Automatic Garlic Powder Production Line

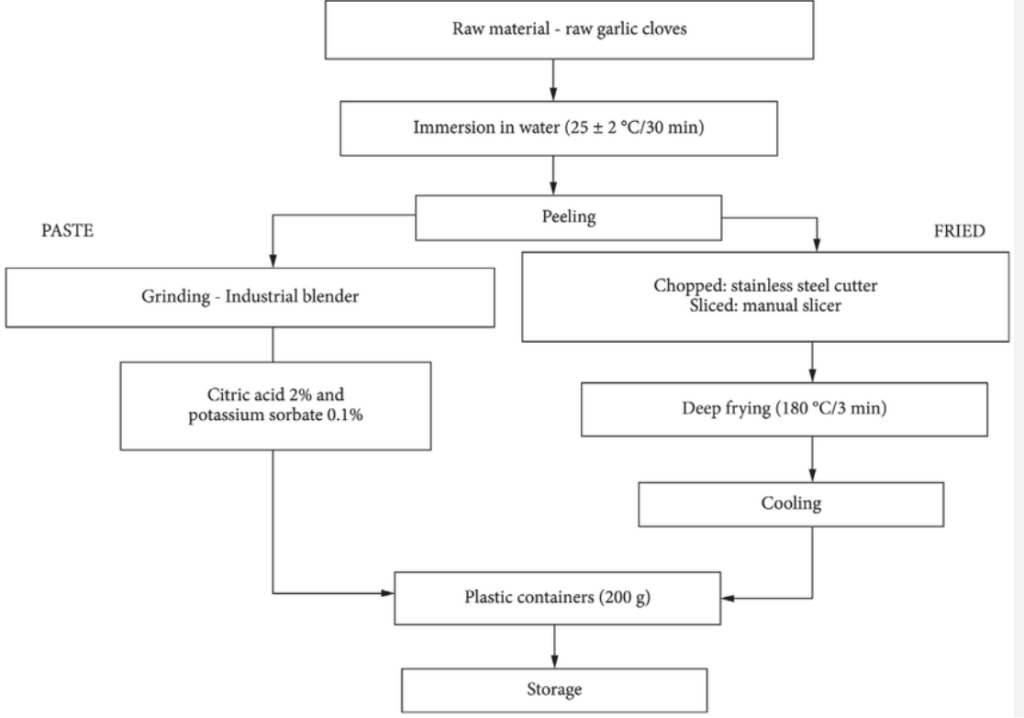

Garlic Powder Process Flow

- Garlic Washing Machine

- Garlic Pealing and Cutting Machine

- Garlic Drying Machine

- Garlic Grinding Machine

- Garlic Powder Mixing Machine

- Garlic Powder Filling Machine

- Garlic Powder Packing Machine

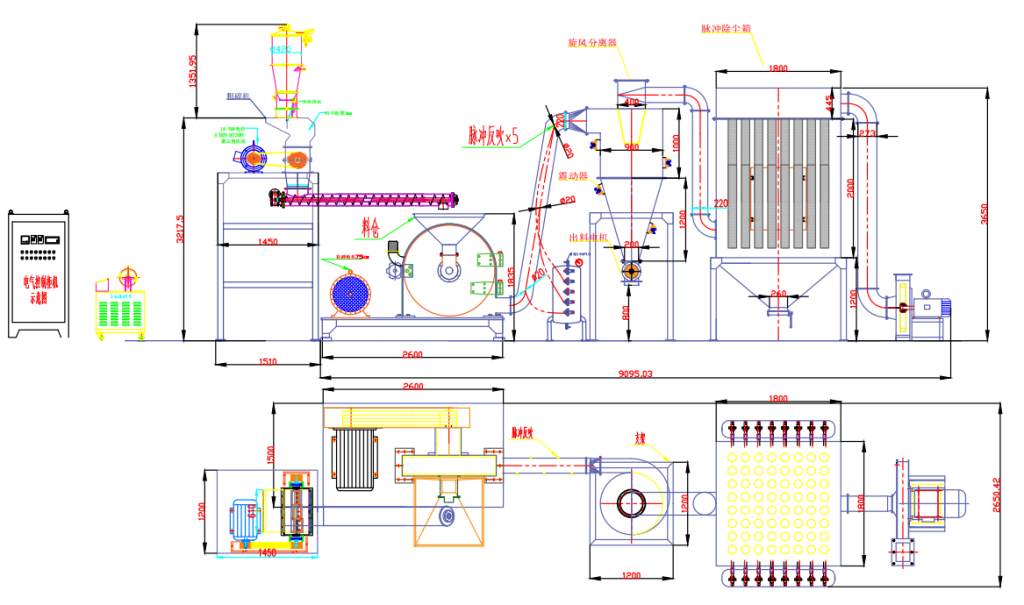

Garlic Powder Automatic Productino Line Design:x`

Automatic Potato Flakes Production Line

An sophisticated and integrated processing system, the Automatic Potato Flakes Production Line produces high-quality potato flakes on a large scale for use in thickeners, quick foods, snacks, and nutritional supplements. This fully automated system meets international food processing regulations for export while greatly increasing production efficiency and successfully maintaining the original flavor, texture, and nutrients of potatoes.

Flow of the Core Process

Raw material handling is the first step in the process. Fresh potatoes are fed into the line to be cleaned, peeled using steam or abrasive techniques, and then sliced and diced. Consistent drying requires uniform slicing, which is frequently accomplished with tools like the YQC 660 multipurpose vegetable cutter.

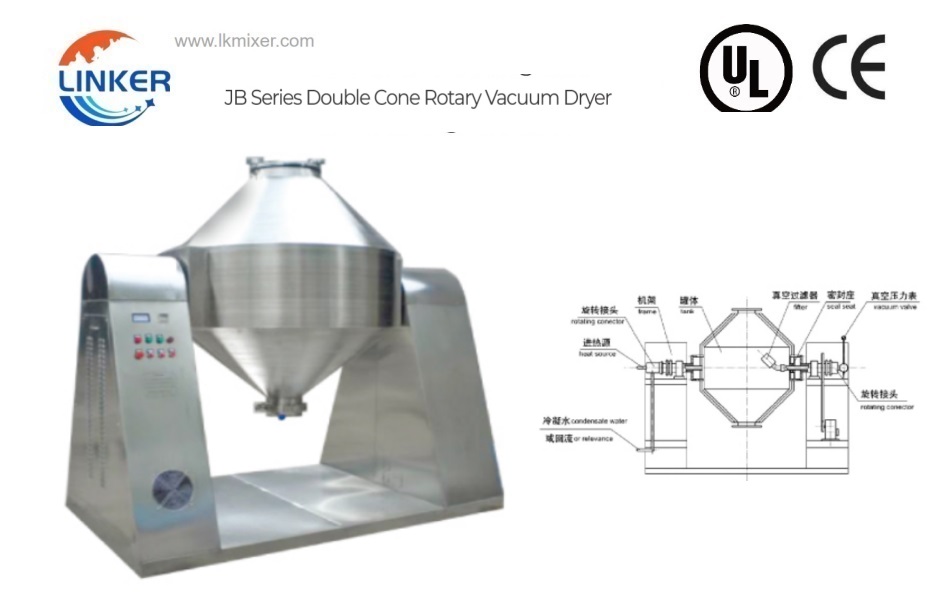

Drying and dehydration are the next crucial steps. A tunnel drier or a multi-layer conveyor belt dryer are used to dehydrate the sliced potatoes. More sophisticated lines might use a vacuum low-temperature multi-stage drying method, in which temperatures are carefully regulated in steps from about 38°C to 5°C. The natural color, flavor, and nutritional content of the potato are best preserved using this delicate technique. The heat source offers eco-friendly and energy-efficient operation by being able to be set up to use electricity, natural gas, or biomass pellets.

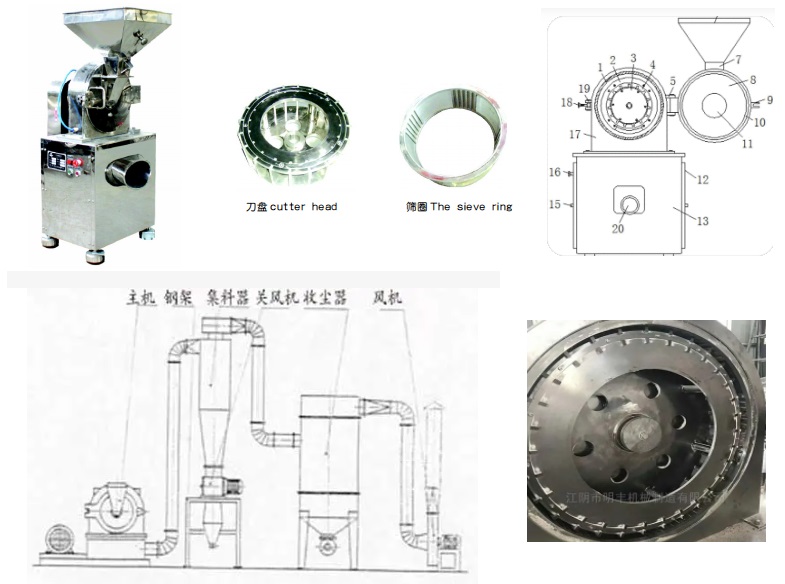

The processed potato pieces are prepared for the last steps after drying. Although this line makes flakes, the grinding step is essential to making potato powder or particular granulations. A high-performance grinding machine is essential in this situation. A cryogenic grinding machine can be used to preserve the quality of materials that are sensitive to heat, such as some food items. Depending on the final product specification, the dried potato pieces or flakes may be further processed using an Ultrafine Grinder for a very fine powder or a Hammer Mill for a coarse reduction. For added versatility, a universal grinder—which can handle a variety of foods like spice, dried ginger, licorice, black pepper, maize, rice, and coffee—could be incorporated.To maintain a clean production environment and guarantee operator safety, the grinding system frequently consists of a dust collector grinder or a dust grinder. An airflow pulverizer or turbo grinder provides effective fine grinding for especially demanding applications. To guarantee product homogeneity, the particle size is modifiable and graded using a vibrating sieve. During processing, supporting machinery such as an air-cooled crusher aids in controlling heat generation. Similar rules apply to various product lines: a dry grinder is used for general bean, chemical, medicinal, or tobacco uses; a dry fruit powder grinder machine is used for fruits; a cassava grinder is used for cassava.A tiny grinder for pilot batches or a large 500KG or 200KG grinder for industrial throughput are examples of different scales. Many of these grinding machines have a CE Certificate grinder label, which guarantees they satisfy European safety regulations and is essential for export. For food safety, these grinders are usually constructed of stainless steel and come in two varieties: impact and cutting. In order to guarantee that the finished product—whether it be flour, sugar, salt, or tea—is pure, they must be strong enough to handle various components without becoming contaminated. There are specialized models, such as a bone grinder for animal waste, a seasam and peanut grinder for nut pastes, or an industrial weed grinder or herb grinder for cannabis or therapeutic plants.Additional examples include grinders for mushrooms, seeds, metal detector-protected grinders, electric grinder units, initial size reduction coarse crushers, meat grinders, wheat grinders, and even vacuum mills for materials sensitive to oxygen.

Automatic packaging is the last step. After passing through weighing and metal detection devices, the final potato powder or flakes are automatically packed into retail bags or bigger export bags that meet international logistical standards, including 25 kg cartons.

Performance and Benefits of Equipment

Fully Automated Operation is one of the main benefits. The line minimizes manual effort and ensures constant quality with its one-touch start, digital monitoring, and automatic temperature control. Five to six tons of raw potatoes can be processed per day.

Additionally, the series is highly versatile and compatible. The same manufacturing line can be modified to process a range of agricultural goods with small changes and the addition of various grinding equipment, such as a universal grinder or a spice grinder. This makes it perfect for a variety of deep-processing operations, such as producing banana flakes, garlic powder, or powders from various dry fruits, herbs, and chemicals.

Another important aspect is the Eco-friendly and Energy-Saving Configuration. Indirect heating hot air furnaces, which guarantee full fuel combustion and lower emissions while adhering to strict environmental rules, are frequently installed along the line.

Support for Export Certification is also essential. In order to guarantee that the entire manufacturing process and the finished potato flake product meet criteria for markets in Europe, North America, and Southeast Asia, reputable suppliers offer equipment with CE, ISO, and other international certifications.

Suppliers and Market Reference Prices

Starting at about ¥360,000, a small-scale automated potato flakes production line includes essential modules like drying and the required grinding machine equipment. The average price range for a standalone commercial-grade automatic peeler is ¥9,800 to ¥10,500. The required capacity and configuration have a substantial impact on the overall integrated line cost. Large suppliers are centered in areas like Jiangsu and Shandong, where businesses like Shandong Ruifang Food Industry Co., Ltd. provide turnkey projects with individualized solutions.

A highly integrated food processing system, the Automatic Potato Flakes Production Line automates every step of the process, from raw potatoes to dried, finished flakes. In order to satisfy the demanding global market for premium instant food ingredients, our technique significantly improves manufacturing efficiency and product consistency while successfully maintaining the potato’s inherent flavor, texture, and essential nutrients.

Comprehensive Core Process Flow

The selection and grading of raw materials marks the start of the trip. Fresh potatoes of superior quality that are free of rot and significant flaws and have a maturity level of at least 90% are chosen. In order to guarantee even processing in later stages like peeling and slicing, which is essential for constant flake quality, they are then put into a drum grader that sorts them by size, usually keeping a uniform batch (e.g., 50-80mm in diameter).

The next steps are peeling and washing. To get rid of dirt and debris, the graded potatoes are thoroughly cleaned in a bubbling wash tank with water at 25 to 30 degrees Celsius for roughly three minutes. After that, they use a steam peeler, where a quick 20-second exposure to high-pressure steam (around 0.3 MPa) loosens the skin and removes more than 98% of the peel. Compared to abrasive peeling, this technique uses less water and loses less product.

Slicing and blanching come next. A precision slicer, such as a YQ-1 directional model, receives the peeled potatoes and slices them uniformly into pieces that are about 4 mm thick. To ensure that the finished flakes have a stable, enticing light color and a consistent texture following dehydration, these slices are then usually blanched—briefly cooked in hot water or steam—to deactivate enzymes that cause browning and off tastes.

Drying and flaking are the main steps in the process. Slices that have been blanched go onto a conveyor drier with multiple layers. In order to avoid case-hardening and nutritional degradation, a carefully regulated, gentle drying procedure is carried out here, frequently employing gradient temperatures from about 38°C down to lower temperatures. After drying, the brittle slices are run through a flaking roll or a specific grinding machine that has been set to an extremely coarse setting. This step employs a coarse crusher or flaking mill to break the dry slices into the distinctive flake shape without turning them into a powder, in contrast to a fine Ultrafine Grinder used to produce flour or spices or a Hammer Mill for corn or chemicals.

The product next undergoes milling and sizing (for potato powder or specific granulations) after flaking. Although flakes are the main product, some lines could have a branch that makes potato powder. A secondary grinding machine system is used in this situation. A universal grinder, a multipurpose stainless steel device frequently used in food processing for products like dried ginger, licorice root, black pepper, rice, or coffee, might be fed the flakes or smaller pieces. A huge 200KG or 500KG grinder may be used for larger capacities.An air-cooled crusher or even a cryogenic grinding machine could be incorporated to preserve the quality of heat-sensitive components. The fine powder is separated from appropriately sized flakes by passing the ground material through a vibrating pulverizer or sifter to achieve the required granulation. To maintain hygiene, this complete section—such as a dust grinder or dust collector grinder system—is frequently connected to a dust collection unit. The same principles apply to dry fruit powder grinders, cassava grinders, and dry grinders for beans, chemicals, or pharmaceuticals. Using a CE Certificate grinder is crucial for export-oriented enterprises to meet international machinery safety regulations.

The next steps in the process include mixing and quality control. To guarantee consistency, the potato flakes (or powder) can be mixed in a mixer with approved fortificants or anti-caking agents (such as 0.2% silicon dioxide). Strict quality inspections are carried out. In order to ensure compliance with regulations such as EU’s EC 1881/2006, this comprises metal detection (sensitive down to 0.5mm) and analysis for critical parameters: moisture (≤6%), microbiological counts (total plate count ≤10,000 CFU/g, pathogens missing), and heavy metals (e.g., lead ≤0.1mg/kg).

Automatic Packaging and Palletizing is the last stage. An automated packaging line receives the completed, authorized flakes. The product is weighed, filled, and sealed by machines into bulk export bags (such as 25kg cartons) or different retail bags (such as 200g or 500g). By displacing oxygen prior to sealing, nitrogen flushing is frequently employed in bags to increase shelf life.

Important Technical Benefits

Energy efficiency and intelligent control are two of the main advantages. Compared to conventional ovens, modern dryers use almost 30% less energy because to their sophisticated heat recovery and air recirculation systems. A central PLC (Programmable Logic Controller) with a touch-screen interface controls the entire line, enabling precise adjustment of crucial parameters like drying temperature, belt speed (which regulates residence time), and feed rates from the charger or hopper, guaranteeing consistent and ideal drying results each batch.

High compatibility and modular design are two more important benefits. This line’s fundamental concepts—cleaning, slicing, drying, and size reduction—apply to a variety of agricultural goods. Other dehydrated goods might be produced by the same line with modular modifications, like switching the final grinding machine module or altering the slicer configuration. For example, it could process herbs, tea, or mushroom powder by incorporating a spice grinder such as an airflow pulverizer or turbo grinder. For making sesame or peanut paste, it might be modified to include a seed grinder. For certain botanical extracts, it could even perform functions akin to those of an industrial weed grinder or herb grinder.Because of its versatility, it is a great investment for food processing facilities that want to maximize their return on investment by producing bone meal, tobacco blends for non-smoking applications, sugar-based mixtures, wheat grass powder, or specialty chemical and medicine powders.

Additionally, the line is designed for both safety and global market compliance. For durability and hygienic reasons, reputable manufacturers build these lines with stainless steel contact parts. They are made to comply with HACCP and FDA regulations, which are essential for exporting to markets in Europe, North America, and Southeast Asia. They also frequently include foreign certifications like CE for machinery safety, ISO 22000 for food safety management, and others.

Parameters:

Model Name | SG-600 | |

| Crushing Capacity(kg/h) | 1000~2000 | |

| Power(kw) | 11 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Model Name | SG-800 | |

| Crushing Capacity(kg/h) | 2000~4000 | |

| Power(kw) | 15 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

Ampere of Motors Customization for Seeds Grinder:

| KW | HP | Ampere |

| 75kw | 100HP | 135A |

| 55kw | 75HP | 99A |

| 30kw | 40HP | 54A |

| 22kw | 30HP | 39A |

| 2.2kw | 3HP | 3.9A |

| 1.5kw | 2HP | 2.7A |

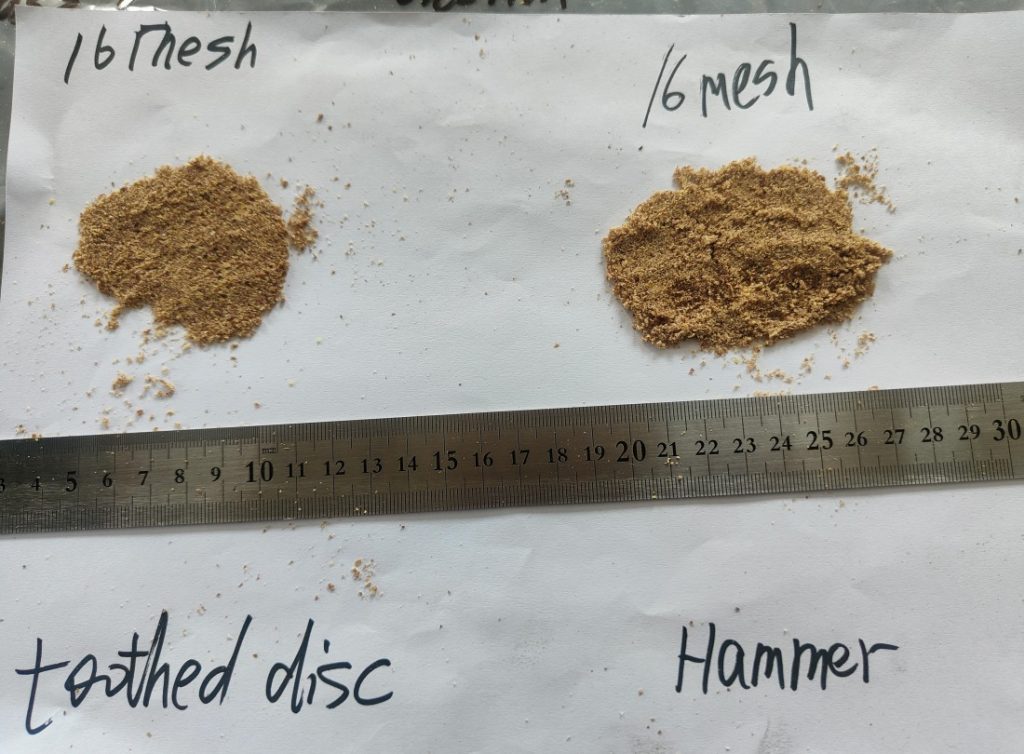

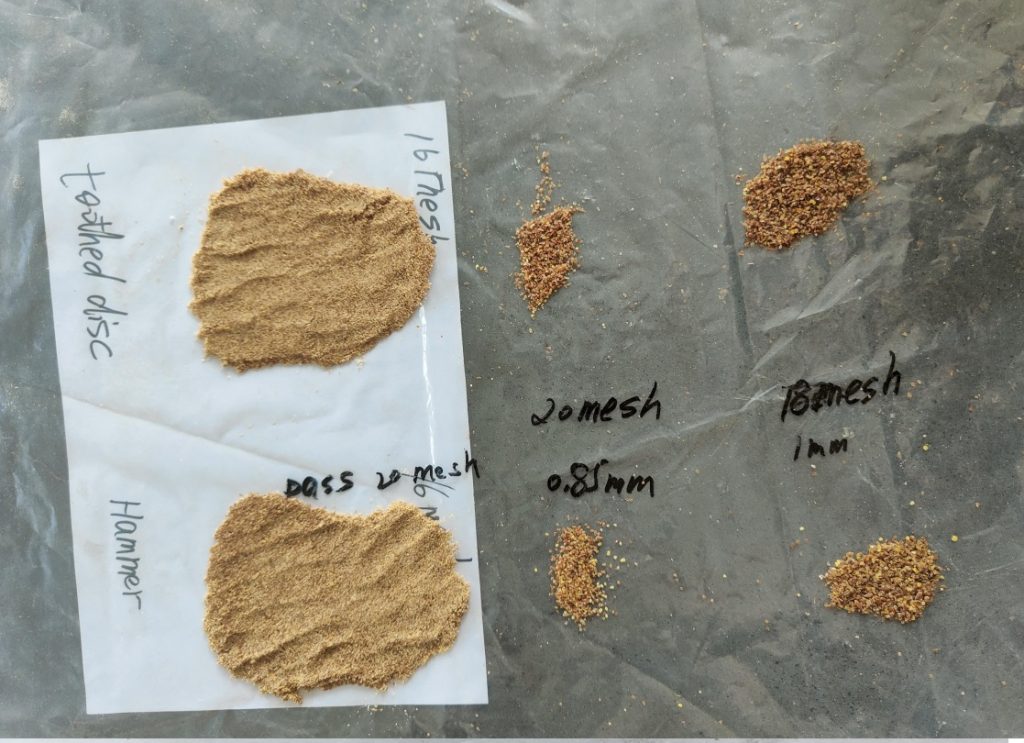

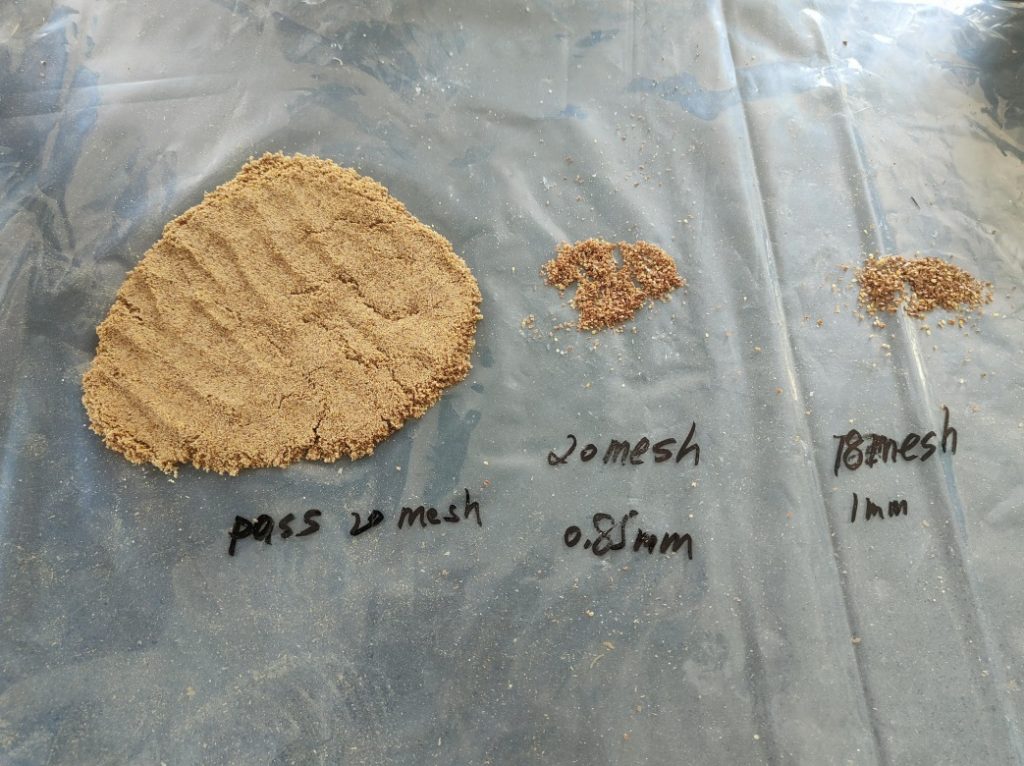

Test Report for Flax Seed Grinder:

A flax seed grinder is a type of seed nut grinder specifically designed for grinding flax seeds. Flax seeds are small, hard seeds that are packed with nutrition and are commonly used in baking and cooking. Grinding flax seeds helps to unlock their nutrients and make them easier to digest.

Flax seed grinders typically feature sharp blades or burrs that rotate to crush the flax seeds into a fine powder. This powder can then be used in a variety of recipes, such as smoothies, baked goods, and yogurt toppings. Some flax seed grinders are manual and require hand-cranking, while others are electric and feature powerful motors for faster grinding.

When choosing a flax seed grinder, it’s important to look for one with durable blades or burrs that can withstand the hard texture of flax seeds.

There are 3 ways of cooling down the grinder: water cooling system; air cooling system and liquid nitrogen freezing system. You can choose the right one if the grinder gets too hot. When machines goes too hot, the metal can expand, causing the grinding wheel to get stuck.

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

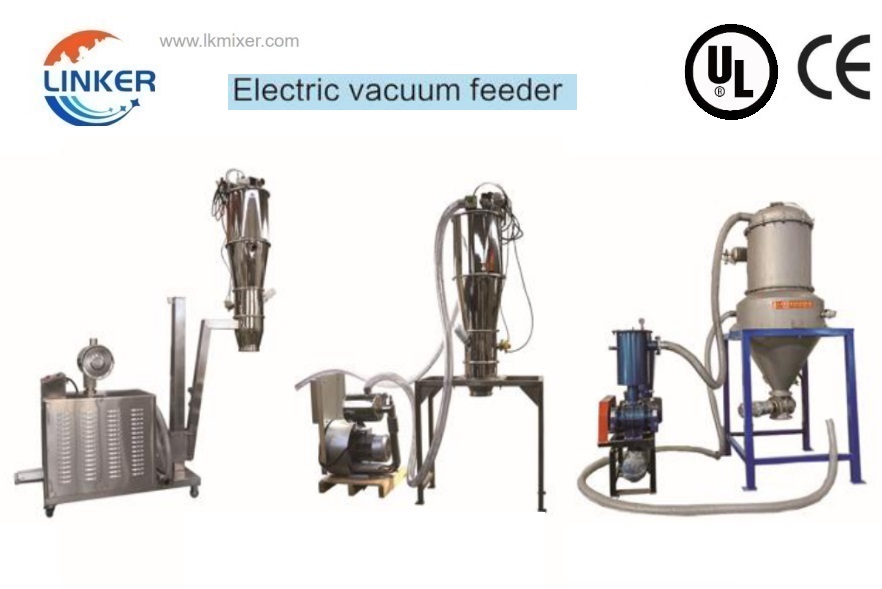

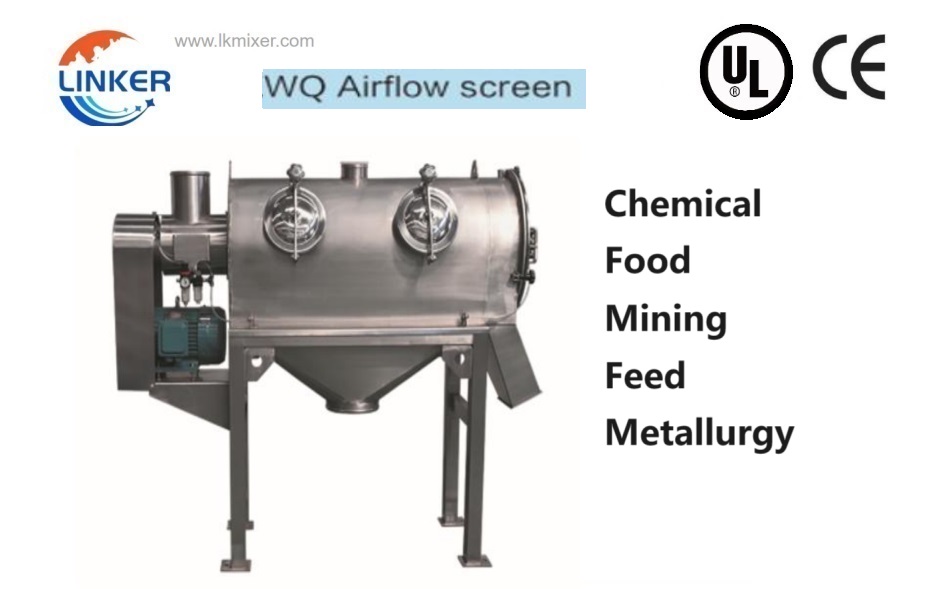

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

Operation Instruction

General Provisions

The operation instructions for a commercial grinder may vary depending on the specific model and manufacturer. However, here are some general guidelines that may apply to many high speed grinders:

- Safety precautions: Before operating the high speed grinder, it is important to review all safety precautions and warnings provided in the user manual. Safety precautions may include wearing appropriate personal protective equipment, such as eye protection and hearing protection, and avoiding loose clothing or jewelry that could become caught in the grinder.

- Preparation: The high speed grinder should be placed on a stable and level surface, and all necessary components should be assembled according to the manufacturer’s instructions. The grinder should also be connected to a power source that is appropriate for its voltage and wattage.

- Loading the grinder: The material to be ground should be loaded into the grinder according to the manufacturer’s instructions. Overloading the grinder may cause damage to the machine and result in poor grinding performance.

- Starting the grinder: The grinder should be started according to the manufacturer’s instructions. This may involve pressing a button, turning a dial, or flipping a switch. The user should ensure that their hands are clear of the grinder and that the material to be ground is positioned properly.

- Adjusting the speed and settings: The speed and other settings of the high speed grinder may be adjusted according to the material being ground and the desired outcome. The user should follow the manufacturer’s instructions for making adjustments to the grinder.

- Monitoring the grinding process: The user should monitor the grinding process to ensure that it is progressing smoothly and that the material is being ground to the desired size and consistency. Any issues or abnormalities should be addressed promptly to prevent damage to the machine.

- Shutting down the grinder: When the grinding process is complete, the grinder should be shut down according to the manufacturer’s instructions. The user should ensure that the machine is completely stopped and that all moving parts have come to a complete stop before attempting to clean or service the grinder.

Overall, the operation instructions for a commercial grinder may involve a number of steps and safety precautions. It is important to carefully review the manufacturer’s instructions and follow proper operating procedures to ensure safe and effective use of the machine.

Preparation Work

Before running a commercial grinder, there are several important preparation steps that should be taken to ensure safe and effective operation of the machine. Here are some general guidelines for preparing to run a high speed grinder:

- Read the user manual: The first step in preparing to run a high speed grinder is to carefully read the user manual provided by the manufacturer. The user manual will provide important information about the specific model of grinder being used, including its features, specifications, and safety precautions.

- Select the appropriate grinding wheel: The grinding wheel used in a high speed grinder should be selected based on the material being ground and the desired outcome. It is important to use the correct type of grinding wheel to prevent damage to the machine and ensure optimal grinding performance.

- Inspect the grinder: Before running the grinder, it is important to inspect it for any signs of damage or wear. The user should check for loose or missing components, cracks or other signs of damage to the machine’s housing or other parts, and any other issues that could affect the grinder’s operation.

- Install the grinding wheel: The grinding wheel should be installed according to the manufacturer’s instructions, making sure that it is securely fastened and aligned properly. The user should also check the wheel for any cracks or other signs of damage before installation.

- Secure the workpiece: The workpiece to be ground should be securely clamped or held in place before starting the grinder. This will help to ensure safe and effective operation and prevent the workpiece from becoming dislodged or damaged during grinding.

- Connect the power source: The high speed grinder should be connected to a power source that is appropriate for its voltage and wattage. It is important to use a properly grounded power source to ensure safe and reliable operation of the machine.

- Test run: Before beginning actual grinding operations, it may be useful to perform a test run to ensure that the grinder is functioning properly and that the grinding wheel is aligned and balanced properly. The user should follow the manufacturer’s instructions for performing a test run.

By following these preparation steps, users can ensure safe and effective operation of a high speed grinder and achieve optimal grinding results.

Treatment of inspection

Inspection of a commercial grinder is an important maintenance procedure that helps ensure safe and effective operation of the machine. Here are some general guidelines for inspecting a high speed grinder:

- Disconnect power source: Before performing any inspection or maintenance on a high speed grinder, the power source should be disconnected to prevent accidental startup.

- Check for wear and damage: The user should inspect the grinder for any signs of wear or damage, such as cracks in the housing, worn or damaged grinding wheels, or loose or missing parts. Any issues should be addressed promptly to prevent further damage to the machine.

- Check alignment and balance of grinding wheel: The grinding wheel should be inspected for proper alignment and balance, as these factors can affect the quality of the grinding operation. If the grinding wheel is not properly aligned or balanced, it should be adjusted or replaced as necessary.

- Check for proper lubrication: The high speed grinder should be inspected for proper lubrication, as inadequate lubrication can cause excessive wear and damage to the machine’s moving parts. The user should follow the manufacturer’s instructions for lubrication, and add lubricant as necessary.

- Inspect electrical components: The electrical components of the high speed grinder, including the wiring, switches, and control panel, should be inspected for any signs of wear, damage, or loose connections. Any issues should be addressed promptly to prevent electrical problems.

- Test run: After completing the inspection, it may be useful to perform a test run of the high speed grinder to ensure that it is functioning properly and that any issues have been addressed.

By following these inspection guidelines, users can help ensure safe and effective operation of a high speed grinder and minimize the risk of damage or injury during grinding operations.

Operation Attention

Running a commercial grinder can be a dangerous operation if proper precautions are not taken. Here are some general guidelines for safe operation of a high speed grinder:

- Personal protective equipment: The user should wear appropriate personal protective equipment, such as safety glasses, hearing protection, and gloves, to prevent injury from flying debris, noise, and contact with the grinding wheel.

- Secure workpiece: The workpiece being ground should be securely clamped or held in place to prevent it from becoming dislodged during grinding.

- Use proper grinding wheel: The user should select the appropriate grinding wheel for the material being ground and ensure that it is installed correctly and securely. The grinding wheel should be inspected for cracks or other damage before use.

- Adjust grinding wheel speed: The speed of the grinding wheel should be adjusted according to the manufacturer’s instructions to ensure optimal grinding performance and prevent damage to the machine or workpiece.

- Avoid excessive pressure: The user should avoid applying excessive pressure to the grinding wheel, as this can cause the wheel to overheat and wear out more quickly.

- Avoid overheating: The high speed grinder should not be operated continuously for extended periods of time, as this can cause overheating and damage to the machine.

- Monitor grinding operation: The user should closely monitor the grinding operation to ensure that the workpiece is being ground properly and that the grinding wheel is functioning correctly.

- Disconnect power source: After completing grinding operations, the power source should be disconnected to prevent accidental startup.

By following these guidelines, users can operate a high speed grinder safely and effectively, and achieve optimal grinding results. It is important to follow the manufacturer’s instructions and all applicable safety regulations when operating any type of machinery.

Applications of Industrial Seed Grinder

Industrial seed grinders are used in a variety of applications across many industries. Here are some of the most common applications of industrial seed grinders:

- Food industry: Industrial seed grinders are used extensively in the food industry to grind seeds, nuts, and spices into fine powders or pastes. These powders and pastes are then used in a variety of products such as sauces, seasonings, and spreads.

- Pharmaceutical industry: In the pharmaceutical industry, industrial seed grinders are used to grind plant material into a fine powder, which is then used to make medicines and supplements.

- Cosmetics industry: Industrial seed grinders are also used in the cosmetics industry to grind plant material into a fine powder or paste, which is then used in products such as face masks, scrubs, and exfoliants.

- Agricultural industry: Industrial seed grinders are used in the agricultural industry to process seeds, such as soybeans, into animal feed.

- Chemical industry: In the chemical industry, industrial seed grinders are used to grind materials such as resins, pigments, and dyes into a fine powder.

- Renewable energy industry: Industrial seed grinders are also used in the renewable energy industry to process biomass into a fine powder, which is then burned to generate electricity.

Overall, industrial seed grinders are versatile machines that are used in many different industries for a variety of applications. They are essential for processing plant material into fine powders and pastes that can be used in many different products.

Food Producing Process Flow:

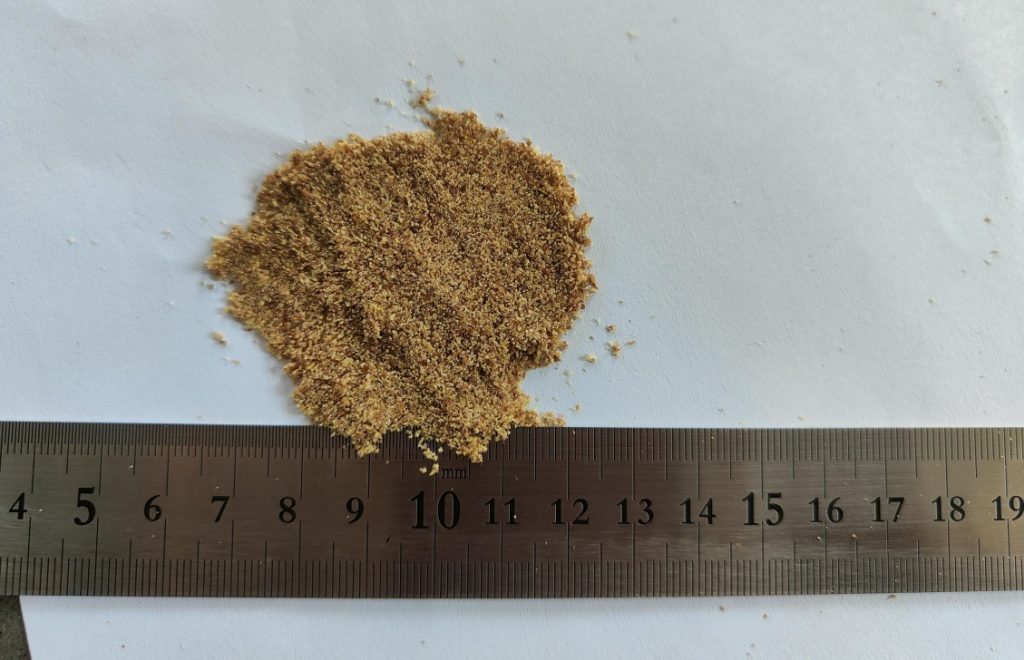

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Automatic Banana Powder Production Line Youtube Video

Customization Seeds Grinder According to your Capacity:

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

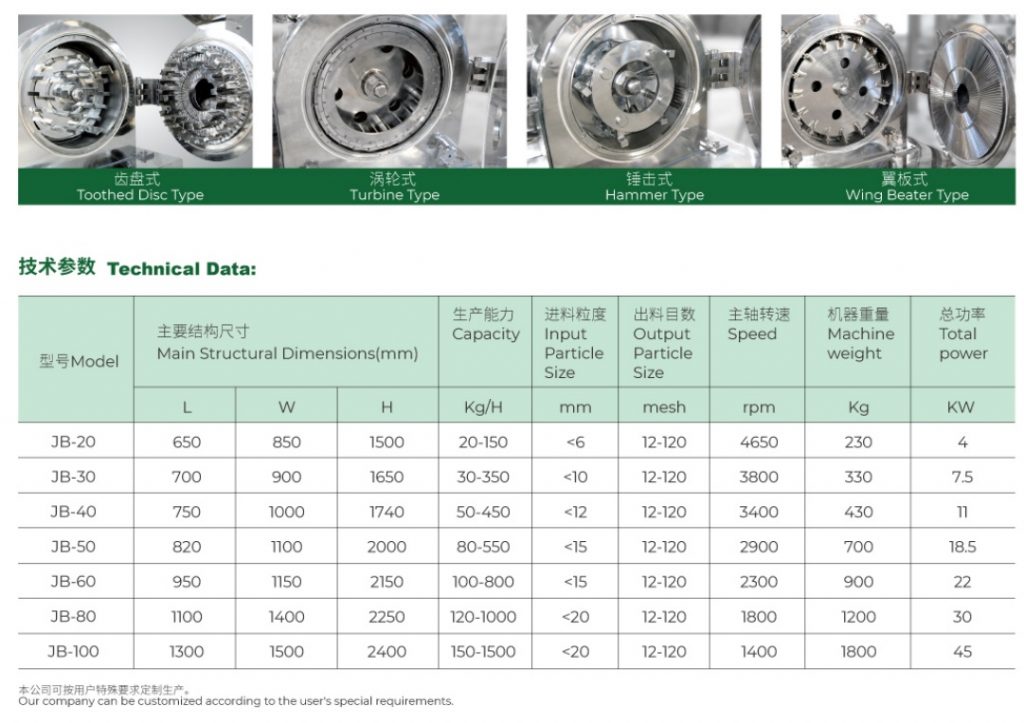

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?