Automatic Coffee Powder Production Line

Coffee Powder Process Flow

- Coffee Washing Machine

- Coffee Pealing and Cutting Machine

- Coffee Drying Machine

- Coffee Grinding Machine

- Coffee Powder Mixing Machine

- Coffee Powder Filling Machine

- Coffee Powder Packing Machine

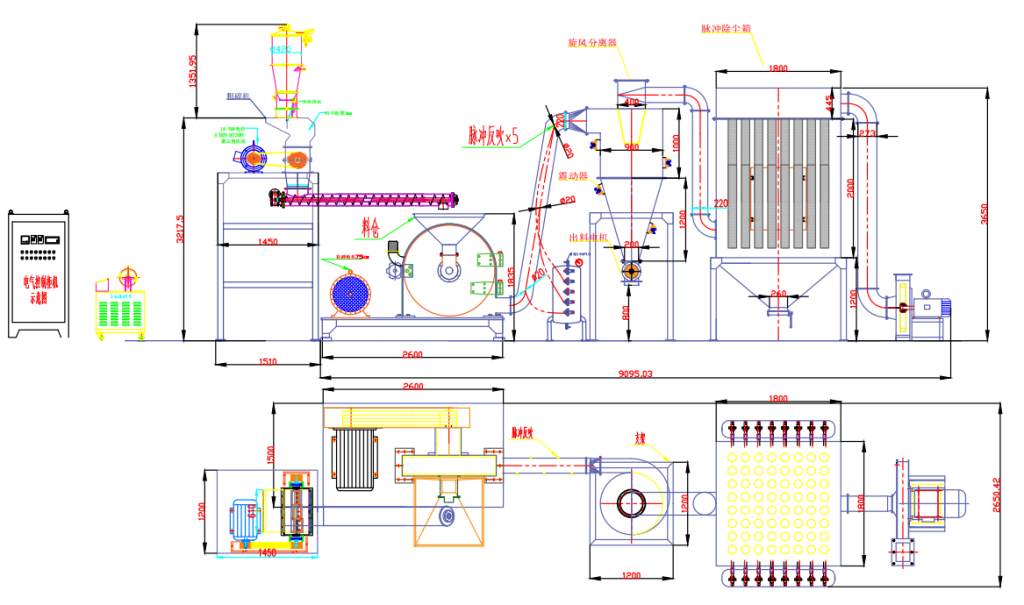

Coffee Powder Automatic Productino Line Design:x`

Production Line for Automatic Coffee Powder

For the large-scale industrial manufacture of several coffee products, such as instant coffee, drip-bag coffee, and capsule coffee powder, an Automatic Coffee Powder manufacture Line is a fully integrated, intelligent processing system. This line is crucial for medium-to large-scale food processing businesses because it centralizes processes from raw material handling to final packaging under automated control, ensuring high efficiency, constant output, and standardized quality.

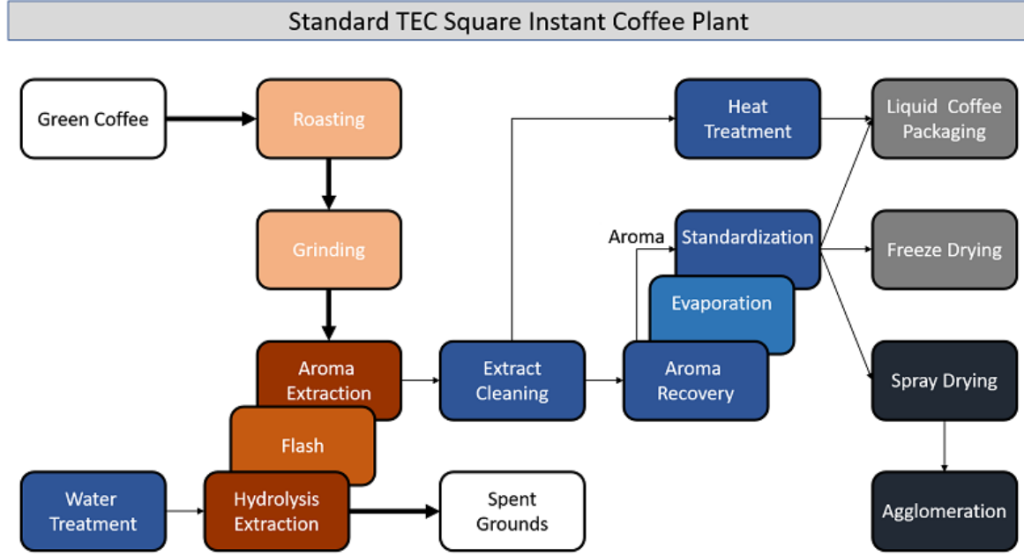

Normal Process Flow

Pre-treatment and raw material screening are the first steps in the process. Green coffee beans are carefully cleaned and sorted. They go through devices like air classifiers to separate lighter contaminants, vibrating screens to remove dust and debris, and sophisticated color sorters that employ optical sensors to detect and discard broken, damaged, and foreign materials beans. This step guarantees a constant, high-quality base of raw materials, which is essential for a consistent flavor in the finished product. Conveyors or charging systems are then used to move the sorted beans to the following phase.

The important Roasting stage comes next. The cleaned beans are fed into a drum roaster that runs continuously. Here, they are subjected to high heat for three to five minutes, usually around 300°C. In order to directly affect the chemical development within the bean and determine the final flavor characteristics, sophisticated computerized control systems precisely regulate the temperature profile throughout the roast. Darker roasts develop richer, bittersweet flavors, while lighter roasts preserve more acidity and origin notes.

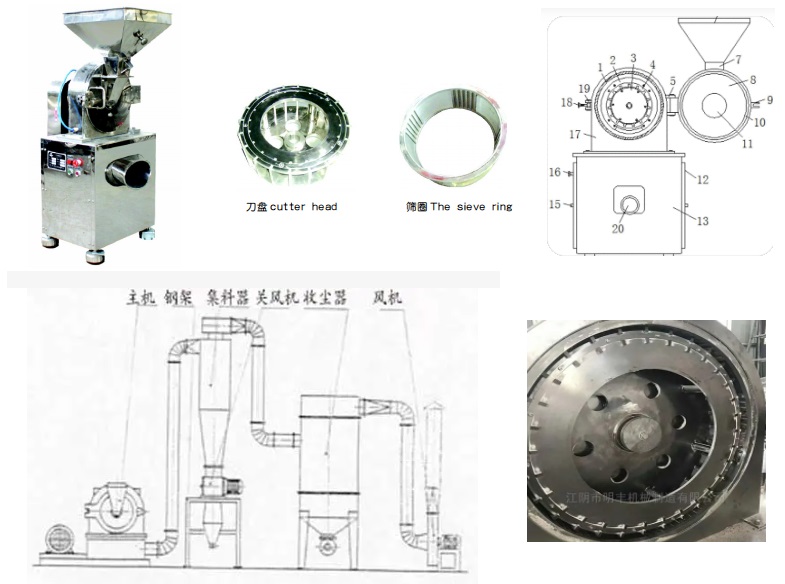

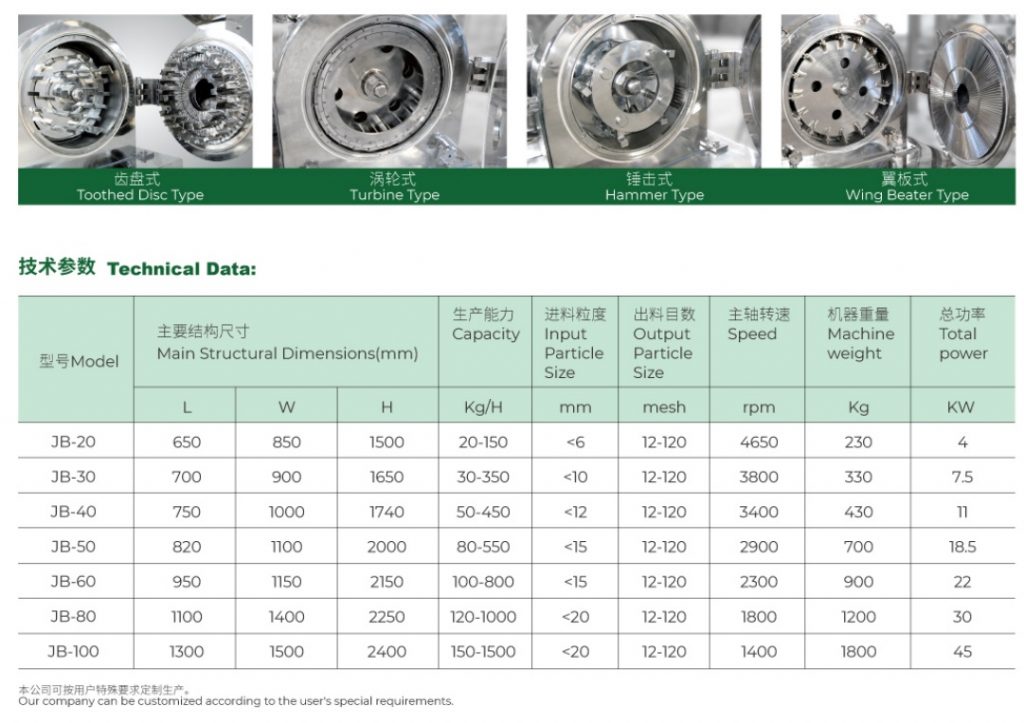

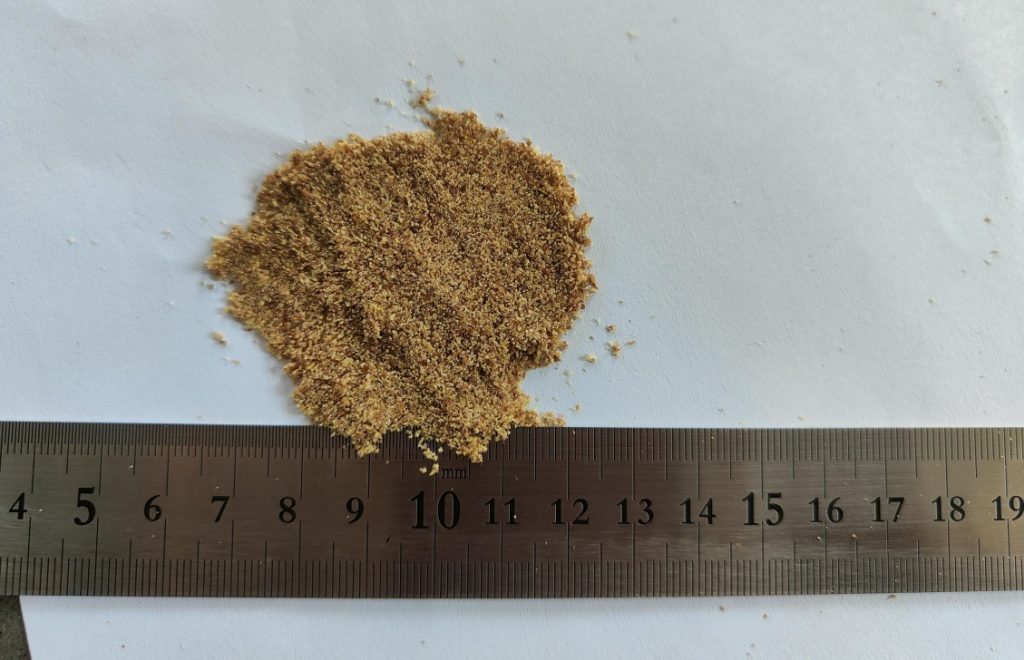

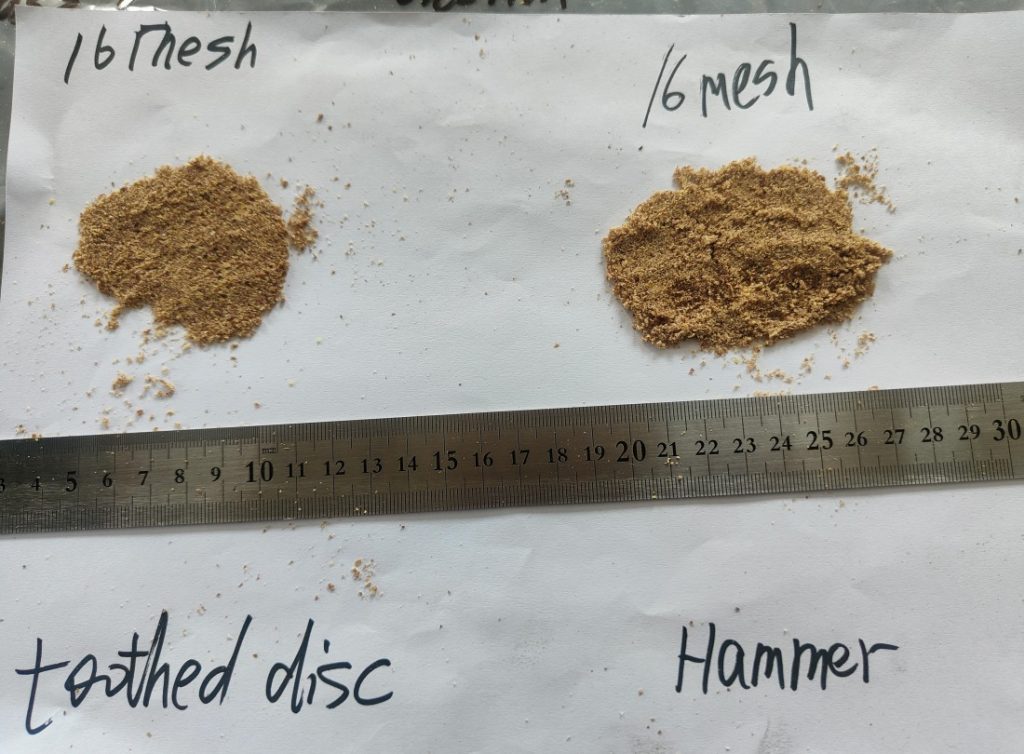

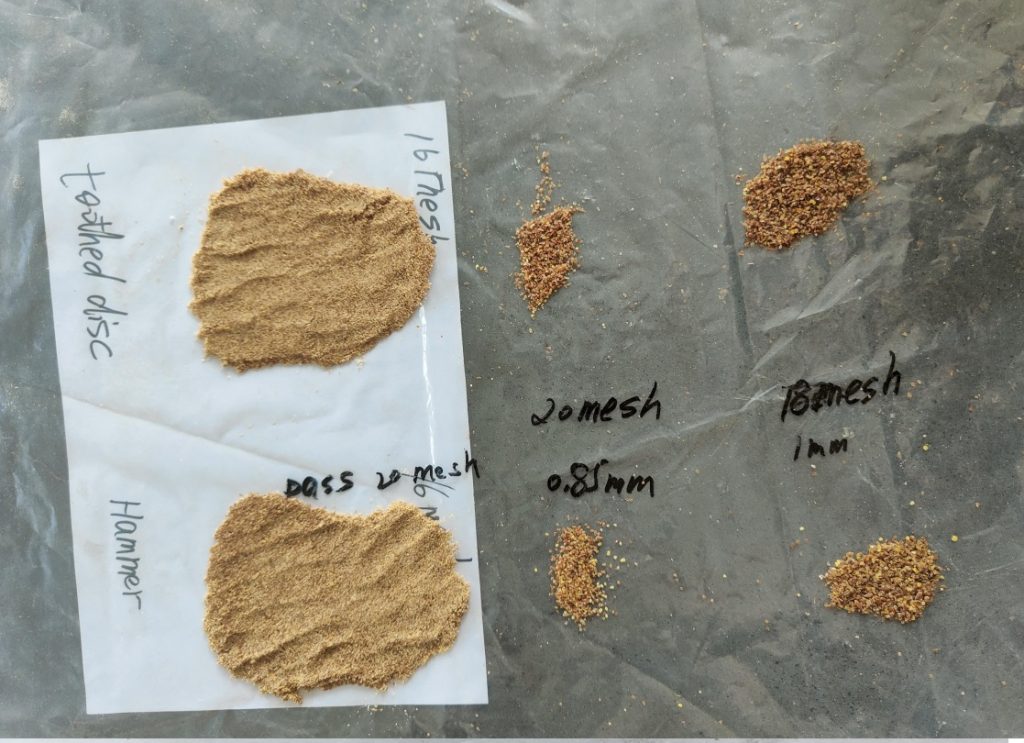

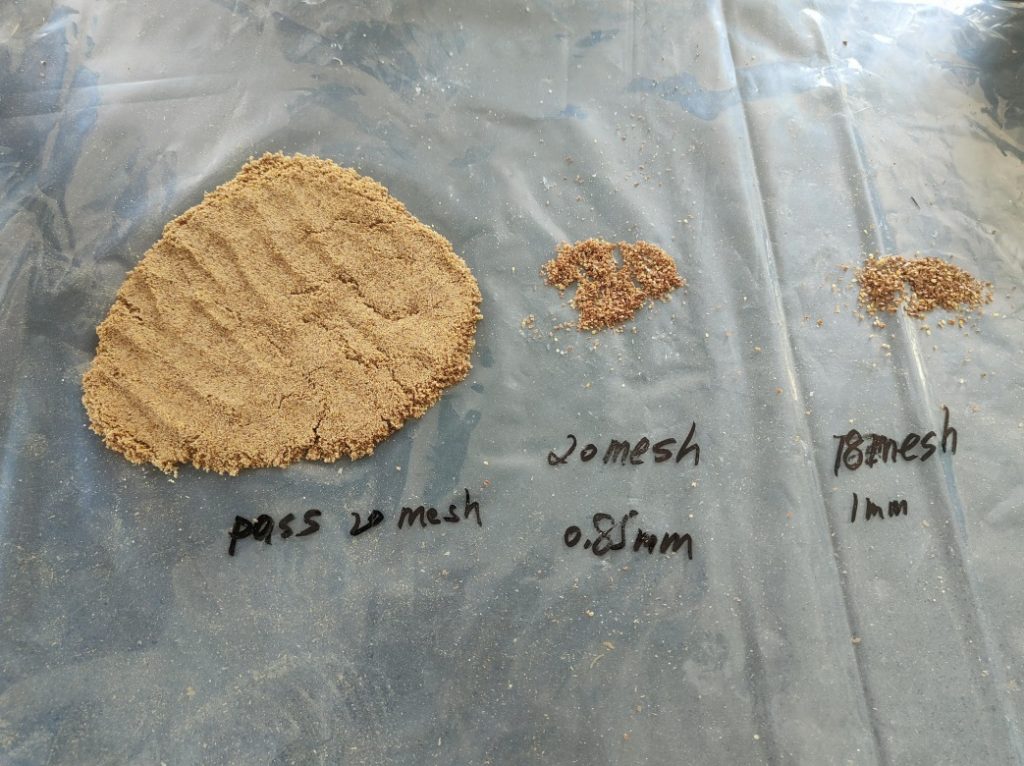

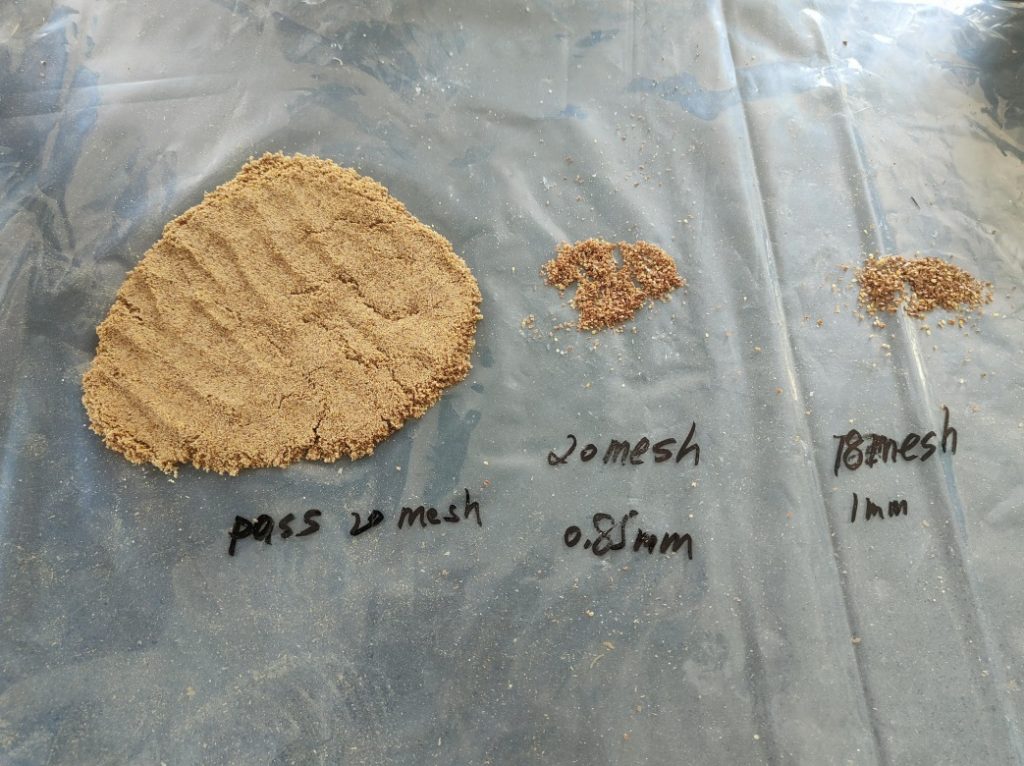

The beans go on to grinding after being roasted and allowed to cool. A specialized industrial grinding machine becomes the focal point in this situation. While production lines utilize massive, high-capacity mills, cafes use modest electric grinders. Conical or flat burr grinders are used for premium ground coffee that needs exact particle size control (usually between 80 and 200 mesh). These are designed especially for coffee, but they work similarly to a high-precision universal grinder. A coarse crusher or hammer mill may be utilized for initial size reduction in other applications, such as establishing a foundation for certain immediate products.To guarantee granulation homogeneity, the ground coffee is then often sieved using a vibrating pulverizer. An air-cooled crusher system is occasionally included to control the substantial heat produced during high-volume grinding, which can weaken the aroma of coffee. To preserve a clean atmosphere and recover precious coffee fines, the complete grinding station is usually connected to a dust collector grinder system.

The next steps in the manufacturing of instant coffee are extraction and concentration. In order to dissolve the soluble solids and produce a strong coffee liquor, the ground coffee is extracted using hot water under pressure in sizable percolation columns.Centrifugal separators are then used to separate this liquid from the discarded grinds. To raise the solid content to 35%–60%, the resultant extract is concentrated, frequently using vacuum evaporation technology. The energy needed for the next drying stage is decreased by this step. A vacuum mill or evaporator, which work under low pressure to lower the boiling point and safeguard heat-sensitive coffee chemicals, may be used in the concentrating process.

The next step for the concentrated coffee extract is drying, which determines the kind of instant powder. Spray drying and freeze drying are the two main techniques. Spray drying is an effective method for large-scale production because it atomizes the liquid concentrate into a hot air chamber, where moisture evaporates immediately to form a fine, dry powder.The concentrate is then frozen into a solid slab at extremely low temperatures (such as -30°C to -50°C) in a process known as freeze drying, which is recommended for higher-quality products. In order to create a porous, highly soluble powder that better preserves the original coffee flavor and aroma, this frozen solid is then put in a vacuum chamber where the ice sublimates straight into vapor.

Secondary grinding and sizing can be necessary after drying. Whether from a freeze-dryer or a spray tower, the dried coffee mass frequently produces flakes or agglomerates. To get the appropriate free-flowing powder consistency, these are fed into a second grinding machine. Here, a turbo grinder or airflow pulverizer can work well to produce an extremely thin, consistent powder that dissolves instantly.A dry grinder or ultrafine grinder may be used for conventional granulation. In order to guarantee acceptable solubility and flow characteristics for packaging, the powder is then sieved to ensure constant particle size. Other powder production lines, such those that use a dry fruit powder grinder machine for powdered bananas or mangos, a dry ginger grinding machine, or a licorice grinding machine for tea and medicine applications, share technological concepts with this process segment.

Automatic Packaging is the last step. Automated packaging equipment receive the resulting coffee powder. These systems weigh pieces exactly (up to ±0.5g), fill them into different kinds of bags (such foil pouches, stand-up bags, or drip-bag filters), seal, code, and output the packages.Multi-lane stick-pack machines are frequently used to produce little sachets at fast speeds. Automatic bag-in-bag machines are utilized for high-end goods in pre-made pouches. To ensure the safety of the finished product, the packaging area must meet the strictest hygiene regulations. Stainless steel contact surfaces and integrated metal detection systems are frequently used to screen for any possible metal contamination.

Composition of Key Equipment

Each stage of the line is made up of specialized modules. Bucket elevators, color sorters, and vibrating screens are all part of the preparation area.The continuous drum roaster is the focal point of the roasting module. Industrial-grade impact grinders or burr mills are used in the grinding stage. High-pressure extraction columns, holding tanks, vacuum concentrators, and ultimately a spray drying tower or a large-scale freeze-dryer are all added to the line for instant coffee. High-speed, computer-controlled powder filling and sealing devices are installed in the packing hall. Importantly, a large number of these essential machines—particularly the grinding machine, hammer mill, and packing systems—are offered as CE Certificate grinders and equipment, which indicates that they adhere to European health, safety, and environmental regulations. This is crucial for enterprises that prioritize exports.

Benefits of Automation and Application Value

Efficiency and scale are the main values. With single-shift outputs of many tons, the line can run continuously for a full day, significantly outperforming manual or semi-automated installations. This is analogous to the productivity leap seen when moving from a small grinder machine to an industrial 500KG Grinder or 200KG grinder in spice processing.

It also provides Unmatched Quality Control and Consistency. Cross-contamination is reduced because the entire process is contained.Automatic Metal Powder Production Line.By ensuring that each batch is treated with the same time, temperature, and grinding settings, Programmable Logic Controller (PLC) systems eliminate human mistake. This degree of control is just as important for making consistent flour, chemical powders, or spice blends as it is for coffee.

Additionally, the line offers safety assurance and strong compliance. It is easy to clean and complies with strict international food safety standards including GMP, ISO 22000, and HACCP thanks to its design and construction materials, which are mostly stainless steel. Gaining access to international markets requires this compliance.

Lastly, long-term value is provided by its modular and scalable design. Smart warehousing solutions, automated CIP (Clean-in-Place) cleaning, and Manufacturing Execution Systems (MES) for real-time production data management are just a few examples of the systems that can be readily added to or integrated with the production line. Because of its inherent flexibility, a coffee processing plant can potentially adapt its technology for other food products by using similar grinding and drying principles used for the production of black pepper grinders, cassava grinding machines, or specialty powders like powdered mushrooms or seeds, much like an industrial weed grinder is adapted for different botanical materials.

Production Line for Automatic Coffee Powder

Depending on the final product type (such as instant coffee powder, drip-bag coffee powder, or ordinary ground coffee), the process flow of a fully automated coffee powder manufacturing line varies slightly, although the fundamental steps are very consistent. Instant coffee powder is the most popular automated line, which includes fully automated processes from handling raw beans to final packing. The extraction and drying methods used are the main differentiators in this line.

The steps involved in making various kinds of coffee powder are broken down as follows:All Coffee Powders Can Use This Universal Front-End Process

Pre-treatment and raw material screening are the first steps in the process. Green coffee beans are carefully cleaned and sorted. In order to ensure a pure raw material input, devices including vibrating screens, air classifiers, and sophisticated color sorters collaborate to exclude physical contaminants, broken beans, and defective beans. A “manual pre-inspection + intelligent sorting” dual-mode method is used by several luxury production lines to improve quality consistency. Usually, a conveyor or automated charger system is used to move the cleaned beans to the following phase.

The critical Roasting stage comes next. A continuous drum roaster receives the sorted green beans. Here, they are roasted for three to five minutes at temperatures that are normally between 180 and 200°C. Darker roasts generate richer, bittersweet flavors, while lighter roasts retain more acidity and origin characteristics thanks to sophisticated temperature control systems that carefully regulate the roasting profile. Following roasting, the beans are immediately chilled to below 20°C using techniques like cold air blasts or a two-step spray-plus-cold-air system. This phase “locks in” the produced aromas and stops the roasting process.

Grinding is the next universal step.An industrial-grade grinding machine receives the roasted beans after they have cooled. In order to produce instant coffee, the beans are ground to a desired particle size, often between 80 and 200 mesh. Since it directly affects the effectiveness and consistency of the soluble solids extraction process, the homogeneity of these particles is crucial. This industrial grinding stage requires massive, high-capacity equipment, which is very different from a tiny grinder machine or a home electric grinder. Specialized mills are frequently used in the manufacturing of coffee, although a universal grinder may be able to handle different food items like rice, corn, or spices. An air-cooled crusher design or cooling system is frequently incorporated to control the substantial frictional heat produced during grinding, which can scorch the coffee and deteriorate tastes.To preserve hygienic conditions and recover tiny particles, the grinding station is additionally linked to a dust collection grinder system.

Mid-Stream Procedure: Product Type-Based Diversion

A. Instant Coffee Powder Spray-Dried

This approach offers better manufacturing capacity and cheaper costs, making it appropriate for mass-market aneous products.

After being ground, the coffee is extracted. In sealed extraction columns, hot water with high pressure and temperature (up to 180°C) percolates through the coffee grinds, dissolving the soluble solids and creating a concentrated coffee liquor. The loss of volatile aromatic chemicals is prevented by the closed system.

Following that, the mixture is subjected to liquid-solid separation. The spent coffee grounds are removed using devices like disc stack centrifuges or filtration systems, producing a clarified coffee extract.

After that, this extract is concentrated. The coffee liquid’s solid content is raised to at least 35% by using vacuum evaporation technology. In order to lower the boiling point, preserve heat-sensitive tastes, and drastically cut down on the energy needed for the subsequent step, this vacuum mill or concentrator runs at lower pressure.

Drying (also known as spray drying) is the last phase in this branch. A spray drier is fed the concentrated coffee extract.In a sizable hot-air chamber, it is atomized into a thin mist. When the small droplets come into contact with heated air, the moisture nearly rapidly evaporates, forming dry powder particles. To prevent the production of off flavors, the process parameters are strictly regulated. The powder that results is gathered in the chamber’s bottom. A pressure nozzle system could be employed in place of a centrifugal atomizer to produce a somewhat coarser, more granular instant powder that might dissolve more readily.

B. Powdered Freeze-Dried Coffee

Premium instant items that retain their flavor and scent better are made using this technique.

For spray-dried powder, the first stages of extraction, liquid-solid separation, and concentration are the same.

Freeze-Drying is a special step.At extremely low temperatures (such as -30°C to -50°C), the concentrated coffee extract is first frozen into solid slabs. After that, these frozen slabs are put inside a vacuum chamber. The primary drying stage occurs when ice sublimates directly from solid to vapor under a deep vacuum without going through a liquid phase. The temperature is then progressively increased in a secondary drying or desorption phase to eliminate any last bonded water molecules. Compared to high-heat procedures, this complete low-temperature, low-pressure process significantly preserves the original coffee flavor profile and aromatic components.

C. Ordinary Ground Coffee Powder

Pre-ground coffee for brewing and specialized drip-bag filters are examples of non-soluble items in this area.

The beans may go through a Secondary Grinding and Sizing (Optional) step that is especially calibrated for the final application after the universal roasting stage. To provide consistent water penetration and ideal extraction during brewing, the beans for drip-bag coffee are ground to a medium-fine consistency (between drip and fine powder settings). A precision grinding machine with programmable settings could be the grinding apparatus used here. Other dry grinding applications, including those carried out by a black pepper grinder, a dry ginger grinding machine, or a licorice grinding machine used for medicine and tea, are comparable to this technology. After that, the ground coffee is usually filtered to guarantee uniformity.

Precision Bagging (Drip-Bag Specific) is the next special phase in the manufacture of drip bags. A drip-bag packaging machine that is fully automated completes a number of complex tasks, including measuring and filling ground coffee with low error (e.g., ≤0.1g), forming filter paper, automatically attaching the “ears” or hanging tabs, sealing the bag with clever temperature-controlled systems to stop leaks, cutting, and outputting the finished bags. These devices are capable of producing 40–60 bags per minute.Back-end processes that are universal (needed for all types)

Metal Identification and Sorting

To ensure food safety compliance, the final coffee powder—whether ground or instant—is run through a very sensitive metal detection system to remove any possible metal contamination. To guarantee a consistent particle size, more sifting may be necessary.

Automatic Packaging

Powder packaging devices that are completely automated are used at this level.Weighing, filling, optional vacuum or gas cleansing (such as using nitrogen to maintain freshness), sealing, and date labeling are among the duties they carry out. Foil bags, stand-up pouches, zipper bags, and drip-bag filters are just a few of the bag types that these machines can handle. With some sophisticated versions achieving tolerances of ±0.1g, packaging accuracy is great and ensures weight constancy for each item. These packaging systems are complex pieces of machinery that may share design concepts with packaging lines for other food powders like flour, sugar, or chemical items. They are frequently built with stainless steel contact parts.

Palletizing and Boxing

After that, the packaged items are automatically collated, put into shipment cases, tagged, and sealed. In order to prepare the cases for storage and transportation, robotic palletizers stack them neatly into pallets in a stable form. This degree of end-of-line automation reduces manual handling and increases efficiency.

Additional Technical Context: The industrial grinding machines utilized in these lines are sturdy technical devices. For large-scale activities, they have capacities ranging from 200 kg to 500 kg. These are supplied by reputable manufacturers as CE Certificate grinder units, guaranteeing that they adhere to European safety regulations.A hammer mill or coarse crusher may be utilized for preliminary size reduction in certain procedures, whereas an airflow pulverizer, turbo grinder, or ultrafine grinder may be utilized for the production of extremely fine powders or for the secondary grinding of instant coffee agglomerates. Similar to an industrial weed grinder or herb grinder used for materials like cannabis or medicinal herbs, the fundamental technology of particle size reduction finds applications in a variety of fields, such as processing cassava into flour using a cassava grinding machine, grinding seasam or peanut for paste, or making powders from mushrooms, bones, seeds, or other botanicals.The basic ideas of high-speed, dry grinding in a regulated, sanitary setting are the same regardless of the material—coffee, beans, tobacco, salt, wheat, or specialty chemical compounds.

Parameters:

Model Name | SG-600 | |

| Crushing Capacity(kg/h) | 1000~2000 | |

| Power(kw) | 11 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Model Name | SG-800 | |

| Crushing Capacity(kg/h) | 2000~4000 | |

| Power(kw) | 15 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

Ampere of Motors Customization for Seeds Grinder:

| KW | HP | Ampere |

| 75kw | 100HP | 135A |

| 55kw | 75HP | 99A |

| 30kw | 40HP | 54A |

| 22kw | 30HP | 39A |

| 2.2kw | 3HP | 3.9A |

| 1.5kw | 2HP | 2.7A |

Test Report for Flax Seed Grinder:

A flax seed grinder is a type of seed nut grinder specifically designed for grinding flax seeds. Flax seeds are small, hard seeds that are packed with nutrition and are commonly used in baking and cooking. Grinding flax seeds helps to unlock their nutrients and make them easier to digest.

Flax seed grinders typically feature sharp blades or burrs that rotate to crush the flax seeds into a fine powder. This powder can then be used in a variety of recipes, such as smoothies, baked goods, and yogurt toppings. Some flax seed grinders are manual and require hand-cranking, while others are electric and feature powerful motors for faster grinding.

When choosing a flax seed grinder, it’s important to look for one with durable blades or burrs that can withstand the hard texture of flax seeds.

There are 3 ways of cooling down the grinder: water cooling system; air cooling system and liquid nitrogen freezing system. You can choose the right one if the grinder gets too hot. When machines goes too hot, the metal can expand, causing the grinding wheel to get stuck.

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

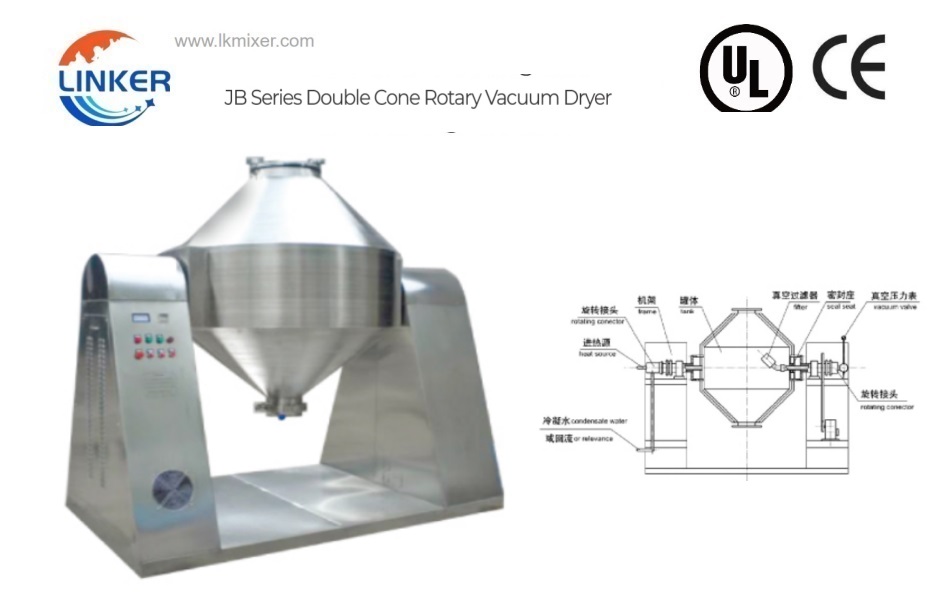

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

Operation Instruction

General Provisions

The operation instructions for a commercial grinder may vary depending on the specific model and manufacturer. However, here are some general guidelines that may apply to many high speed grinders:

- Safety precautions: Before operating the high speed grinder, it is important to review all safety precautions and warnings provided in the user manual. Safety precautions may include wearing appropriate personal protective equipment, such as eye protection and hearing protection, and avoiding loose clothing or jewelry that could become caught in the grinder.

- Preparation: The high speed grinder should be placed on a stable and level surface, and all necessary components should be assembled according to the manufacturer’s instructions. The grinder should also be connected to a power source that is appropriate for its voltage and wattage.

- Loading the grinder: The material to be ground should be loaded into the grinder according to the manufacturer’s instructions. Overloading the grinder may cause damage to the machine and result in poor grinding performance.

- Starting the grinder: The grinder should be started according to the manufacturer’s instructions. This may involve pressing a button, turning a dial, or flipping a switch. The user should ensure that their hands are clear of the grinder and that the material to be ground is positioned properly.

- Adjusting the speed and settings: The speed and other settings of the high speed grinder may be adjusted according to the material being ground and the desired outcome. The user should follow the manufacturer’s instructions for making adjustments to the grinder.

- Monitoring the grinding process: The user should monitor the grinding process to ensure that it is progressing smoothly and that the material is being ground to the desired size and consistency. Any issues or abnormalities should be addressed promptly to prevent damage to the machine.

- Shutting down the grinder: When the grinding process is complete, the grinder should be shut down according to the manufacturer’s instructions. The user should ensure that the machine is completely stopped and that all moving parts have come to a complete stop before attempting to clean or service the grinder.

Overall, the operation instructions for a commercial grinder may involve a number of steps and safety precautions. It is important to carefully review the manufacturer’s instructions and follow proper operating procedures to ensure safe and effective use of the machine.

Preparation Work

Before running a commercial grinder, there are several important preparation steps that should be taken to ensure safe and effective operation of the machine. Here are some general guidelines for preparing to run a high speed grinder:

- Read the user manual: The first step in preparing to run a high speed grinder is to carefully read the user manual provided by the manufacturer. The user manual will provide important information about the specific model of grinder being used, including its features, specifications, and safety precautions.

- Select the appropriate grinding wheel: The grinding wheel used in a high speed grinder should be selected based on the material being ground and the desired outcome. It is important to use the correct type of grinding wheel to prevent damage to the machine and ensure optimal grinding performance.

- Inspect the grinder: Before running the grinder, it is important to inspect it for any signs of damage or wear. The user should check for loose or missing components, cracks or other signs of damage to the machine’s housing or other parts, and any other issues that could affect the grinder’s operation.

- Install the grinding wheel: The grinding wheel should be installed according to the manufacturer’s instructions, making sure that it is securely fastened and aligned properly. The user should also check the wheel for any cracks or other signs of damage before installation.

- Secure the workpiece: The workpiece to be ground should be securely clamped or held in place before starting the grinder. This will help to ensure safe and effective operation and prevent the workpiece from becoming dislodged or damaged during grinding.

- Connect the power source: The high speed grinder should be connected to a power source that is appropriate for its voltage and wattage. It is important to use a properly grounded power source to ensure safe and reliable operation of the machine.

- Test run: Before beginning actual grinding operations, it may be useful to perform a test run to ensure that the grinder is functioning properly and that the grinding wheel is aligned and balanced properly. The user should follow the manufacturer’s instructions for performing a test run.

By following these preparation steps, users can ensure safe and effective operation of a high speed grinder and achieve optimal grinding results.

Treatment of inspection

Inspection of a commercial grinder is an important maintenance procedure that helps ensure safe and effective operation of the machine. Here are some general guidelines for inspecting a high speed grinder:

- Disconnect power source: Before performing any inspection or maintenance on a high speed grinder, the power source should be disconnected to prevent accidental startup.

- Check for wear and damage: The user should inspect the grinder for any signs of wear or damage, such as cracks in the housing, worn or damaged grinding wheels, or loose or missing parts. Any issues should be addressed promptly to prevent further damage to the machine.

- Check alignment and balance of grinding wheel: The grinding wheel should be inspected for proper alignment and balance, as these factors can affect the quality of the grinding operation. If the grinding wheel is not properly aligned or balanced, it should be adjusted or replaced as necessary.

- Check for proper lubrication: The high speed grinder should be inspected for proper lubrication, as inadequate lubrication can cause excessive wear and damage to the machine’s moving parts. The user should follow the manufacturer’s instructions for lubrication, and add lubricant as necessary.

- Inspect electrical components: The electrical components of the high speed grinder, including the wiring, switches, and control panel, should be inspected for any signs of wear, damage, or loose connections. Any issues should be addressed promptly to prevent electrical problems.

- Test run: After completing the inspection, it may be useful to perform a test run of the high speed grinder to ensure that it is functioning properly and that any issues have been addressed.

By following these inspection guidelines, users can help ensure safe and effective operation of a high speed grinder and minimize the risk of damage or injury during grinding operations.

Operation Attention

Running a commercial grinder can be a dangerous operation if proper precautions are not taken. Here are some general guidelines for safe operation of a high speed grinder:

- Personal protective equipment: The user should wear appropriate personal protective equipment, such as safety glasses, hearing protection, and gloves, to prevent injury from flying debris, noise, and contact with the grinding wheel.

- Secure workpiece: The workpiece being ground should be securely clamped or held in place to prevent it from becoming dislodged during grinding.

- Use proper grinding wheel: The user should select the appropriate grinding wheel for the material being ground and ensure that it is installed correctly and securely. The grinding wheel should be inspected for cracks or other damage before use.

- Adjust grinding wheel speed: The speed of the grinding wheel should be adjusted according to the manufacturer’s instructions to ensure optimal grinding performance and prevent damage to the machine or workpiece.

- Avoid excessive pressure: The user should avoid applying excessive pressure to the grinding wheel, as this can cause the wheel to overheat and wear out more quickly.

- Avoid overheating: The high speed grinder should not be operated continuously for extended periods of time, as this can cause overheating and damage to the machine.

- Monitor grinding operation: The user should closely monitor the grinding operation to ensure that the workpiece is being ground properly and that the grinding wheel is functioning correctly.

- Disconnect power source: After completing grinding operations, the power source should be disconnected to prevent accidental startup.

By following these guidelines, users can operate a high speed grinder safely and effectively, and achieve optimal grinding results. It is important to follow the manufacturer’s instructions and all applicable safety regulations when operating any type of machinery.

Applications of Industrial Seed Grinder

Industrial seed grinders are used in a variety of applications across many industries. Here are some of the most common applications of industrial seed grinders:

- Food industry: Industrial seed grinders are used extensively in the food industry to grind seeds, nuts, and spices into fine powders or pastes. These powders and pastes are then used in a variety of products such as sauces, seasonings, and spreads.

- Pharmaceutical industry: In the pharmaceutical industry, industrial seed grinders are used to grind plant material into a fine powder, which is then used to make medicines and supplements.

- Cosmetics industry: Industrial seed grinders are also used in the cosmetics industry to grind plant material into a fine powder or paste, which is then used in products such as face masks, scrubs, and exfoliants.

- Agricultural industry: Industrial seed grinders are used in the agricultural industry to process seeds, such as soybeans, into animal feed.

- Chemical industry: In the chemical industry, industrial seed grinders are used to grind materials such as resins, pigments, and dyes into a fine powder.

- Renewable energy industry: Industrial seed grinders are also used in the renewable energy industry to process biomass into a fine powder, which is then burned to generate electricity.

Overall, industrial seed grinders are versatile machines that are used in many different industries for a variety of applications. They are essential for processing plant material into fine powders and pastes that can be used in many different products.

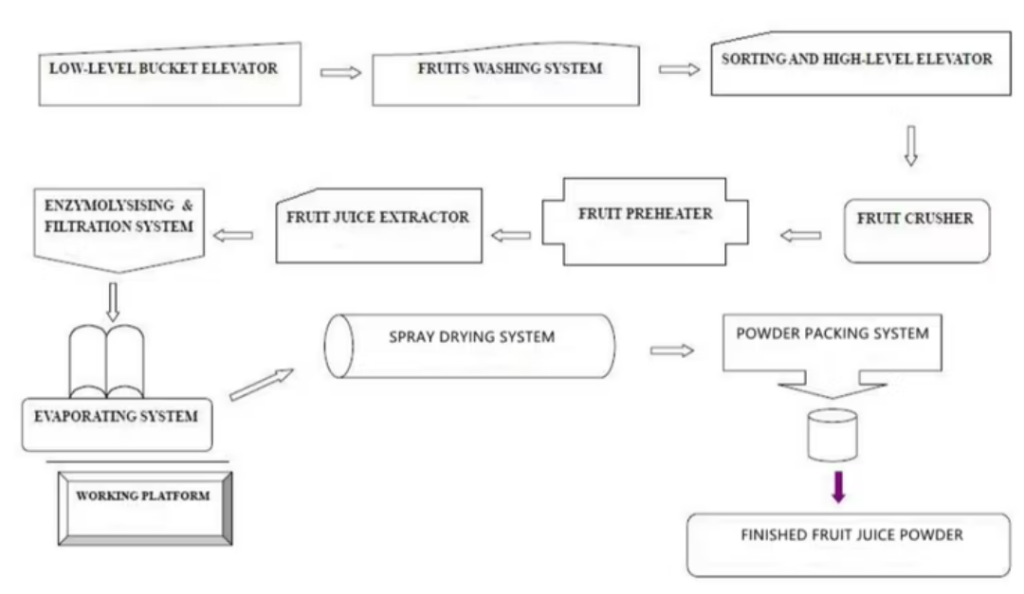

Food Producing Process Flow:

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Automatic Banana Powder Production Line Youtube Video

Customization Seeds Grinder According to your Capacity:

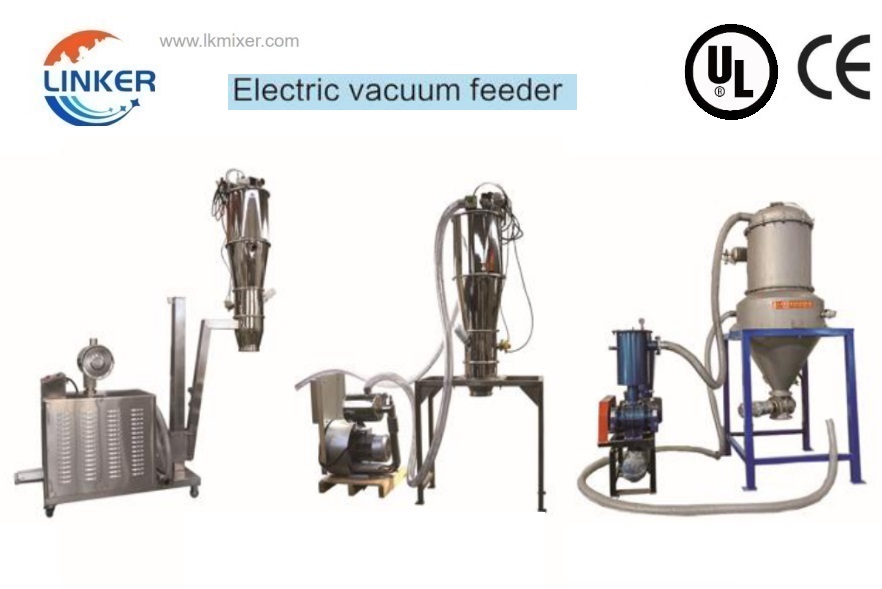

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

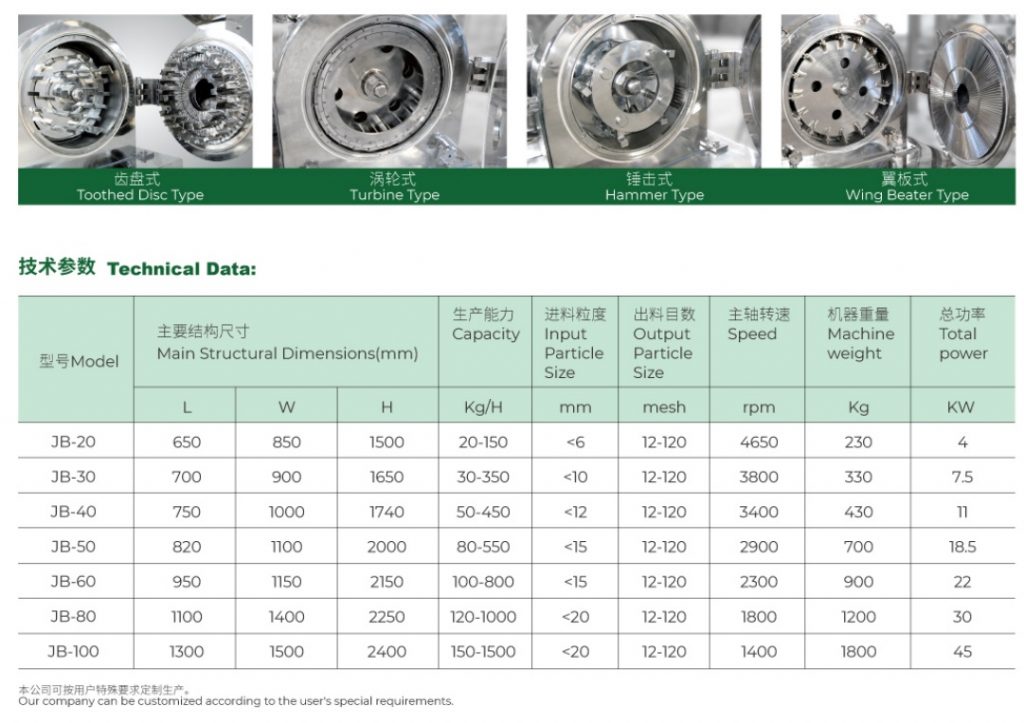

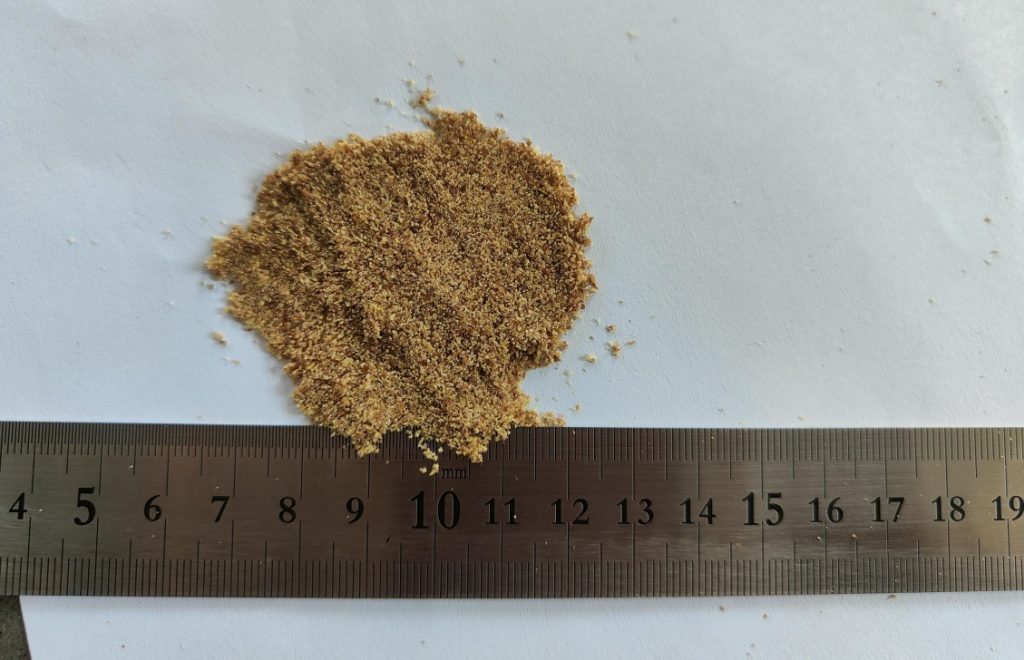

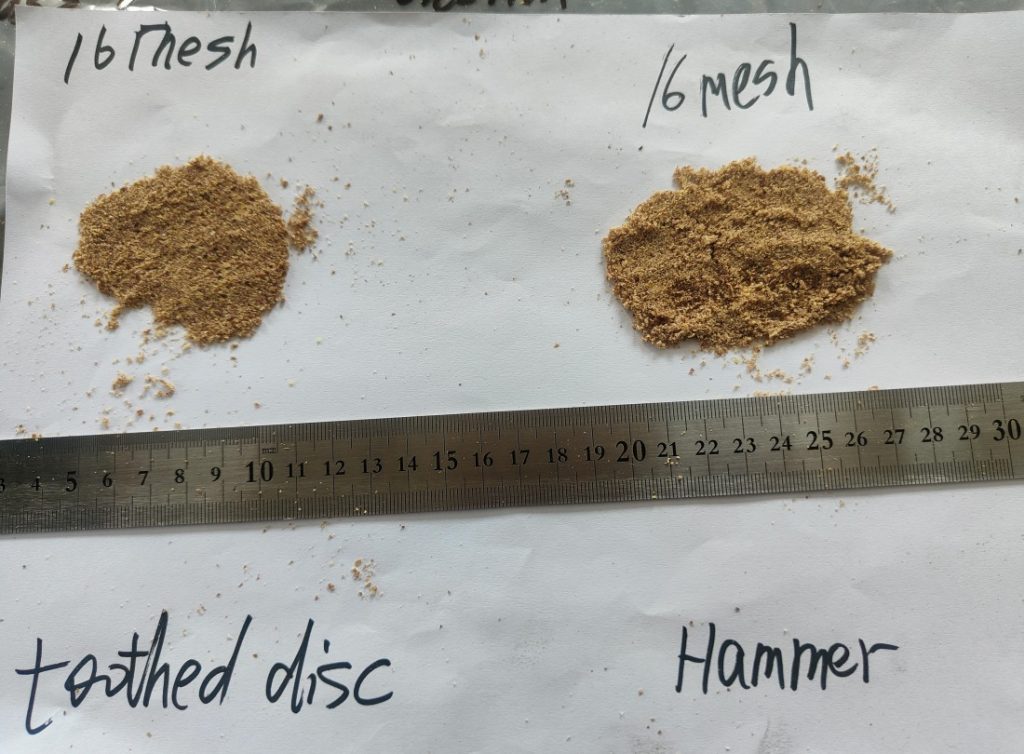

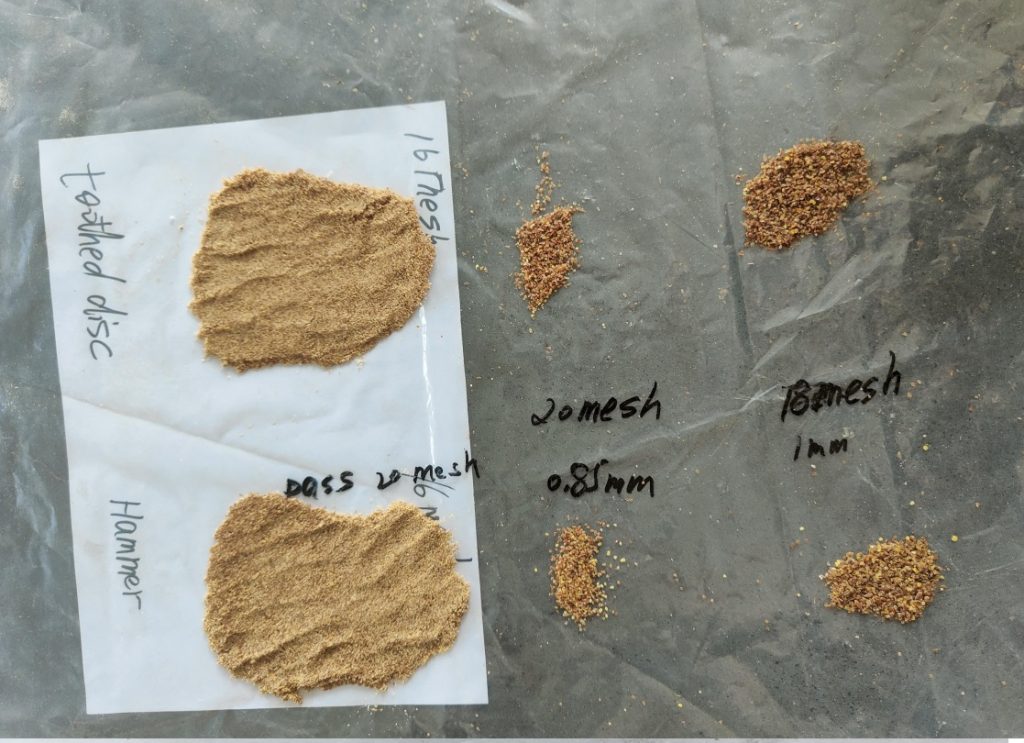

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?

Click and read more about mushroom grinder:

Click and Read More about Pulverizer:

Click to more questions about Seeds grinder:

Grinding Machine for Sale:

Blending and Mixing Machine for Sale

Granulating Machine for Sale:

Auxiliary Machine for Sale:

Recommend Reading

Industrial Dry Granulating Machine for Sale:

Industrial Grinder for Sale:

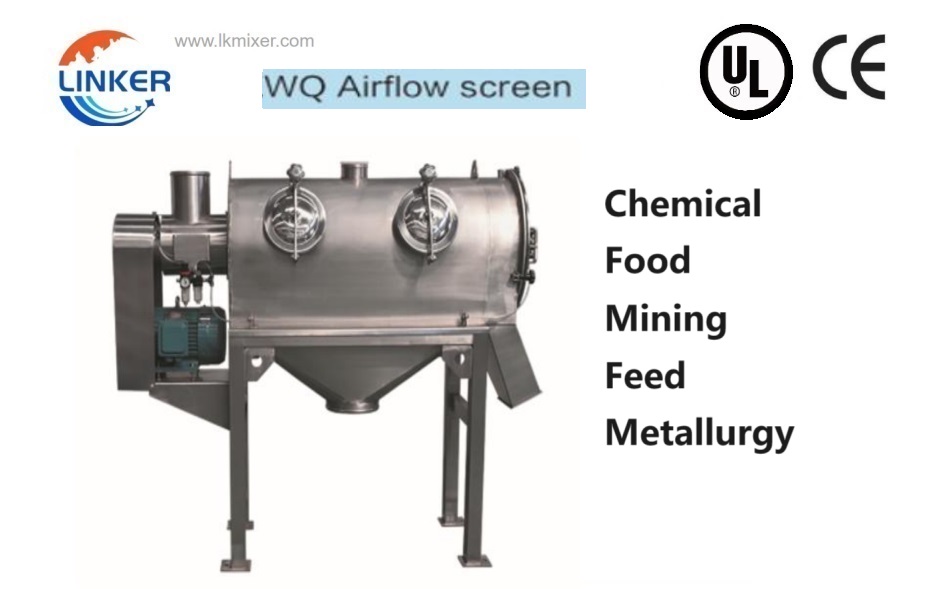

Industrial Vibrating Screen for Sale:

Industrial Vacuum Feeder for Sale:

Potato Flakes Process Flow

- Banana Washing Machine

- Banana Pealing and Cutting Machine

- Banana Drying Machine

- Banana Grinding Machine

- Banana Powder Mixing Machine

- Banana Powder Filling Machine

- Banana Powder Packing Machine

Potato Flakes Automatic Productino Line Design:x`

Automated Production Line for Potato Flakes

An Automatic Potato Flakes Production Line is a highly integrated, continuous food processing system that uses a fully automated process of washing, peeling, slicing, blanching, frying, de-oiling, seasoning, and packaging to turn raw potatoes into finished, packaged potato chips (crisps). Its main goal is to accomplish large-scale, efficient, standardized manufacturing that will greatly increase output capacity and guarantee consistent, high-quality output.

A Comprehensive Explanation of the Core Process Flow

Raw potatoes are automatically ingested to start the process. The potatoes are raised into the processing stream by an elevator or charger device. The initial crucial phase entails meticulous cleaning and peeling. An ᵸ泡 and brush-washing peeling machine efficiently eliminates dirt, debris, and skins from potatoes, leaving a clean surface for slicing. The cleaned potatoes are then transported to the slicing station. Here, straight edges and regular slice thickness are ensured by high-precision cutting slicers, which frequently have interchangeable blades. This is essential for reliable frying. This slicer is designed to meet the precise texture and size criteria of potato flakes, but it operates with the accuracy of a specialized industrial weed grinder or herb grinder.

The potato chunks are sliced and then blanched. In addition to removing extra surface starch for a cleaner fry and inactivating enzymes to prevent discolouration, this hot water or steam treatment also slightly pre-cooks the product. The slices are dewatered using vibrating screens or centrifugal force after blanching. Here, efficient dehydration is essential because it lowers the initial moisture content, which results in less oil absorption during frying and a crispier finished texture. After that, the dewatered slices go into the continuous frying system, which is the center of the line. They pass through a heated oil bath at a steady, perfectly regulated temperature. Unlike batch frying, this continual frying ensures consistent color and crispness.The chips go through a de-oiling system as soon as they are fried; this is usually a basket similar to a centrifugal dry grinder, although it is made to remove oil gently rather than reduce particle size. By spinning off extra surface oil, the chips become less oily and more appetizing.

After being heated and de-oiled, the chips proceed to the seasoning area. Chips are evenly coated with powdered seasonings such as cheese, salt, or barbecue flavors using a revolving drum or powder-dusting equipment, which is similar to a universal grinder or spice blender in terms of mixing function. This apparatus guarantees a uniform taste application for each chip. Lastly, automated packing equipment receive the seasoned chips. Here, they are weighed, put into bags, and sealed. To increase shelf life, these bags are frequently filled with inert gas, such as nitrogen (modified atmosphere packaging). From the first charger to the last bag, every step of the process is smooth and coordinated, needing little personal intervention.

Important Characteristics and Benefits of the Production Line

The distinguishing feature is high automation and continuous operation. Conveyors and control systems connect every step of the line, from the first elevator to the last packaging machine. By doing this, labor costs are reduced, throughput is increased, and the irregularities that come with manual handling are eliminated. The production process is as continuous as material processing in a large industrial stainless steel mill or a high-output 500KG grinder.

Automatic Banana Powder Production Line

Raw material treatment, color preservation, pulping, homogenization, heating, spray drying, and packing are the main operations of a fully automated banana powder production line. Each phase is highly automated to ensure production efficiency and reliable product quality.

Overview of the Automatic Production Line for Banana Powder

Through a continuous, automated series of processes, an automatic banana powder production line is made to turn fresh bananas into a fine, shelf-stable powder. From raw material intake to final packing, this system incorporates cutting-edge technology to maximize productivity, maintain consistent quality, and retain nutrients and flavor.

Raw Material Washing and Sorting

Fresh bananas are carried by a belt into the washing section, where a high-pressure spray system eliminates surface dirt and impurities. Fruits that are immature, damaged, or of poor quality are then automatically identified and eliminated by optical sorting equipment. Similar to the sorting procedures used for other food products like coffee beans, seeds, or corn, this first step is essential for guaranteeing consistent raw material quality. The automated procedure guarantees only the best fruits progress, setting the foundation for a high-quality end powder.

Slicing and Peeling

The cleaned bananas pass into an automatic peeling machine, which efficiently removes the peel by mechanical pressure or steam-assisted methods. After peeling, the bananas are chopped into uniformly thin slices using an automatic cutter. This homogeneity is crucial for consistent future processing, similar to the preparatory slicing employed in operations for mushroom or dry ginger powder manufacture. The slices give the subsequent processes the best possible surface area.

Color Preservation Treatment

The banana slices instantly enter the color preservation stage to prevent enzymatic browning. This is typically done by immersing them in a 0.2%-0.5% sodium bisulfite solution or through sulfur fumigation in a sealed tank. The procedure includes circulation recovery, timed control, and automated solution dosing. This step is vital for maintaining the appealing color and natural flavor of the banana powder, akin to treatments used in preserving the color of certain spice or tea extracts during processing.

Removal of Impurities and Pulping

The treated slices are fed into a stainless steel pulping machine, which breaks them down into a paste. Black seeds and coarse fibers are next removed from this paste by passing it through a sieve with an opening of roughly 0.5 mm. The end product is a smooth slurry with a solid content that is ideally between 13% and 15%. For beans, nuts like peanuts, or cassava, this pulping process is comparable to the first size reduction carried out by a coarse crusher prior to finer grinding.

Uniformity

The slurry undergoes a two-stage refining process. First, it runs through a colloid mill, and then through a high-pressure homogenizer. This decreases particle size to below 0.05mm, optimizing the homogeneity for spray drying and improving the solubility of the finished powder. The notion of particle size reduction is important to many grinding applications, from the ultrafine grinder used for medicine or chemicals to the hammer mill used for food materials like wheat or rice.

Heating

The homogenized slurry is moved to an insulated tank that has been heated to between 45 and 50 degrees Celsius. In order to facilitate atomization during spray drying, this step reduces the viscosity. Equipped with an agitator to prevent localized overheating, the temperature and time are accurately controlled by the PLC system. In other powder production lines, such those for dry fruit powder or the processing of heat-sensitive materials in a cryogenic grinding machine, precise thermal control is also essential.

Spray Drying

A high-pressure pump transports the heated slurry into a co-current pressure spray drying tower. When the slurry comes into contact with heated air inside the tower, it is quickly atomized and dehydrated into powder. To guarantee that the moisture level of the banana powder stays below 4.16% and maintains optimum flowability, the tower has an automated powder discharge and cooling system. Drying technique is a cornerstone of powder production, distinguishing from methods used for bone meal or tobacco, which could employ a dry grinder or vacuum mill after initial drying.

Sieving and Cooling

A fluidized bed cooler is used to cool the powder that leaves the drying tower to below 50°C. It next goes through a vibrating sieve for particle size classification, ensuring the final product is loose and free of lumps. Sieving or sifting is a frequent final step in powder processing, whether for banana powder, flour, sugar, salt, or specific powders produced by an airflow pulverizer or vibrating pulverizer.

Automatic Packaging

An automated packing machine receives the cooled and sieved banana powder. Weighing, vacuum sealing, and inert gas flushing (such as nitrogen) are all done by this equipment. To stop moisture absorption and increase shelf life, the powder is usually wrapped in aluminum foil or composite film bags. Automated packaging is standard in the food and chemical industries, ensuring hygiene and efficiency for products ranging from spice blends to tea granules.A central control system (PLC + HMI) manages the entire production line. Belt conveyors or elevators connect the equipment, allowing for completely automated operation from the feeding of raw materials to the packing of the final product. This configuration is suited for large-scale industrial production. Although this line is focused on bananas, it’s crucial to remember that many sectors share the fundamental ideas of automation, size reduction (using tools like a universal grinder, turbo grinder, or high speed grinder), drying, and packaging. For instance, a huge stainless steel dry fruit powder grinder machine shares design principles with components here, and a dust collector grinder is important in any process, like licorice grinding or black pepper grinder operation, to keep a clean environment.Additionally, whether it’s a small grinder machine for boutique spice shops or a 500KG grinder for bulk food processing, equipment bearing the CE Certificate grinder logo guarantees conformity with international safety requirements. Though they are adapted to particular materials like metal (for machining), meat (for rendering), or delicate herbs, the basic objectives of effective, controlled size reduction and product handling remain the same whether using an electric grinder in a kitchen, an industrial cannabis grinder, or specialized cannabis processing equipment.

Parameters:

Model Name | SG-600 | |

| Crushing Capacity(kg/h) | 1000~2000 | |

| Power(kw) | 11 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Model Name | SG-800 | |

| Crushing Capacity(kg/h) | 2000~4000 | |

| Power(kw) | 15 | |

| Feeding Size(mm) | <5mm | |

| Fineness(mesh) | 20~40mesh |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

Ampere of Motors Customization for Seeds Grinder:

| KW | HP | Ampere |

| 75kw | 100HP | 135A |

| 55kw | 75HP | 99A |

| 30kw | 40HP | 54A |

| 22kw | 30HP | 39A |

| 2.2kw | 3HP | 3.9A |

| 1.5kw | 2HP | 2.7A |

Test Report for Flax Seed Grinder:

A flax seed grinder is a type of seed nut grinder specifically designed for grinding flax seeds. Flax seeds are small, hard seeds that are packed with nutrition and are commonly used in baking and cooking. Grinding flax seeds helps to unlock their nutrients and make them easier to digest.

Flax seed grinders typically feature sharp blades or burrs that rotate to crush the flax seeds into a fine powder. This powder can then be used in a variety of recipes, such as smoothies, baked goods, and yogurt toppings. Some flax seed grinders are manual and require hand-cranking, while others are electric and feature powerful motors for faster grinding.

When choosing a flax seed grinder, it’s important to look for one with durable blades or burrs that can withstand the hard texture of flax seeds.

There are 3 ways of cooling down the grinder: water cooling system; air cooling system and liquid nitrogen freezing system. You can choose the right one if the grinder gets too hot. When machines goes too hot, the metal can expand, causing the grinding wheel to get stuck.

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

Operation Instruction

General Provisions

The operation instructions for a commercial grinder may vary depending on the specific model and manufacturer. However, here are some general guidelines that may apply to many high speed grinders:

- Safety precautions: Before operating the high speed grinder, it is important to review all safety precautions and warnings provided in the user manual. Safety precautions may include wearing appropriate personal protective equipment, such as eye protection and hearing protection, and avoiding loose clothing or jewelry that could become caught in the grinder.

- Preparation: The high speed grinder should be placed on a stable and level surface, and all necessary components should be assembled according to the manufacturer’s instructions. The grinder should also be connected to a power source that is appropriate for its voltage and wattage.

- Loading the grinder: The material to be ground should be loaded into the grinder according to the manufacturer’s instructions. Overloading the grinder may cause damage to the machine and result in poor grinding performance.

- Starting the grinder: The grinder should be started according to the manufacturer’s instructions. This may involve pressing a button, turning a dial, or flipping a switch. The user should ensure that their hands are clear of the grinder and that the material to be ground is positioned properly.

- Adjusting the speed and settings: The speed and other settings of the high speed grinder may be adjusted according to the material being ground and the desired outcome. The user should follow the manufacturer’s instructions for making adjustments to the grinder.

- Monitoring the grinding process: The user should monitor the grinding process to ensure that it is progressing smoothly and that the material is being ground to the desired size and consistency. Any issues or abnormalities should be addressed promptly to prevent damage to the machine.

- Shutting down the grinder: When the grinding process is complete, the grinder should be shut down according to the manufacturer’s instructions. The user should ensure that the machine is completely stopped and that all moving parts have come to a complete stop before attempting to clean or service the grinder.

Overall, the operation instructions for a commercial grinder may involve a number of steps and safety precautions. It is important to carefully review the manufacturer’s instructions and follow proper operating procedures to ensure safe and effective use of the machine.

Preparation Work

Before running a commercial grinder, there are several important preparation steps that should be taken to ensure safe and effective operation of the machine. Here are some general guidelines for preparing to run a high speed grinder:

- Read the user manual: The first step in preparing to run a high speed grinder is to carefully read the user manual provided by the manufacturer. The user manual will provide important information about the specific model of grinder being used, including its features, specifications, and safety precautions.

- Select the appropriate grinding wheel: The grinding wheel used in a high speed grinder should be selected based on the material being ground and the desired outcome. It is important to use the correct type of grinding wheel to prevent damage to the machine and ensure optimal grinding performance.

- Inspect the grinder: Before running the grinder, it is important to inspect it for any signs of damage or wear. The user should check for loose or missing components, cracks or other signs of damage to the machine’s housing or other parts, and any other issues that could affect the grinder’s operation.

- Install the grinding wheel: The grinding wheel should be installed according to the manufacturer’s instructions, making sure that it is securely fastened and aligned properly. The user should also check the wheel for any cracks or other signs of damage before installation.

- Secure the workpiece: The workpiece to be ground should be securely clamped or held in place before starting the grinder. This will help to ensure safe and effective operation and prevent the workpiece from becoming dislodged or damaged during grinding.

- Connect the power source: The high speed grinder should be connected to a power source that is appropriate for its voltage and wattage. It is important to use a properly grounded power source to ensure safe and reliable operation of the machine.

- Test run: Before beginning actual grinding operations, it may be useful to perform a test run to ensure that the grinder is functioning properly and that the grinding wheel is aligned and balanced properly. The user should follow the manufacturer’s instructions for performing a test run.

By following these preparation steps, users can ensure safe and effective operation of a high speed grinder and achieve optimal grinding results.

Treatment of inspection

Inspection of a commercial grinder is an important maintenance procedure that helps ensure safe and effective operation of the machine. Here are some general guidelines for inspecting a high speed grinder:

- Disconnect power source: Before performing any inspection or maintenance on a high speed grinder, the power source should be disconnected to prevent accidental startup.

- Check for wear and damage: The user should inspect the grinder for any signs of wear or damage, such as cracks in the housing, worn or damaged grinding wheels, or loose or missing parts. Any issues should be addressed promptly to prevent further damage to the machine.

- Check alignment and balance of grinding wheel: The grinding wheel should be inspected for proper alignment and balance, as these factors can affect the quality of the grinding operation. If the grinding wheel is not properly aligned or balanced, it should be adjusted or replaced as necessary.

- Check for proper lubrication: The high speed grinder should be inspected for proper lubrication, as inadequate lubrication can cause excessive wear and damage to the machine’s moving parts. The user should follow the manufacturer’s instructions for lubrication, and add lubricant as necessary.

- Inspect electrical components: The electrical components of the high speed grinder, including the wiring, switches, and control panel, should be inspected for any signs of wear, damage, or loose connections. Any issues should be addressed promptly to prevent electrical problems.

- Test run: After completing the inspection, it may be useful to perform a test run of the high speed grinder to ensure that it is functioning properly and that any issues have been addressed.

By following these inspection guidelines, users can help ensure safe and effective operation of a high speed grinder and minimize the risk of damage or injury during grinding operations.

Operation Attention

Running a commercial grinder can be a dangerous operation if proper precautions are not taken. Here are some general guidelines for safe operation of a high speed grinder:

- Personal protective equipment: The user should wear appropriate personal protective equipment, such as safety glasses, hearing protection, and gloves, to prevent injury from flying debris, noise, and contact with the grinding wheel.

- Secure workpiece: The workpiece being ground should be securely clamped or held in place to prevent it from becoming dislodged during grinding.

- Use proper grinding wheel: The user should select the appropriate grinding wheel for the material being ground and ensure that it is installed correctly and securely. The grinding wheel should be inspected for cracks or other damage before use.

- Adjust grinding wheel speed: The speed of the grinding wheel should be adjusted according to the manufacturer’s instructions to ensure optimal grinding performance and prevent damage to the machine or workpiece.

- Avoid excessive pressure: The user should avoid applying excessive pressure to the grinding wheel, as this can cause the wheel to overheat and wear out more quickly.

- Avoid overheating: The high speed grinder should not be operated continuously for extended periods of time, as this can cause overheating and damage to the machine.

- Monitor grinding operation: The user should closely monitor the grinding operation to ensure that the workpiece is being ground properly and that the grinding wheel is functioning correctly.

- Disconnect power source: After completing grinding operations, the power source should be disconnected to prevent accidental startup.

By following these guidelines, users can operate a high speed grinder safely and effectively, and achieve optimal grinding results. It is important to follow the manufacturer’s instructions and all applicable safety regulations when operating any type of machinery.

Applications of Industrial Seed Grinder

Industrial seed grinders are used in a variety of applications across many industries. Here are some of the most common applications of industrial seed grinders:

- Food industry: Industrial seed grinders are used extensively in the food industry to grind seeds, nuts, and spices into fine powders or pastes. These powders and pastes are then used in a variety of products such as sauces, seasonings, and spreads.

- Pharmaceutical industry: In the pharmaceutical industry, industrial seed grinders are used to grind plant material into a fine powder, which is then used to make medicines and supplements.

- Cosmetics industry: Industrial seed grinders are also used in the cosmetics industry to grind plant material into a fine powder or paste, which is then used in products such as face masks, scrubs, and exfoliants.

- Agricultural industry: Industrial seed grinders are used in the agricultural industry to process seeds, such as soybeans, into animal feed.

- Chemical industry: In the chemical industry, industrial seed grinders are used to grind materials such as resins, pigments, and dyes into a fine powder.

- Renewable energy industry: Industrial seed grinders are also used in the renewable energy industry to process biomass into a fine powder, which is then burned to generate electricity.

Overall, industrial seed grinders are versatile machines that are used in many different industries for a variety of applications. They are essential for processing plant material into fine powders and pastes that can be used in many different products.

Food Producing Process Flow:

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Automatic Banana Powder Production Line Youtube Video

Customization Seeds Grinder According to your Capacity:

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?