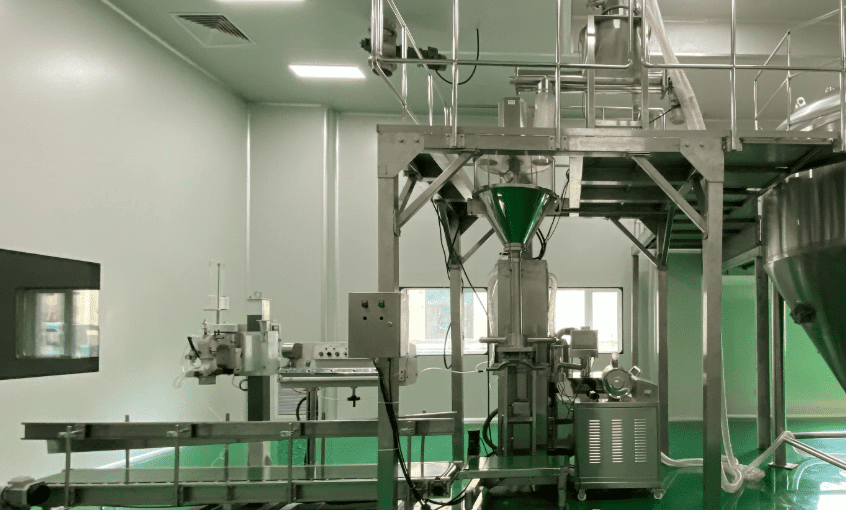

Automatic Powder Production Line

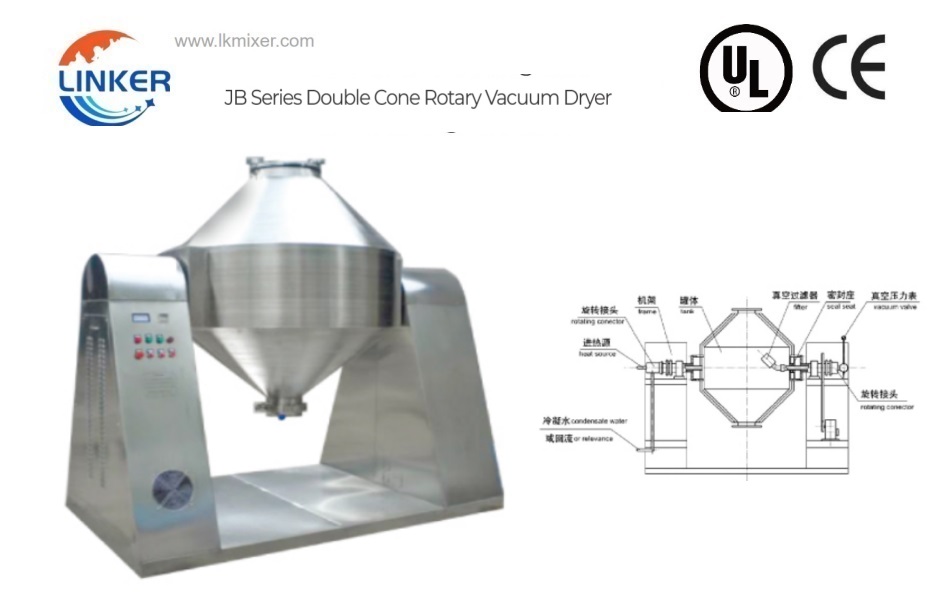

The fully automatic powder packaging production line is automated packaging equipment. It is primarily used for the metering, filling, sealing, capping, and coding operations of powder and granular materials in industries such as food, chemical, and pharmaceuticals. Its core modules include a semi-automatic powder filling and packaging machine, automatic capping machine, electromagnetic induction aluminum foil sealing machine, vertical labeling machine, and small-character inkjet printer, supporting three-phase 380V or single-phase 220V power adaptation.

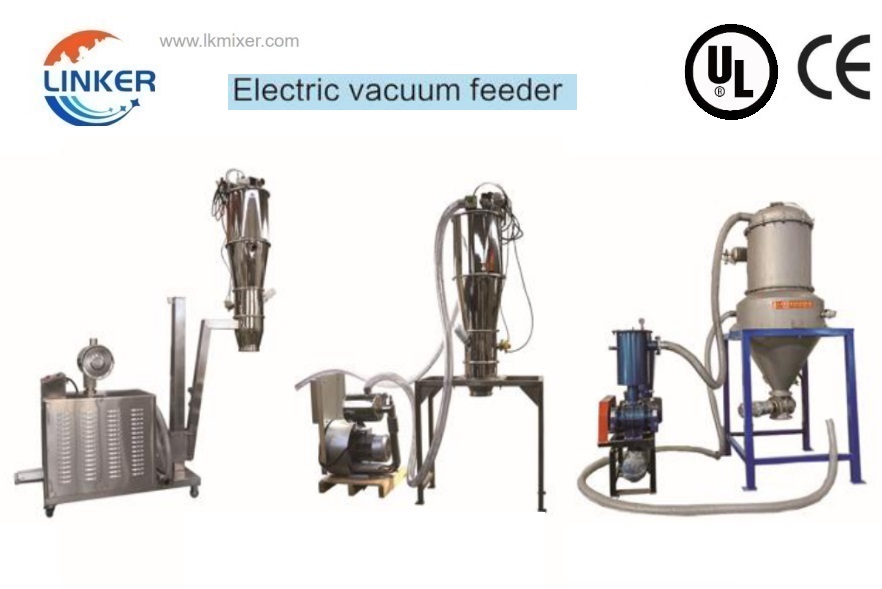

The production line features an all-stainless-steel structure, complies with QS and GMP certification standards, and is equipped with a PLC touchscreen human-machine interface and 10 formula storage functions. The filling process is driven by a servo motor via a spiral component, achieving a metering accuracy of ±0.5%–1% and a packaging speed of 20–50 bags per minute. The capping machine is compatible with bottles with diameters of 30–80 mm, with a capacity of 20–40 bottles per minute. Supporting systems include a dust-proof raw material bin, horizontal ribbon mixer, and automatic weighing and proportioning control, with a single mixing batch capacity of 500–600 kg, suitable for processing viscous materials.

Automatic Banana Powder Production Line

Automatic Yellow Onion Powder Production Line

Automatic Potato Flakes Production Line

Automatic Ginger Powder Production Line

Automatic Garlic Powder Production Line

Automatic Coffee Powder Production Line

Automatic Metal Powder Production Line

Automatic Laudry Powder Production Line

Automatic Diamond Line Powder Production Line

Automatic Turmeric Powder Production Line

Automatic Protein Powder Production Line

Automatic Crumb Rubber Powder Production Line

Automatic Laudry Detergent Production Line

Automatic Chalk Production Line

Automatic Ceramic Powder Production Line

Automatic Green Onion Powder Production Line

Automatic Rubber Powder Production Line

Automatic Potato Powder Production Line

Automatic Talc Powder Production Line

Automatic Putty Powder Production Line

Automatic Tomato Powder Production Line

Automatic Egg Shell Powder Production Line

Automatic Protein Powder Production Line

Automatic Milk Powder Production Line

Automatic Quartz Powder Production Line

Automatic Butyl Rubber Powder Production Line

Automatic Zenith Industrial Powder Production Line

Automatic Elf Powder Production Line

Automatic Red Onion Powder Production Line

Automatic Potato Chip Production Line

Automatic Hair Line Powder Production Line

Automatic Chilli Powder Production Line

Automatic Coca Powder Production Line

Automatic Aluminum Powder Production Line

Automatic Fruit Powder Production Line

Automatic Washing Powder Production Line

Automatic Gypsum Powder Production Line

Automatic Moringa Leaf Powder Production Line

Automatic Epdm Rubber Powder Production Line

Automatic Detergent Powder Production Line

Automatic Fruit Powder Production Line

Automatic Baobab Powder Production Line

Automatic Liquid Production Line

Automatic Liquid Detergent Production Line

Food Producing Process Flow:

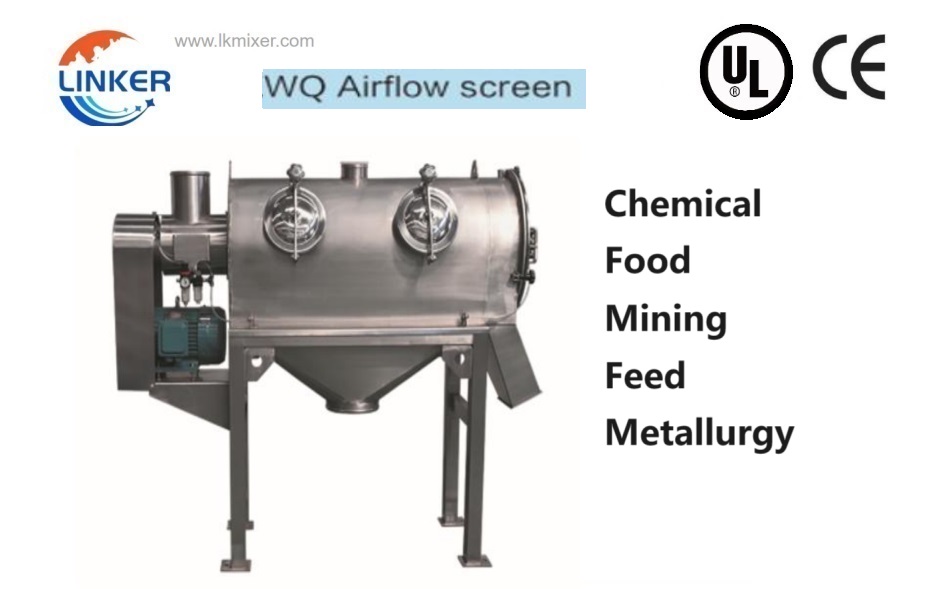

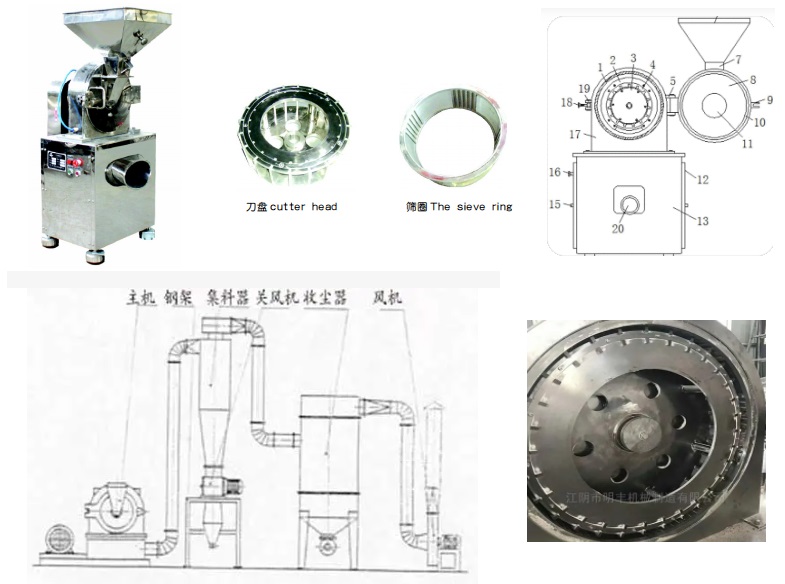

Ultrafine grinding is one of the very key procedure in whole production line. It depends how many mesh that customer need to produce. That’s to say this machine can decide what kind of material will get finally before mxing.

Coarse Crusher Machine —>Grinding Machine —> Vibrating Table Sifter Machine—>Mixing Machine—>Packing Machine —> (Printed Packaging Film Roll or bags ) —> Filling, sealing machine, capping and Labeling Machine —>Pack into Box.

Contact us for detail proposal and cost:

Automatic Banana Powder Production Line Youtube Video

Customization Seeds Grinder According to your Capacity:

We can customize the capacity according to your special requirement, we can also customize the vacuum feeder connect with your production line (the dimension and width of grinder), for detail contact with our sales for proposal and price.

Videos of Seeds Grinder Machine:

Many model of Seeds Grinder, the universal grinder is suitable to cut the seeds into 12-120mesh, the high efficient grinder is useful, but cost a little bit higher than universal. The super fine grinder can grind into 100mesh to 320mesh. Customer can choose according to your own requirement. here show some example:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

FAQ(Click and See More)

Read More about Herb Grinder:

Why are herb grinders so expensive?

Are electric herb grinders good?

What is the best way to grind up herbs?

Can you chop herbs in a coffee grinder?

How to grind dried herbs into powder?