Automatic Green Onion Powder Production Line

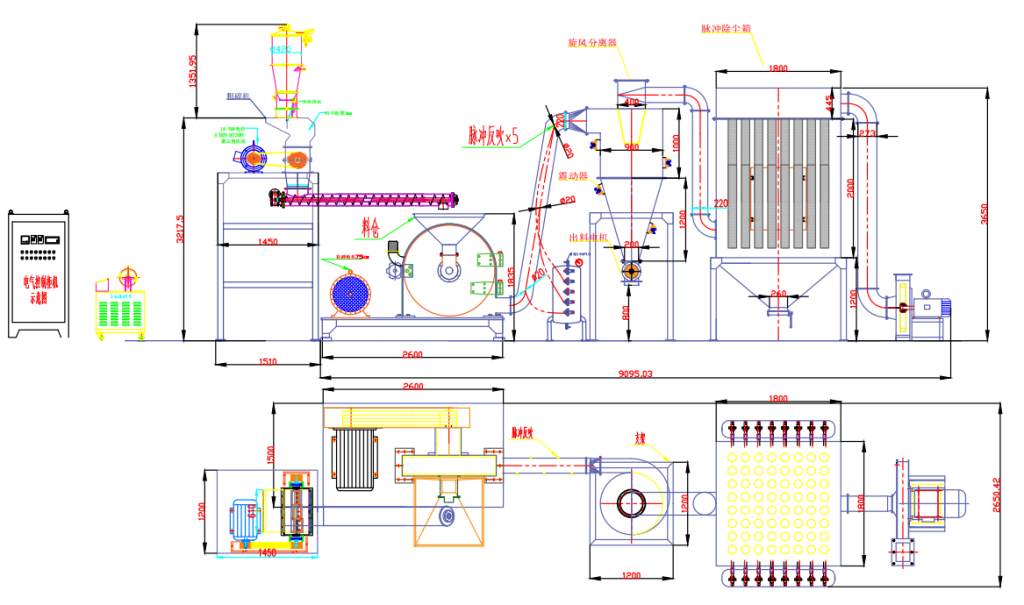

Green Onion Powder Automatic Productino Line Design:

Through a smooth, automated process of cleaning, slicing, drying, grinding, and packaging, an Automatic Green Onion Powder Production Line is a fully integrated, intelligent, and hygienic food processing system designed to convert fresh allium vegetables, such as green onions, scallions, or bulb onions, into a consistent, high-quality seasoning powder. This ensures optimal flavor retention, color preservation, and food safety for the seasoning, instant food, and culinary industries.

Intake of Raw Materials and Extensive Cleaning

Fresh onions are carefully fed into the system to start the production process.The raw material flow is controlled by an automatic charger or conveyor belt, preventing overburden in the early stages. Thorough cleaning is the first crucial step. To efficiently remove soil, filth, and surface residues, the alliums go through a multi-stage washing system that frequently combines high-pressure water sprays with bubbling tanks. This is just as important as cleaning other food items like fruit, cassava, or mushrooms. After washing, sophisticated optical sorting technology automatically detects and eliminates any rotting, discolored, or faulty pieces, guaranteeing that only premium-grade material continues on to other stages, upholding stringent quality control akin to that of processing grains, beans, or seeds.

Slicing evenly for the best drying

After cleaning, the onions are transferred to machinery for precise slicing.These devices cut the alliums into uniform rings or pieces, usually 2–5 mm thick, using a rotary cutting kind of blade mechanism. Maintaining uniform thickness is essential for even drying, which has a direct effect on the effectiveness and quality of the finished product. The slicing technology, which can operate at a high speed and has customizable settings, is conceptually comparable to machinery used to dehydrate fruit, tobacco leaves, or some meat items.

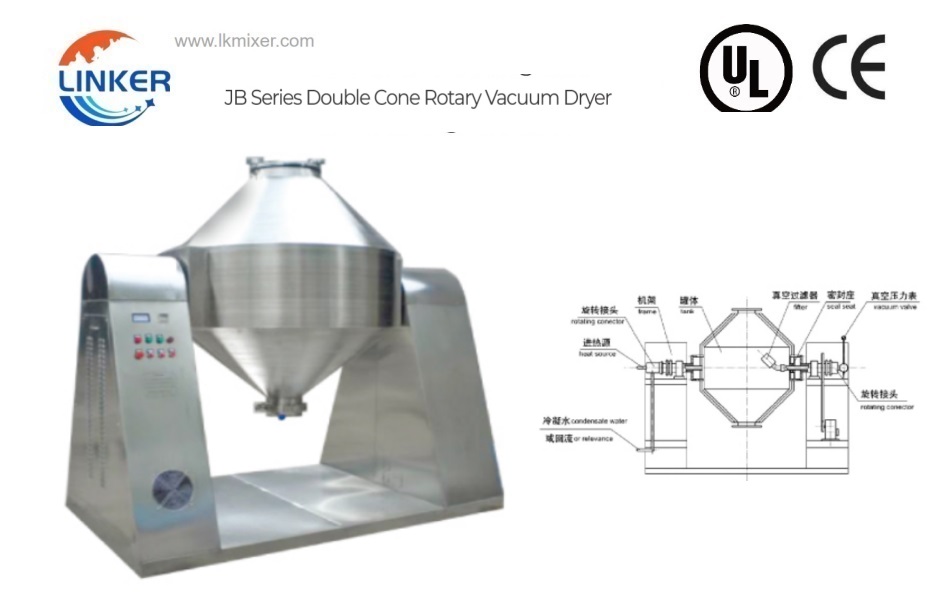

Gently Drying at Low Temperatures

The onion slices move into the stage of core dehydration. They are transported by a multi-tiered belt dryer or a low-temperature drying tunnel. Here, moisture is gradually removed over many hours by circulating warm air at a carefully regulated temperature (45–50°C).The onions’ original green or golden color, volatile aromatic compounds, and nutritional content are all purposefully preserved by this low-heat, gentle technique, which also avoids the flavor degradation that might happen at higher temperatures. This method of preserving flavor is similar to the meticulous drying of valuable herbs, tea leaves, or spices, such as those ground in a dry ginger grinder, or cannabis used in specific medical applications where the preservation of active compounds is crucial.

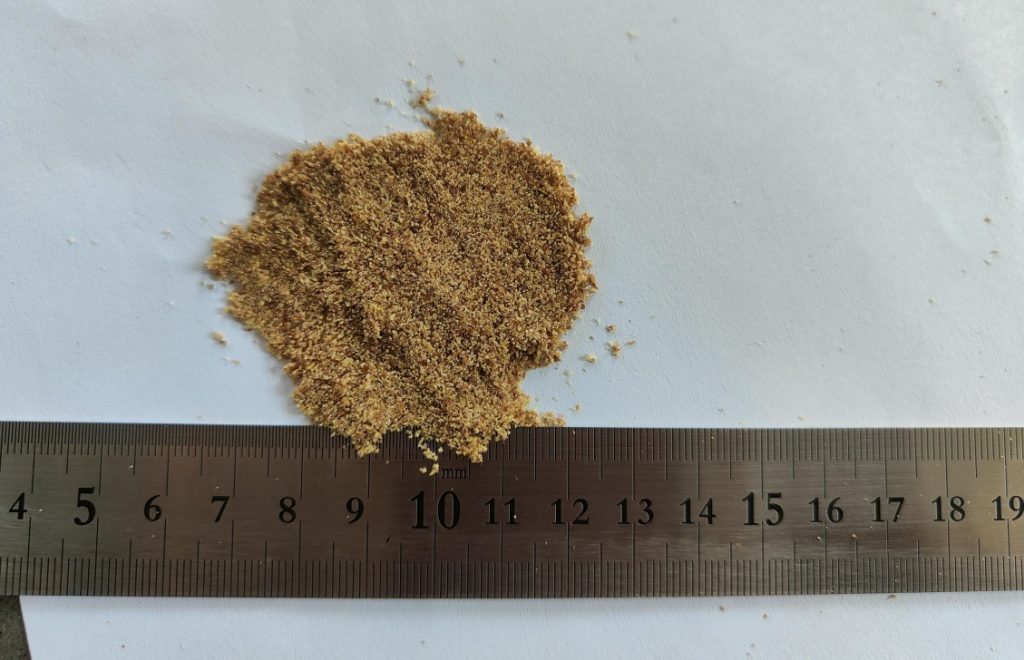

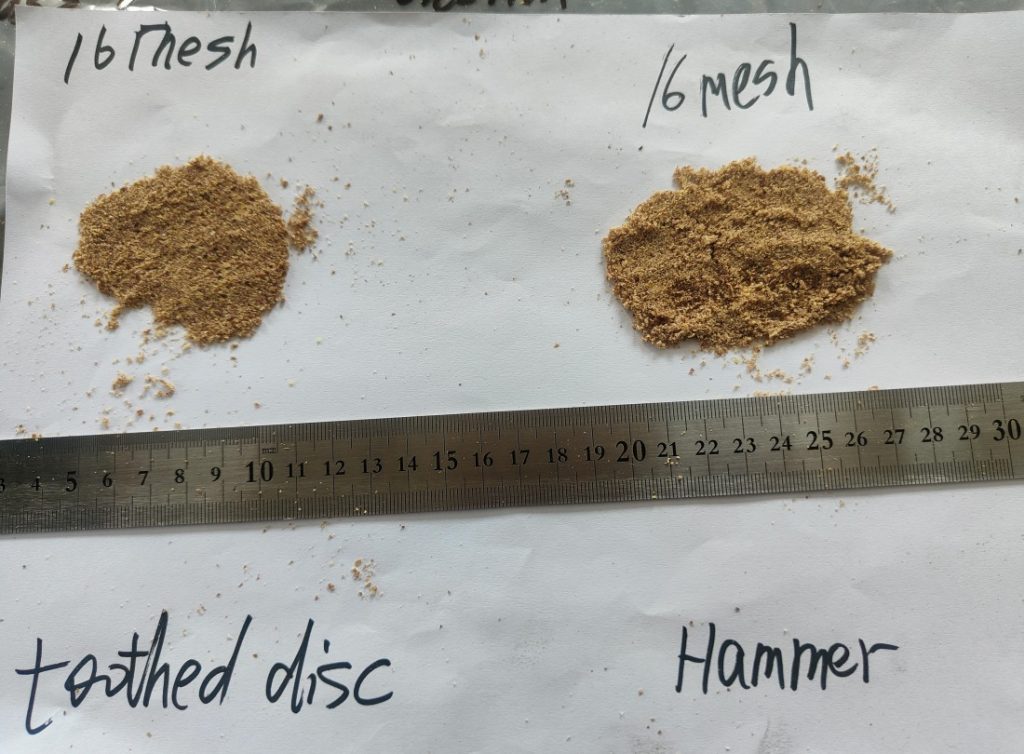

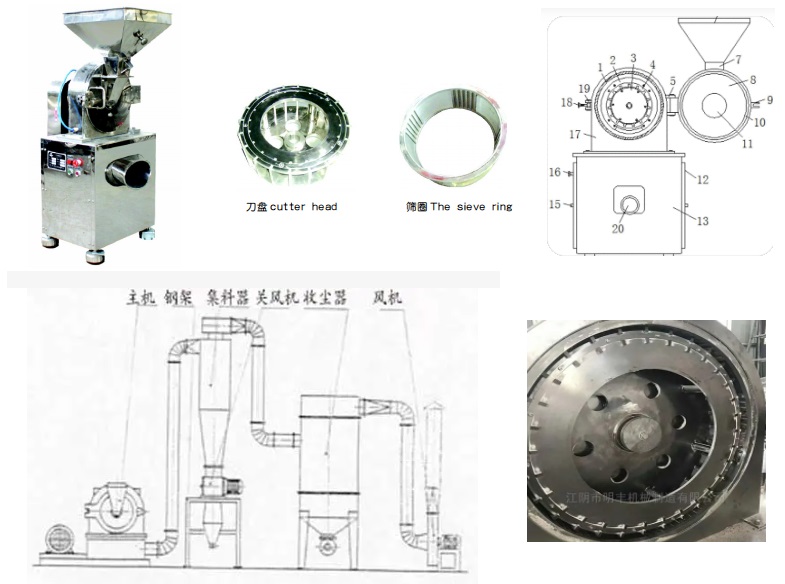

The Process’s Core: Size Reduction and Grinding

The onion slices are prepared for the crucial size reduction step once they are completely dried and crisp. Usually, a Hammer Mill or an initial coarse crusher are used to break them down.The line uses specialized grinding machines for the final transformation into a fine, consistent powder. Commonly used tools include airflow pulverizers, universal grinders, and high speed dry grinders. An ultrafine grinder or turbo grinder may be used to produce an extremely fine, flour-like consistency that can be easily mixed into food preparations. Large, food-grade stainless steel is used to build the grinding chambers and every part that comes into touch with the product, guaranteeing cleanliness, robustness, and corrosion resistance. This part is directly attached to a strong dust collector grinder or a vacuum mill system due to the extremely dusty nature of grinding dried spices and vegetables.This is necessary to meet industrial health regulations, maximize product yield, and maintain a clean and safe production environment. These requirements are shared by flour mills, sugar refineries, and facilities that process metal or chemical powders.

Accurate Categorization and Safety Guarantee

After that, the ground onion powder moves on to the classification phase. The powder is carefully separated by particle size using a vibrating pulverizer or a multi-deck sieve machine. A consistently fine final product is ensured by automatically recycling oversized particles back to the grinding machine for reprocessing. In the production of consistent corn starch, wheat flour, or powdered salt, this process is similar to quality control.Additionally, the line has metal detectors or magnetic separators to ensure the highest standards of food safety. In the production of modern food, medicine, and chemical ingredients, these machines eliminate any possible metal contaminants—a safety requirement that must be compromised.

System-Wide Control and Intelligent Packaging

Before being sent to the automated packaging station, the sifted and filtered onion powder is chilled to room temperature to guarantee storage stability. The powder can be precisely dispensed into bags, jars, or drums using precision electric grinder-style auger fillers or computerized weigh-fill machines with stainless steel contact parts.The line may have nitrogen gas flushing devices to remove oxygen before to sealing for increased shelf life; this method is also essential for the preservation of coffee, peanut products, and seasam seeds. A central Programmable Logic Controller (PLC) system controls the entire production line. Recipe storage, smooth transitions, and full production traceability are made possible by this sophisticated control center, which keeps an eye on and controls every parameter, from washer cycles and dryer temperatures to grinding machine speeds and package weights.

Compliance, Adaptability, and Hygienic Design

The entire line, which was created with strict food safety standards in mind, has an emphasis on cleanliness and preventing contamination. Where feasible, enclosed processing and smooth stainless steel surfaces are used. It is constructed in accordance with international food safety regulations like GMP and HACCP. Similar to a licorice grinding machine or a black pepper grinder line, the line’s main technology is adaptable; by altering settings and parts like screens or cutting type blades, it may process a range of alliums and related spices. The Automatic Green Onion Powder Production Line is the epitome of dependable, hygienic, and efficient food ingredient production, from the first charger that feeds fresh vegetables to the last seasoning that is packaged.

Food Producing Process Flow:

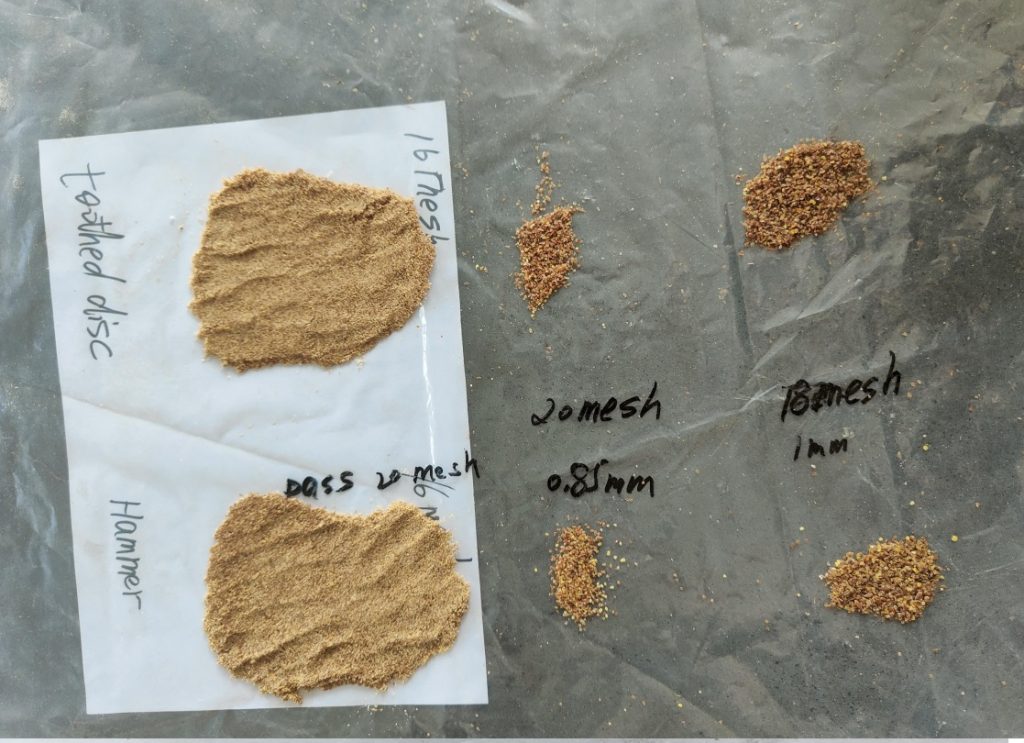

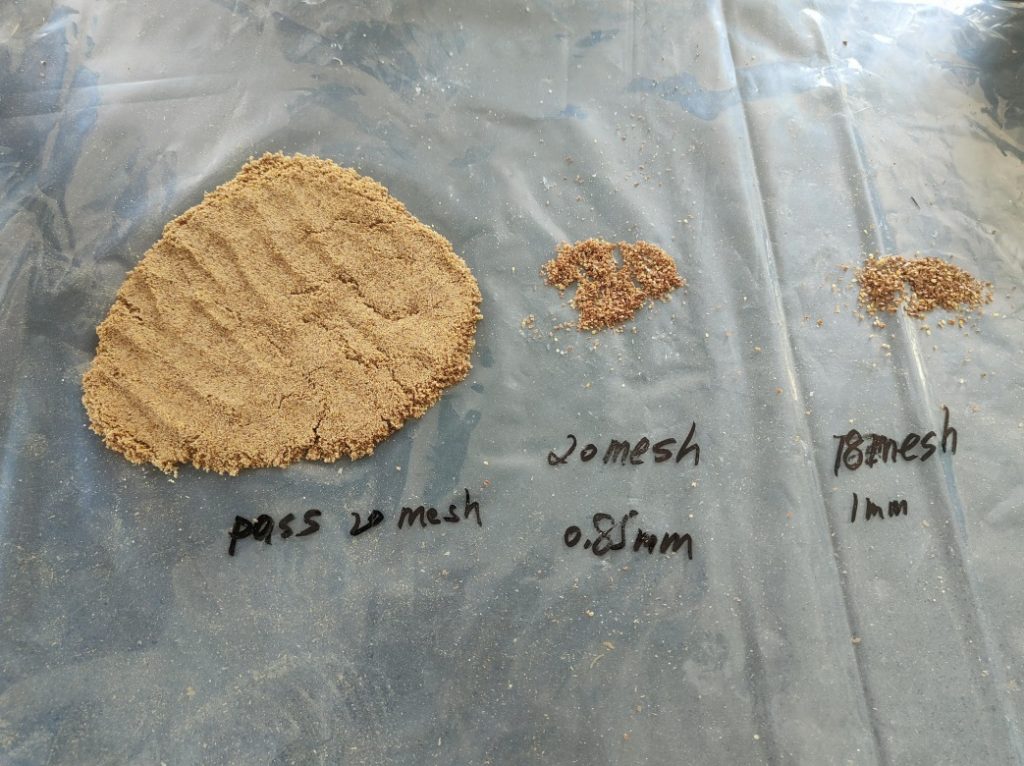

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Automatic Banana Powder Production Line Youtube Video

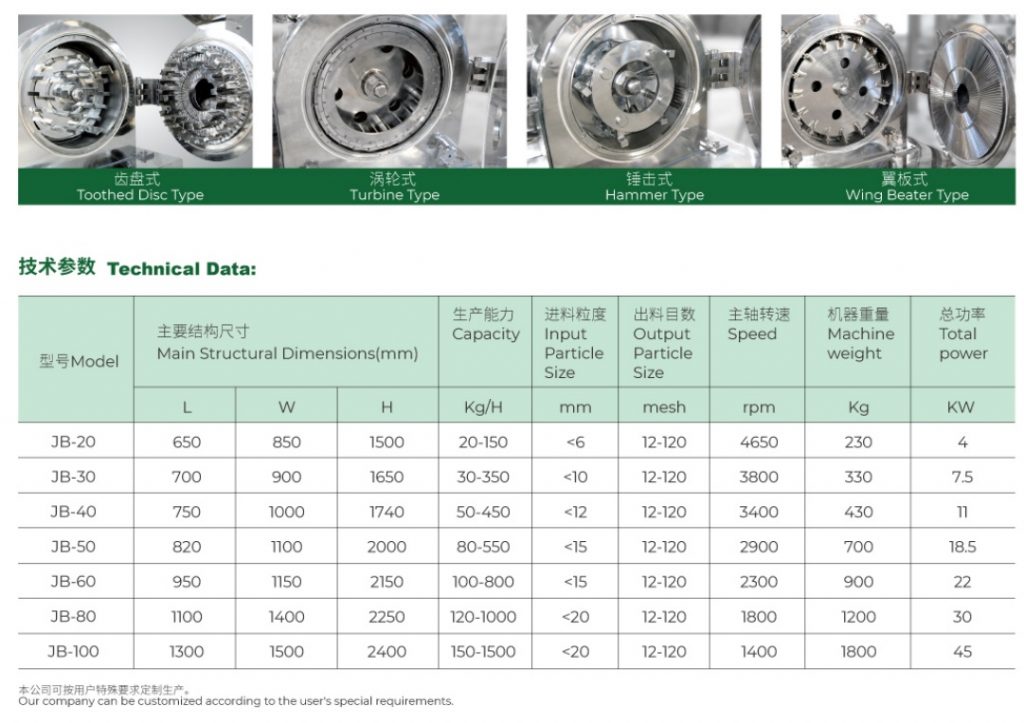

Customization Seeds Grinder According to your Capacity:

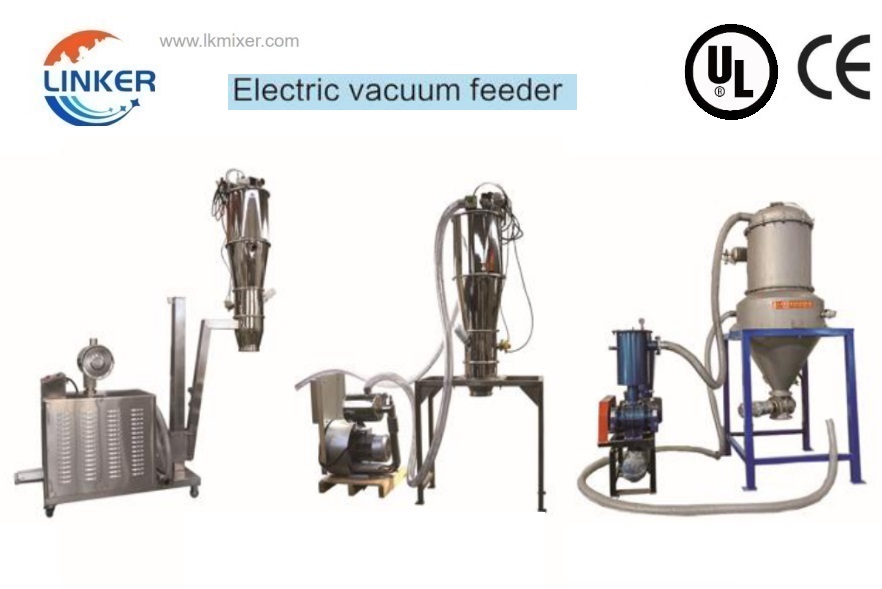

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?