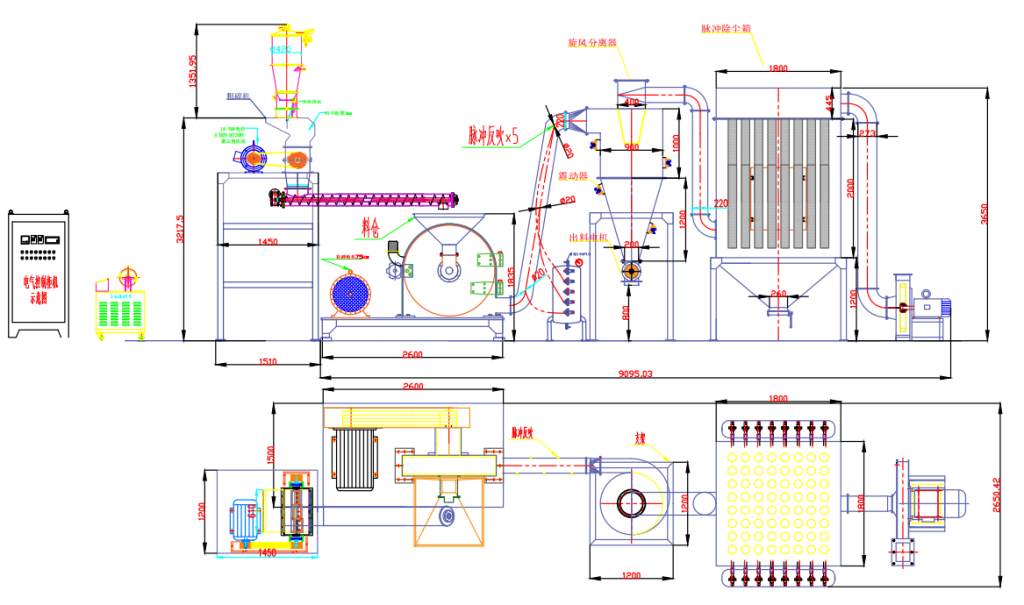

Automatic Rubber Powder Production Line

Rubber Powder Automatic Productino Line Design:

Waste tires can be continuously converted into fine rubber powder using an Automatic Rubber Powder Production Line, which uses intelligent equipment. The main steps in this process are preparation, separation, fine grinding, and automated packaging.

Preparing Raw Materials

Tire preparation is the first step in the entire procedure. The steel bead wires are first extracted from waste tires using a tire de-beading machine. After that, the tires are put into block or strip cutting machines, which cut them into consistent rubber chunks that are usually about 50 by 50 mm in size.These pieces serve as the main source of feedstock for the phases that follow. Similar to the initial crushing or chopping in other sectors, whether it’s breaking down bones in rendering processes or preparing cassava for a cassava grinding mill, this initial size is essential for effective handling and processing. These chunks are usually moved to the following stage by an automatic charger or conveyor system, which guarantees a consistent and regulated material flow into the main processing line.

Impurity Separation and Secondary Crushing

After that, the produced rubber pieces move on to the critical step of impurity removal. They are initially fed through a primary crusher, which usually consists of a heavy-duty dual-shaft shear shredder. The crusher breaks them up into smaller granules that are between 8 and 15 mm in size.Compared to a small herb grinder or a standard corn hammer mill, this machine works on a considerably bigger scale. Water spray systems are frequently utilized to reduce dust, cool the equipment, and lubricate during this initial shredding. Rubber, steel wires, and textile fibers must be separated from one another. More than 99% of the ferrous metal (steel) is eliminated using strong hanging magnets or magnetic drums. Vibrating pulverizer screens or air classifiers are subsequently used to sort the residual lighter textile fibers. Similar to the cleaning and winnowing procedures for agricultural products like wheat, rice, or seeds before they are ground into flour or other products, this thorough cleaning stage is essential for generating pure rubber powder.The rubber granules may go through a further crushing process after purification in order to optimize their size and uniformity for the fine grinding stage.

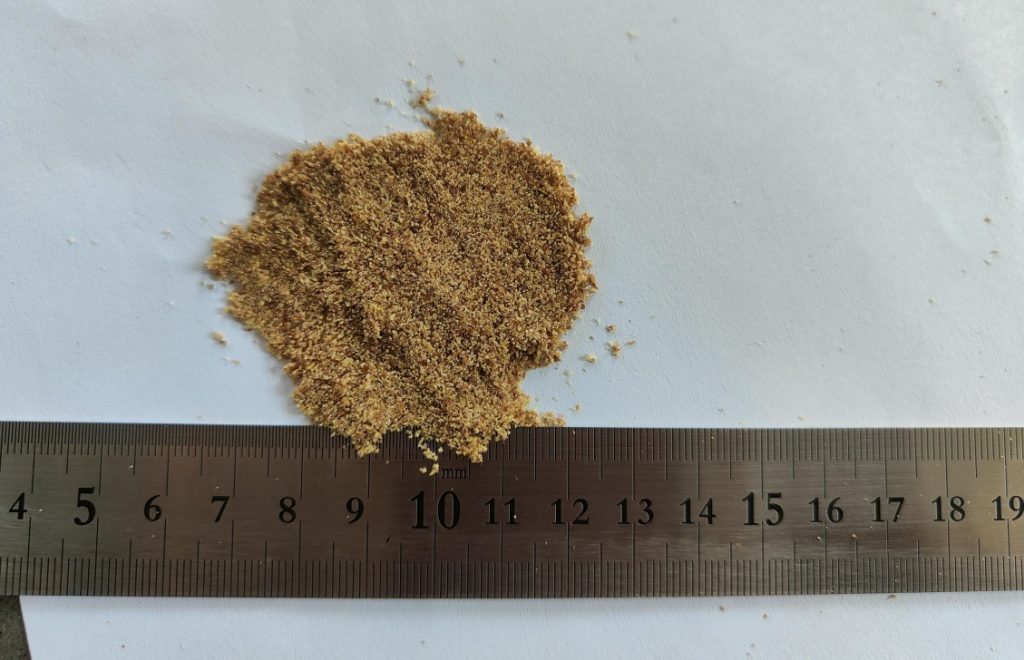

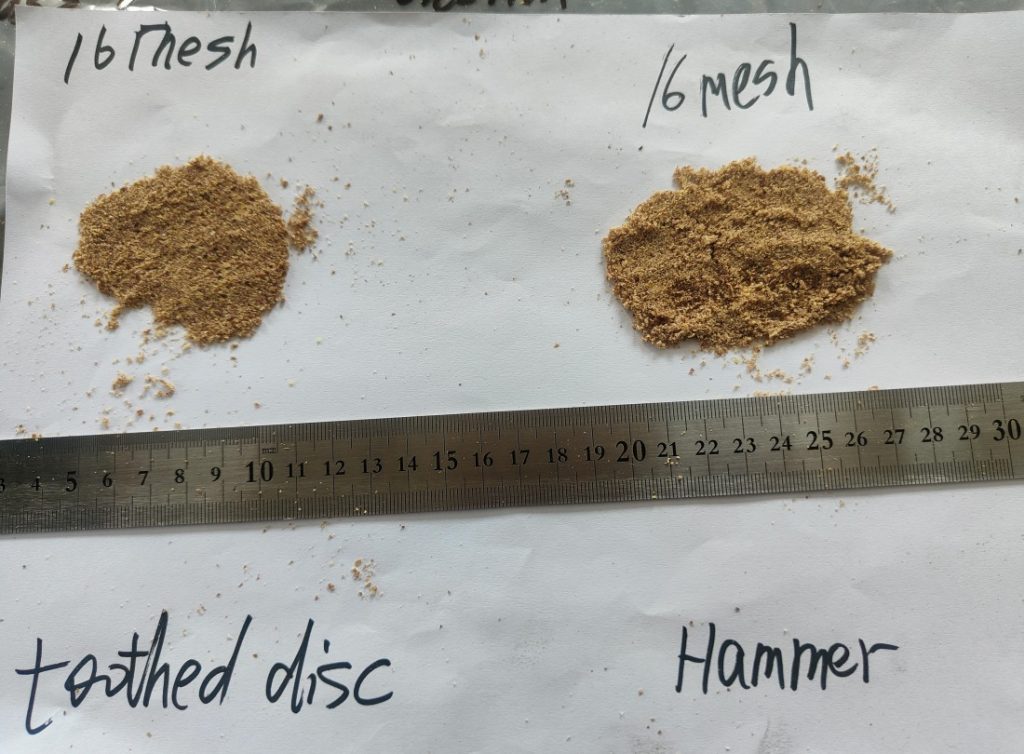

Classification of Particle Size and Fine Grinding

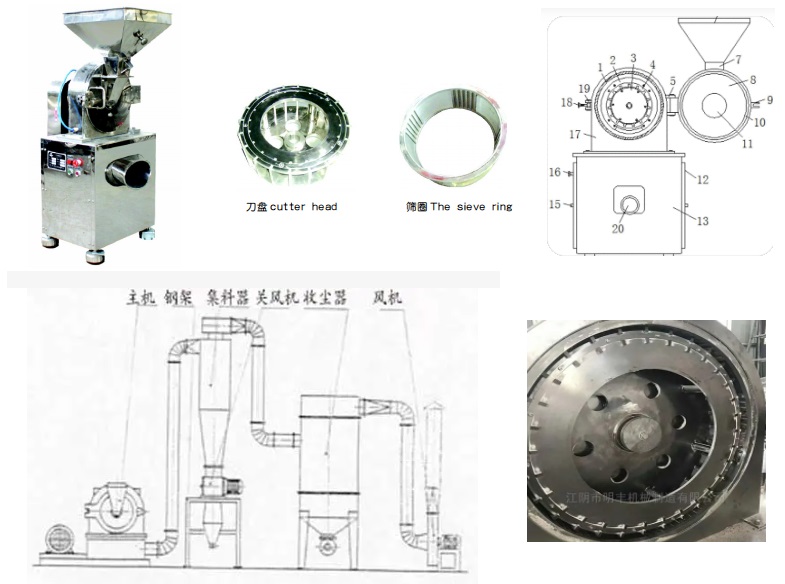

The rubber is turned into powder here, at the center of the production line. Rubber granules that have been cleaned and sized are put into specialized grinding machines. The quality and fineness of the finished product are greatly influenced by the technology selection. Ambient grinding with cooling is typical for standard to fine rubber powder (e.g., 10-100 mesh).These grinding devices, which can be impact or roller mills, frequently have water-cooled jackets or air-cooled crusher systems to disperse the heat produced by friction and stop the rubber from softening and re-agglomerating.

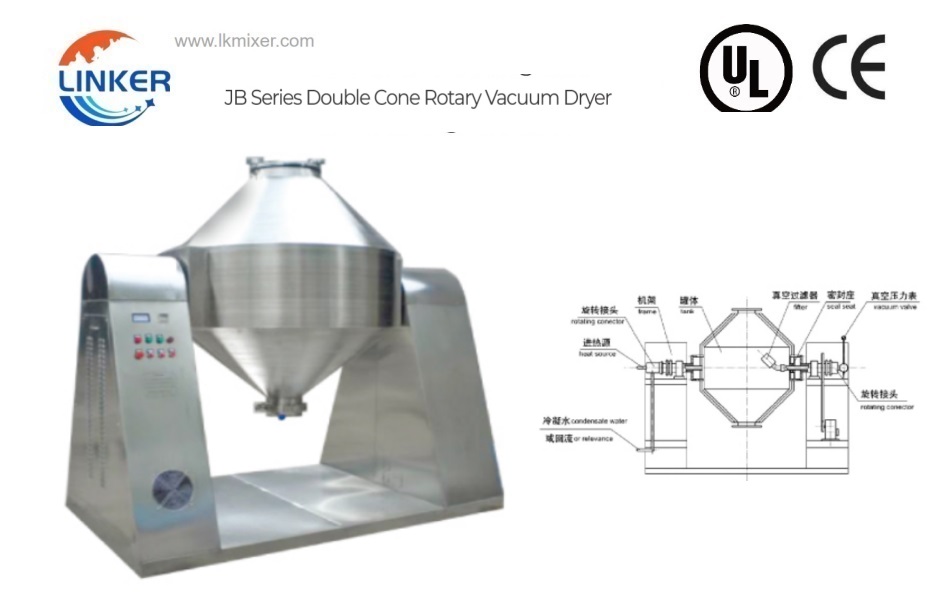

Cryogenic grinding is the recommended technique for creating ultra-fine rubber powder (up to 240 mesh or more) or for applications requiring exceptional particle characteristics. Rubber granules are subjected to liquid nitrogen (at about -195.8°C) in a cryogenic grinding machine, which embrittles the substance. This makes it easier to break up into smaller particles with less heat production and a more regulated particle shape.Although this technology is designed to meet the high volume requirements of rubber recycling, it is conceptually comparable to that used for grinding heat-sensitive spices, specific medicinal herbs, or other temperature-sensitive materials in specialized applications. Multi-stage recovery systems are frequently used to effectively handle cold energy. Vibrating pulverizers or, for more accurate separation, airflow pulverizers (air classifiers) are then used to classify the ground powder by particle size. These devices sort the powder into different mesh sizes, like 80–100 mesh or 10–40 mesh. High yield and constant product quality are ensured by automatically recycling any large particles back into the grinding process. With integrated dust collector grinder systems catching any airborne particles, this entire grinding and classification area is subject to strict dust control.

Automated Packaging and Environmental Control

An essential component of the design is environmental responsibility. Comprehensive dust collection systems, including pulse-jet baghouse filters, are used at all transfer points and processing stations, and the entire production line is usually enclosed. This guarantees that the levels of dust in the workshop meet national environmental and occupational health regulations. Following classification, the completed rubber powder is delivered to the automated packaging station using pneumatic conveying equipment. Here, the powder is doped into bags, usually weighing 25 kg or 50 kg, using precision weighing devices.Similar to methods used to preserve coffee or some food items, the packaging line may offer choices for vacuum packing or nitrogen gas flushing to increase the product’s shelf life by preventing oxidation. The completely automated process from waste tire to packaged product is subsequently completed by robots sealing, labeling, and frequently palletizing the bags.

In conclusion, an Automatic Rubber Powder Production Line is an advanced recycling system that turns a difficult waste stream into a useful product.Although it serves a particular purpose, numerous processing sectors share the underlying technologies of size reduction (using equipment far more robust than a universal grinder or a dry fruit powder grinder machine), precise separation, and automated control. The concepts of effective, clean, and controlled manufacturing are applicable anywhere, from a 500KG grinder in an industrial facility to a CE Certificate grinder guaranteeing safety standards. The line’s construction, which frequently uses massive stainless steel components for longevity and hygienic reasons, demonstrates a dedication to cutting-edge and sustainable manufacturing techniques.

Food Producing Process Flow:

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Automatic Banana Powder Production Line Youtube Video

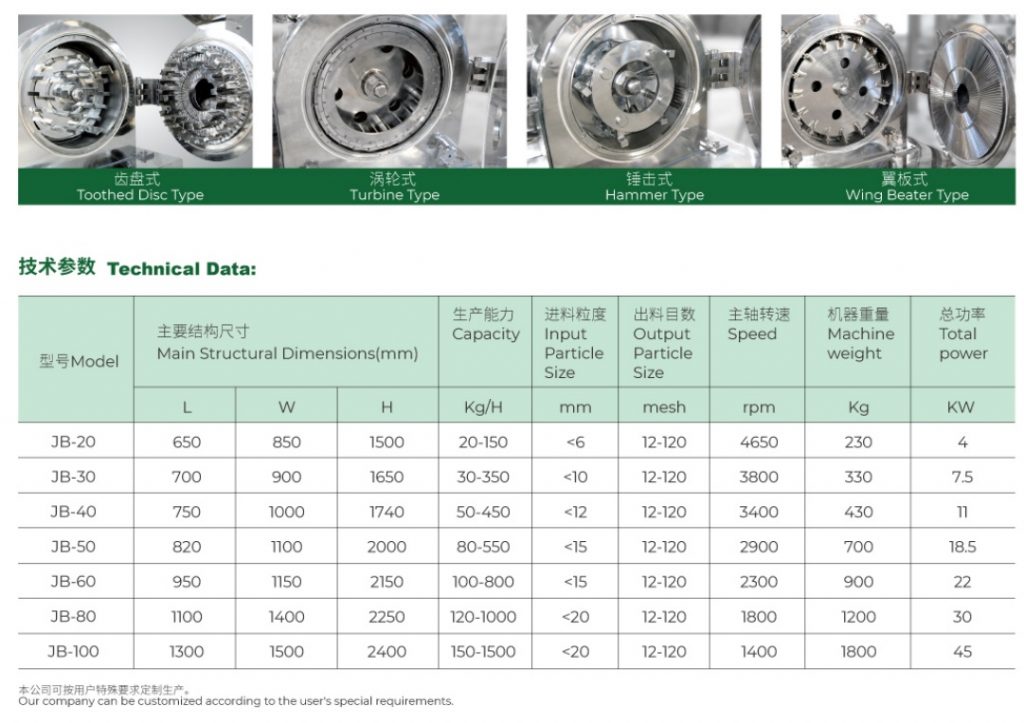

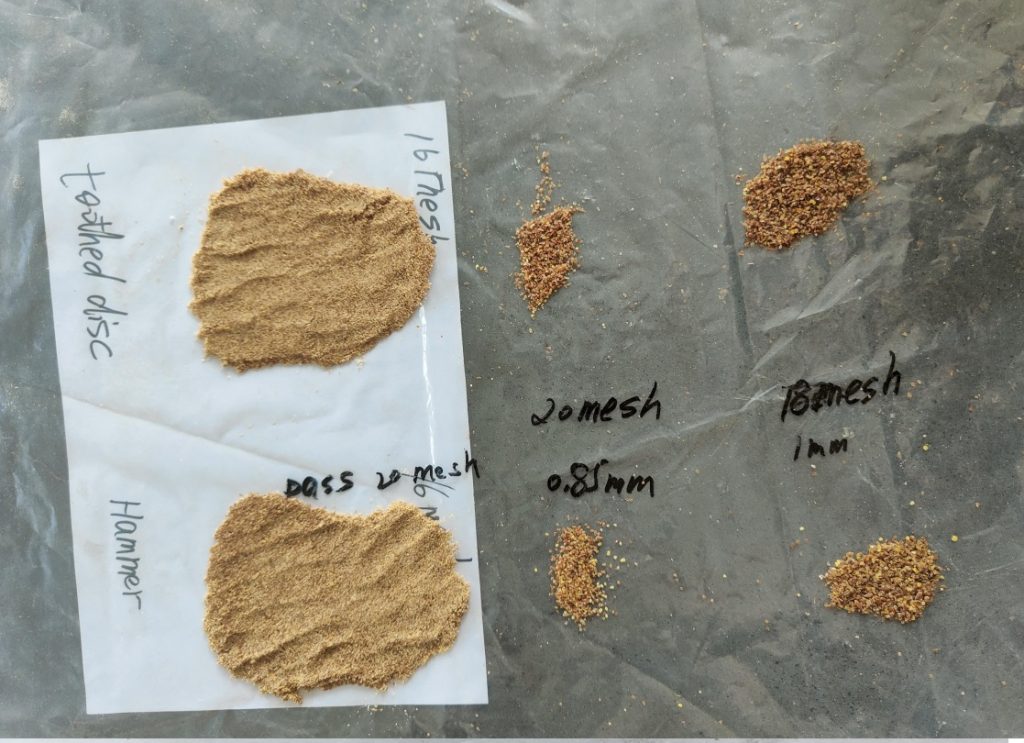

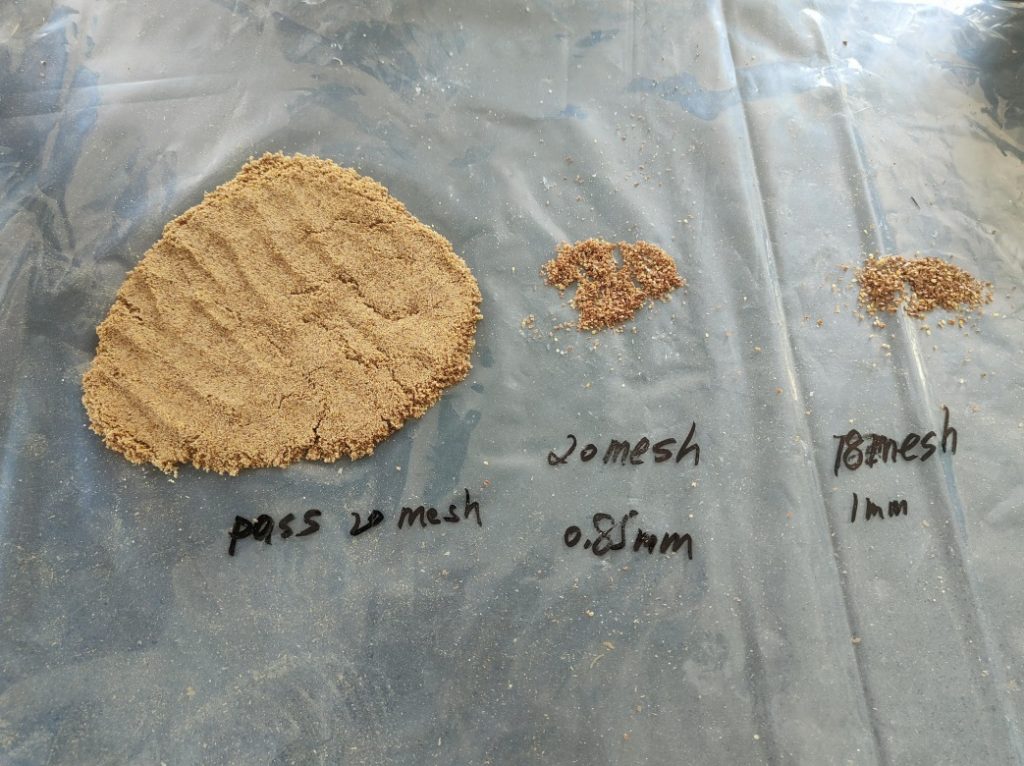

Customization Seeds Grinder According to your Capacity:

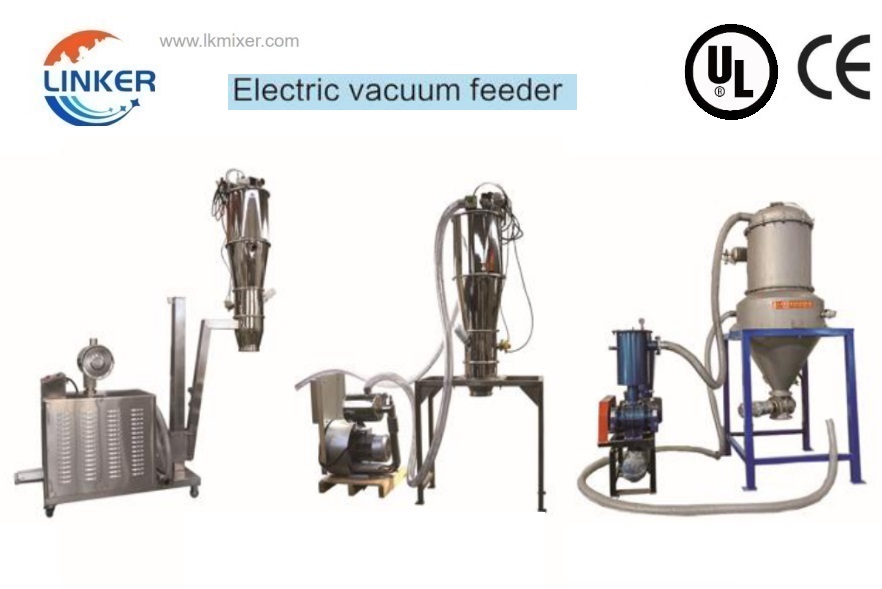

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?