Automatic Laundry Powder Production Line

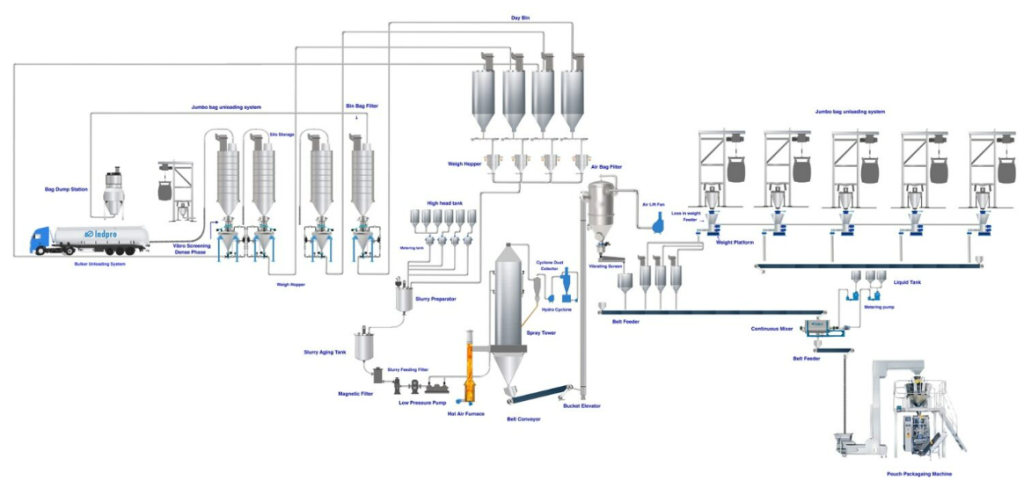

Laundry Powder Process Flow

- Laundry Washing Machine

- Laundry Pealing and Cutting Machine

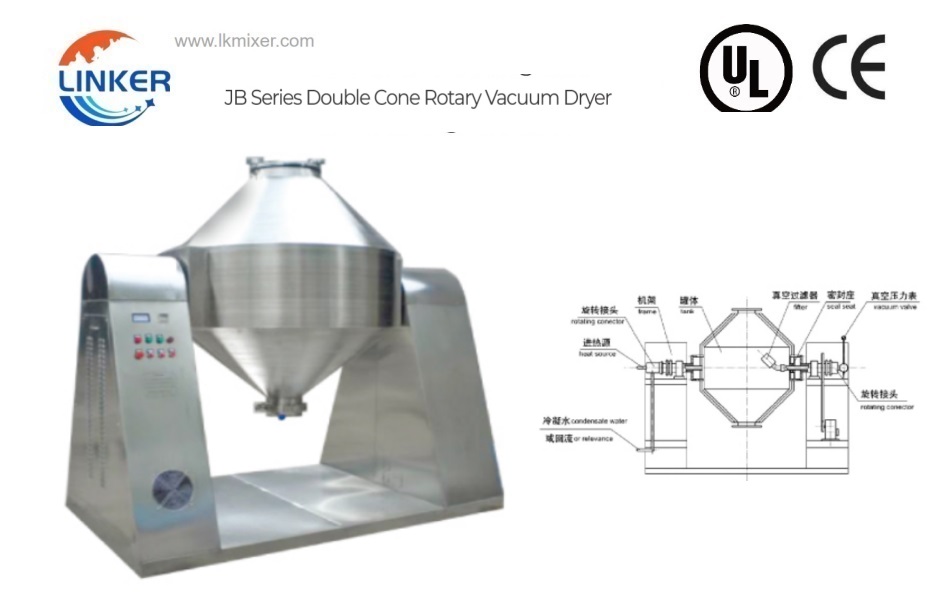

- Laundry Drying Machine

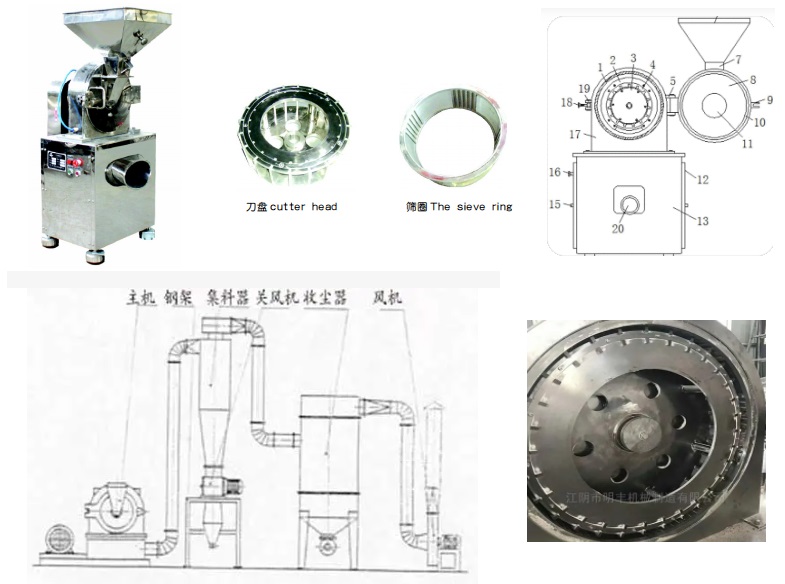

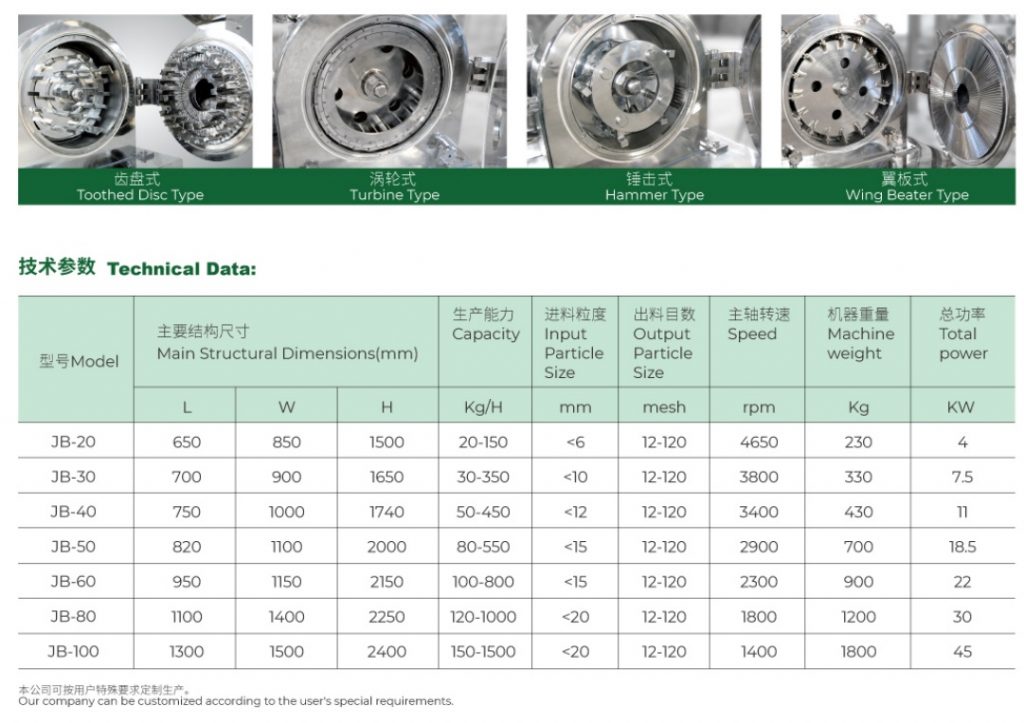

- Laundry Grinding Machine

- Laundry Powder Mixing Machine

- Laundry Powder Filling Machine

- Laundry Powder Packing Machine

Laundry Powder Automatic Productino Line Design:x`

- Description

- Flow Chart

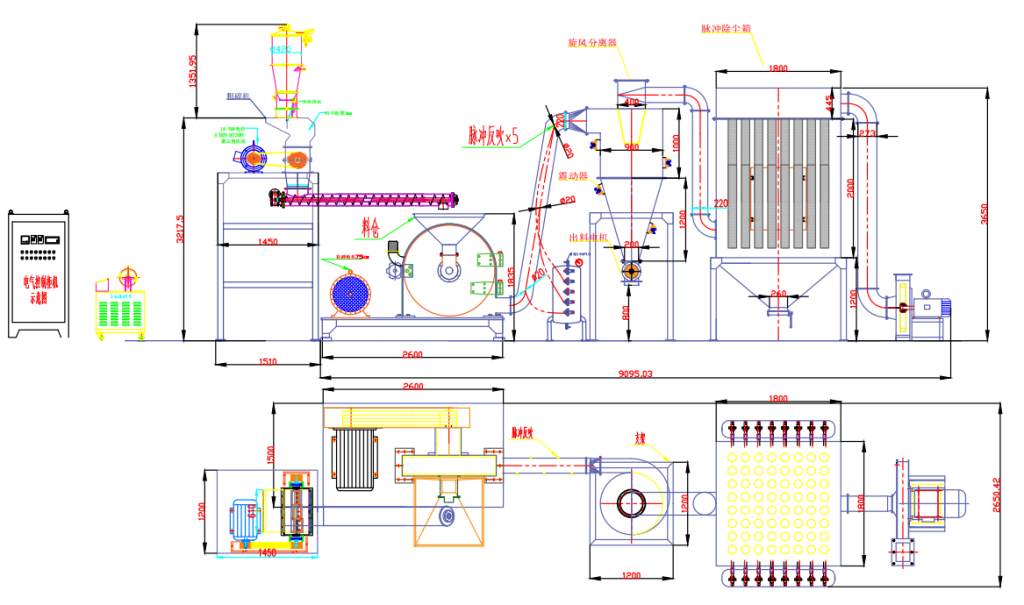

- Drawing

- Proposal and Price

- Parameters

- Test Report

- Factory

- Shipment

- Operation Instruction

- Installation Layout

Automatic Laundry Powder Production Line

From the processing of raw materials to the finished packaged product, an automated laundry powder production line is a fully integrated industrial system that permits the large-scale, standardized, and effective manufacturing of detergent powder. This complex line represents the essence of contemporary, automated chemical manufacturing by combining chemical processing with sophisticated mechanical handling and precise packing.

The Whole Process and Essential Tools

Laundry powder’s journey starts long before it is mixed. In order to obtain the proper particle size and consistency for the finished recipe, raw materials frequently need extensive pre-processing. As the fundamental charger for the entire production process, a variety of specialized grinding and milling equipment becomes essential in this situation. For example, a strong coarse crusher or a Hammer Mill could be used to initially reduce raw chemical blocks, dried herbs, or other solid ingredients. A universal grinder or an ultrafine grinder are used for more sensitive foods that need finer textures, including some spices or additives.A cryogenic grinding machine may be used in applications that need temperature control to protect volatile molecules, which are prevalent when processing medications, particular foods, or particular chemicals. For particular additive compositions, the line may include specialized equipment such as a black pepper grinder, a licorice grinder, or a dry ginger grinder. A tiny grinder machine is adequate for pilot batches or specialty ingredients, while heavy-duty equipment like a 500KG grinder or a 200KG grinder handle bulk materials for large, continuous operations. Many of these grinders, particularly those for food-grade or chemical usage, are constructed of stainless steel and frequently have a CE Certificate to ensure product purity and worker safety.To control dust and keep a clean production environment, related systems like a vacuum mill, dust collector grinder, or airflow pulverizer are essential. This first size-reduction step guarantees that all ingredients are precisely ready for the primary mixing reaction, whether it’s a specialized Dry Fruit Powder Grinder Machine, a vibrating pulverizer for tea or tobacco, or a turbo grinder for high speed reduction of maize or rice derivatives.

The Automated Production Host Unit: The Process’s Center

The carefully ground materials are transported to the production host, the central “laundry powder machine,” after pre-processing. The chemical wizardry takes place in this unit. Usually made of corrosion-resistant stainless steel, this fully automated reactor is managed by a central computer system equipped with sensors and programmable logic.The entire synthesis process is automated, including the precise metering and mixing of ground base powders (such as surfactants, builders, and bleaches), the regulation of liquid and steam introduction, the management of critical chemical reactions under particular pressure and temperature conditions, and the final formation of the slurry or wet mix that will turn into powder. High speed, efficiency, and environmental friendliness are key features of contemporary host units. Modern designs reduce energy expenses significantly and emit no hazardous emissions by optimizing the heating process to do away with the requirement for conventional fuels. By adding unique chemicals that provide further advantages like disinfection, the formulation effectiveness is also improved, enabling higher cleaning power with less active agent.

Advanced Packaging Systems and Final Processing

The final washing powder foundation is produced by drying and cooling the host unit’s wet mixture. Before it reaches the packing lines, this foundation may go through a last, mild milling or screening with tools like a Dry Grinder or a specialist Dust Grinder to guarantee a consistent, free-flowing consistency. The packing stage, which is primarily separated into two categories according to the final product form, is a wonder of precision engineering.

The Fully Automatic Laundry Powder Filling Production Line handles containerized goods. Using auger or weigh-fill technology, this system automatically feeds empty cans or bottles, fills them precisely, closes them, and labels them. A high-precision filling head, frequently a complex auger system akin to an electric grinder, is the core of this line and may be adjusted for varying powder densities. It has weight-check devices and high-speed servo motors to ensure that every container satisfies precise weight requirements, like ±0.5% for sizes exceeding 500g.

The Automatic Powder Bagging and Filling Packaging Line is utilized for packaged goods.Using roll stock, this adaptable line makes bags, fills them with precisely measured powder, and then cuts, dates, and seals them. To achieve uniform dosage, its filling mechanism—which is essential for handling light, fluffy powders—may use technology based on the principles of airflow pulverizers. This line, which is controlled by a PLC and touchscreen, can rapidly transition between various bag sizes and styles while adhering to stringent weight limits (such as ±1% for bags weighing between 100 and 500g) at remarkable rates.

Design Versatility, Safety, and Quality

The importance of quality and safety is paramount throughout the whole production line. All surfaces that come into touch with products should be made of stainless steel to maintain hygienic conditions and avoid contamination. In powder handling, dust management is crucial, so centralized vacuum networks and integrated dust collector grinder systems are common to safeguard the product and the workers. The line’s capacity to handle different formulations demonstrates its adaptability. The same line may manufacture several grades of laundry powder by simply altering the recipes and, if required, the type of grinding machine or filling head. It can also be modified to make similar powdered items like flour, salt, sugar, or specialty chemical blends.Every part is made to be dependable and consistent, from the first cassava grinding machine that processes a starch-based builder to the last air-cooled crusher that guarantees lump-free powder before to packaging.

To sum up, an industrial integration masterpiece is an automated laundry powder production line. It effortlessly combines the regulated chemistry of the host reactor and the micrometric precision of automated packing with the raw power of size reduction—using anything from a huge Industrial Weed Grinder-style mill for tough aggregates to a delicate Seasam, Peanut grinder for additives. The modern cleaning products industry’s benchmark for efficiency and quality is established by this synergy, which produces a continuous, closed-loop system that produces consistent, high-quality detergent products with no human interaction.

Automatic Laundry Powder Production Line

A fully integrated industrial system created for the effective, continuous, and standardized production of detergent powder is called an automatic laundry powder production line. It mostly uses either the Dry Mixing/Agglomeration method, which is the most extensive and commonly used for high-volume output, or the Spray Drying method, which is dominant for large-scale manufacturing. Raw material handling, chemical mixing, particle production, drying, post-addition, and packing are all seamlessly integrated into a closed-loop operation, making the entire process a marvel of automation.

Preparing Raw Materials and the Significance of Size Reduction

The careful handling of raw materials marks the start of the trip. Bulk silos or tanks are used to store components such as water softeners, builders (sodium carbonate, STPP), surfactants (such Linear Alkylbenzene Sulfonate), and anti-redeposition agents (CMC). Particle size reduction is an essential first step for many solid components in order to guarantee homogeneity and reactivity during subsequent mixing. Specialized grinding equipment is useful in this situation. For example, a Hammer Mill or a sturdy coarse crusher may be used to initially process big lumps of raw chemical ingredients or specific salts. Equipment such as a universal grinder or a high-speed dry grinder may be found in more complex setups or for specific additive compositions.The technology behind devices like a cassava grinder for starches, a dry fruit powder grinder, or a licorice grinder for organic additives is comparable, even if it isn’t always employed directly for regular detergent salts. The line may include a 200KG grinder for rice husk ash or a 500KG grinder for bulk corn-based builders; both are usually constructed of stainless steel and frequently have a CE Certificate grinder for compliance. Similar to how they would be used in the processing of flour, sugar, spices, or coffee, related systems such as an airflow pulverizer, a dust collector grinder, or a vacuum mill are crucial for managing powder dispersion and preserving a hygienic, secure environment.

The Core Spray Drying Process, Aging, and Slurry Preparation

After being carefully weighed and processed, the powders are transported to pre-mixing tanks containing liquid surfactants. Here, they are mixed with water in a regulated setting to create a uniform slurry that is then allowed to mature in aging tanks. This improves the flowability of the finished powder by enabling crucial hydration reactions. The spray tower is the central component of the spray drying process. High-pressure pumps carry the slurry to the summit of the tower, where it is atomized into a fine mist via nozzles. Hot air is simultaneously blown into the tower. When the small droplets come into contact with the hot air, the water instantly evaporates, forming hollow, spherical foundation powder grains.To get the right particle size and density, this procedure is carefully regulated. After that, the base powder is chilled in an air-cooled crusher-style device, which breaks up any weak agglomerates and maintains the temperature.

Final Blending, Post-Addition, and Accurate Packaging

“Post-additives”—delicate, heat-sensitive components like enzymes, fragrances, and bleach activators that would be destroyed in the hot spray tower—are added to the base powder after it has dried and cooled. These are mixed in with large-volume, gentle mixers.After that, completely automated packaging systems receive the completed laundry powder. For bagging, precise volumes are measured into pre-made bags using high-speed auger fillers that operate with the accuracy of an electric grinder’s controlled dispensing. Similar precise fillers are utilized for packaged powders. To create a whole line, these packagers are combined with cartoning, date-coding, and sealing units.

System Integration, Alternative Techniques, and Quality Control

Throughout, thorough quality checks are carried out, including bulk density, active matter concentration, and pH testing. A central PLC or DCS control system oversees the entire production line, keeping an eye on everything from the final packaging weight to the charger providing raw materials.The Dry Mixing/Agglomeration process is known for having a lower capital cost than spray drying. In order to create granules through agglomeration, dry powders are immediately mixed in a high-shear mixer while liquid ingredients are sprayed in. Although effective on smaller scales, it frequently yields less homogeneous particles than the spherical granules produced by spray drying. The modern Automatic Laundry Powder Production Line is the epitome of bulk chemical and food-adjacent processing technology, whether it uses the popular spray method or agglomeration. It shares engineering principles with machinery made for processing anything from industrial materials to beans to mushrooms, all with the goal of producing a reliable, high-quality consumer product.

Parameters:

Model Name | SG-600 | |

| Crushing Capacity(kg/h) | 1000~2000 | |

| Power(kw) | 11 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Model Name | SG-800 | |

| Crushing Capacity(kg/h) | 2000~4000 | |

| Power(kw) | 15 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

Ampere of Motors Customization for Seeds Grinder:

| KW | HP | Ampere |

| 75kw | 100HP | 135A |

| 55kw | 75HP | 99A |

| 30kw | 40HP | 54A |

| 22kw | 30HP | 39A |

| 2.2kw | 3HP | 3.9A |

| 1.5kw | 2HP | 2.7A |

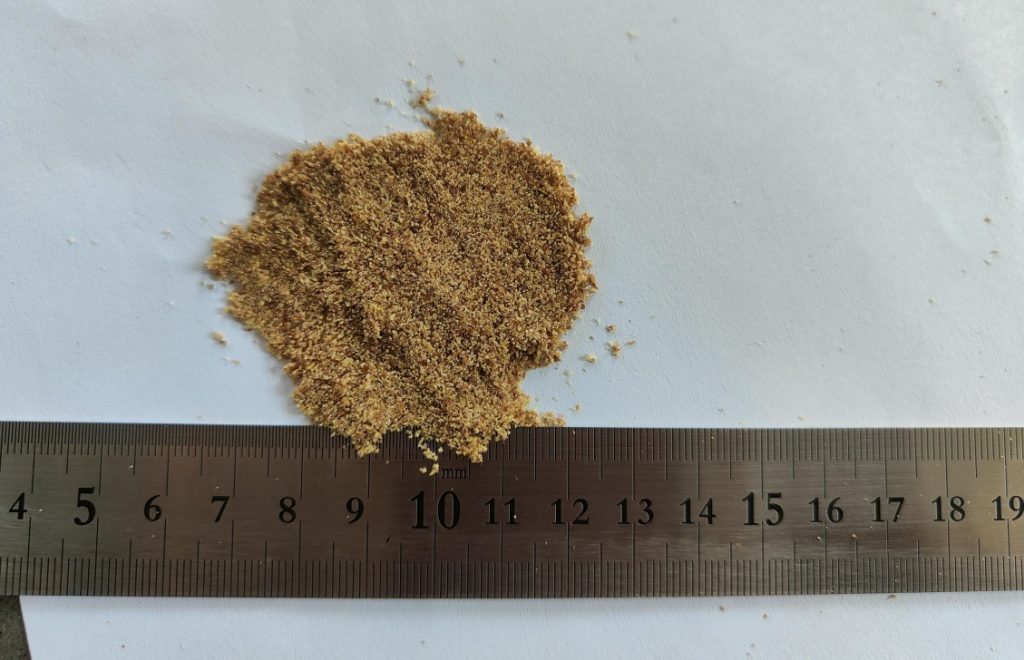

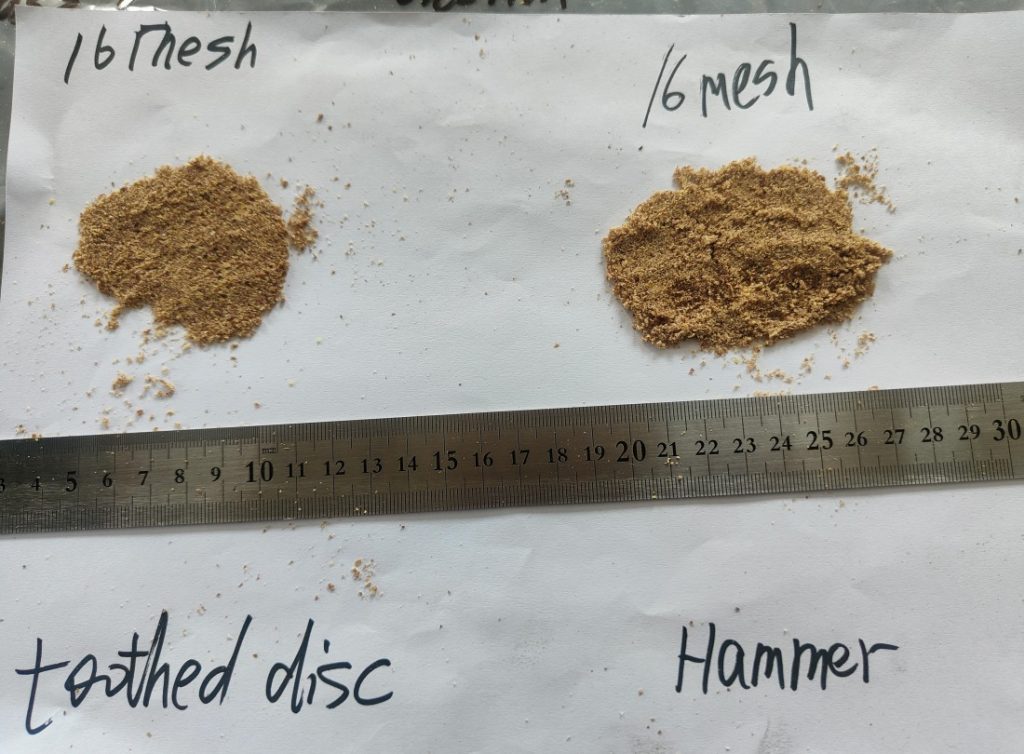

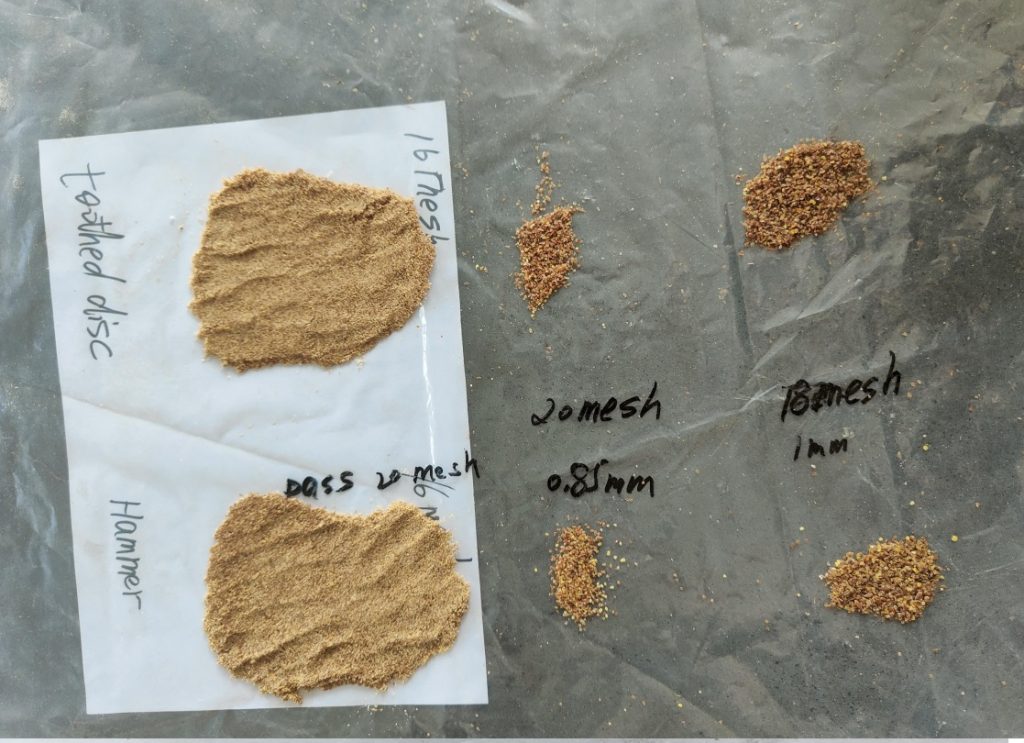

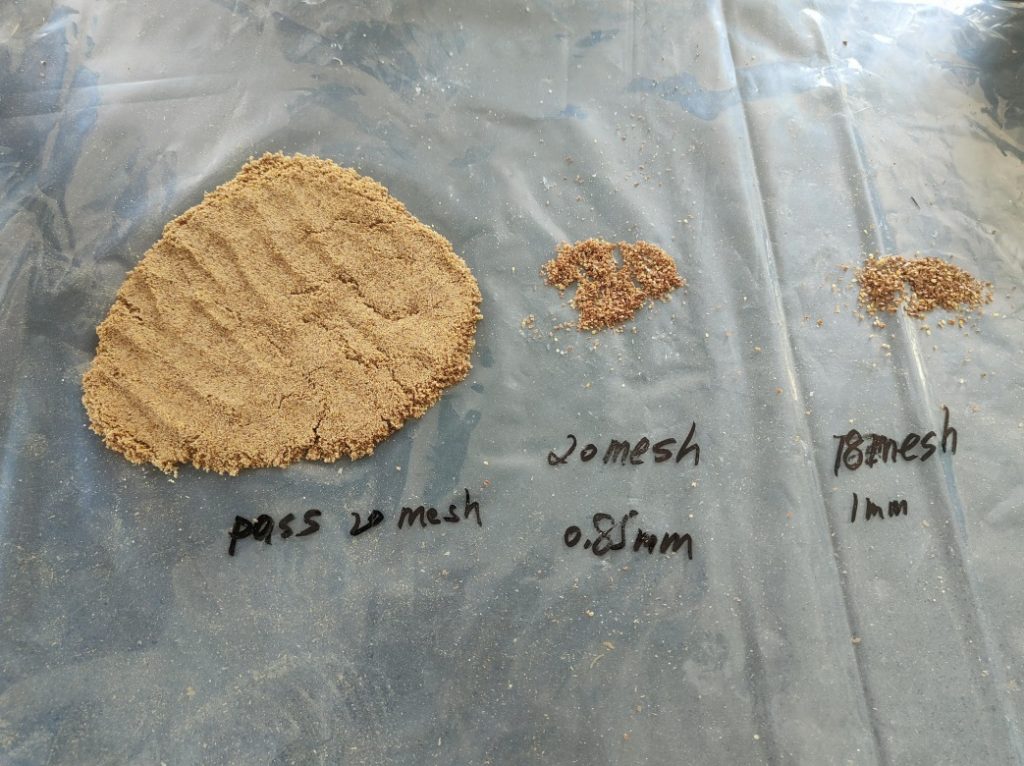

Test Report for Flax Seed Grinder:

A flax seed grinder is a type of seed nut grinder specifically designed for grinding flax seeds. Flax seeds are small, hard seeds that are packed with nutrition and are commonly used in baking and cooking. Grinding flax seeds helps to unlock their nutrients and make them easier to digest.

Flax seed grinders typically feature sharp blades or burrs that rotate to crush the flax seeds into a fine powder. This powder can then be used in a variety of recipes, such as smoothies, baked goods, and yogurt toppings. Some flax seed grinders are manual and require hand-cranking, while others are electric and feature powerful motors for faster grinding.

When choosing a flax seed grinder, it’s important to look for one with durable blades or burrs that can withstand the hard texture of flax seeds.

There are 3 ways of cooling down the grinder: water cooling system; air cooling system and liquid nitrogen freezing system. You can choose the right one if the grinder gets too hot. When machines goes too hot, the metal can expand, causing the grinding wheel to get stuck.

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

Operation Instruction

General Provisions

The operation instructions for a commercial grinder may vary depending on the specific model and manufacturer. However, here are some general guidelines that may apply to many high speed grinders:

- Safety precautions: Before operating the high speed grinder, it is important to review all safety precautions and warnings provided in the user manual. Safety precautions may include wearing appropriate personal protective equipment, such as eye protection and hearing protection, and avoiding loose clothing or jewelry that could become caught in the grinder.

- Preparation: The high speed grinder should be placed on a stable and level surface, and all necessary components should be assembled according to the manufacturer’s instructions. The grinder should also be connected to a power source that is appropriate for its voltage and wattage.

- Loading the grinder: The material to be ground should be loaded into the grinder according to the manufacturer’s instructions. Overloading the grinder may cause damage to the machine and result in poor grinding performance.

- Starting the grinder: The grinder should be started according to the manufacturer’s instructions. This may involve pressing a button, turning a dial, or flipping a switch. The user should ensure that their hands are clear of the grinder and that the material to be ground is positioned properly.

- Adjusting the speed and settings: The speed and other settings of the high speed grinder may be adjusted according to the material being ground and the desired outcome. The user should follow the manufacturer’s instructions for making adjustments to the grinder.

- Monitoring the grinding process: The user should monitor the grinding process to ensure that it is progressing smoothly and that the material is being ground to the desired size and consistency. Any issues or abnormalities should be addressed promptly to prevent damage to the machine.

- Shutting down the grinder: When the grinding process is complete, the grinder should be shut down according to the manufacturer’s instructions. The user should ensure that the machine is completely stopped and that all moving parts have come to a complete stop before attempting to clean or service the grinder.

Overall, the operation instructions for a commercial grinder may involve a number of steps and safety precautions. It is important to carefully review the manufacturer’s instructions and follow proper operating procedures to ensure safe and effective use of the machine.

Preparation Work

Before running a commercial grinder, there are several important preparation steps that should be taken to ensure safe and effective operation of the machine. Here are some general guidelines for preparing to run a high speed grinder:

- Read the user manual: The first step in preparing to run a high speed grinder is to carefully read the user manual provided by the manufacturer. The user manual will provide important information about the specific model of grinder being used, including its features, specifications, and safety precautions.

- Select the appropriate grinding wheel: The grinding wheel used in a high speed grinder should be selected based on the material being ground and the desired outcome. It is important to use the correct type of grinding wheel to prevent damage to the machine and ensure optimal grinding performance.

- Inspect the grinder: Before running the grinder, it is important to inspect it for any signs of damage or wear. The user should check for loose or missing components, cracks or other signs of damage to the machine’s housing or other parts, and any other issues that could affect the grinder’s operation.

- Install the grinding wheel: The grinding wheel should be installed according to the manufacturer’s instructions, making sure that it is securely fastened and aligned properly. The user should also check the wheel for any cracks or other signs of damage before installation.

- Secure the workpiece: The workpiece to be ground should be securely clamped or held in place before starting the grinder. This will help to ensure safe and effective operation and prevent the workpiece from becoming dislodged or damaged during grinding.

- Connect the power source: The high speed grinder should be connected to a power source that is appropriate for its voltage and wattage. It is important to use a properly grounded power source to ensure safe and reliable operation of the machine.

- Test run: Before beginning actual grinding operations, it may be useful to perform a test run to ensure that the grinder is functioning properly and that the grinding wheel is aligned and balanced properly. The user should follow the manufacturer’s instructions for performing a test run.

By following these preparation steps, users can ensure safe and effective operation of a high speed grinder and achieve optimal grinding results.

Treatment of inspection

Inspection of a commercial grinder is an important maintenance procedure that helps ensure safe and effective operation of the machine. Here are some general guidelines for inspecting a high speed grinder:

- Disconnect power source: Before performing any inspection or maintenance on a high speed grinder, the power source should be disconnected to prevent accidental startup.

- Check for wear and damage: The user should inspect the grinder for any signs of wear or damage, such as cracks in the housing, worn or damaged grinding wheels, or loose or missing parts. Any issues should be addressed promptly to prevent further damage to the machine.

- Check alignment and balance of grinding wheel: The grinding wheel should be inspected for proper alignment and balance, as these factors can affect the quality of the grinding operation. If the grinding wheel is not properly aligned or balanced, it should be adjusted or replaced as necessary.

- Check for proper lubrication: The high speed grinder should be inspected for proper lubrication, as inadequate lubrication can cause excessive wear and damage to the machine’s moving parts. The user should follow the manufacturer’s instructions for lubrication, and add lubricant as necessary.

- Inspect electrical components: The electrical components of the high speed grinder, including the wiring, switches, and control panel, should be inspected for any signs of wear, damage, or loose connections. Any issues should be addressed promptly to prevent electrical problems.

- Test run: After completing the inspection, it may be useful to perform a test run of the high speed grinder to ensure that it is functioning properly and that any issues have been addressed.

By following these inspection guidelines, users can help ensure safe and effective operation of a high speed grinder and minimize the risk of damage or injury during grinding operations.

Operation Attention

Running a commercial grinder can be a dangerous operation if proper precautions are not taken. Here are some general guidelines for safe operation of a high speed grinder:

- Personal protective equipment: The user should wear appropriate personal protective equipment, such as safety glasses, hearing protection, and gloves, to prevent injury from flying debris, noise, and contact with the grinding wheel.

- Secure workpiece: The workpiece being ground should be securely clamped or held in place to prevent it from becoming dislodged during grinding.

- Use proper grinding wheel: The user should select the appropriate grinding wheel for the material being ground and ensure that it is installed correctly and securely. The grinding wheel should be inspected for cracks or other damage before use.

- Adjust grinding wheel speed: The speed of the grinding wheel should be adjusted according to the manufacturer’s instructions to ensure optimal grinding performance and prevent damage to the machine or workpiece.

- Avoid excessive pressure: The user should avoid applying excessive pressure to the grinding wheel, as this can cause the wheel to overheat and wear out more quickly.

- Avoid overheating: The high speed grinder should not be operated continuously for extended periods of time, as this can cause overheating and damage to the machine.

- Monitor grinding operation: The user should closely monitor the grinding operation to ensure that the workpiece is being ground properly and that the grinding wheel is functioning correctly.

- Disconnect power source: After completing grinding operations, the power source should be disconnected to prevent accidental startup.

By following these guidelines, users can operate a high speed grinder safely and effectively, and achieve optimal grinding results. It is important to follow the manufacturer’s instructions and all applicable safety regulations when operating any type of machinery.

Applications of Industrial Seed Grinder

Industrial seed grinders are used in a variety of applications across many industries. Here are some of the most common applications of industrial seed grinders:

- Food industry: Industrial seed grinders are used extensively in the food industry to grind seeds, nuts, and spices into fine powders or pastes. These powders and pastes are then used in a variety of products such as sauces, seasonings, and spreads.

- Pharmaceutical industry: In the pharmaceutical industry, industrial seed grinders are used to grind plant material into a fine powder, which is then used to make medicines and supplements.

- Cosmetics industry: Industrial seed grinders are also used in the cosmetics industry to grind plant material into a fine powder or paste, which is then used in products such as face masks, scrubs, and exfoliants.

- Agricultural industry: Industrial seed grinders are used in the agricultural industry to process seeds, such as soybeans, into animal feed.

- Chemical industry: In the chemical industry, industrial seed grinders are used to grind materials such as resins, pigments, and dyes into a fine powder.

- Renewable energy industry: Industrial seed grinders are also used in the renewable energy industry to process biomass into a fine powder, which is then burned to generate electricity.

Overall, industrial seed grinders are versatile machines that are used in many different industries for a variety of applications. They are essential for processing plant material into fine powders and pastes that can be used in many different products.

Food Producing Process Flow:

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Automatic Banana Powder Production Line Youtube Video

Customization Seeds Grinder According to your Capacity:

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

We have 20 years manufacturing experiences; 15600 cubic meters factory area; 5000sets annual capacity; 55 professional engineers;

South America: Brazil, Colombia, Peru, Bolivia, Uruguay, Paraguay ;Romania;

USA with UL Certification

Middle East: Saudi, Arabia, Oman, Turkey

Europe: Russia, Australia, Belarus, Ukraine, Poland

– Yes, OEM or ODM. Machine can be customized according to customer detail requirement, including capacity and voltages, motor certifications.

– Drawing and raw materials also can be customized.

Our Factory located in Jiangsu Province, very near to Shanghai, you can fly to Shanghai Pudong Airport, we pick you up and take you by car 2 hours ride, can reach our factory, welcome your visit.

1) Before your purchasing, we need to know your detail request, such as what kind of material you want to grind and mixing, what final product powder or granule you want to reach. Because different material and powder sizes request of different machine to do. We can provide professional advice and rich experience help to choose machine. Most of the products we have already did before for other customer, trail test or run mass production, so we knows which machine is best in performance of grinding and mixing. This is of very importance in helping you choose the right model. We also wish this can help our customer a lot. Even the material we didn’t do before, we will prepare the same material and to do the trail test and send video to you for your reference.

2) One Year guarantee of machine quality. If the machine have problem within one year, we will send you the spare parts to you for replacement, but this not including the damage caused by human causes. We also have 24 hours on line guide for customer, if you have operation difficulty, we will guide by video and on line communication with our engineer for your emergency debug.

3) For small machine, we sell with whole machine, it’s no need to install, and easy to operation, no problems for operation. While for large machine, its’s also not difficult to install with video guideline, but if you need, we can assign our technicians to go abroad, the round ticket, food and residents will be paid by customer.

Our payment term is T/T. 50% payment in advance, rest of 50% payment finish before the goods shipped. When we finish the machine production we will do trail test and run the machine take videos for your green light. You pay the rest of 50% payment then.

– 7*24 customer service online;

– 7*24 engineers online services;

– 12 months warranty services.

We majorly produce CRUSHER, GRINDER, MIXER, and also have auxiliary machines like DRYER, GRANULATOR, VIBRATING SIFTER, CONVEYOR, etc.

We can customize whole production line according to your capacity, material, output sizes of mesh and mm of granule and powder.

YES ! Our f have factory build more than 20 years now, we can design and customize whole line, besides of the grinding machine, mixing machine, we can also fully support to provide the washing machine, cutting machine, drying machine, packing machine, filling machine. Though we are not producing these machine, but our brother companies co-work together for over 20 years, we have rich experience in providing you a full effective production line, fully automatically or semi-automatically.

There are several ways to grind flax seeds without a coffee grinder. Here are a few methods:

Mortar and pestle: If you have a mortar and pestle, you can use it to grind your flax seeds. Simply put a small amount of flax seeds in the mortar and use the pestle to grind them into a fine powder.

Blender or food processor: If you have a blender or food processor, you can use it to grind your flax seeds. Put the flax seeds in the blender or food processor and pulse until they are ground into a fine powder.

Rolling pin: You can also use a rolling pin to grind your flax seeds. Put the flax seeds in a plastic bag and seal it. Use the rolling pin to crush the seeds until they are ground into a fine powder.

Spice grinder: If you have a spice grinder, you can use it to grind your flax seeds. Simply put the seeds in the grinder and pulse until they are ground into a fine powder.

Note that whatever method you choose, it’s best to grind only what you need for immediate use as ground flaxseed can quickly become rancid if not stored properly.

There are several ways to grind flax seeds without a coffee grinder. Here are a few methods:

Mortar and pestle: If you have a mortar and pestle, you can use it to grind your flax seeds. Simply put a small amount of flax seeds in the mortar and use the pestle to grind them into a fine powder.

Blender or food processor: If you have a blender or food processor, you can use it to grind your flax seeds. Put the flax seeds in the blender or food processor and pulse until they are ground into a fine powder.

Rolling pin: You can also use a rolling pin to grind your flax seeds. Put the flax seeds in a plastic bag and seal it. Use the rolling pin to crush the seeds until they are ground into a fine powder.

Spice grinder: If you have a spice grinder, you can use it to grind your flax seeds. Simply put the seeds in the grinder and pulse until they are ground into a fine powder.

Note that whatever method you choose, it’s best to grind only what you need for immediate use as ground flaxseed can quickly become rancid if not stored properly.

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?

Click and read more about mushroom grinder:

Click and Read More about Pulverizer:

Click to more questions about Seeds grinder:

Grinding Machine for Sale:

Blending and Mixing Machine for Sale

Granulating Machine for Sale:

Auxiliary Machine for Sale:

Recommend Reading

Industrial Dry Granulating Machine for Sale:

No posts

Industrial Grinder for Sale:

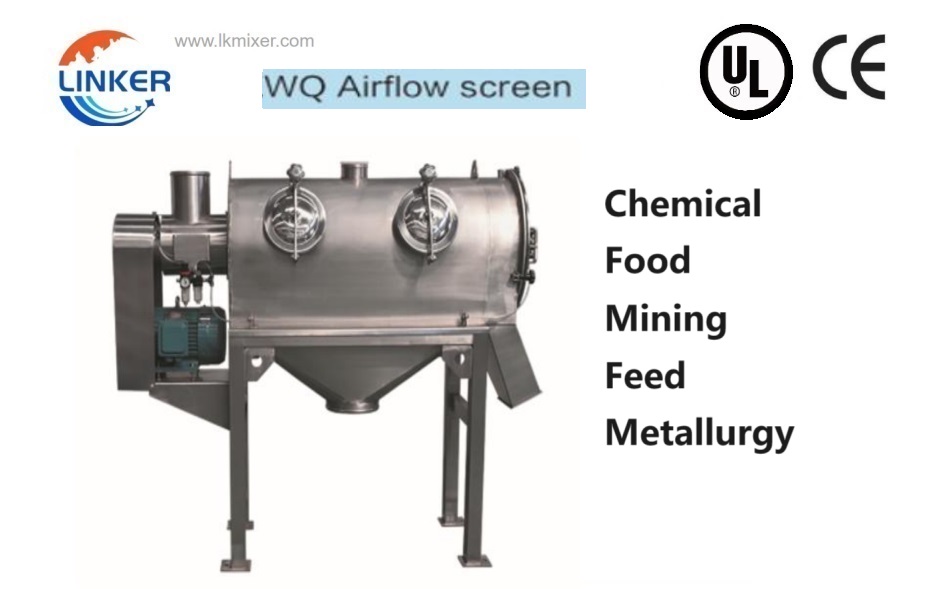

Industrial Vibrating Screen for Sale:

No posts

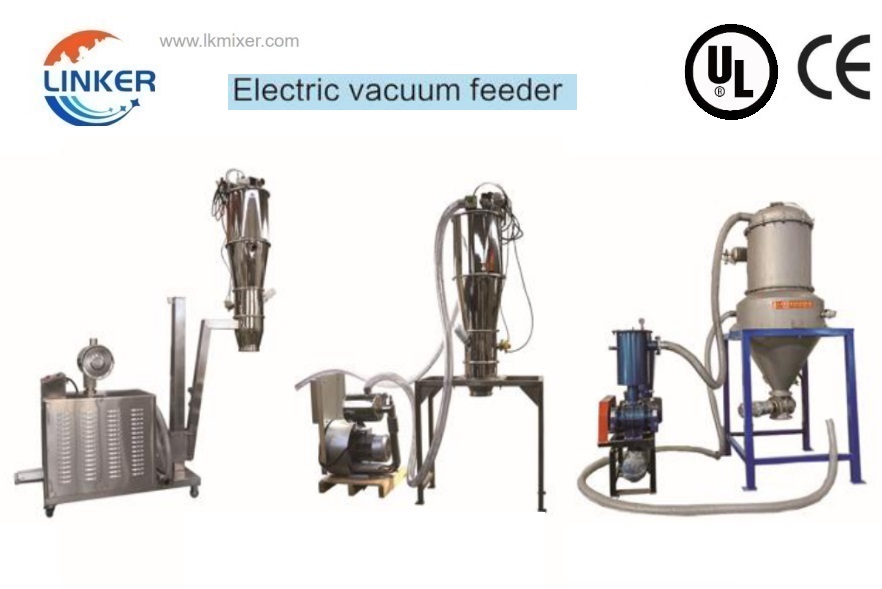

Industrial Vacuum Feeder for Sale:

No posts

Industrial Shredder for Sale:

Table of Contents

Toggle