Automatic Ceramic Powder Production Line

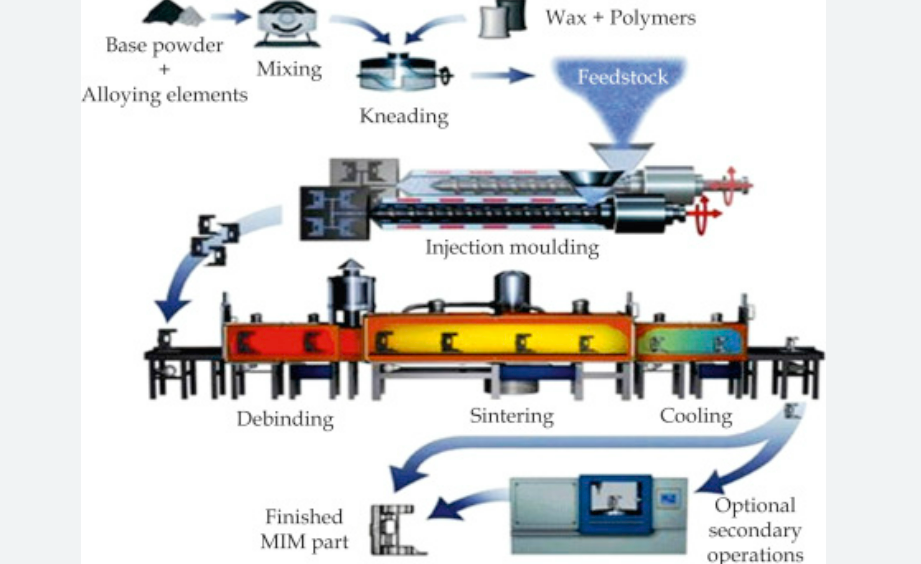

Ceramic Powder Automatic Productino Line Design:

An Automatic Ceramic Powder Production Line is a cutting-edge, highly integrated manufacturing system that makes it possible to produce ceramic powder products continuously and intelligently from raw materials by means of automated controls and perfect process coordination. This process, which offers the benefits of high efficiency, high consistency, and low energy consumption, is widely utilized in electronic ceramics, new energy materials, high-end equipment, and other industries.

Preparation and Storage of Raw Materials

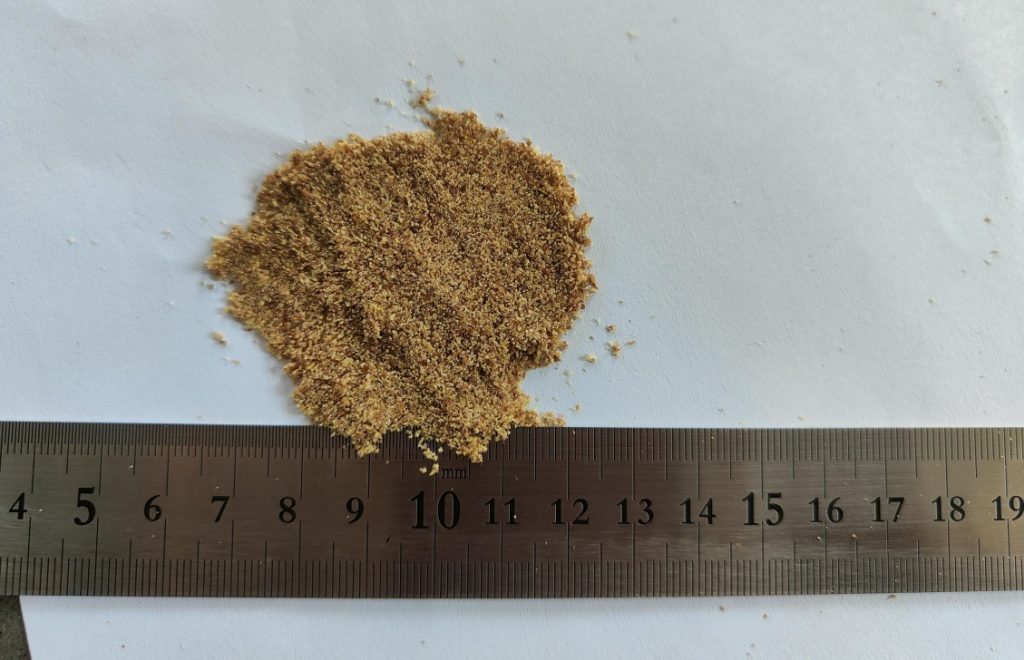

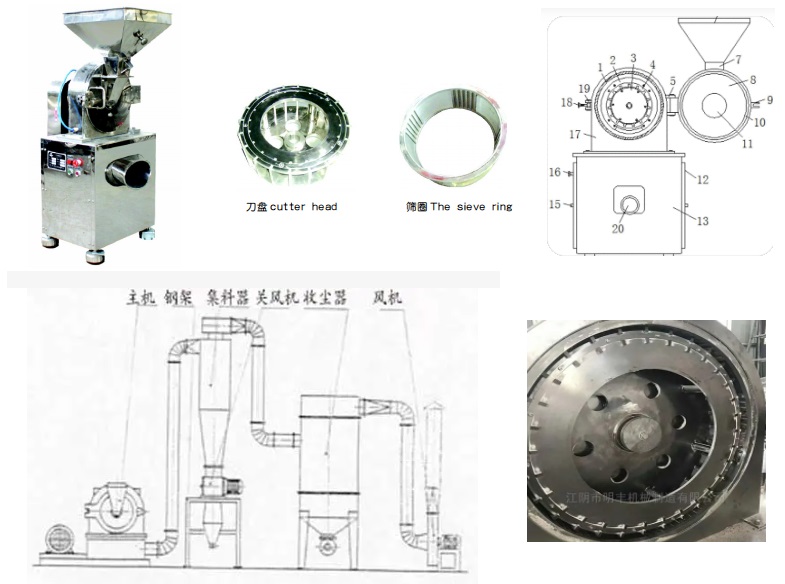

Alumina (AlO₃), zirconia (ZrO₂), quartz, and feldspar are examples of high-purity raw materials that must be carefully chosen and stored before the complete process can begin.The performance requirements of the target product are used to calculate the formulation ratios. To avoid moisture absorption, caking, or contamination, these items are kept apart in dry, well-ventilated warehouses. In order to maintain the consistency of raw material quality, modern production lines are outfitted with sophisticated temperature and humidity monitoring systems. Processing these basic ingredients is the first step. Large chunks are first put through primary crushing in a coarse crusher, such as a jaw crusher. Grinding machinery is subsequently used to further refine the resultant material. For processing goods like tea, spices, or cannabis, a basic herb grinder or small grinder machine might work well, but heavy-duty industrial machinery is needed for ceramic manufacture. A homogeneous powder is achieved through fine grinding in an airflow pulverizer or a ball mill.The particle size is tightly regulated, usually to adhere to 80–200 mesh industry requirements. By preventing particles that are excessively fine or coarse, which could have an adverse effect on future forming and sintering, real-time monitoring using laser particle size analyzers guarantees the distribution curve is appropriate.

Mixing and Batching

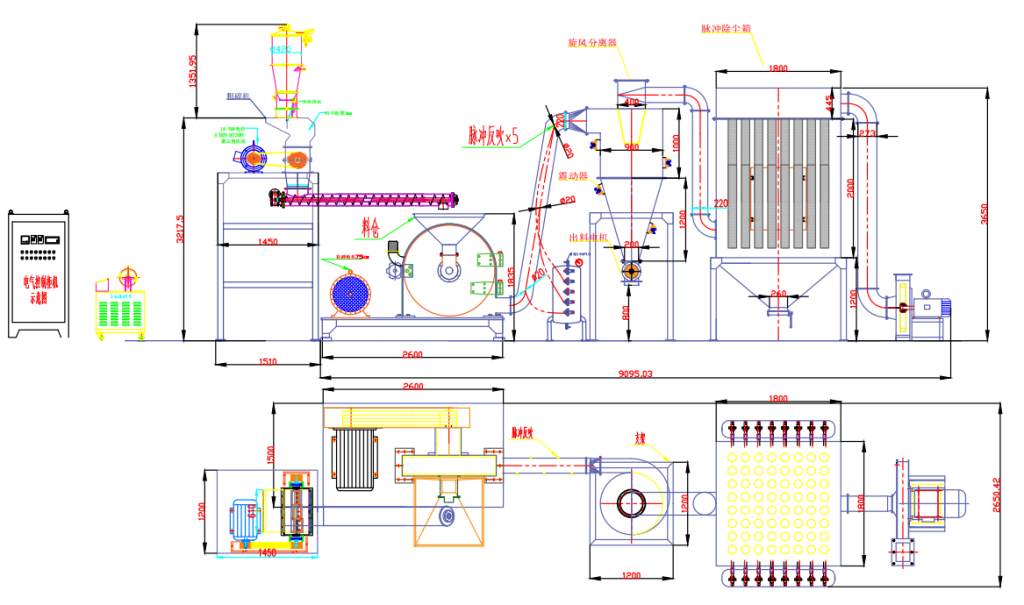

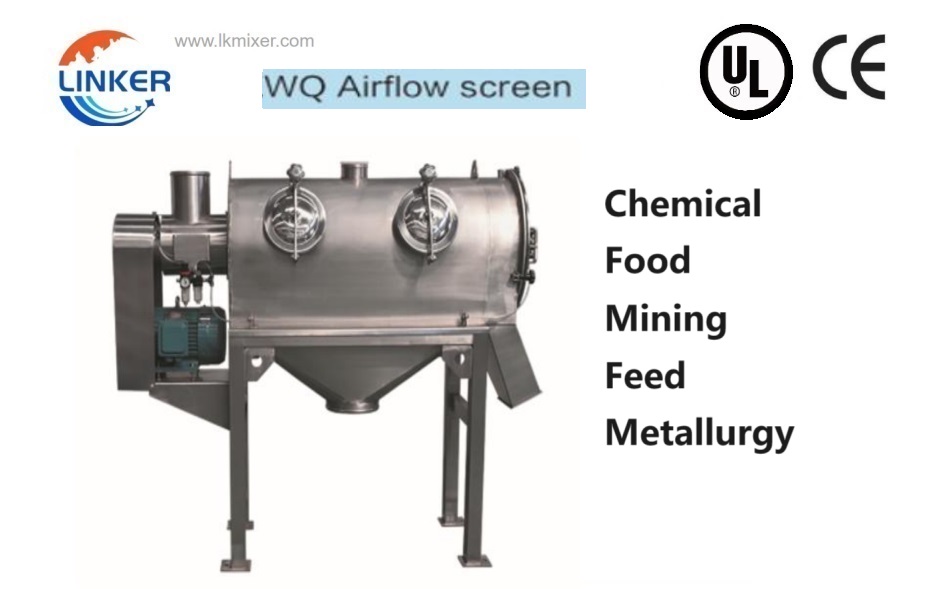

The goal of this stage is to combine basic elements in a precisely homogenous manner. Batching errors are kept within ±0.5% thanks to a coordinated system of electronic scales and belt weighers that guarantees accurate measurement of several substances. Dry mixing and wet mixing are the two main mixing techniques used.Ceramic systems that are susceptible to moisture employ dry mixing. A consistent dry blend is produced by devices like multi-stage blenders and twin-screw mixers. Although it is done on a far bigger and more accurate industrial scale, this technique is essentially comparable to the blending of dry materials used in the food business, such as wheat, salt, sugar, or spice blends. In a ball mill, wet mixing entails mixing the raw materials with water in a precise proportion (30–40% moisture content). This improves homogeneity and dispersion by forming a slurry. To create a free-flowing granulated powder, the slurry is then spray-dried. Following mixing, the slurry or powder is categorized, and cyclones and bag filter dust collector grinder systems are used to collect the fine powder. These devices are essential for keeping the production area clean and catchingFollowing mixing, the slurry or powder is categorized, and the fine powder is gathered using bag filter dust collector grinder systems and cyclones, which are essential for keeping the production area clean and capturing valuable product.

Preparing Powder (Grinding and Granulation)

In order to produce high-performance ceramic powder with the required qualities, this stage is essential. Spray granulation and mechanical grinding are its main components. Mechanical preparation reduces the material to micron or even nanometer-scale fineness using a variety of techniques, such as ball milling, sand milling, or jet milling. The main piece of equipment in this situation is frequently an ultrafine grinder or a specialized airflow pulverizer that runs quickly to produce the desired particle size.A cryogenic grinding machine may be used for some advanced or heat-sensitive materials, just like it is used to treat sensitive medicines, spices (such as black pepper grinder applications), or botanical extracts. The slurry is turned into spherical granules by spray granulation. In a drying tower, the slurry is atomized under high pressure to create spherical particles through quick dehydration. The flowability and compaction behavior of the powder during the ensuing pressing stage are greatly enhanced by this. During this stage, it’s also critical to make sure that sintering aids are evenly distributed throughout the powder for covalent ceramics like silicon nitride.

Pressing and Forming

Automatic powder forming presses, including servo-electric or hydraulic presses, are then used to shape the prepared powder. Typical pressure levels are between 100 and 400 tons.To guarantee consistent green body density, these presses support methods like floating pressing and multi-level structure creation. The entire process of powder feeding, demolding, and part removal is automated by robotic arms, allowing for high equipment utilization rates appropriate for mass manufacturing. The efficiency desired in other industries, such as food packing and electronics assembly, is mirrored in this automation.

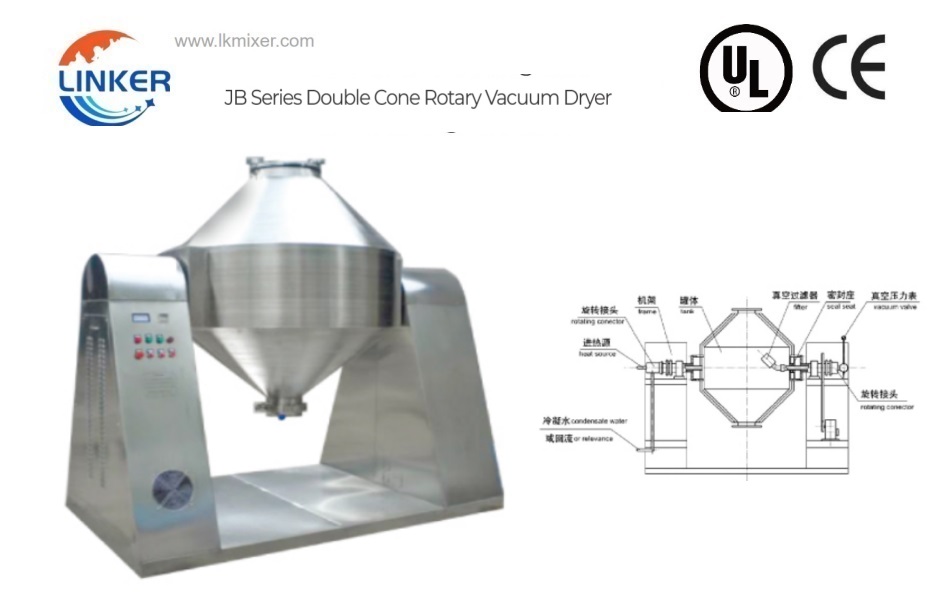

Sintering and drying

The green bodies that have formed are then dried and sintered. They first go into a drying oven with a roller hearth, where they are subjected to heated air that circulates between 80°C and 120°C.By doing this, residual moisture is eliminated and cracking during the high-temperature sintering stage is avoided. For high-volume production, the drying process is made to be quick and effective. The dried bodies are then placed in high-temperature kilns for sintering, such as roller hearth kilns or tunnel kilns. To encourage densification and grain growth, they are burnt at temperatures ranging from 1200°C to 1400°C with carefully regulated holding periods. The most used technique in industrial production is pressureless sintering because of its easier procedure and lower cost.

Examination of Quality and Packaging

The completed goods go through a thorough quality inspection before packaging. Surface flaws (such as bubbles or fractures), dimensional accuracy, hardness, water absorption, and thermal resistance are among the criteria that are tested.Multi-stage magnetic separation devices are employed to prevent metal contamination, and machine vision systems automatically check for surface flaws. Lastly, products that meet the requirements are automatically packaged and palletized for storage. To avoid deterioration or damage from moisture, they are stored in dry, dark conditions. As crucial as it is in the chemical, pharmaceutical, or high-value food industries (e.g., storing rice or coffee), this last handling step ensures the integrity of the product until it is delivered to the consumer.

In conclusion, the Automatic Ceramic Powder Production Line is the ultimate example of industrial automation in the production of sophisticated materials.Although it serves a specific purpose, it is connected to a vast ecosystem of powder processing through the fundamental principles of precise size reduction (using equipment far more robust than a Dry Fruit Powder Grinder Machine or a universal grinder), controlled mixing, automated forming, and strict quality control. The desire for efficiency, consistency, and purity is a common industry objective, whether it’s a 500KG grinder line for making peanut paste or a licorice grinding machine for herbal supplements. Key pieces of equipment in this type of ceramic line are designed to satisfy the exacting requirements of contemporary high-tech manufacturing. They are frequently built with massive stainless steel contact parts and may have certifications like CE Certificate grinder.

Food Producing Process Flow:

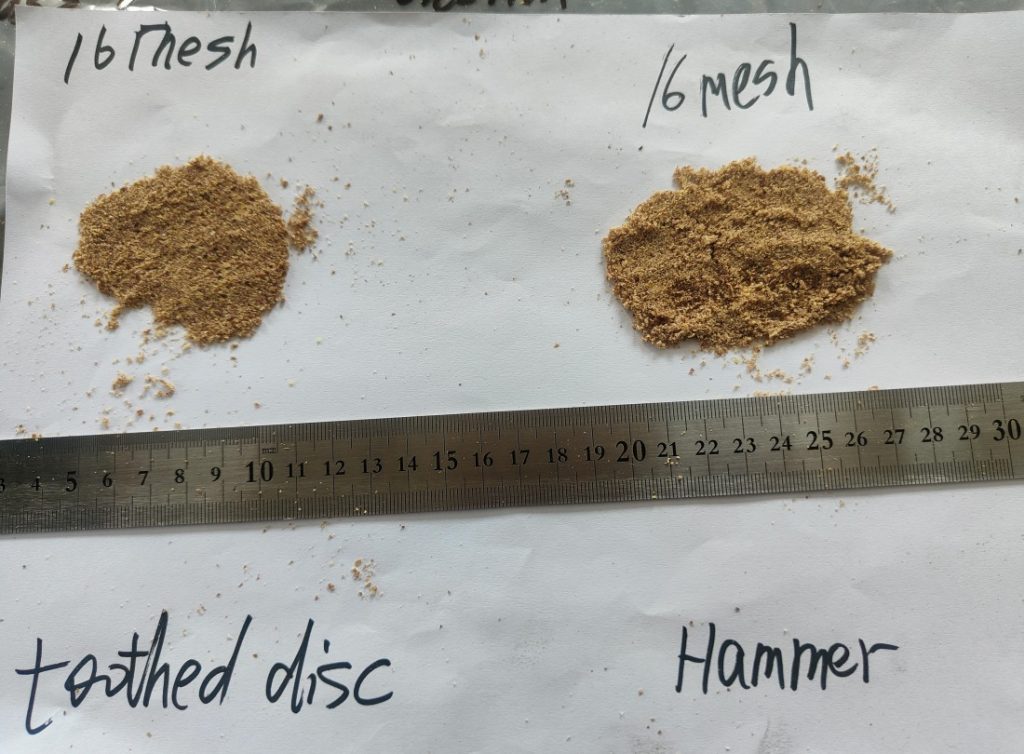

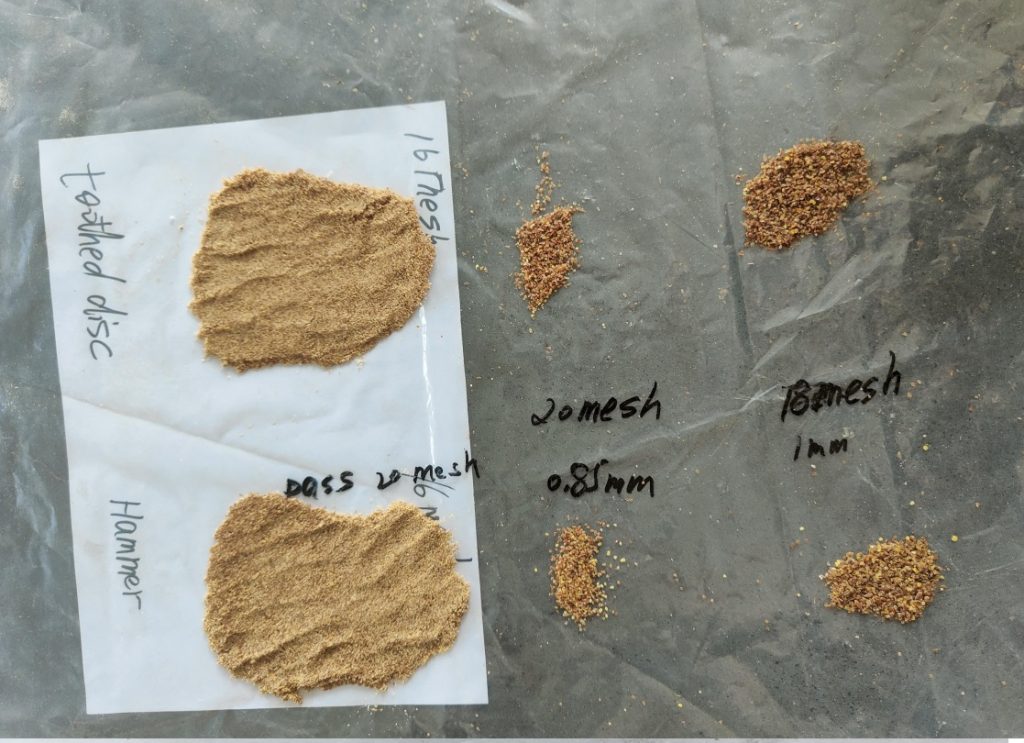

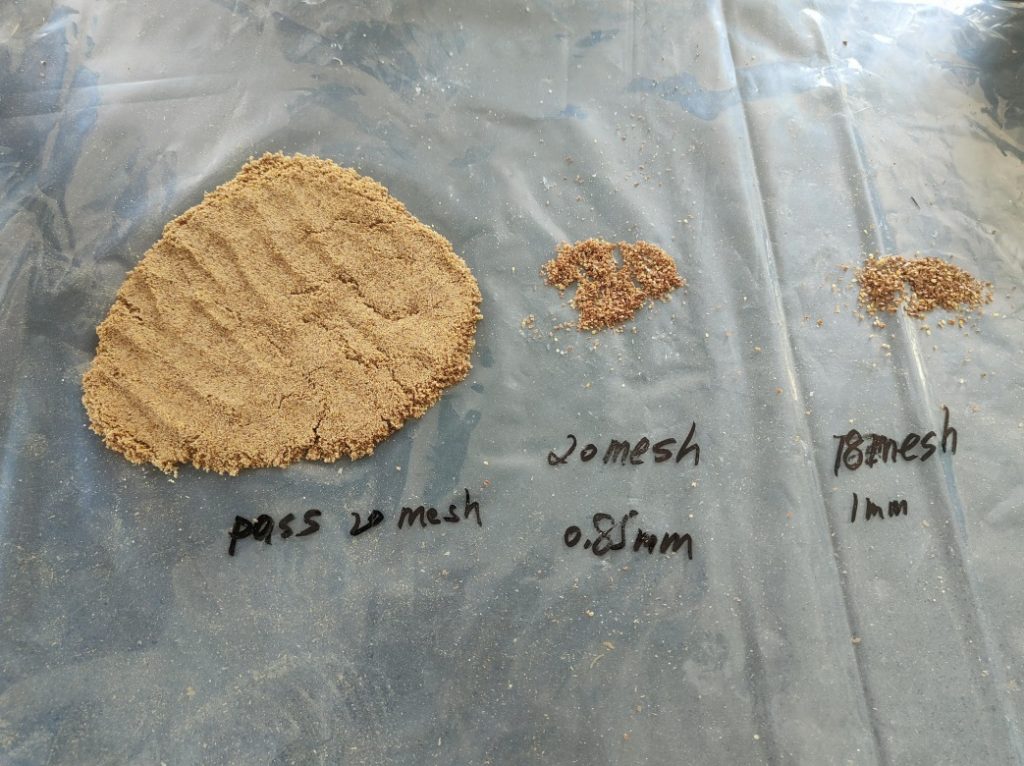

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Automatic Banana Powder Production Line Youtube Video

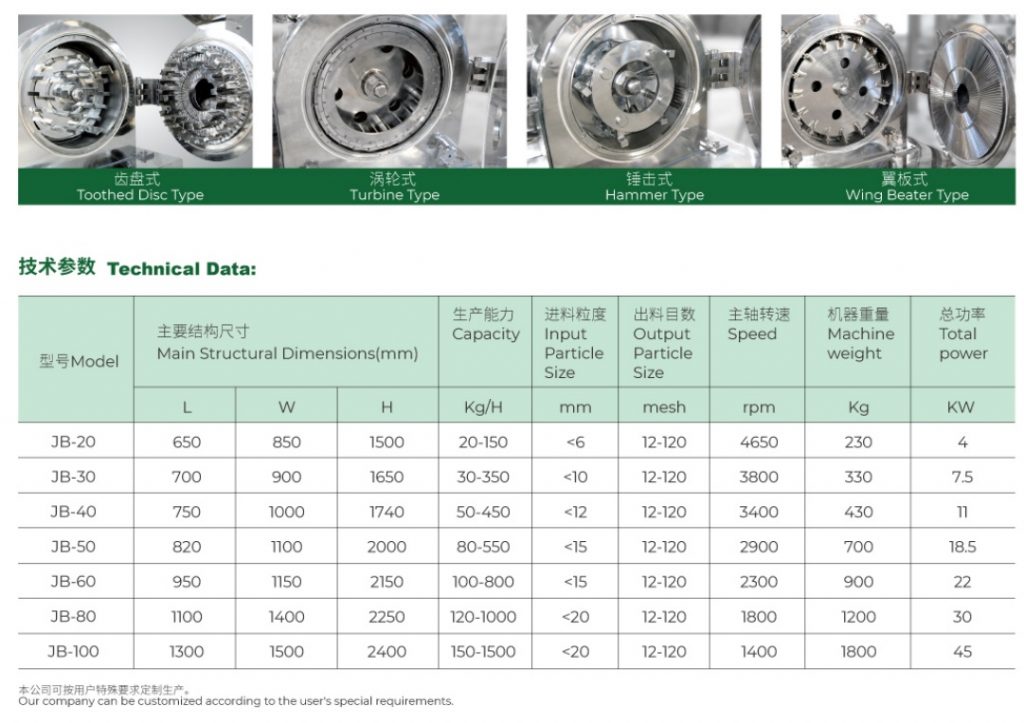

Customization Seeds Grinder According to your Capacity:

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?