Automatic Potato Powder Production Line

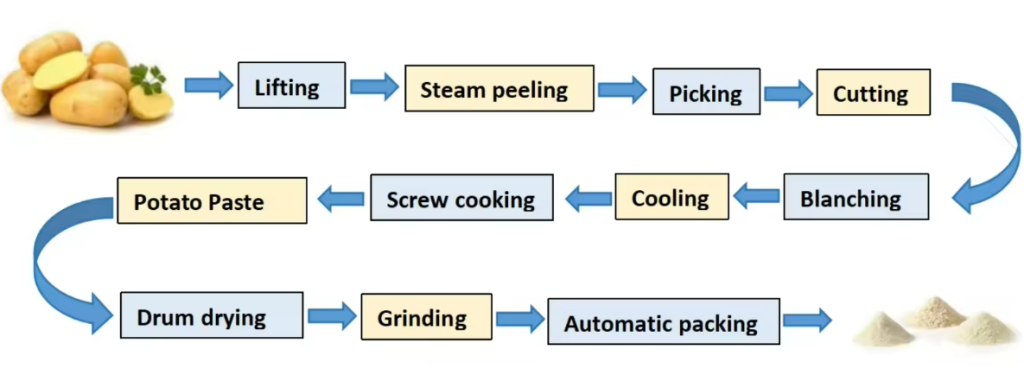

Potato Powder Automatic Productino Line Design:

An Automatic Potato Powder Production Line is a fully integrated, intelligent industrial system designed for the continuous, large-scale production of high-purity potato starch and its derived products, like vermicelli or noodles, using a smooth process that includes cleaning raw materials, extracting starch, purifying it, drying, forming optional products, and automating packaging.

Intake of Raw Materials and Thorough Cleaning

Freshly picked potatoes are unloaded and fed into the system to start the process. The flow of raw tubers entering the line is managed by a hydraulic conveyor or regulated charger.The first crucial stage is thorough cleaning. The potatoes go through a multi-stage washing process that usually combines a high-pressure spray tunnel with a revolving drum washer. All dirt, clay, sand, and field debris are successfully eliminated in this way. In terms of technology, this process is just as important as the first cleaning of other root crops, such as sweet potatoes or cassava. To ensure that only clean potatoes move forward, advanced lines use trash and stone removal equipment to separate lighter items like vines from heavy pollutants like stones. In order to smooth out variations in the raw material supply and provide a consistent, uninterrupted flow to the following stage, the cleaned potatoes are thereafter kept in a sizable buffer hopper.

Breakdown of Cells and Extraction of Primary Starch

After being cleaned, the potatoes are sent to the stage of disintegration.Here, the objective is to release the starch granules by fully rupturing the potato cells. High-efficiency rasping machines or specialized grinding equipment are used to accomplish this. These devices work similarly to an ultra-high-speed, industrial-scale Hammer Mill or a coarse crusher made especially for processing tubers. They turn the potatoes into a slurry or fine, moist pulp. After being combined with water, this slurry—which contains soluble proteins, potato fibers (pulp), and starch granules—is pushed to the separation stage. Centrifugal screens or rotating sieves are commonly used for the initial separation of starch from the coarse fiber. While the fibrous pulp is dewatered and frequently utilized as animal feed or for the manufacture of biogas, the extracted starch milk—a mixture of water and starch—continues.

Starch Washing, Refining, and Purification

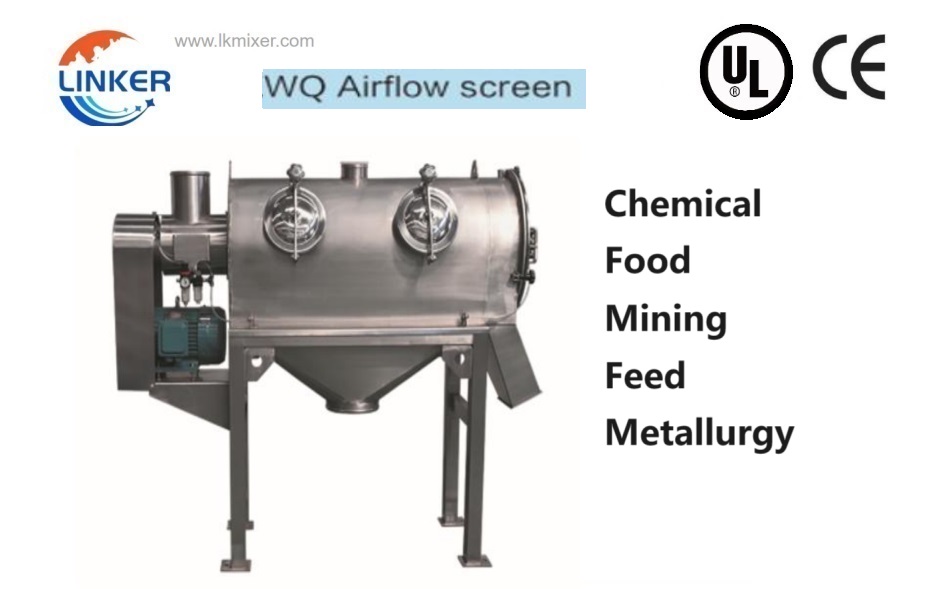

Fine fibers, soluble proteins, and other contaminants are present in the crude starch milk. The refinement procedure is multi-stage in order to get food-grade purity. To get rid of any leftover tiny fibers and sand particles, the milk initially goes through centrifugal separators or hydrocyclones. In a multi-stage (e.g., 12 to 18 steps) hydrocyclone battery, the core is purified. Here, fresh water is used to counter-current wash the starch milk. Centrifugal force powers this complex process, which effectively removes soluble proteins, sugars, and other contaminants, leaving behind a highly concentrated, pure starch slurry. The technique is equally accurate but focuses on separation, which is different from the grinding action of an airflow pulverizer or universal grinder.

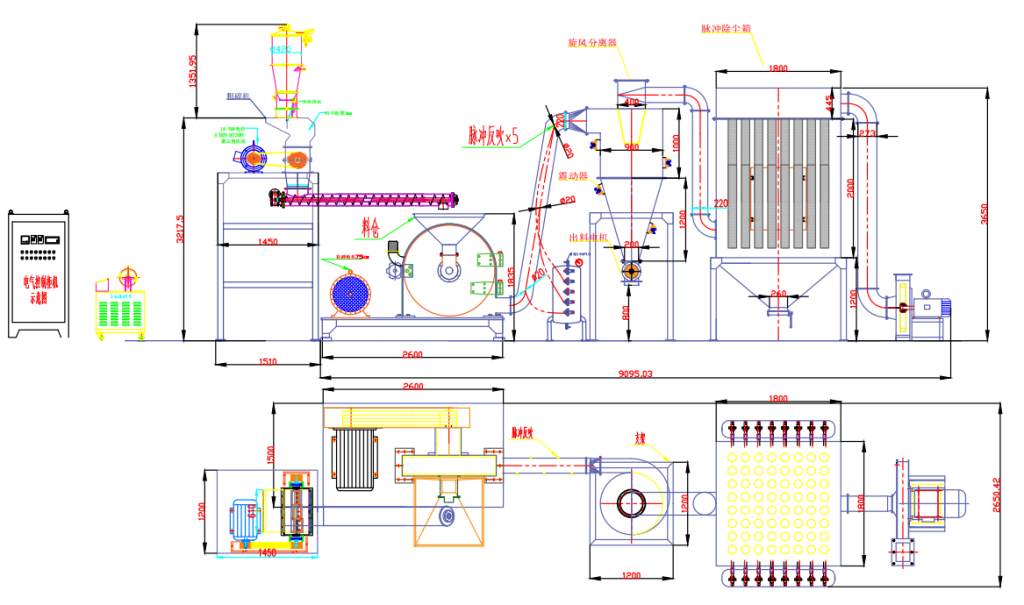

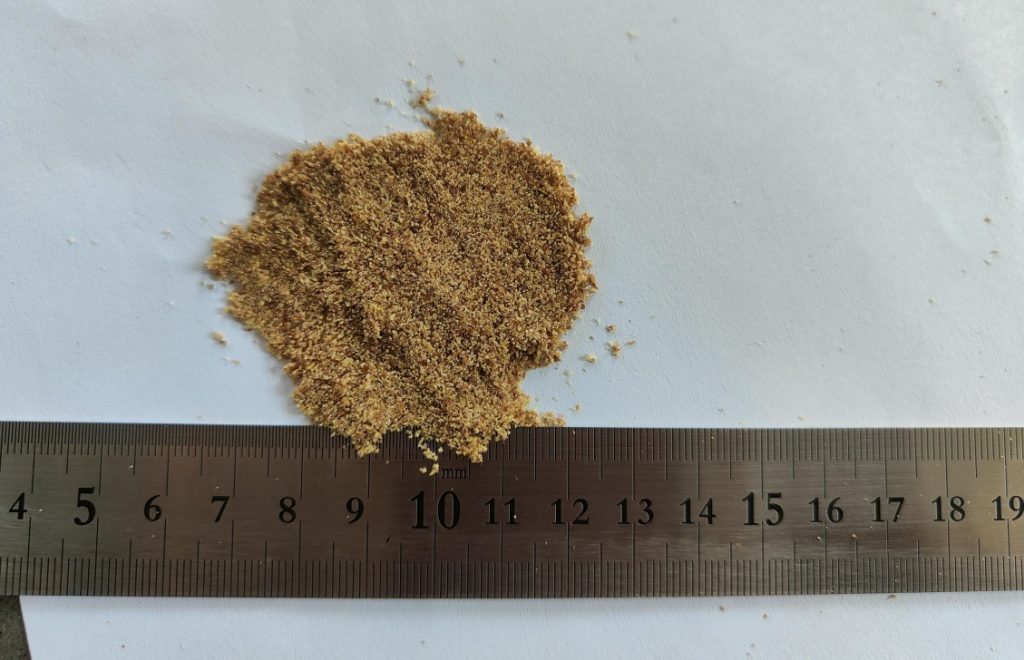

Final Powder Production, Drying, and Dewatering

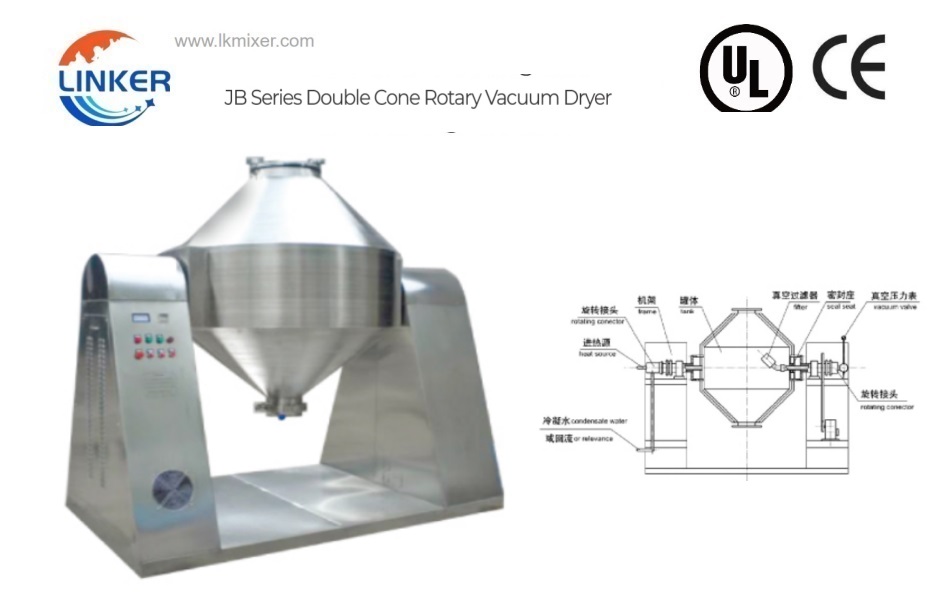

After that, the concentrated, purified starch slurry is dewatered. This is frequently accomplished with a vacuum belt filter or peeler centrifuge, which eliminates the majority of the free water and produces a wet starch cake with a moisture content of about 35–40%. After that, this cake is put into the drying apparatus. Flash drying is the most popular and effective technique. This high-speed airflow pulverizer-style dryer breaks up the wet cake and introduces it into a stream of heated air. As the starch granules pass through the drying duct, they are dried practically instantly. The starch’s natural quality is maintained by this quick drying.After cooling, the final dry starch powder may be gently ground or sieved, possibly with a vibrating pulverizer, to guarantee a consistent particle size. Similar to systems in flour, corn starch, or rice powder mills, the entire drying and powder handling section is enclosed and connected to a sturdy dust collector grinder or vacuum mill system to guarantee a safe, dust-free environment and to recover valuable product.

Vermicelli and Noodles as Optional Product Forming

Purified potato starch is the starting ingredient for lines that make vermicelli or starch noodles.In a mixing tank, it is automatically balanced with water and any allowed additives (such as for flexibility). After being heated (gelatinized), this slurry is cast or extruded using specialized shaping equipment to create thin sheets or strands. After being created, the noodles are chilled, dried in a controlled low-temperature dryer to develop texture, and then cut to length.

Packaging Automation and Intelligent System Management

The finished product is sent to the automated packaging area, regardless of whether it is packed noodles or pure potato starch powder. Powder is dosed into bags using weigh-fill machines or precise electric grinder-type auger fillers. Automatic weighing and bagging devices are employed for noodles. For hygienic reasons, the packing machines have contact parts made of stainless steel.A central computerized system (PLC/SCADA) controls the entire line, from the first charger to the palletizing robot. Feed rates, grinding intensity, separation efficiency, dryer temperatures, and packaging weights are all monitored and controlled by this system, which guarantees consistent quality, permits recipe management, and offers complete production traceability. The line complies with strict food safety regulations (GMP, HACCP) and is built with broad stainless steel surfaces that are easy to clean. Its core equipment is frequently certified (for example, the CE Certificate grinder for essential machinery). The Automatic Potato Powder Production Line is a prime example of high-capacity, dependable, and efficient food ingredient and product manufacture, from raw tuber to shelf-ready product.

Food Producing Process Flow:

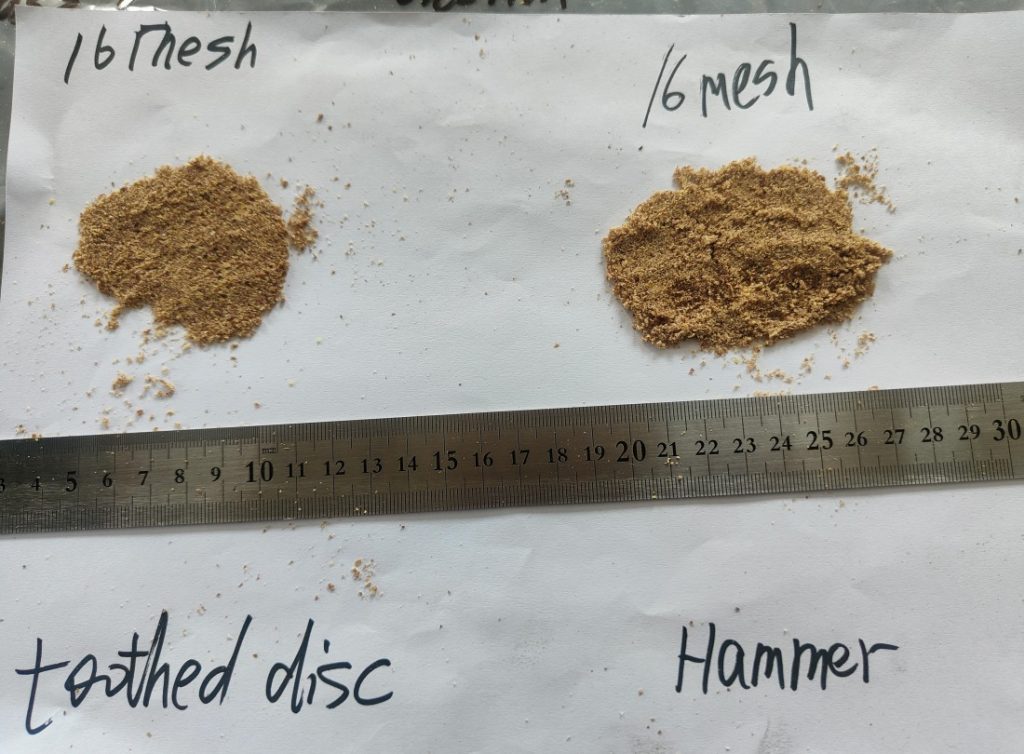

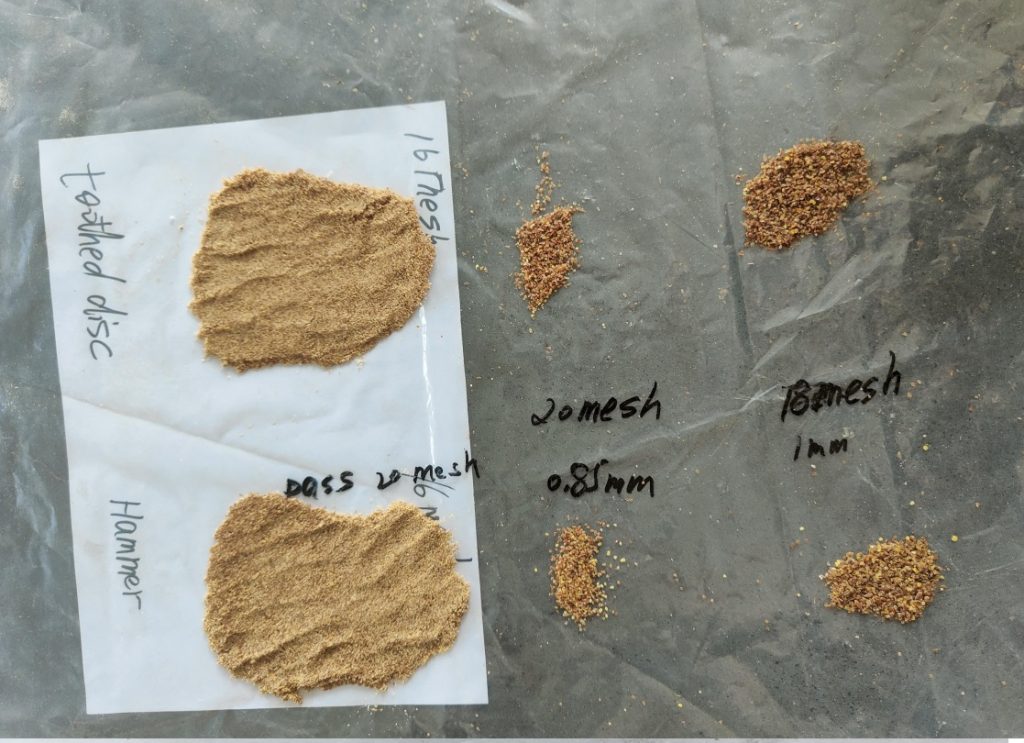

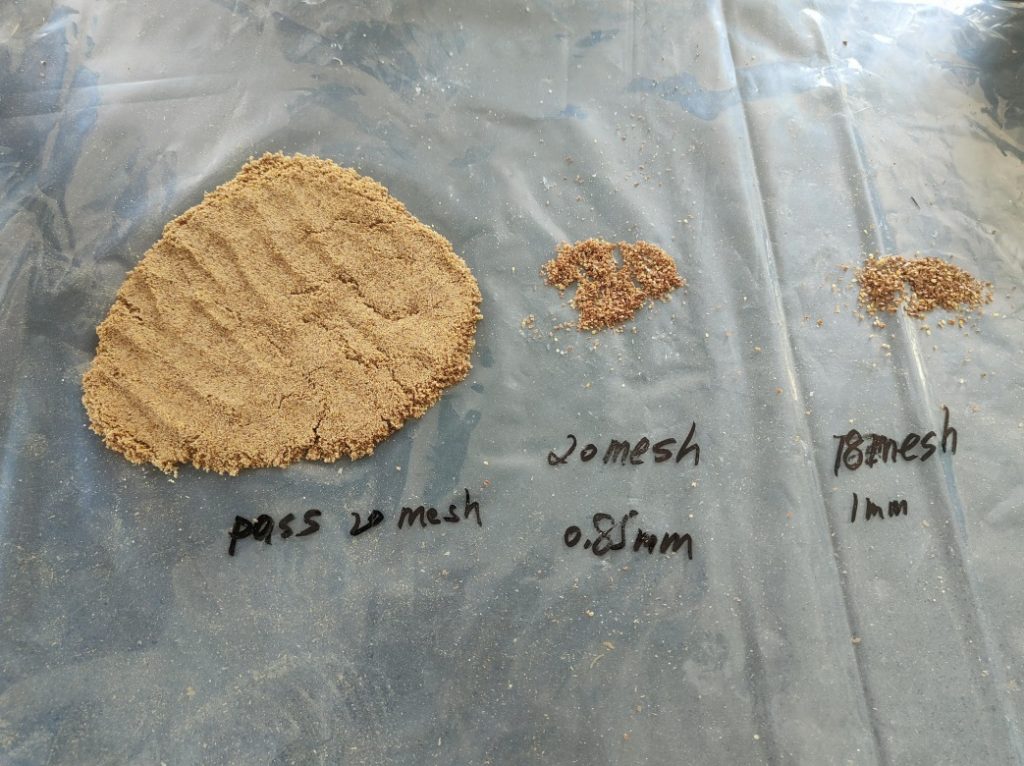

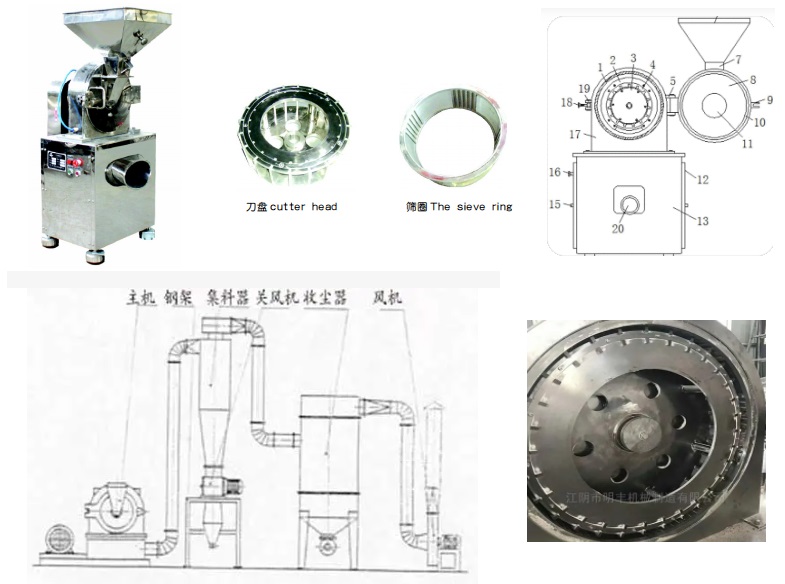

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Automatic Banana Powder Production Line Youtube Video

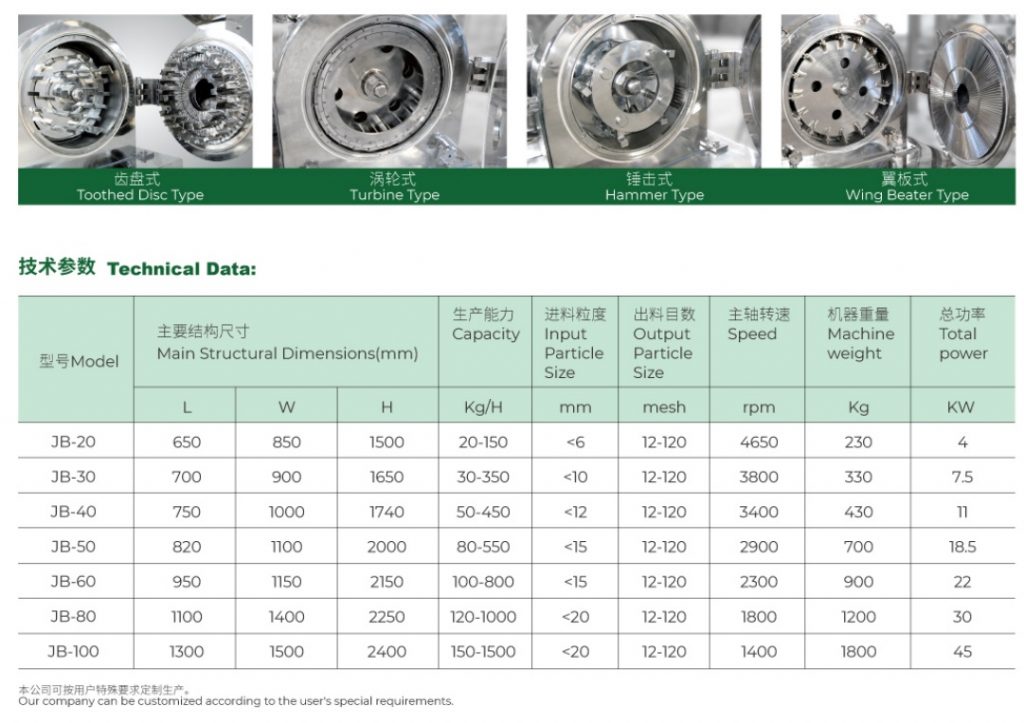

Customization Seeds Grinder According to your Capacity:

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?