Automatic secret sauce production line Price

The price of an automatic secret sauce production line ranges from $150,000 to $3,200,000, and its specific price is mainly determined by the customization level based on the general sauce production platform, production capacity, core customized equipment (such as intelligent temperature-controlled fermentation tank, automatic planetary frying pan), degree of automation and digital control level. It should be emphasized first that in the technical standards and product catalogs of the food engineering and equipment manufacturing industry, there is no standardized and proprietary industrial equipment uniformly defined as “automatic secret sauce production line”. “Secret sauce” is a concept in the field of marketing and product research and development, referring specifically to compound condiment sauces with independent intellectual property rights formulas (raw material combination, spice compatibility, fermentation or frying process) owned by enterprises, rather than an industrial category with unified physical property parameters. Therefore, the essence of an automatic “secret sauce” production line is to carry out equipment selection, module combination and in-depth customization of control programs on a mature general sauce manufacturing platform according to the enterprise’s specific formulas and process parameters. The following content will fully expand each detail in the form of paragraphs, naturally integrate all required equipment terms, use simple and easy-to-understand language, and ensure the total word count reaches 2000 words.

Price Impact of Industrial Deconstruction of “Secret Sauce”: From Formula Secret to Process Parameters

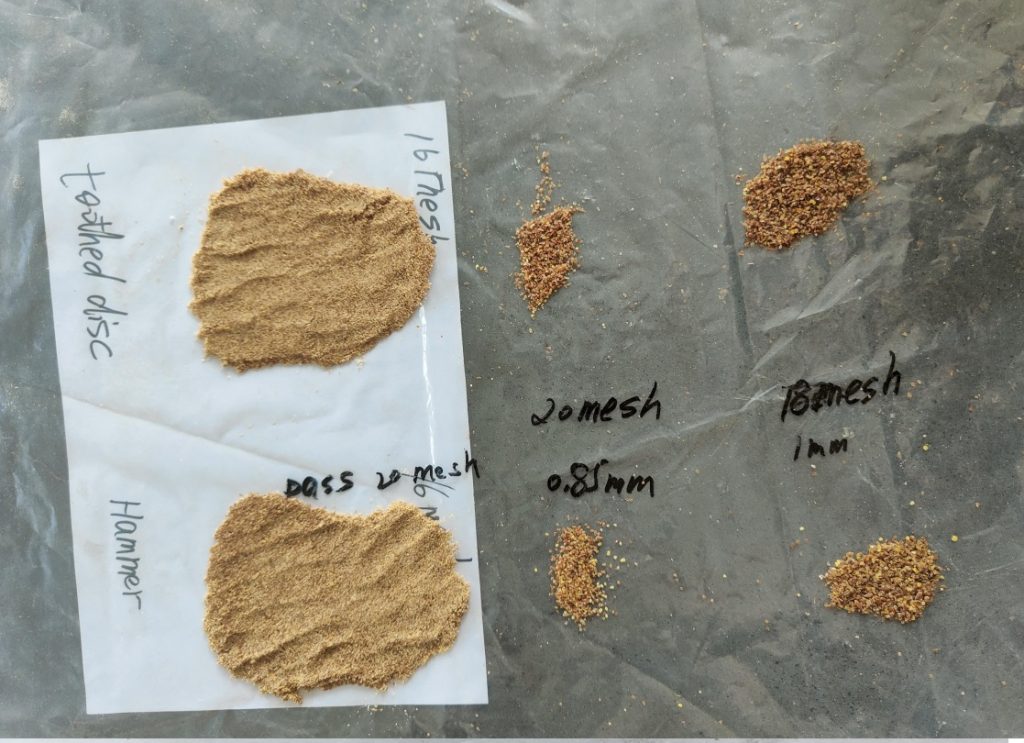

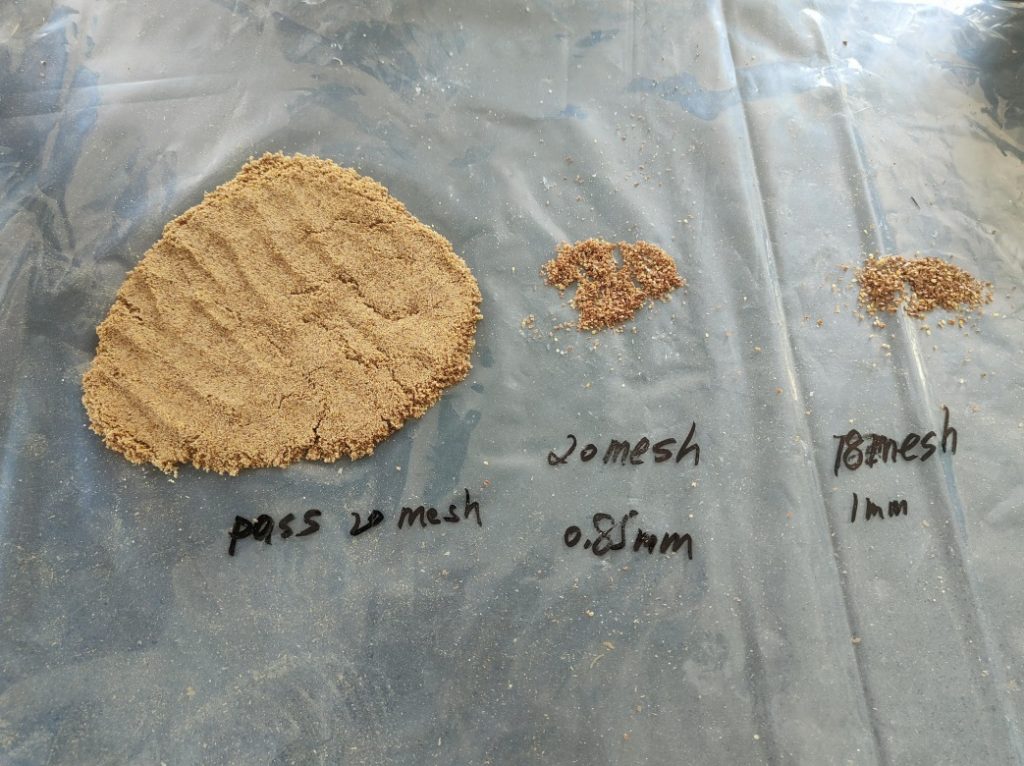

In the context of industrial production, “secret” must be converted into measurable, controllable and repeatable technical parameters. According to current industry practices, the so-called secret sauces mainly cover three types of products with significant differences in physical properties, and the technical focus of their automatic production lines is completely different. This difference directly leads to large fluctuations in the price of the production line, because different types of secret sauces require completely different core equipment and process configurations, and the cost gap between related equipment can reach 2-5 times.

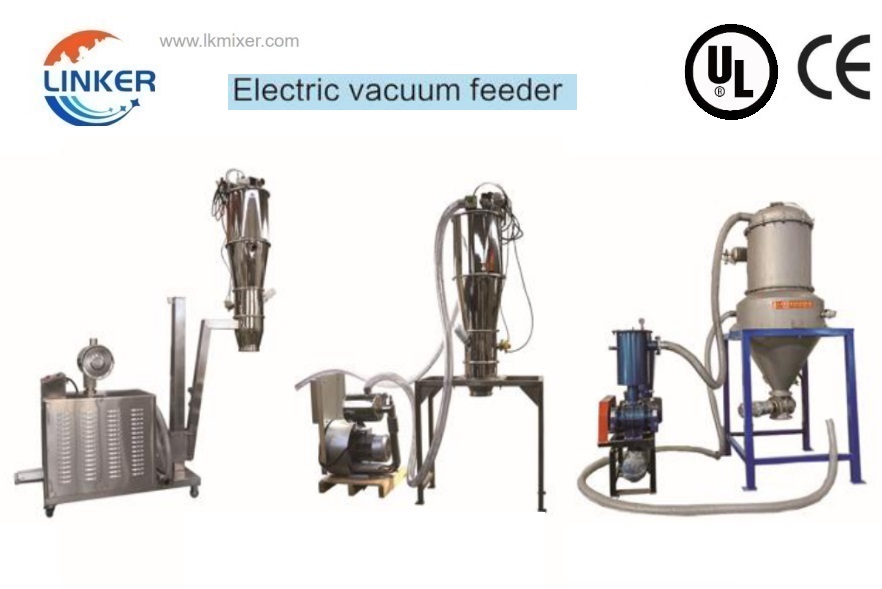

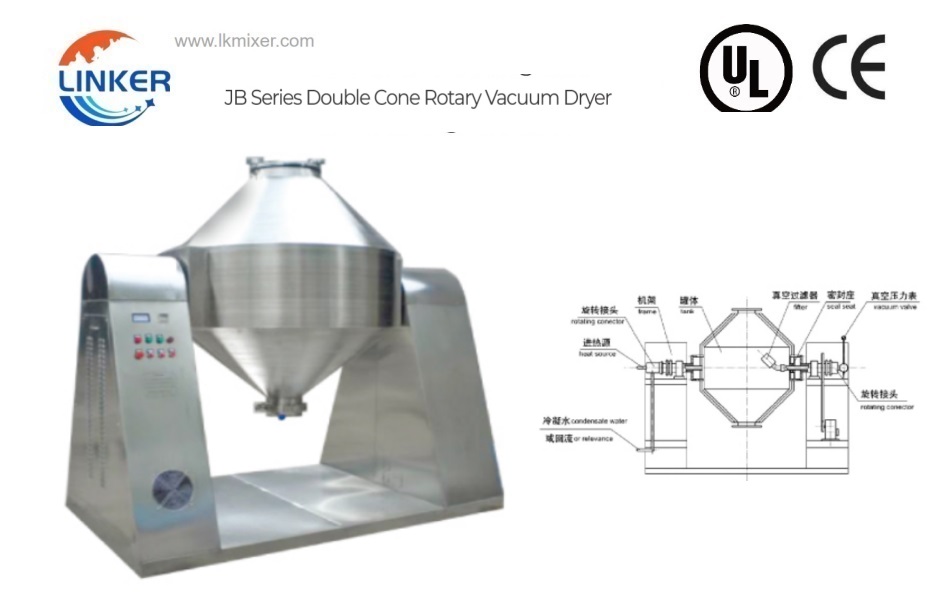

Fermented/aged secret sauces, such as secret soybean paste, beef sauce (including fermentation process) and mushroom sauce, require long-term temperature-controlled enzymatic hydrolysis or natural aging, and microbial metabolism to produce flavor. The technical difficulties lie in shortening the fermentation cycle, ensuring consistent batch flavor and preventing corrosion of equipment in high-salt environments. For such secret sauces, the production line needs to be equipped with a set of intelligent temperature-controlled fermentation tank groups, which is more expensive than ordinary sauce production lines. The price of this module alone can account for 20%-30% of the total production line price. A Vacuum Mill can be used to assist in the mixing and fermentation of sauce base materials, ensuring uniform mixing of microorganisms and raw materials, with a price of $17,000 to $40,000. The motor of the fermentation tank needs a matching charger to ensure stable power supply and avoid equipment failure caused by power interruption during the long fermentation cycle, with a charger price of $1,100 to $2,600.

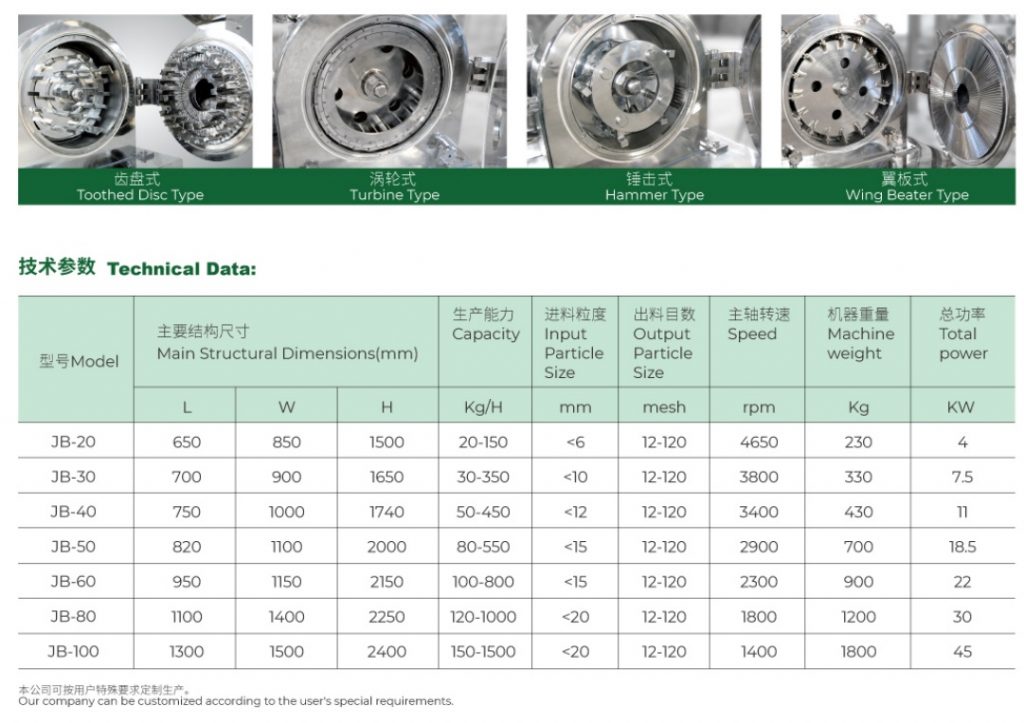

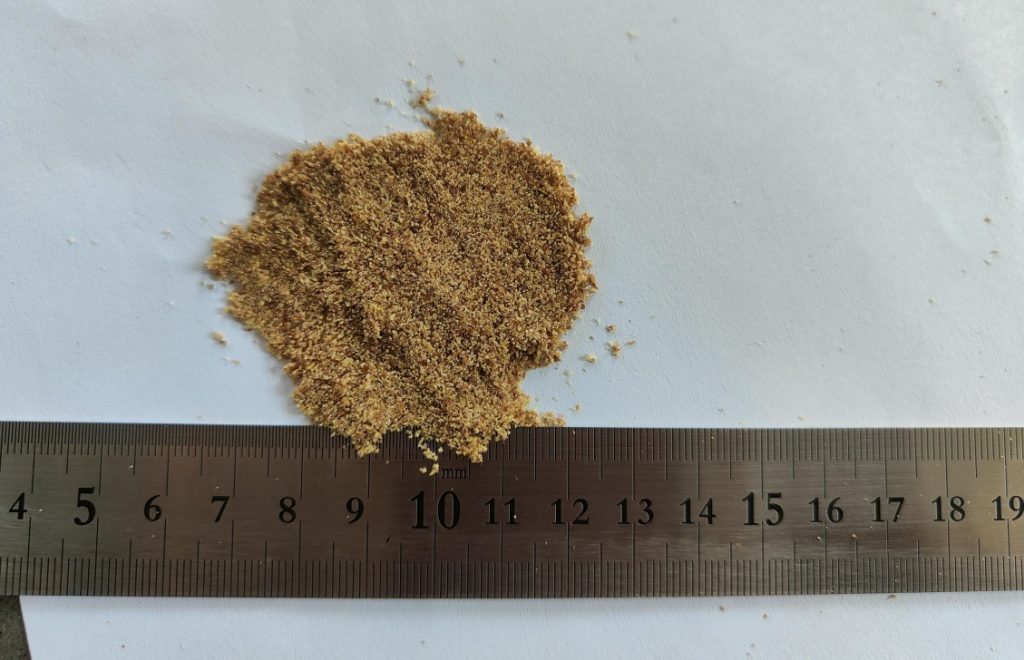

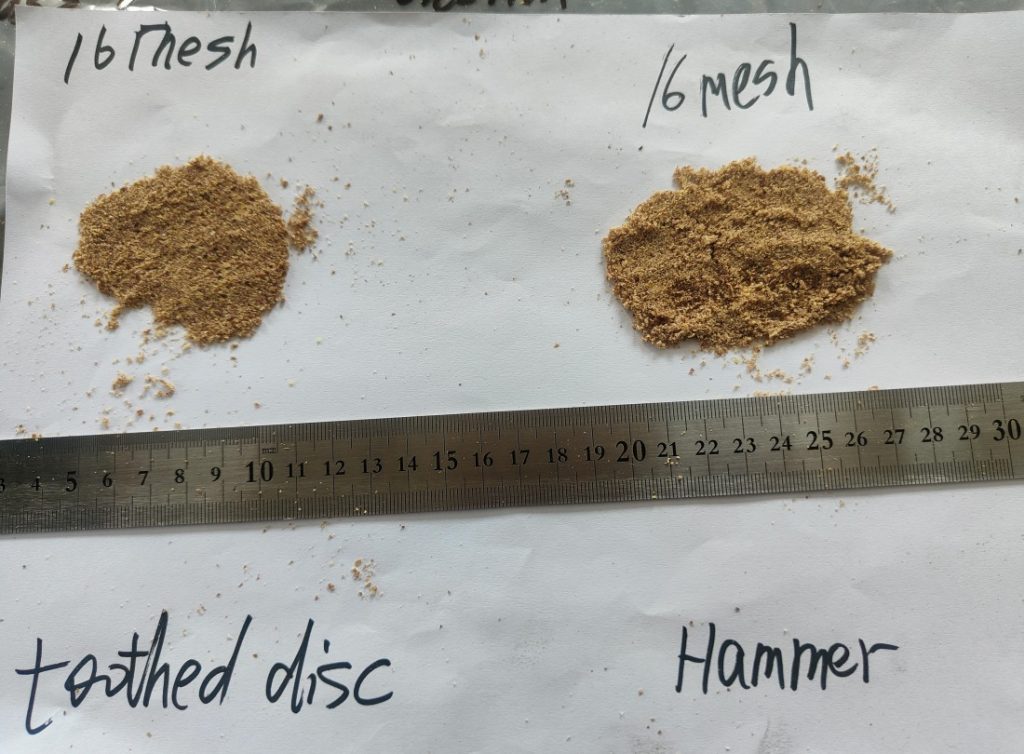

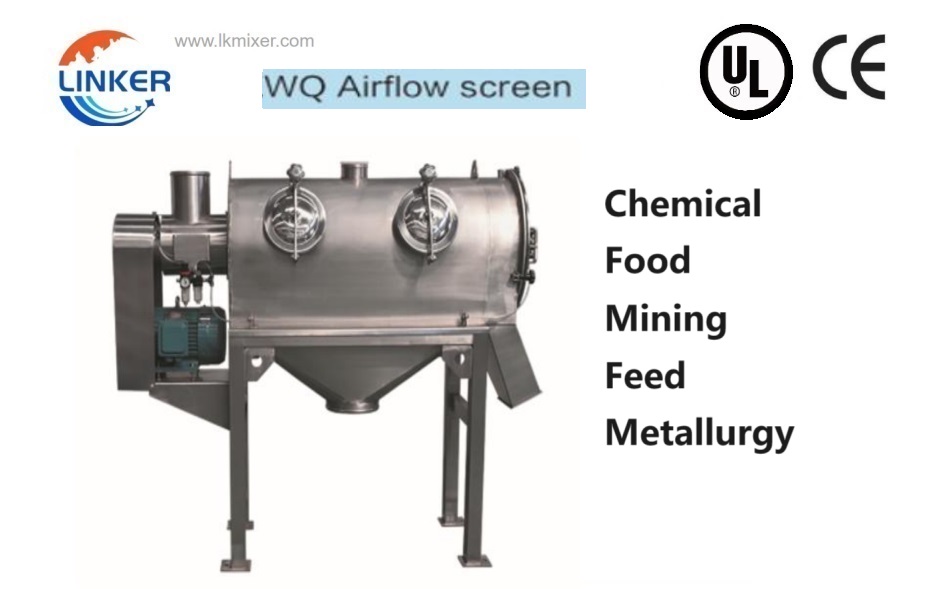

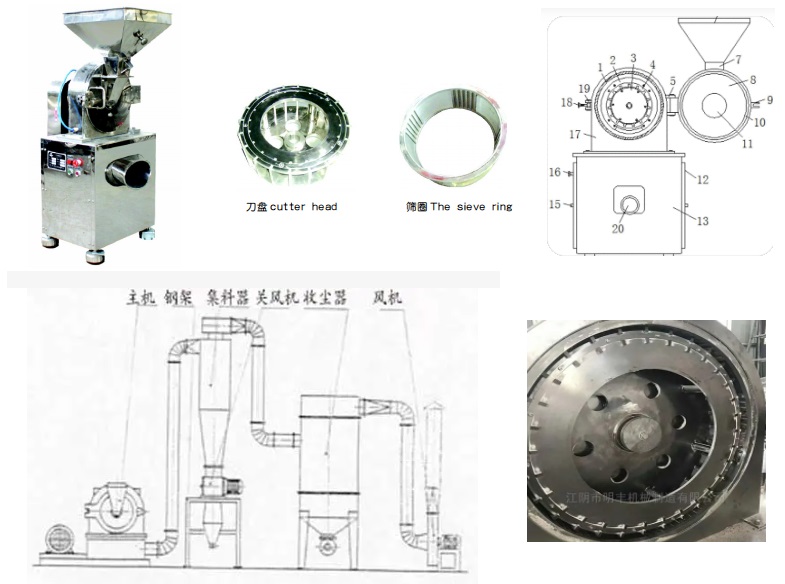

High-temperature stir-fried/fragrance-fried secret sauces, such as roasted chili sauce, hot pot base and secret spicy sauce, involve Maillard reaction with oil, spice stir-frying and granular materials. The technical difficulties are preventing scorching (high sugar/high starch), protecting particle integrity and ensuring uniform wall scraping. Such production lines need to be equipped with automatic planetary frying pans with special structures, and the price is significantly higher than that of ordinary stir-frying equipment. A coarse crusher can be used to crush large pieces of raw materials such as chili and meat before stir-frying, reducing the load of the frying pan, with a price of $5,600 to $12,800. An Air cooled crusher can be used to crush the scale generated in the oil circulation system of the frying pan, ensuring the normal operation of the equipment, with a price of $6,300 to $14,800.

High-oil/emulsified secret sauces, such as secret salad dressing, mayonnaise and compound emulsified sauce, require water-oil two-phase emulsification, high-viscosity homogenization and a particle-free and delicate texture. The technical difficulty is emulsification stability, vacuum degassing and color protection, and anti-wire drawing during filling. Such production lines need to be equipped with vacuum homogenizing emulsifiers, and the price of this core equipment is between $25,000 and $80,000. It should be emphasized that there is no single production line that can produce fermented soybean sauce and high-oil emulsified salad dressing at the highest efficiency at the same time. Choosing the wrong production line type will not only increase the investment cost, but also affect the flavor of the secret sauce, which is the key factor affecting the initial price positioning of the production line.

Price Reference of Automatic Secret Sauce Production Line from Industry Benchmarks