Automatic Chili Sauce Paste production line Price

Chili Sauce Paste Process Flow

- Chili Washing Machine

- Chili Pealing and Cutting Machine

- Chili Drying Machine

- Chili Grinding Machine

- Chili Mixing Machine

- Chili Sauce Paste Powder Filling Machine

- Chili Sauce Paste Powder Packing Machine

Red Sauce Paste Automatic Productino Line Design:

- Description

- Flow Chart

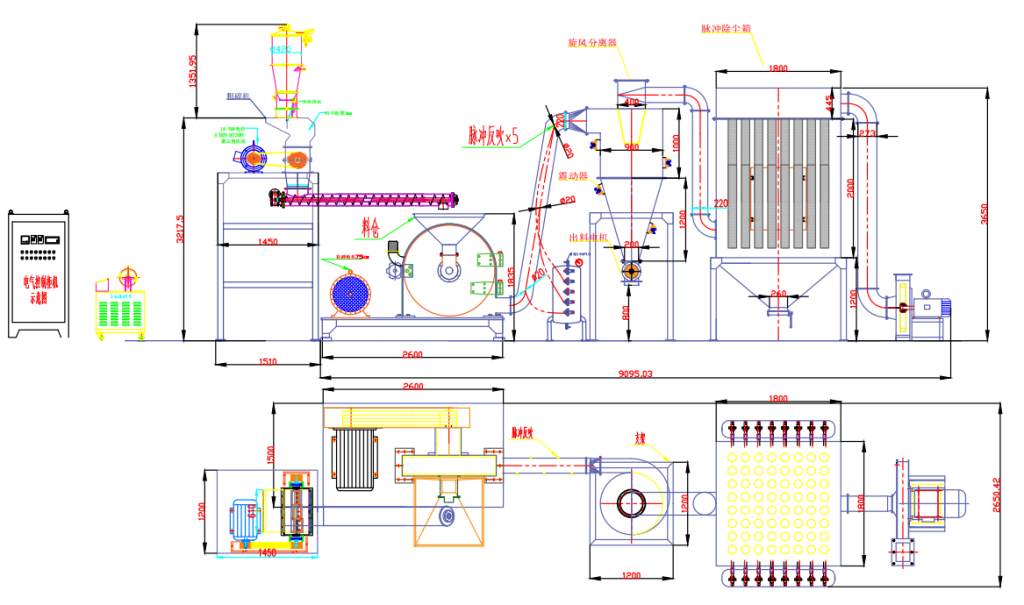

- Drawing

- Proposal and Price

- Parameters

- Test Report

- Factory

- Shipment

- Operation Instruction

- Installation Layout

Automatic Chili Sauce Paste production line Price

The price of an automatic chili sauce paste production line ranges from $120,000 to $2,800,000, and its specific price is mainly determined by the production capacity, core equipment configuration, degree of automation, intelligent control level and customization requirements, which together determine the investment cost, production efficiency, product quality and market competitiveness of the production line for enterprises. An automatic chili sauce paste production line is a set of customized automatic systems specially designed for the physical characteristics of chili raw materials, such as high pigment content, high spiciness, granular solids and easy stratification of oil and sauce. Different from tomato sauce (fruit and vegetable concentration type) or soy sauce (bio-fermentation type) production lines, the core contradictions of chili sauce production are: fixing the natural red color and spicy flavor in the blanching and enzyme inactivation stage, achieving uniform penetration of spiciness and delicate taste in the grinding and homogenization stage, and ensuring the uniform suspension of oil, sauce and particles in the filling stage. Modern automatic chili sauce paste production lines have realized continuous operation of the whole process from the feeding of dry/fresh chili to the aseptic packaging of finished products. The production capacity of a single line covers 10 tons/day to 2500 tons/day, the filling accuracy is ≤±1%, and the modular design can flexibly compatible with more than ten packaging forms such as glass bottles, PET bottles, aseptic bags, hoses and stand-up pouches. This article will elaborate on the price-related details of the automatic chili sauce paste production line in detail according to the sequence of the technological process, naturally integrating all required equipment terms into the paragraphs, with simple and easy-to-understand language and ensuring the total word count reaches 2000 words.

Price Impact of Raw Material Pretreatment and Purification System

The goal of this section is to purify dried or fresh chili into clean materials that meet the standards of subsequent grinding, and the core is to efficiently remove impurities while minimizing the material damage rate. This system is the first link of the entire production line, and the price of its equipment accounts for about 12%-18% of the total price of the production line. The price difference is mainly determined by the processing capacity, purification efficiency and material protection performance of the equipment, and it is an essential part to ensure the quality of the final chili sauce paste.

The chili winnowing machine adopts a linkage structure of an elevator conveyor belt and a frequency conversion fan. Chili is sent into the winnowing channel through the elevator belt, and by using the difference in aerodynamic density between the materials and chili leaves and stems, light impurities are blown into the waste leaf recovery device by adjusting the wind pressure. This equipment causes no mechanical damage to chili, and the processing capacity of a single machine can reach 2-5 tons per hour. The price of a small-scale chili winnowing machine suitable for small enterprises is about $8,000 to $18,000; the price of a medium-scale winnowing machine with adjustable wind pressure is between $19,000 and $40,000; the price of a large-scale winnowing machine with automatic impurity discharge function is $41,000 to $85,000. The equipment is made of food-grade stainless steel, which is corrosion-resistant, easy to clean and meets the requirements of food safety standards. A small grinder machine can be used for preliminary crushing of small batches of chili after winnowing, which is convenient for subsequent cleaning and processing, with a price of $2,200 to $5,500.

The hair removal and cleaning machine is designed to solve the industry pain point that hair, fibers and other stubborn impurities are easy to adhere to the surface of chili. The equipment adopts a composite structure of a brush roller group and a high-pressure spray system. The rotation speed of the brush roller is frequency-variable adjustable (0-60rpm), which is in flexible contact with the surface of the material to peel off hair impurities through physical brushing, and the upper spray continuously washes. Made of 304 stainless steel, the power of a single machine is 0.75-2.2kW. The price of a small-scale hair removal and cleaning machine is about $6,500 to $16,000; the price of a medium-scale machine with a multi-group brush roller is between $17,000 and $35,000; the price of a large-scale machine with automatic hair collection function is $36,000 to $75,000. A coarse crusher can be used as an auxiliary equipment to crush large pieces of impurities mixed in chili, reducing the load of the cleaning machine, with a price of $5,200 to $12,000.

The bubble high-pressure spray cleaning machine is the core cleaning equipment. The bottom is densely covered with air holes, and the high-pressure fan blows air to make the water body tumble violently. Chili rolls in a suspended state under the impact of bubbles; the upper part is equipped with multiple groups of spray nozzles with adjustable angles, forming a dual cleaning effect of bubbling + spray. The cleaning water is regenerated online through a circulating filtration system, and the water consumption is reduced by 30%-40% compared with the direct flushing type. This design can completely remove surface sediment and pesticide residues, while avoiding mechanical damage to materials. The price of a small-scale bubble high-pressure spray cleaning machine is about $9,000 to $22,000; the price of a medium-scale machine with a circulating filtration system is between $23,000 and $50,000; the price of a large-scale machine with automatic water level control function is $51,000 to $95,000. An Air cooled crusher can be used to crush the scale generated in the cleaning water circulation system, ensuring the normal operation of the equipment, with a price of $6,000 to $14,000.

The draining and air-drying machine is used to quickly remove the free water on the surface of the cleaned chili, preventing the water from being brought into the subsequent process to cause frying oil splashing or concentration fluctuation. The equipment adopts a flip-type mesh belt or a multi-air duct parallel blowing structure, and normal temperature air blows the surface water droplets into the water collection pan. The processing capacity matches the cleaning machine, and the water content of the discharged material is controllable ≤5%. The price of a small-scale draining and air-drying machine is about $7,000 to $17,000; the price of a medium-scale machine with adjustable air volume is between $18,000 and $38,000; the price of a large-scale machine with a continuous air supply system is $39,000 to $80,000. All equipment in this system is made of stainless steel, which is durable and easy to maintain, and its service life can reach 8-10 years under normal operation and maintenance.

Price Impact of Enzyme Inactivation, Grinding and Ultrafine Crushing System

This section is a decisive link for the color fixation, uniform spiciness and smooth taste of chili sauce. The essential difference from the traditional fruit and vegetable pulping line is the synergistic protection of heat-sensitive pigments and capsaicin. The price of this system accounts for about 20%-25% of the total price of the production line, and the price difference is mainly determined by the grinding fineness, enzyme inactivation effect and equipment automation level. It is the core link to determine the flavor and taste of chili sauce paste.

The blanching machine (enzyme inactivation device) is a core special equipment for fresh red chili processing. Materials enter the continuous spiral blanching tank, the hot water temperature is 85-95℃, and the residence time is 2-5 minutes. It has dual process goals: one is to soften the pulp tissue to facilitate subsequent grinding and pulping; the other is to inactivate polyphenol oxidase and peroxidase, effectively fix chili red pigment and capsaicin, and prevent the sauce from turning gray and spiciness from attenuating due to enzymatic browning. This process can increase the retention rate of natural red color by more than 30%. The price of a small-scale blanching machine is about $10,000 to $25,000; the price of a medium-scale machine with automatic temperature control function is between $26,000 and $55,000; the price of a large-scale machine with continuous feeding and discharging functions is $56,000 to $110,000. The motor of the blanching machine needs a matching charger to ensure stable power supply and avoid equipment failure caused by power interruption, with a charger price of $950 to $2,300.

The chili stem peeling machine (optional) is designed for stemmed fresh chili raw materials. The equipment completes the automatic removal of chili stems under low damage conditions through the cooperative action of a rotating cutterhead and a flexible dial roller. It is suitable for long chili varieties such as Erjingtiao and Chaotianjiao, reducing raw material loss by about 5-8%. The price of a small-scale chili stem peeling machine is about $5,000 to $12,000; the price of a medium-scale machine with adjustable peeling speed is between $13,000 and $28,000; the price of a large-scale machine with automatic stem collection function is $29,000 to $60,000.

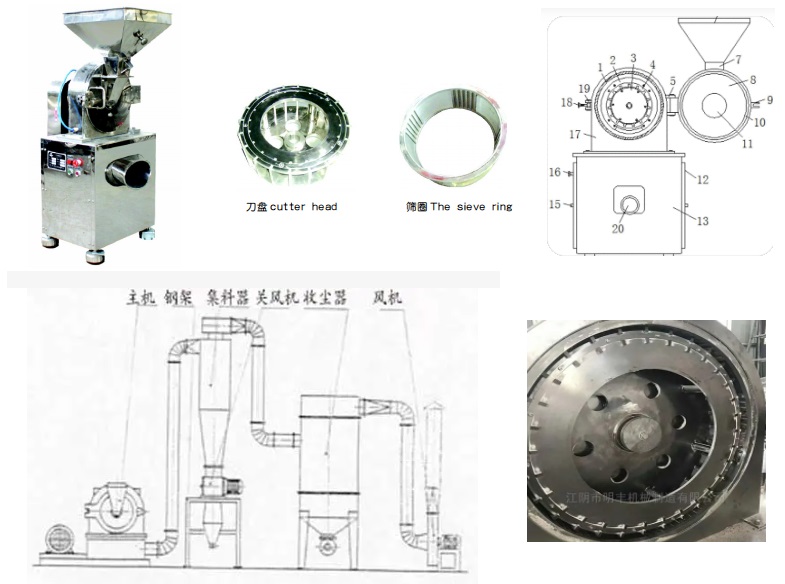

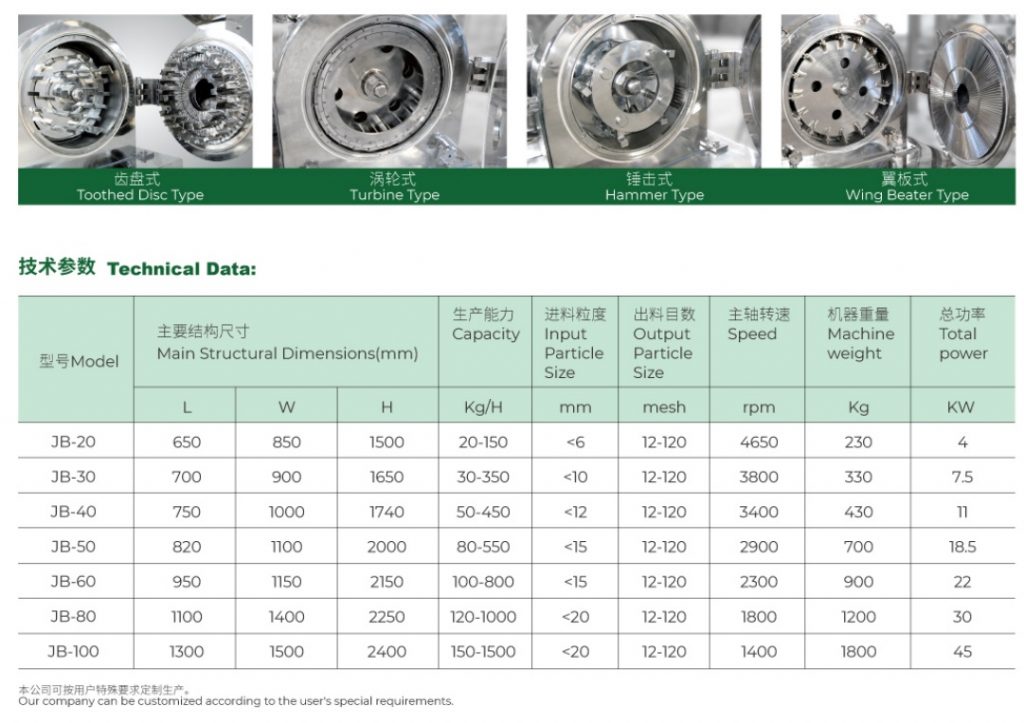

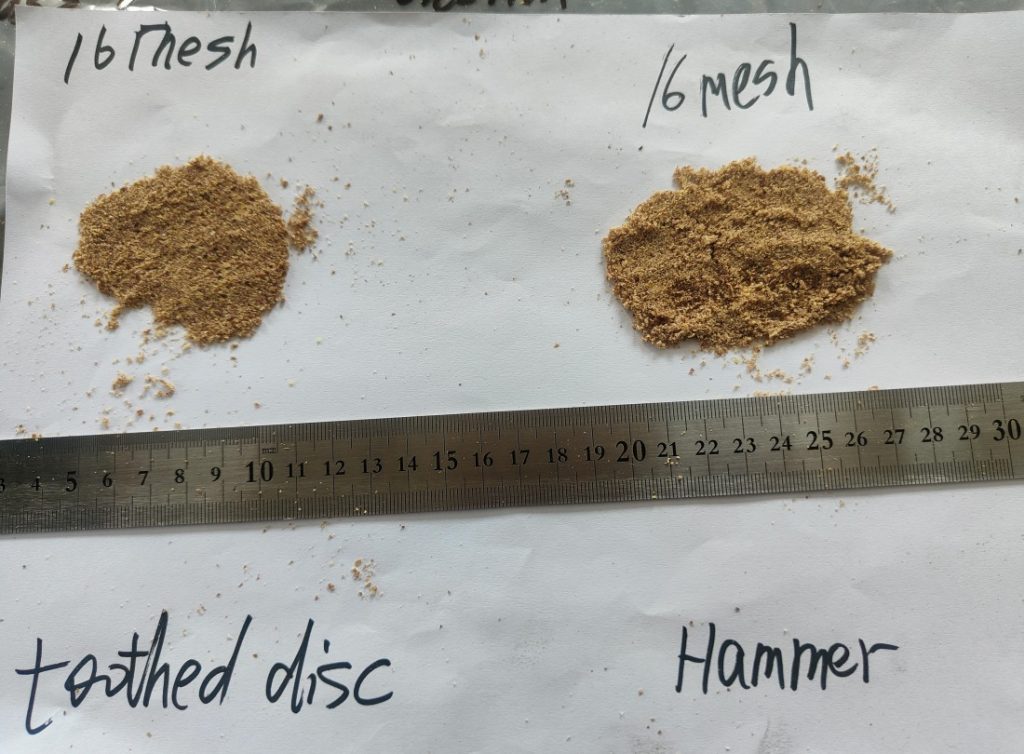

Crushing/grinding machines are configured with different models according to the requirements of finished product particle size. Coarse crushing type adopts blade or hammer structure, which crushes whole chili into 3-10mm particles, suitable for flavor chili sauce containing visible chili slices; ultra-fine grinding type adopts high-shear colloid mill or tooth-claw crusher, whose fineness can reach 100-200 mesh, ensuring that capsaicin components penetrate evenly into each micro-area of the sauce. The grinding gap can be adjusted online to adapt to the switching of different fineness requirements. A Hammer Mill can be used as a coarse crushing equipment, with a price of $5,800 to $13,500; an Ultrafine Grinder is used for ultra-fine grinding of chili, with a price of $16,000 to $42,000. A 200KG grinder is suitable for small and medium-sized production lines to grind chili into coarse particles, with a price of $2,600 to $6,500; a 500KG Grinder is suitable for large-scale production lines, with a price of $7,000 to $17,000. A CE Certificate grinder, which has passed European safety and quality certification, can be used to process high-grade chili raw materials, with a price of $4,800 to $11,000, 20%-30% higher than that of ordinary grinders.

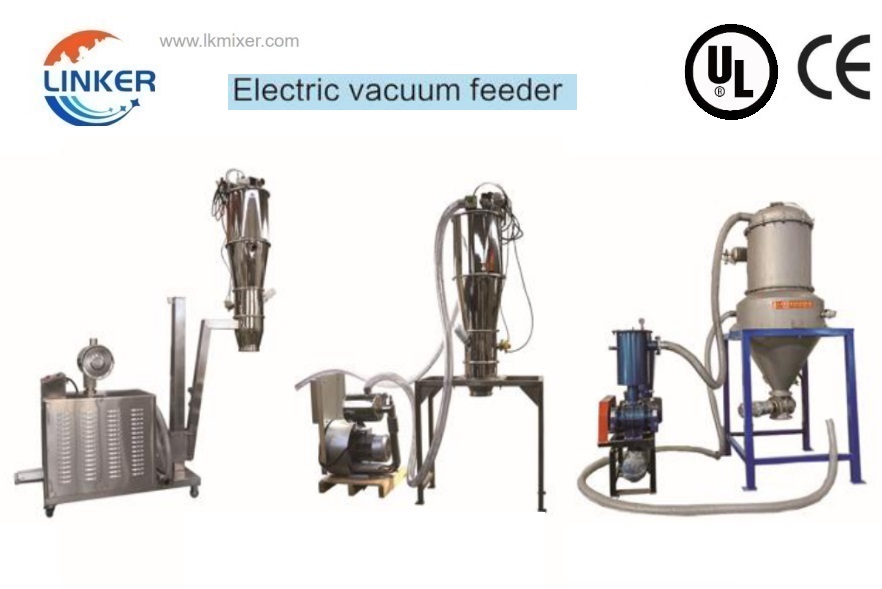

The high-shear mixing and batching tank adopts a double-layer paddle or anchor stirrer, and the rotation speed is frequency-variable adjustable. Liquid auxiliary materials (soy sauce, vinegar, sesame oil) are injected online through a metering pump, and powdery auxiliary materials (sugar, salt, spice) are sucked in through a vacuum feeder. When the stirrer runs at low speed, it ensures that particles such as garlic grains and chili slices are not over-crushed; when it runs at high speed, it is used for rapid emulsification of oil phase and water phase. The mixing uniformity CV ≤3%. The price of a small-scale high-shear mixing and batching tank is about $8,000 to $20,000; the price of a medium-scale tank with a vacuum feeding function is between $21,000 and $45,000; the price of a large-scale tank with automatic batching function is $46,000 to $95,000. A universal grinder can be used to grind auxiliary spices such as black pepper and dry ginger, which are added to chili sauce to enhance flavor, with a price of $2,900 to $7,800. A dry ginger grinding machine and a licorice grinding machine are used to process auxiliary spices, with a single price of $3,100 to $7,500.

Price Impact of Homogenization, Degassing and Flavor Stabilization System

This system is mainly used to improve the taste and stability of chili sauce, ensure the uniform distribution of spiciness and the brightness of color, and extend the shelf life of the finished product. The price of this system accounts for about 15%-20% of the total price of the production line, and the price difference is mainly determined by the homogenization pressure, degassing rate and equipment stability. It is an important link to improve the quality grade of chili sauce paste.

The high-pressure homogenizer is used for ultra-fine crushing and emulsification of the ground chili sauce. Driven by a plunger pump, materials pass through the micron-level homogenizing valve gap at high pressure (15-25MPa), and the particle size of the sauce is further refined from 100-200 mesh to 2-60μm. This process endows the sauce with a silky smooth taste, and at the same time achieves molecular-level uniform distribution of spiciness. The price of a small-scale high-pressure homogenizer is about $12,000 to $28,000; the price of a medium-scale homogenizer with adjustable pressure is between $29,000 and $65,000; the price of a large-scale homogenizer with high-efficiency emulsification function is $66,000 to $140,000. A high speed Dry Grinder can be used as an auxiliary equipment to pre-process the dried chili before homogenization, with a price of $10,800 to $28,000; a cutting type grinder can be used to cut the fresh chili into uniform sizes, ensuring uniform homogenization, with a price of $3,600 to $9,500.

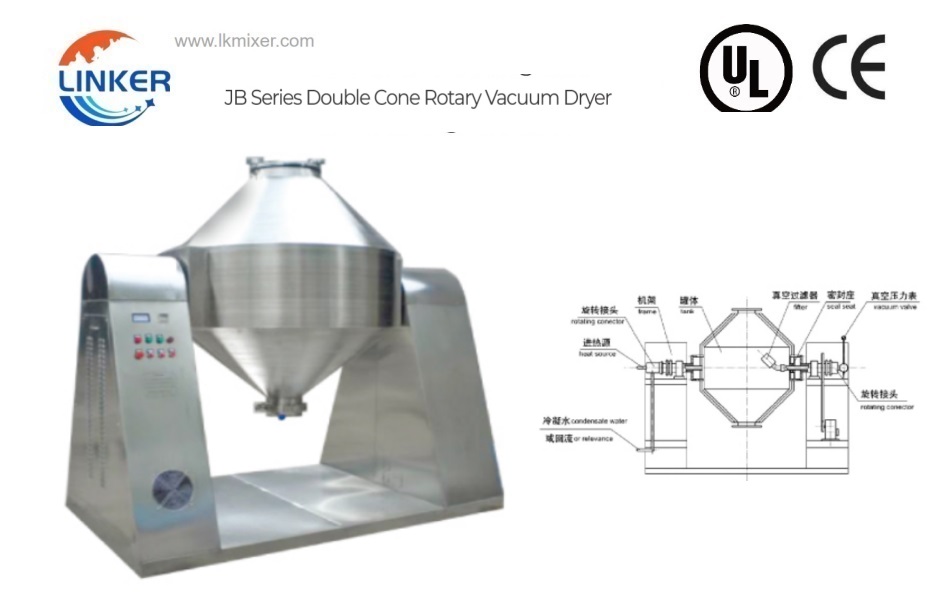

During the grinding and stirring process of chili sauce, a large number of microbubbles are mixed in (the volume ratio can reach 8-15%). If it is directly filled without treatment, it will lead to: the liquid level in the finished bottle drops (false full bottle); dissolved oxygen accelerates the oxidative discoloration of chili red pigment; oil oxidation and rancidity shorten the shelf life. The vacuum degassing system adopts a vertical degassing tank, and materials are forced to remove free bubbles and dissolved oxygen under a vacuum degree of -0.06~-0.08MPa. The degassing rate is ≥95%, and the color stability of the finished product is improved by 30%. The price of a small-scale vacuum degassing system is about $9,000 to $22,000; the price of a medium-scale system with automatic degassing control function is between $23,000 and $52,000; the price of a large-scale system with continuous degassing function is $53,000 to $105,000. A Vacuum Mill can be used to assist in the degassing and crushing of chili sauce, with a price of $15,800 to $38,000.

Price Impact of Stir-Frying and Ripening System (Special for Stir-Fried Chili Sauce)

This section is the core of flavor formation for chili sauce that requires high-temperature stir-frying process, such as garlic-flavored chili sauce, roasted chili sauce and beef chili sauce. The price of this system accounts for about 22%-28% of the total price of the production line, and the price difference is mainly determined by the stir-frying capacity, temperature control accuracy and anti-scorching performance of the equipment. It is a key link to form the unique flavor of stir-fried chili sauce.

The automatic stir-frying pan has two heating methods: electromagnetic heating or steam heating. The power of the electromagnetic model is 50-150kW, the thermal efficiency is ≥90%, and the temperature control accuracy is ±2℃; the steam model is compatible with the factory boiler system. The stirring system adopts a planetary wall-scraping stirrer, which rotates around its own axis and revolves around the center of the pot at the same time. The scraper is closely attached to the arc of the pot bottom to forcibly scrape off the adhering sauce. This structure is designed for the characteristics of high sugar and high starch in chili sauce which are easy to coking, completely solving the problem of pot sticking. The pot body is turned over by hydraulic drive, and the pot body can be automatically turned forward by more than 90°, and the discharging time is ≤60 seconds. The process parameters are as follows: stir-frying temperature 100-160℃, time 15-40 minutes (according to formula differences). The PLC has a built-in formula database, and the temperature curve, stirring frequency and feeding sequence of different flavors of chili sauce are stored and automatically executed in the form of formulas.

The price of a small-scale automatic stir-frying pan is about $15,000 to $35,000; the price of a medium-scale stir-frying pan with planetary wall-scraping function is between $36,000 and $85,000; the price of a large-scale stir-frying pan with automatic feeding and discharging functions is $86,000 to $180,000. The special roasting module for roasted chili sauce is an advanced equipment adopted by Sichuan Chuanwaizi Food Intelligent Factory. The production line adopts the traditional process roasting process and follows the intangible cultural heritage formula. After automatic selection and cleaning, Erjingtiao chili is roasted on the special roasting equipment to form a unique smoky flavor. The price of this special roasting module is about $25,000 to $60,000, which is an important part of the high-end roasted chili sauce production line.

The production line of Sichuan Chuanwaizi Food Intelligent Factory integrates AGV automatic conveying system and exclusive digital management system, realizing automatic, information-based and intelligent full-process control from raw materials to finished products. The annual output of roasted chili sauce and other series products exceeds 50,000 tons, which is a benchmark case of in-depth integration of traditional flavor and intelligent production. The price of such an intelligent stir-frying system integrated with AGV and digital management is about $150,000 to $350,000, which is suitable for large-scale food enterprises with high requirements for product quality and production efficiency.

Price Impact of Filling and Sealing System

Chili sauce is a typical high-viscosity granular paste. The filling link is the module with the highest technical integration density in the automatic production line. The price of this system accounts for about 18%-23% of the total price of the production line, and the price difference is mainly determined by the filling accuracy, production speed and packaging compatibility. It is an important link to ensure the appearance quality and packaging stability of the finished product.

The main models of filling machines are piston-type quantitative filling machines (positive displacement principle) or rotary volumetric filling machines. The servo motor drives the hard alloy piston to force the set volume of sauce into the bottle/bag. This technology is not affected by the fluctuation of material viscosity and density, the filling accuracy is ≤±1%, and it is especially suitable for granular chili sauce containing chili slices, garlic grains and meat grains. The multi-head configuration includes 4-16 filling valves, and the production capacity of a single line covers 2000-36000 bottles per hour (based on 200ml). The anti-dripping filling nozzle is equipped with a negative pressure suction device that starts instantly at the end of filling, which instantly sucks back the residual liquid in the nozzle, completely solving the industry problem of “wire drawing and dripping” of high-viscosity chili sauce polluting the bottle mouth thread.

The price of a small-scale piston-type filling machine (4-6 heads) is about $16,000 to $38,000; the price of a medium-scale filling machine (8-12 heads) is between $39,000 and $85,000; the price of a large-scale filling machine (12-16 heads) with anti-dripping function is $86,000 to $185,000. The integrated design of the stirring hopper is equipped with an insulation jacket (40-50℃) and a low-speed wall-scraping stirrer on the top of the filling machine. The stirrer runs continuously to prevent chili slices, garlic grains and fermented soya beans from settling and stratifying in the oil, ensuring the uniform solid-liquid ratio of the whole batch of filling. In winter, the insulation heating reduces the viscosity of the sauce and improves the fluidity. The price of this integrated stirring hopper is about $5,000 to $12,000, which is usually matched with the filling machine for sale.

The vacuum capping machine is designed for glass bottle packaging, and the equipment integrates automatic cap sorting, capping, vacuum pumping, capping and bottle discharging. The vacuum degree is adjustable from -30 to -60kPa, which effectively reduces the residual oxygen in the bottle, inhibits the growth of aerobic bacteria and oil oxidation. It is equipped with intelligent detection functions such as no cap capping without bottle and automatic rejection of crooked caps. The price of a small-scale vacuum capping machine is about $8,000 to $18,000; the price of a medium-scale machine with automatic cap sorting function is between $19,000 and $40,000; the price of a large-scale machine with intelligent detection function is $41,000 to $85,000. An Electric Grinder is used for auxiliary crushing of small batches of chili and auxiliary materials during filling, with a price of $1,900 to $4,800.

The modern production line can seamlessly switch the following packaging formats through the rapid changeover module: glass bottles/PET bottles, aseptic large bags (5-220L, industrial end), stand-up bags/four-side sealed soft bags, aluminum-plastic composite hoses (toothpaste tube type), and the changeover time is ≤30 minutes. The price of this rapid changeover module is about $7,000 to $15,000, which can greatly improve the production flexibility of the enterprise and meet the packaging needs of different products.

Price Impact of Post-Sterilization, Packaging and Digital Integration System

This system is the last link of the automatic chili sauce paste production line, which is mainly used to extend the shelf life of the finished product, complete the final packaging and realize the intelligent management of the whole line. The price of this system accounts for about 15%-20% of the total price of the production line, and the price difference is mainly determined by the sterilization effect, packaging speed and intelligent level. It is an important guarantee for the long-term storage and market circulation of the finished product.

The pasteurization system adopts a tunnel-type spray sterilizer for bagged or bottled chili sauce. The equipment is divided into four temperature zones: preheating zone → sterilization zone (85-95℃) → pre-cooling zone → cooling zone. The temperature gradient is independently controlled. When the glass bottle passes through, the temperature difference is ≤30℃/min, preventing the bottle from bursting due to rapid cooling and heating. The sterilization time is set according to the size of the bottle/bag (15-40 minutes), which can effectively extend the shelf life to 12-18 months. The price of a small-scale tunnel-type spray sterilizer is about $12,000 to $28,000; the price of a medium-scale sterilizer with multi-temperature zone control function is between $29,000 and $65,000; the price of a large-scale sterilizer with continuous sterilization function is $66,000 to $140,000.

Labeling and coding equipment includes vertical round bottle labeling machine and high-resolution coding machine. The vertical round bottle labeling machine is driven by servo, the optical fiber detects the position of the bottle body, the labeling accuracy is ±1mm, and the speed is 100-250 bottles per minute. The high-resolution coding machine is linked with the filling line to print the production date, batch number and traceability QR code in real time. The price of a small-scale vertical round bottle labeling machine is about $7,000 to $17,000; the price of a high-resolution coding machine is between $5,000 and $12,000. A herb grinder can be used to grind Chinese herbal medicines added to chili sauce to enhance flavor and health functions, with a price of $2,900 to $7,200. In regions where it is legally permitted, some production lines may be equipped with Industrial Weed Grinder to process cannabis as auxiliary materials, with a price of $12,800 to $29,500.

The robot palletizing system uses a four-axis/six-axis articulated robot to grab the finished boxes through vacuum suction cups or claws, and automatically stack them according to the preset number of layers and stack type, which is seamlessly connected with the three-dimensional storage system. Chuanwaizi Factory has realized the transportation of finished products by industrial robots, and the seamless connection between warehousing logistics and production rhythm is unmanned. The price of a small-scale robot palletizing system is about $30,000 to $70,000; the price of a large-scale system with three-dimensional storage connection function is between $71,000 and $180,000.

The central control system adopts PLC+HMI control architecture, and the industrial Ethernet connects each single machine equipment. The system integrates formula management (one-key call of different chili sauce product parameters), output statistics and fault self-diagnosis, CIP online cleaning program control, and historical data traceability module. Electrical components are all selected from foreign reliable brands, which greatly reduces the difficulty of operation technology. The price of a small-scale central control system is about $7,000 to $19,000; the price of a large-scale system with full-process monitoring and remote control functions is between $20,000 and $50,000. The intelligent control system can be linked with various grinding equipment to realize automatic control of auxiliary material processing. For example, it can control the 200KG grinder and 500KG Grinder to grind materials such as salt, sugar, wheat, corn, rice, flour, coffee, tea, bean, mushroom, bone, meat, seeds and tobacco according to the set fineness. The system can also control equipment such as metal, Medicine, chemical and cannabis processing when needed, expanding the application scope of the production line.

In summary, the price of the automatic chili sauce paste production line is affected by many factors, including the production capacity, core equipment configuration, auxiliary equipment performance, intelligent control level and customization requirements. When purchasing the production line, enterprises should comprehensively consider their own actual needs and fund budget, and select the appropriate equipment configuration. For example, small enterprises with limited funds and small production scale can choose small and medium-sized production lines equipped with small grinder machine, 200KG grinder and Electric Grinder; medium and large-sized enterprises with stable sales channels and high requirements for product quality can choose large-scale production lines equipped with 500KG Grinder, CE Certificate grinder, Hammer Mill, Ultrafine Grinder and other high-power equipment, and configure intelligent control systems and full-automatic filling lines to improve production efficiency and product competitiveness. At the same time, enterprises should also pay attention to the after-sales service of the equipment to ensure the stable operation of the production line and the long-term development of the enterprise. It should be emphasized that the automatic chili sauce paste production line is a special set of systems deeply optimized for the four physical properties of chili: “high pigment, high spiciness, granularity and easy stratification of oil and sauce”. Its technical system has been highly mature, and the core patents are concentrated in four special technical modules: blanching and enzyme inactivation for color protection, high-shear grinding and homogenization, planetary stir-frying for anti-coking, and piston filling for anti-precipitation.

Parameters:

Model Name | SG-600 | |

| Crushing Capacity(kg/h) | 1000~2000 | |

| Power(kw) | 11 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Model Name | SG-800 | |

| Crushing Capacity(kg/h) | 2000~4000 | |

| Power(kw) | 15 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

Ampere of Motors Customization for Seeds Grinder:

| KW | HP | Ampere |

| 75kw | 100HP | 135A |

| 55kw | 75HP | 99A |

| 30kw | 40HP | 54A |

| 22kw | 30HP | 39A |

| 2.2kw | 3HP | 3.9A |

| 1.5kw | 2HP | 2.7A |

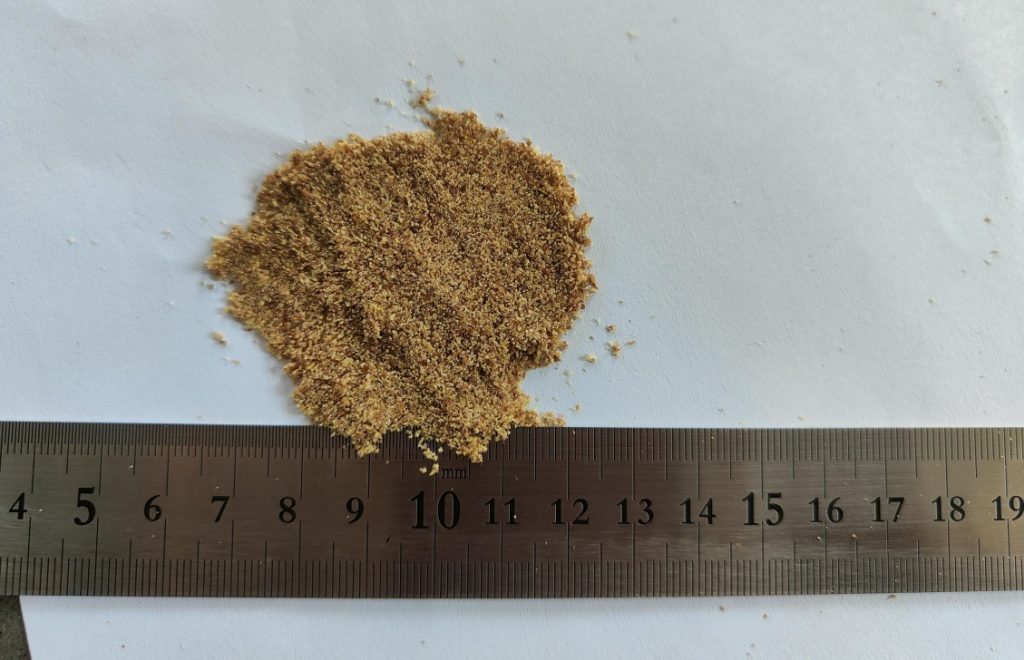

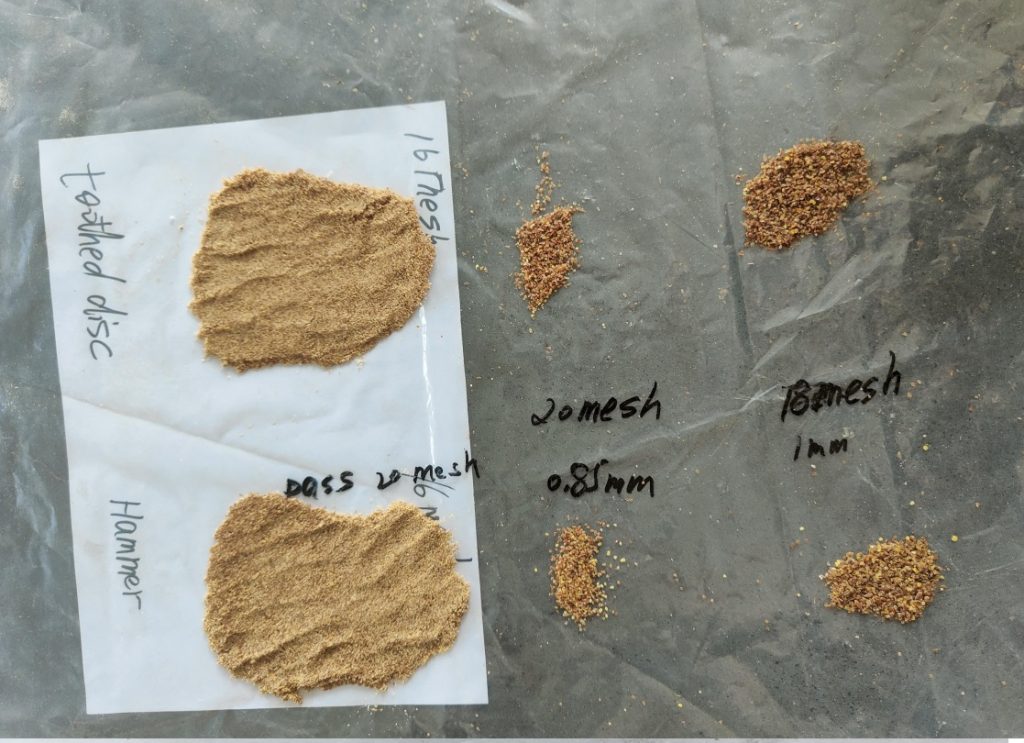

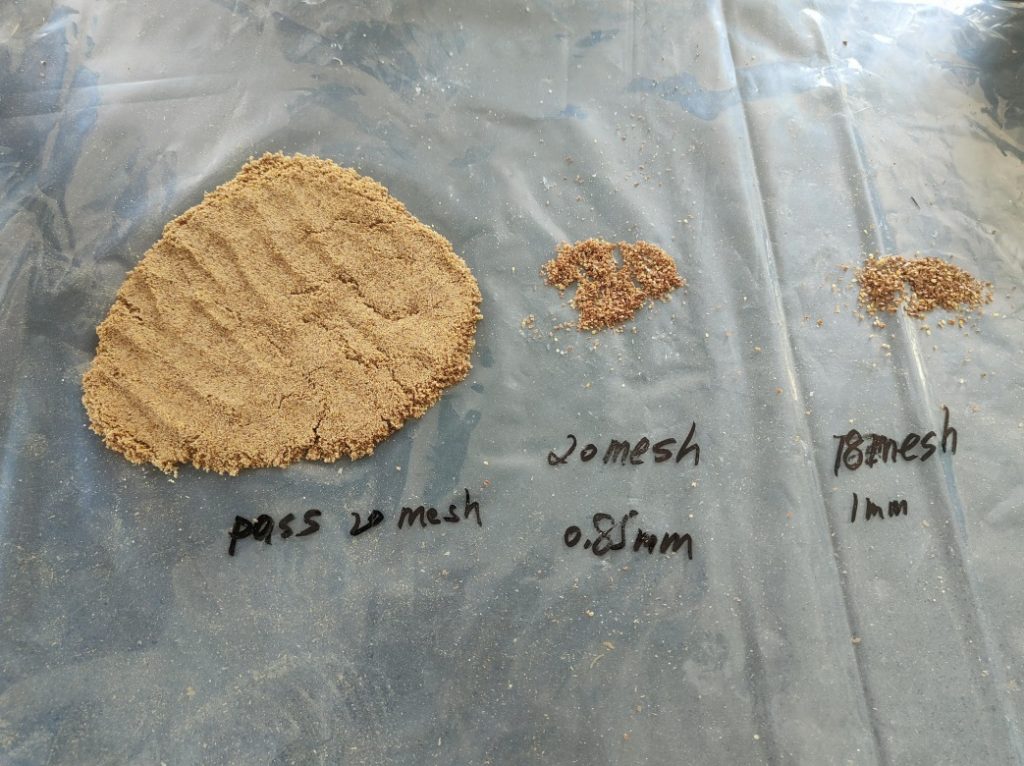

Test Report for Flax Seed Grinder:

A flax seed grinder is a type of seed nut grinder specifically designed for grinding flax seeds. Flax seeds are small, hard seeds that are packed with nutrition and are commonly used in baking and cooking. Grinding flax seeds helps to unlock their nutrients and make them easier to digest.

Flax seed grinders typically feature sharp blades or burrs that rotate to crush the flax seeds into a fine powder. This powder can then be used in a variety of recipes, such as smoothies, baked goods, and yogurt toppings. Some flax seed grinders are manual and require hand-cranking, while others are electric and feature powerful motors for faster grinding.

When choosing a flax seed grinder, it’s important to look for one with durable blades or burrs that can withstand the hard texture of flax seeds.

There are 3 ways of cooling down the grinder: water cooling system; air cooling system and liquid nitrogen freezing system. You can choose the right one if the grinder gets too hot. When machines goes too hot, the metal can expand, causing the grinding wheel to get stuck.

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

Operation Instruction

General Provisions

The operation instructions for a commercial grinder may vary depending on the specific model and manufacturer. However, here are some general guidelines that may apply to many high speed grinders:

- Safety precautions: Before operating the high speed grinder, it is important to review all safety precautions and warnings provided in the user manual. Safety precautions may include wearing appropriate personal protective equipment, such as eye protection and hearing protection, and avoiding loose clothing or jewelry that could become caught in the grinder.

- Preparation: The high speed grinder should be placed on a stable and level surface, and all necessary components should be assembled according to the manufacturer’s instructions. The grinder should also be connected to a power source that is appropriate for its voltage and wattage.

- Loading the grinder: The material to be ground should be loaded into the grinder according to the manufacturer’s instructions. Overloading the grinder may cause damage to the machine and result in poor grinding performance.

- Starting the grinder: The grinder should be started according to the manufacturer’s instructions. This may involve pressing a button, turning a dial, or flipping a switch. The user should ensure that their hands are clear of the grinder and that the material to be ground is positioned properly.

- Adjusting the speed and settings: The speed and other settings of the high speed grinder may be adjusted according to the material being ground and the desired outcome. The user should follow the manufacturer’s instructions for making adjustments to the grinder.

- Monitoring the grinding process: The user should monitor the grinding process to ensure that it is progressing smoothly and that the material is being ground to the desired size and consistency. Any issues or abnormalities should be addressed promptly to prevent damage to the machine.

- Shutting down the grinder: When the grinding process is complete, the grinder should be shut down according to the manufacturer’s instructions. The user should ensure that the machine is completely stopped and that all moving parts have come to a complete stop before attempting to clean or service the grinder.

Overall, the operation instructions for a commercial grinder may involve a number of steps and safety precautions. It is important to carefully review the manufacturer’s instructions and follow proper operating procedures to ensure safe and effective use of the machine.

Preparation Work

Before running a commercial grinder, there are several important preparation steps that should be taken to ensure safe and effective operation of the machine. Here are some general guidelines for preparing to run a high speed grinder:

- Read the user manual: The first step in preparing to run a high speed grinder is to carefully read the user manual provided by the manufacturer. The user manual will provide important information about the specific model of grinder being used, including its features, specifications, and safety precautions.

- Select the appropriate grinding wheel: The grinding wheel used in a high speed grinder should be selected based on the material being ground and the desired outcome. It is important to use the correct type of grinding wheel to prevent damage to the machine and ensure optimal grinding performance.

- Inspect the grinder: Before running the grinder, it is important to inspect it for any signs of damage or wear. The user should check for loose or missing components, cracks or other signs of damage to the machine’s housing or other parts, and any other issues that could affect the grinder’s operation.

- Install the grinding wheel: The grinding wheel should be installed according to the manufacturer’s instructions, making sure that it is securely fastened and aligned properly. The user should also check the wheel for any cracks or other signs of damage before installation.

- Secure the workpiece: The workpiece to be ground should be securely clamped or held in place before starting the grinder. This will help to ensure safe and effective operation and prevent the workpiece from becoming dislodged or damaged during grinding.

- Connect the power source: The high speed grinder should be connected to a power source that is appropriate for its voltage and wattage. It is important to use a properly grounded power source to ensure safe and reliable operation of the machine.

- Test run: Before beginning actual grinding operations, it may be useful to perform a test run to ensure that the grinder is functioning properly and that the grinding wheel is aligned and balanced properly. The user should follow the manufacturer’s instructions for performing a test run.

By following these preparation steps, users can ensure safe and effective operation of a high speed grinder and achieve optimal grinding results.

Treatment of inspection

Inspection of a commercial grinder is an important maintenance procedure that helps ensure safe and effective operation of the machine. Here are some general guidelines for inspecting a high speed grinder:

- Disconnect power source: Before performing any inspection or maintenance on a high speed grinder, the power source should be disconnected to prevent accidental startup.

- Check for wear and damage: The user should inspect the grinder for any signs of wear or damage, such as cracks in the housing, worn or damaged grinding wheels, or loose or missing parts. Any issues should be addressed promptly to prevent further damage to the machine.

- Check alignment and balance of grinding wheel: The grinding wheel should be inspected for proper alignment and balance, as these factors can affect the quality of the grinding operation. If the grinding wheel is not properly aligned or balanced, it should be adjusted or replaced as necessary.

- Check for proper lubrication: The high speed grinder should be inspected for proper lubrication, as inadequate lubrication can cause excessive wear and damage to the machine’s moving parts. The user should follow the manufacturer’s instructions for lubrication, and add lubricant as necessary.

- Inspect electrical components: The electrical components of the high speed grinder, including the wiring, switches, and control panel, should be inspected for any signs of wear, damage, or loose connections. Any issues should be addressed promptly to prevent electrical problems.

- Test run: After completing the inspection, it may be useful to perform a test run of the high speed grinder to ensure that it is functioning properly and that any issues have been addressed.

By following these inspection guidelines, users can help ensure safe and effective operation of a high speed grinder and minimize the risk of damage or injury during grinding operations.

Operation Attention

Running a commercial grinder can be a dangerous operation if proper precautions are not taken. Here are some general guidelines for safe operation of a high speed grinder:

- Personal protective equipment: The user should wear appropriate personal protective equipment, such as safety glasses, hearing protection, and gloves, to prevent injury from flying debris, noise, and contact with the grinding wheel.

- Secure workpiece: The workpiece being ground should be securely clamped or held in place to prevent it from becoming dislodged during grinding.

- Use proper grinding wheel: The user should select the appropriate grinding wheel for the material being ground and ensure that it is installed correctly and securely. The grinding wheel should be inspected for cracks or other damage before use.

- Adjust grinding wheel speed: The speed of the grinding wheel should be adjusted according to the manufacturer’s instructions to ensure optimal grinding performance and prevent damage to the machine or workpiece.

- Avoid excessive pressure: The user should avoid applying excessive pressure to the grinding wheel, as this can cause the wheel to overheat and wear out more quickly.

- Avoid overheating: The high speed grinder should not be operated continuously for extended periods of time, as this can cause overheating and damage to the machine.

- Monitor grinding operation: The user should closely monitor the grinding operation to ensure that the workpiece is being ground properly and that the grinding wheel is functioning correctly.

- Disconnect power source: After completing grinding operations, the power source should be disconnected to prevent accidental startup.

By following these guidelines, users can operate a high speed grinder safely and effectively, and achieve optimal grinding results. It is important to follow the manufacturer’s instructions and all applicable safety regulations when operating any type of machinery.

Applications of Industrial Seed Grinder

Industrial seed grinders are used in a variety of applications across many industries. Here are some of the most common applications of industrial seed grinders:

- Food industry: Industrial seed grinders are used extensively in the food industry to grind seeds, nuts, and spices into fine powders or pastes. These powders and pastes are then used in a variety of products such as sauces, seasonings, and spreads.

- Pharmaceutical industry: In the pharmaceutical industry, industrial seed grinders are used to grind plant material into a fine powder, which is then used to make medicines and supplements.

- Cosmetics industry: Industrial seed grinders are also used in the cosmetics industry to grind plant material into a fine powder or paste, which is then used in products such as face masks, scrubs, and exfoliants.

- Agricultural industry: Industrial seed grinders are used in the agricultural industry to process seeds, such as soybeans, into animal feed.

- Chemical industry: In the chemical industry, industrial seed grinders are used to grind materials such as resins, pigments, and dyes into a fine powder.

- Renewable energy industry: Industrial seed grinders are also used in the renewable energy industry to process biomass into a fine powder, which is then burned to generate electricity.

Overall, industrial seed grinders are versatile machines that are used in many different industries for a variety of applications. They are essential for processing plant material into fine powders and pastes that can be used in many different products.

Food Producing Process Flow:

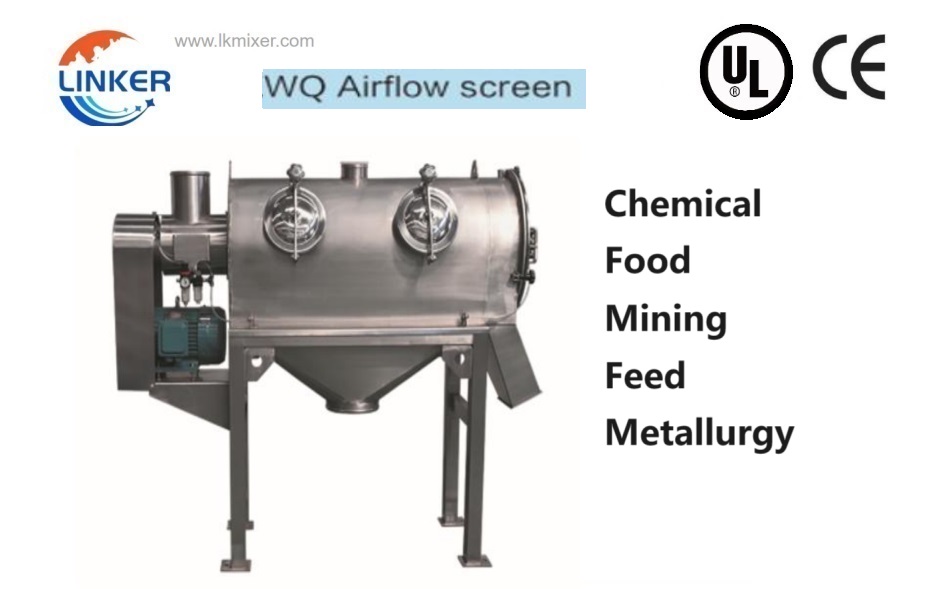

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Automatic Banana Powder Production Line Youtube Video

Customization Seeds Grinder According to your Capacity:

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

We majorly produce CRUSHER, GRINDER, MIXER, and also have auxiliary machines like DRYER, GRANULATOR, VIBRATING SIFTER, CONVEYOR, etc.

We can customize whole production line according to your capacity, material, output sizes of mesh and mm of granule and powder.

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

There are several ways to grind flax seeds without a coffee grinder. Here are a few methods:

Mortar and pestle: If you have a mortar and pestle, you can use it to grind your flax seeds. Simply put a small amount of flax seeds in the mortar and use the pestle to grind them into a fine powder.

Blender or food processor: If you have a blender or food processor, you can use it to grind your flax seeds. Put the flax seeds in the blender or food processor and pulse until they are ground into a fine powder.

Rolling pin: You can also use a rolling pin to grind your flax seeds. Put the flax seeds in a plastic bag and seal it. Use the rolling pin to crush the seeds until they are ground into a fine powder.

Spice grinder: If you have a spice grinder, you can use it to grind your flax seeds. Simply put the seeds in the grinder and pulse until they are ground into a fine powder.

Note that whatever method you choose, it’s best to grind only what you need for immediate use as ground flaxseed can quickly become rancid if not stored properly.

There are several ways to grind flax seeds without a coffee grinder. Here are a few methods:

Mortar and pestle: If you have a mortar and pestle, you can use it to grind your flax seeds. Simply put a small amount of flax seeds in the mortar and use the pestle to grind them into a fine powder.

Blender or food processor: If you have a blender or food processor, you can use it to grind your flax seeds. Put the flax seeds in the blender or food processor and pulse until they are ground into a fine powder.

Rolling pin: You can also use a rolling pin to grind your flax seeds. Put the flax seeds in a plastic bag and seal it. Use the rolling pin to crush the seeds until they are ground into a fine powder.

Spice grinder: If you have a spice grinder, you can use it to grind your flax seeds. Simply put the seeds in the grinder and pulse until they are ground into a fine powder.

Note that whatever method you choose, it’s best to grind only what you need for immediate use as ground flaxseed can quickly become rancid if not stored properly.

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?

Click and read more about mushroom grinder:

Click and Read More about Pulverizer:

Click to more questions about Seeds grinder:

Grinding Machine for Sale:

Blending and Mixing Machine for Sale

Granulating Machine for Sale:

Auxiliary Machine for Sale:

Recommend Reading

Industrial Dry Granulating Machine for Sale:

No posts

Industrial Grinder for Sale:

Industrial Vibrating Screen for Sale:

No posts

Industrial Vacuum Feeder for Sale:

No posts

Industrial Shredder for Sale:

Table of Contents

Toggle