but more energy-saving.

Precise Controllable Particle Size: It is usually equipped with a high-precision classifier, which can precisely control the product particle size distribution and avoid over-crushing. Data shows that the counter-jet airflow pulverizer can crush glass powder to 1300 meshes.

Good Particle Morphology: The crushed particles are mostly spherical with good dispersibility, which is better than the particle morphology of glass powder processed by a dry ginger grinding machine and licorice grinding machine.

Main Types

The two primary types of airflow mills are counter-jet and fluidized bed. The fluidized bed type is particularly well-suited for ultra-fine crushing of high-hardness and high-purity materials like glass because of its low wear. It may be used in conjunction with a dust collector grinder to guarantee a hygienic workplace.

3.2 Vibrating Mill

This is a kind of equipment that uses high-frequency vibration to make the grinding media impact and grind the materials, and can also be used for ultra-fine crushing of glass. It is more efficient than a small grinder machine in processing small-batch ultra-fine glass powder.

Characteristics

It can operate in both dry and wet modes, has a high grinding efficiency, and can produce medium-fine and ultra-fine powder. But since the noise level is somewhat high, a sound-isolating device needs to be installed. Compared to standard industrial weed grinders and cannabis grinders, which are not made for hard materials, it has a higher level of wear resistance.

With a little tweaking, it may be used to grind items like spices, seeds, and mushrooms in addition to producing ultra-fine glass powder in small batches.

4. Specialized and Supporting Equipment

A complete glass powder production line not only needs main grinding equipment, but also requires a series of specialized and supporting equipment to ensure continuous and safe production. These supporting equipment are as important as the main machine, similar to the supporting role of a charger and electric control system for the main machine.

4.1 Specialized Grinder for Glass Recycling Line

Some specialized equipment is designed to handle waste from float glass production lines. This type of equipment is usually integrated into the production line, and continuously crushes glass waste with low noise and almost no dust through devices such as star rollers, and automatically transports it to the collection container, realizing the automation of the production process and higher safety.

It is usually equipped with a dust collector grinder and Dust Grinder to avoid dust pollution, and the key components are made of stainless steel to ensure durability. Its production capacity can be matched with a 500KG Grinder for large-scale glass recycling production.

4.2 Small Laboratory Crusher

A compact cross-knock crusher can be utilized in quality inspection or research and development departments. This kind of apparatus can prepare glass samples on a laboratory scale since its feed size can reach up to 25 millimeters and its ultimate discharge particle size may be less than 100 microns.

It is compact, simple to use, and comparable to a tiny laboratory electric grinder. It may also be used to grind small amounts of materials for experiments, including rice, tea, and coffee.

5. Selection Suggestions and Summary

In conclusion, the final product’s intended use, manufacturing volume, and purity standards should all be taken into consideration when choosing a glass powder grinding machine. In contrast to choosing standard grinding tools like rice and coffee grinders, greater attention must be paid to the tools’ resilience to wear and their capacity to regulate fineness.

5.1 If the Goal is Glass Recycling, Producing Coarsely Crushed Glass Sand or Glass Particles

If you want to recycle glass, produce coarsely crushed glass sand or glass particles (such as for glass product remelting and building material aggregates), you should choose the combined scheme of “jaw crusher + impact/hammer crusher”. Focus on the wear-resistant part material (such as high-chromium alloy) and production capacity parameters of the equipment.

This type of equipment has mature technology, and the investment and operation costs are relatively low. Large models can be matched with a 500KG Grinder to form a large-scale production line, and attention should be paid to the configuration of the charger to ensure stable power supply.

5.2 If the Goal is to Produce Medium-Fine Glass Powder

If you want to produce medium-fine glass powder (such as 10-320 meshes, used for fiberglass products and ordinary fillers), the vertical shaft glass grinder or ball mill is a cost-effective choice. When selecting models, pay attention to its fineness adjustment range and the configuration of the screen or classification system.

The vertical shaft glass grinder is suitable for medium-scale production, and its output can be matched with a 200KG grinder. The ball mill is suitable for large-scale continuous production, and most models have CE Certificate grinder qualification, meeting international standards.

5.3 If the Goal is to Produce Ultrafine, High-Purity Glass Micro Powder

If you want to produce ultrafine, high-purity glass micro powder (such as micron or even submicron level, used for electronic materials, high-grade coatings, and special fillers), you should choose an airflow pulverizer (fluidized bed type or counter-jet type).

Although the one-time equipment investment and operation energy consumption are relatively high, its unique advantages of no pollution, precise controllable particle size, and low-temperature crushing are necessary conditions for producing high-value-added products. It is more suitable for high-end applications than an Ultrafine Grinder and vibrating pulverizer.

Key Points to Consider in Any Case

Wear Resistance: Glass has high hardness, so it is necessary to confirm whether the easily worn parts of the equipment (hammer heads, liners, grinding wheels, etc.) are made of high-wear-resistant materials. This is the core requirement for selecting glass powder grinding machines, which is different from selecting equipment such as a black pepper grinder and spice grinder.

Dust Removal and Safety: Glass dust is harmful to the human body, so an efficient bag dust collector must be equipped to ensure that the production environment meets the standards. At the same time, the entire system should have good airtightness, which is the same as the dust removal requirement of grinding equipment such as a cannabis grinder and Industrial Weed Grinder.

Automation Level: For large-scale production, a production line with automatic feeding, discharging and control systems can greatly improve efficiency and safety. It can be matched with a charger and electric control system to realize unmanned operation, reducing labor costs and operational risks.

In summary, “wear resistance” and “fineness control” are key considerations when choosing a glass powder grinding machine. Selecting the best equipment may be aided by making clear the particular application scenario, such as glass recycling or the creation of high-end powder. Regardless of the equipment type chosen, it is necessary to perform routine maintenance and replace worn parts in order to prolong the equipment’s lifespan and guarantee the stability of product quality.

For instance, the equipment’s interior chamber should be cleaned promptly to prevent the buildup of glass powder, and the wear-resistant components should be changed on a regular basis. To guarantee steady functioning of the whole production line, consideration should also be given to the equipment’s compatibility with other pieces of equipment, such as a dust collector grinder and charger.

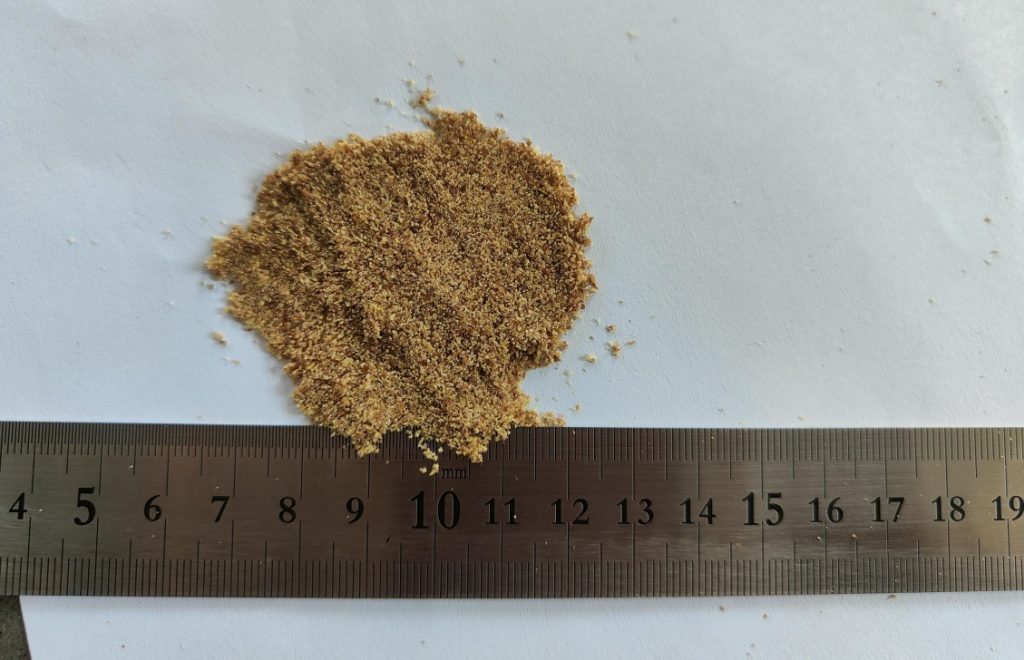

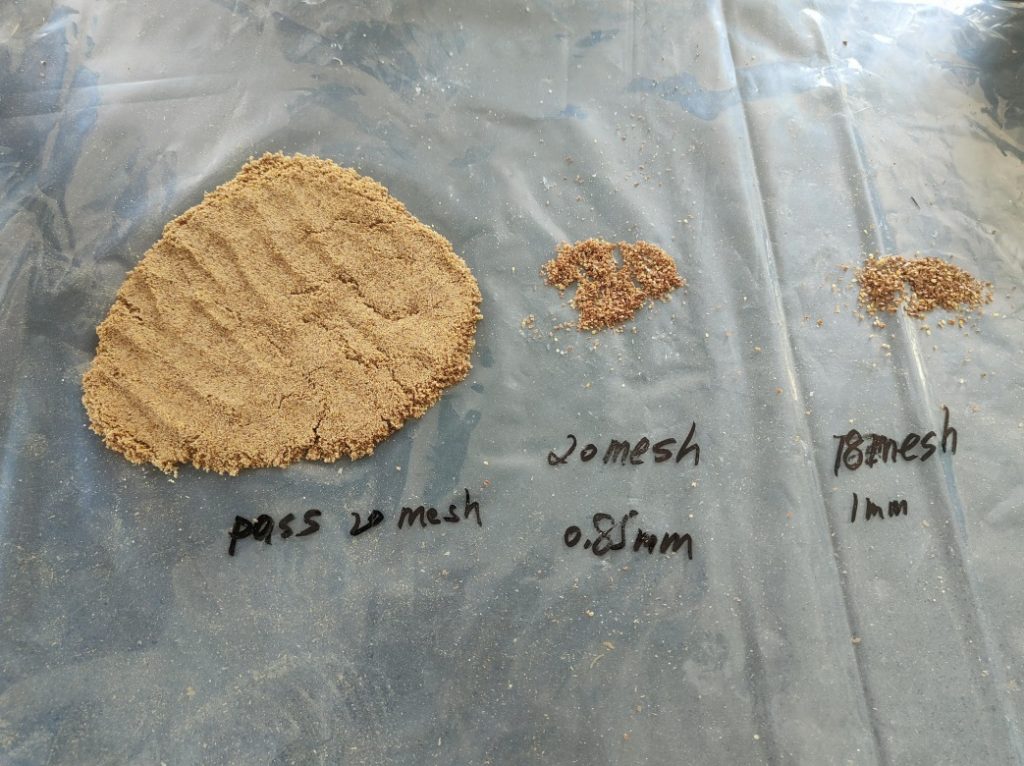

Test Report for Flax Seed Grinder:

A flax seed grinder is a type of seed nut grinder specifically designed for grinding flax seeds. Flax seeds are small, hard seeds that are packed with nutrition and are commonly used in baking and cooking. Grinding flax seeds helps to unlock their nutrients and make them easier to digest.

Flax seed grinders typically feature sharp blades or burrs that rotate to crush the flax seeds into a fine powder. This powder can then be used in a variety of recipes, such as smoothies, baked goods, and yogurt toppings. Some flax seed grinders are manual and require hand-cranking, while others are electric and feature powerful motors for faster grinding.

When choosing a flax seed grinder, it’s important to look for one with durable blades or burrs that can withstand the hard texture of flax seeds.

There are 3 ways of cooling down the grinder: water cooling system; air cooling system and liquid nitrogen freezing system. You can choose the right one if the grinder gets too hot. When machines goes too hot, the metal can expand, causing the grinding wheel to get stuck.

| 1 Unit Pirce(FOB USD) | 5 Units Wholesale Unit Price (FOB USD) | |

| SG-600 | 6646 | 5982 |

| SG-800 | 10154 | 9138 |

Feature:

Industrial seed grinders are specialized machines that are designed to grind seeds and other materials into a fine powder or paste. Here are some features that are commonly found in industrial seed grinders:

- High throughput: Industrial seed grinders are designed to process large volumes of seeds quickly and efficiently. They are often used in production environments where a high throughput is essential.

- Variable speed: Many industrial seed grinders have variable speed controls, which allow the operator to adjust the speed of the grinding mechanism. This feature is useful for achieving a consistent particle size and for processing different types of seeds.

- Customizable grinding plates: Some industrial seed grinders come with customizable grinding plates that can be swapped out to accommodate different types of seeds and produce different particle sizes.

- Easy to clean: Industrial seed grinders are designed to be easy to clean and maintain. They often feature removable grinding plates, hopper, and discharge chute that can be easily cleaned and sanitized.

- Heavy-duty construction: Industrial seed grinders are built to withstand heavy use and are constructed with durable materials such as stainless steel or hardened alloys. This ensures that the machine can withstand the rigors of daily use and last for many years.

- Versatility: Industrial seed grinders can often be used to process a variety of materials in addition to seeds, such as nuts, grains, and spices.

Overall, the features of an industrial seed grinder are designed to make the grinding process fast, efficient, and consistent, while also being easy to use and maintain.

Parameters:

Model Name | SG-600 | |

| Crushing Capacity(kg/h) | 1000~2000 | |

| Power(kw) | 11 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Model Name | SG-800 | |

| Crushing Capacity(kg/h) | 2000~4000 | |

| Power(kw) | 15 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

Ampere of Motors Customization for Seeds Grinder:

| KW | HP | Ampere |

| 75kw | 100HP | 135A |

| 55kw | 75HP | 99A |

| 30kw | 40HP | 54A |

| 22kw | 30HP | 39A |

| 2.2kw | 3HP | 3.9A |

| 1.5kw | 2HP | 2.7A |

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Electric Cabinet with UL Certification

Cyclone Processor and Motors:

Spare Parts:

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

Operation Instruction

General Provisions

The operation instructions for a commercial grinder may vary depending on the specific model and manufacturer. However, here are some general guidelines that may apply to many high speed grinders:

- Safety precautions: Before operating the high speed grinder, it is important to review all safety precautions and warnings provided in the user manual. Safety precautions may include wearing appropriate personal protective equipment, such as eye protection and hearing protection, and avoiding loose clothing or jewelry that could become caught in the grinder.

- Preparation: The high speed grinder should be placed on a stable and level surface, and all necessary components should be assembled according to the manufacturer’s instructions. The grinder should also be connected to a power source that is appropriate for its voltage and wattage.

- Loading the grinder: The material to be ground should be loaded into the grinder according to the manufacturer’s instructions. Overloading the grinder may cause damage to the machine and result in poor grinding performance.

- Starting the grinder: The grinder should be started according to the manufacturer’s instructions. This may involve pressing a button, turning a dial, or flipping a switch. The user should ensure that their hands are clear of the grinder and that the material to be ground is positioned properly.

- Adjusting the speed and settings: The speed and other settings of the high speed grinder may be adjusted according to the material being ground and the desired outcome. The user should follow the manufacturer’s instructions for making adjustments to the grinder.

- Monitoring the grinding process: The user should monitor the grinding process to ensure that it is progressing smoothly and that the material is being ground to the desired size and consistency. Any issues or abnormalities should be addressed promptly to prevent damage to the machine.

- Shutting down the grinder: When the grinding process is complete, the grinder should be shut down according to the manufacturer’s instructions. The user should ensure that the machine is completely stopped and that all moving parts have come to a complete stop before attempting to clean or service the grinder.

Overall, the operation instructions for a commercial grinder may involve a number of steps and safety precautions. It is important to carefully review the manufacturer’s instructions and follow proper operating procedures to ensure safe and effective use of the machine.

Preparation Work

Before running a commercial grinder, there are several important preparation steps that should be taken to ensure safe and effective operation of the machine. Here are some general guidelines for preparing to run a high speed grinder:

- Read the user manual: The first step in preparing to run a high speed grinder is to carefully read the user manual provided by the manufacturer. The user manual will provide important information about the specific model of grinder being used, including its features, specifications, and safety precautions.

- Select the appropriate grinding wheel: The grinding wheel used in a high speed grinder should be selected based on the material being ground and the desired outcome. It is important to use the correct type of grinding wheel to prevent damage to the machine and ensure optimal grinding performance.

- Inspect the grinder: Before running the grinder, it is important to inspect it for any signs of damage or wear. The user should check for loose or missing components, cracks or other signs of damage to the machine’s housing or other parts, and any other issues that could affect the grinder’s operation.

- Install the grinding wheel: The grinding wheel should be installed according to the manufacturer’s instructions, making sure that it is securely fastened and aligned properly. The user should also check the wheel for any cracks or other signs of damage before installation.

- Secure the workpiece: The workpiece to be ground should be securely clamped or held in place before starting the grinder. This will help to ensure safe and effective operation and prevent the workpiece from becoming dislodged or damaged during grinding.

- Connect the power source: The high speed grinder should be connected to a power source that is appropriate for its voltage and wattage. It is important to use a properly grounded power source to ensure safe and reliable operation of the machine.

- Test run: Before beginning actual grinding operations, it may be useful to perform a test run to ensure that the grinder is functioning properly and that the grinding wheel is aligned and balanced properly. The user should follow the manufacturer’s instructions for performing a test run.

By following these preparation steps, users can ensure safe and effective operation of a high speed grinder and achieve optimal grinding results.

Treatment of inspection

Inspection of a commercial grinder is an important maintenance procedure that helps ensure safe and effective operation of the machine. Here are some general guidelines for inspecting a high speed grinder:

- Disconnect power source: Before performing any inspection or maintenance on a high speed grinder, the power source should be disconnected to prevent accidental startup.

- Check for wear and damage: The user should inspect the grinder for any signs of wear or damage, such as cracks in the housing, worn or damaged grinding wheels, or loose or missing parts. Any issues should be addressed promptly to prevent further damage to the machine.

- Check alignment and balance of grinding wheel: The grinding wheel should be inspected for proper alignment and balance, as these factors can affect the quality of the grinding operation. If the grinding wheel is not properly aligned or balanced, it should be adjusted or replaced as necessary.

- Check for proper lubrication: The high speed grinder should be inspected for proper lubrication, as inadequate lubrication can cause excessive wear and damage to the machine’s moving parts. The user should follow the manufacturer’s instructions for lubrication, and add lubricant as necessary.

- Inspect electrical components: The electrical components of the high speed grinder, including the wiring, switches, and control panel, should be inspected for any signs of wear, damage, or loose connections. Any issues should be addressed promptly to prevent electrical problems.

- Test run: After completing the inspection, it may be useful to perform a test run of the high speed grinder to ensure that it is functioning properly and that any issues have been addressed.

By following these inspection guidelines, users can help ensure safe and effective operation of a high speed grinder and minimize the risk of damage or injury during grinding operations.

Operation Attention

Running a commercial grinder can be a dangerous operation if proper precautions are not taken. Here are some general guidelines for safe operation of a high speed grinder:

- Personal protective equipment: The user should wear appropriate personal protective equipment, such as safety glasses, hearing protection, and gloves, to prevent injury from flying debris, noise, and contact with the grinding wheel.

- Secure workpiece: The workpiece being ground should be securely clamped or held in place to prevent it from becoming dislodged during grinding.

- Use proper grinding wheel: The user should select the appropriate grinding wheel for the material being ground and ensure that it is installed correctly and securely. The grinding wheel should be inspected for cracks or other damage before use.

- Adjust grinding wheel speed: The speed of the grinding wheel should be adjusted according to the manufacturer’s instructions to ensure optimal grinding performance and prevent damage to the machine or workpiece.

- Avoid excessive pressure: The user should avoid applying excessive pressure to the grinding wheel, as this can cause the wheel to overheat and wear out more quickly.

- Avoid overheating: The high speed grinder should not be operated continuously for extended periods of time, as this can cause overheating and damage to the machine.

- Monitor grinding operation: The user should closely monitor the grinding operation to ensure that the workpiece is being ground properly and that the grinding wheel is functioning correctly.

- Disconnect power source: After completing grinding operations, the power source should be disconnected to prevent accidental startup.

By following these guidelines, users can operate a high speed grinder safely and effectively, and achieve optimal grinding results. It is important to follow the manufacturer’s instructions and all applicable safety regulations when operating any type of machinery.

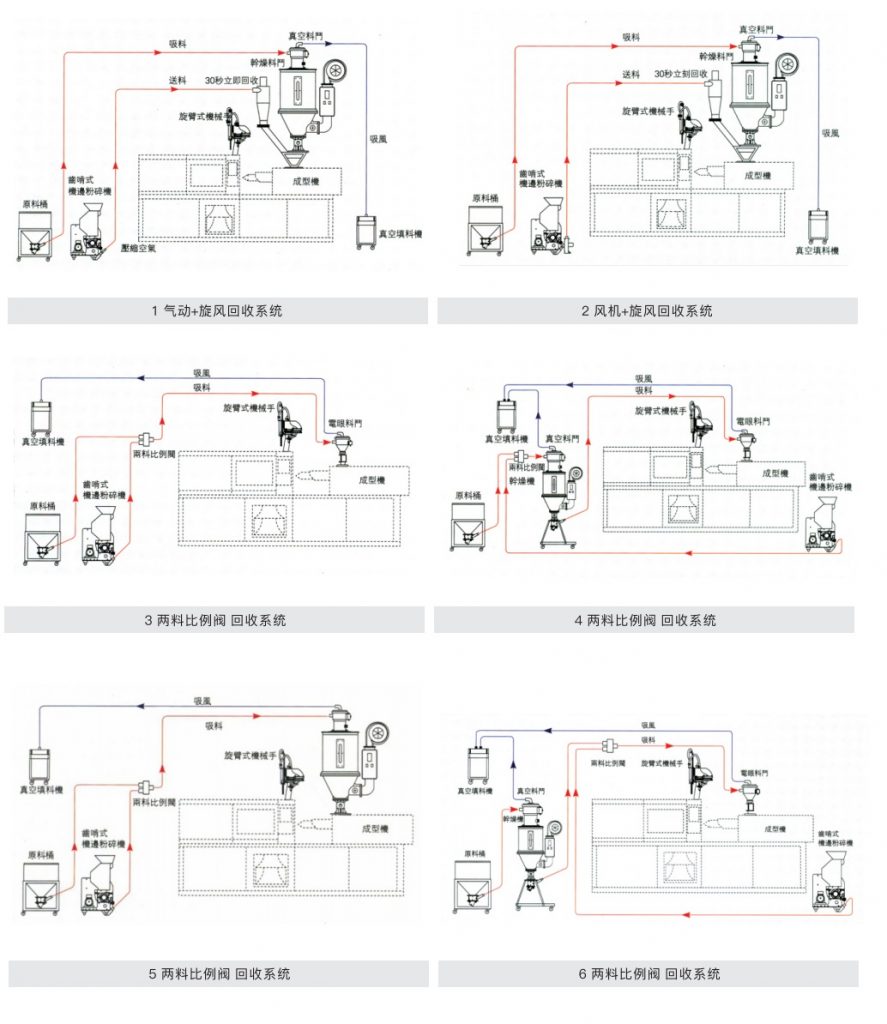

Installation Layout:

Applications of Industrial Seed Grinder

Industrial seed grinders are used in a variety of applications across many industries. Here are some of the most common applications of industrial seed grinders:

- Food industry: Industrial seed grinders are used extensively in the food industry to grind seeds, nuts, and spices into fine powders or pastes. These powders and pastes are then used in a variety of products such as sauces, seasonings, and spreads.

- Pharmaceutical industry: In the pharmaceutical industry, industrial seed grinders are used to grind plant material into a fine powder, which is then used to make medicines and supplements.

- Cosmetics industry: Industrial seed grinders are also used in the cosmetics industry to grind plant material into a fine powder or paste, which is then used in products such as face masks, scrubs, and exfoliants.

- Agricultural industry: Industrial seed grinders are used in the agricultural industry to process seeds, such as soybeans, into animal feed.

- Chemical industry: In the chemical industry, industrial seed grinders are used to grind materials such as resins, pigments, and dyes into a fine powder.

- Renewable energy industry: Industrial seed grinders are also used in the renewable energy industry to process biomass into a fine powder, which is then burned to generate electricity.

Overall, industrial seed grinders are versatile machines that are used in many different industries for a variety of applications. They are essential for processing plant material into fine powders and pastes that can be used in many different products.

Customization Seeds Grinder According to your Capacity:

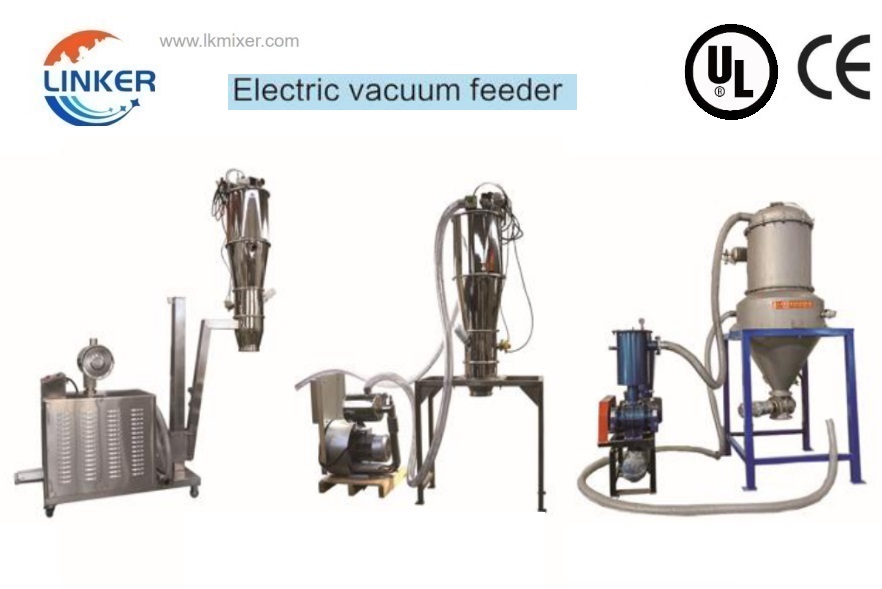

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

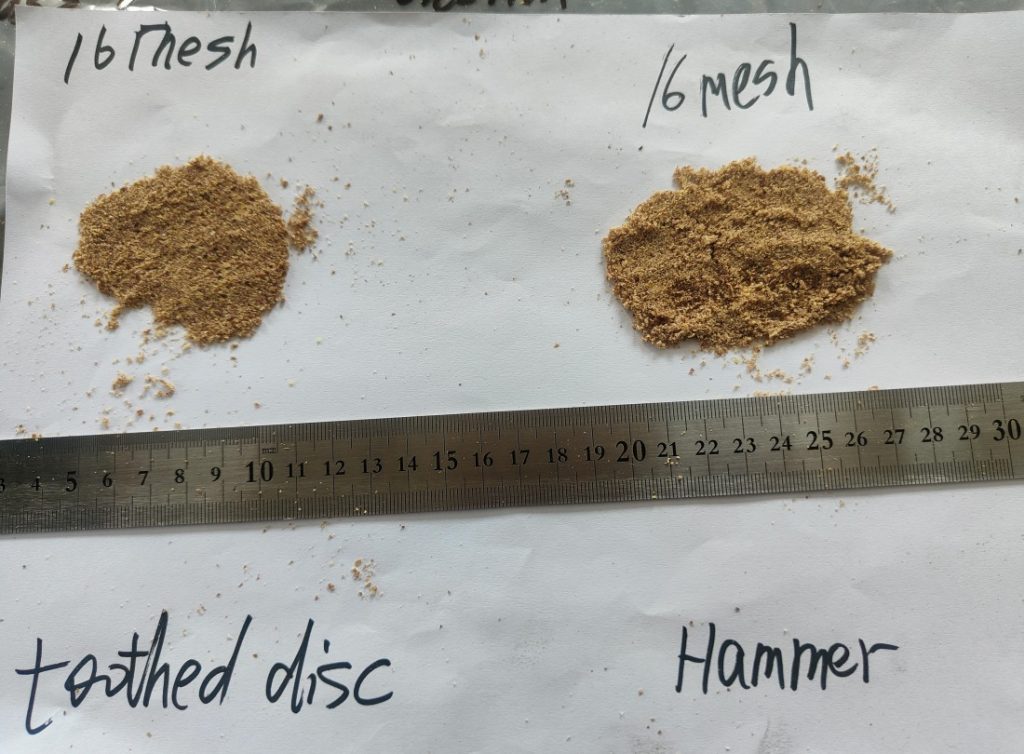

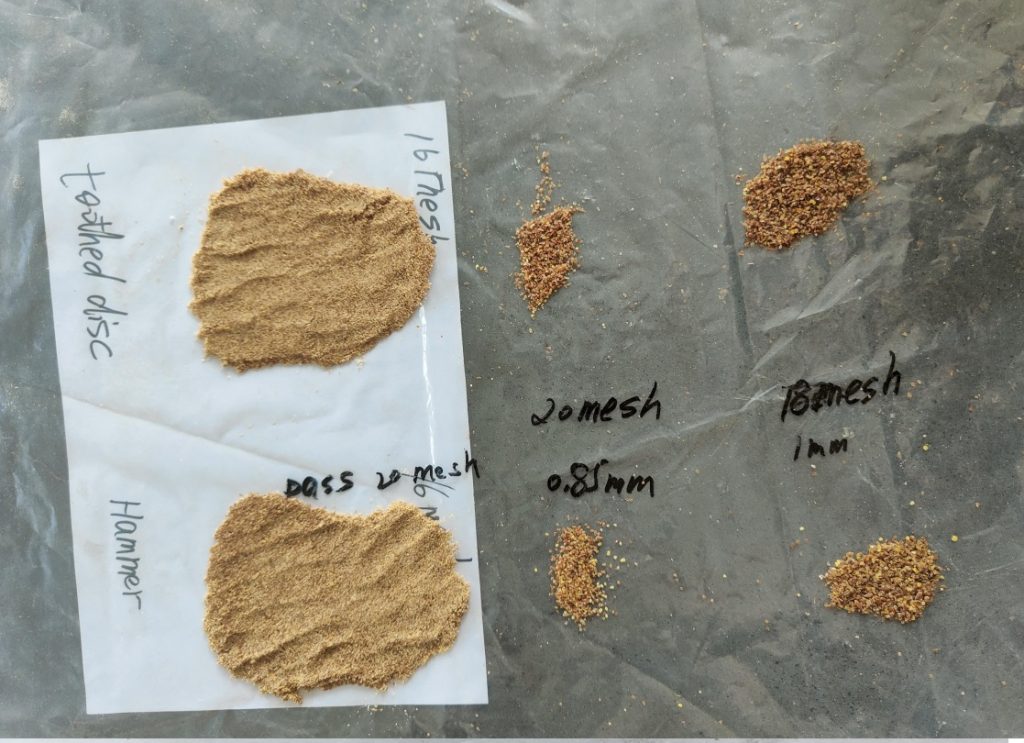

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

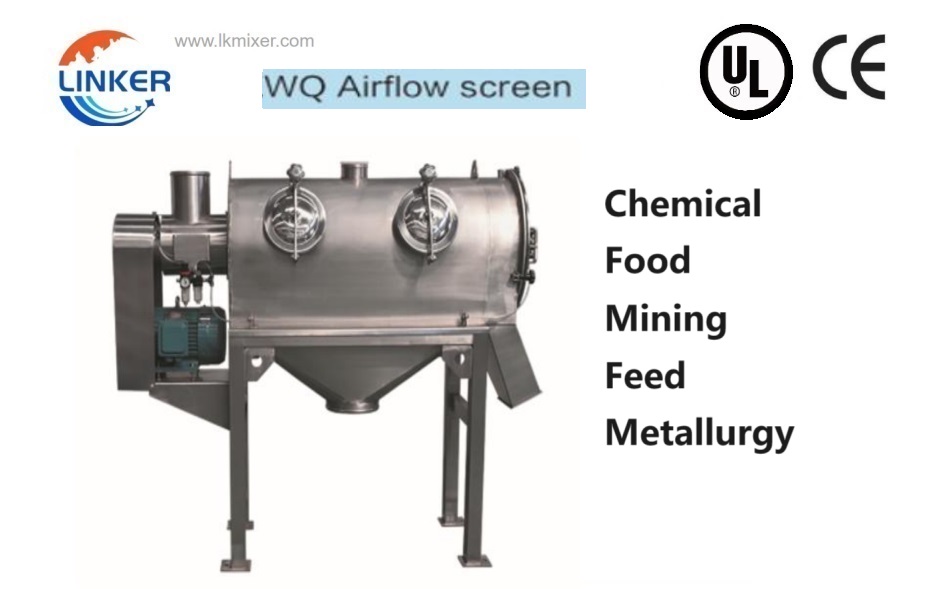

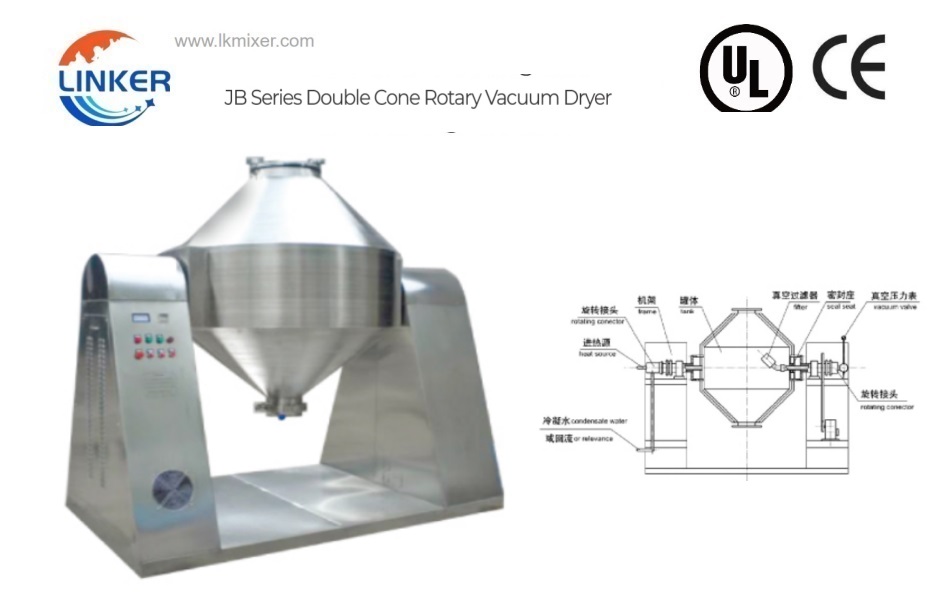

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?