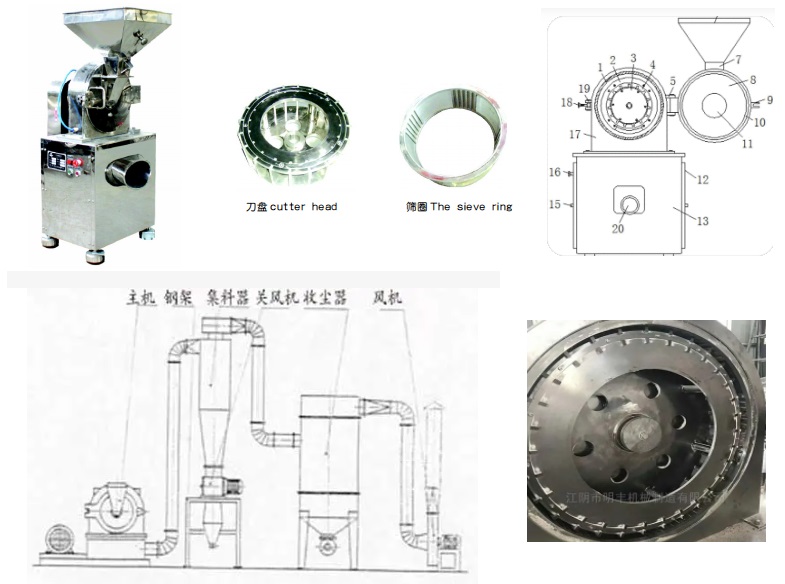

Medium Speed Grinder TGK

Medium Speed Grinder

- Motor Power (KW): 2.2~3.7kw;

- Axis Rotating Speed(r/min):143;

- Dimension(mm):970*460*1240~1750*470*1250.

- Price: $ 50-1,179.

| Model Name | Slow-medium 8 knives | Slow-medium 10 knives | Slow-medium 13 knives | Slow-medium 15 knives |

| Motor Power (KW) | 2.2KW | 2.2KW | 3.7KW | 3.7KW |

| Grinding diameter | 236*270mm | 270*290mm | 310*375mm | 265*430mm |

| Feeder Spec(mm) | 310*270mm 470*520mm horn shape | 310*270mm 470*520mm horn shape | 440*310mm 470*520mm horn shape | 580*330mm |

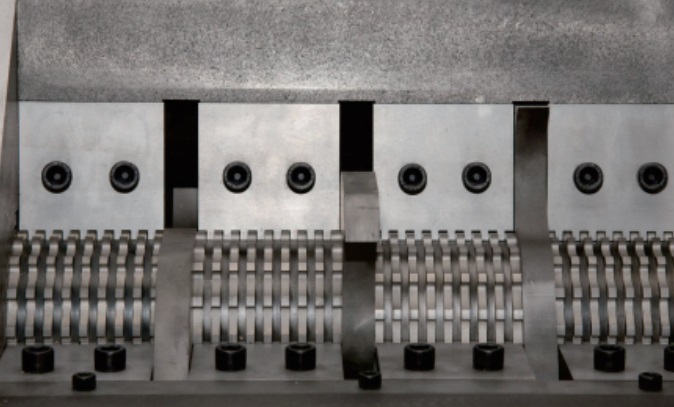

| Move Knife Quantity(pcs) | 8pcs*3=24pcs | 10pcs*3=30pcs | 13pcs*3=39pcs | 15pcs*3=45pcs |

| Knife Material | SKD-11 | SKD-11 | SKD-11 | SKD-11 |

| Rotating Speed(r/min) | 143 | 143 | 143 | 143 |

| Screen | Standard 6mm | Standard 6mm | Standard 6mm | Standard 6mm |

| Feeder Spec(mm) | 250*260 | 310*320 | 330*420 | 350*420 |

| Dimension(mm) | 1750*470*1250 | 970*460*1240 | 1180*560*1460 | 1100*800*1350 |

| Weight(kg) | 185KG | 192KG | 265KG | 233KG |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

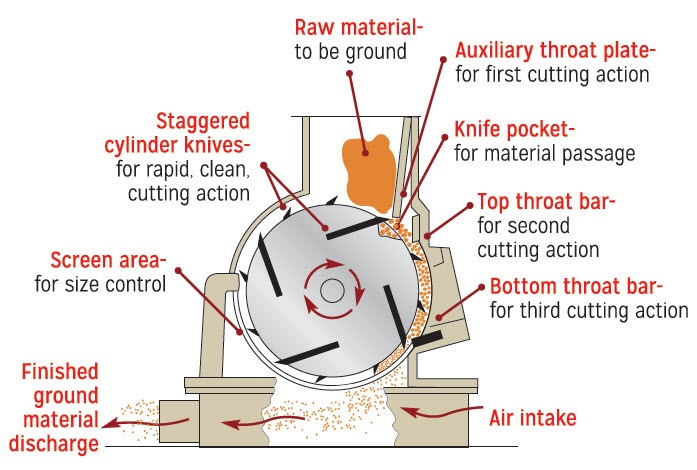

What is Medium Speed Grinder?

The difference between medium speed grinder and low speed grinder:

Slow speed grinder is suitable for grinding and recycling of machine edge waste material. It is convenient in operation, with excellent quality, small space occuping, quiet, uniform particles, less dust, long tool life.

In fact, the medium speed grinder and slow speed grinder are almost the same in appearance. But the medium speed grinder is suitable for the crushing and reuse of waste material, simple operation, excellent performance, the moderate speed of operation will be dust, noise generation and tool wear to the lowest point, and set a variety of safety protection devices and measures in line with the safety standards. While, slow speed grinders are with smaller size, smaller footprint, and are more suitable for placed in the edge of the machine, recycler, dryer next to them to cooperate with the use. This helps to form a set of rapid recovery system, this system can save the cumbersome intermediate link in the recovery process, greatly avoid the waste of manpower, material and materials caused by so, so as to achieve the effect of crushing recovery.

Advantages of slow machine edge grinder:

There are 3 ways of cooling down the grinder: water cooling system; air cooling system and liquid nitrogen freezing system. You can choose the right one if the grinder gets too hot. When machines goes too hot, the metal can expand, causing the grinding wheel to get stuck.

Popular Low Speed Grinder for Sale:

Medium Speed Grinder

Features:

- Advantages of low speed, low noise, low dust;

- UsingTaiwan brand reducer motor, it is with fetures of low noise, high efficiency and stability, durable;

- The motor drive mode is driven by the direct-coupled gear motor, which is more stable and reliable than the traditional drive mode;

- Using SKD-11 material and tool steel cutter structure, durable

- Using well-designed “concave” tool, so that it remains in the grinding after a fixed cutting curve and cutting interval. Without the need for complex adjustments so that more efficient tool disassembly, greatly extending the service life of the machine. Static knife can be re-used 4 times after re-grinding;

- The use of strong rotor device andV-type ladder arrangement of cutting tools greatly enhanced the cutting torque and ability toimprove the crushing yield enhance the crushing efficiency;

- With double-damping material, built-in sound insulation sandwich structure, this helps reduce noise, improve the environment. The use of mobile screen, easy disassembly, easy to clean, change color and maintenance;

- The quick disassembly mode, disassembly easier, installation,operation, cleaning maintenance more convenient European design, steel box, solid materials, beautiful and strong;

- Efficient crushing recovery,improve production efficiency. Bottom comes with suction mouth can be directly connected;

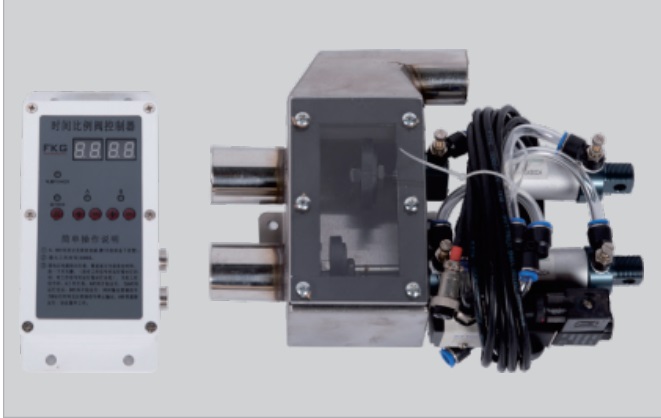

- With the suction machine for immediate recovery. optional two material proportional vaive. the new material can be controlledaccording to a certain proportion ofconveying to achieve the proportion of mixed transport function.

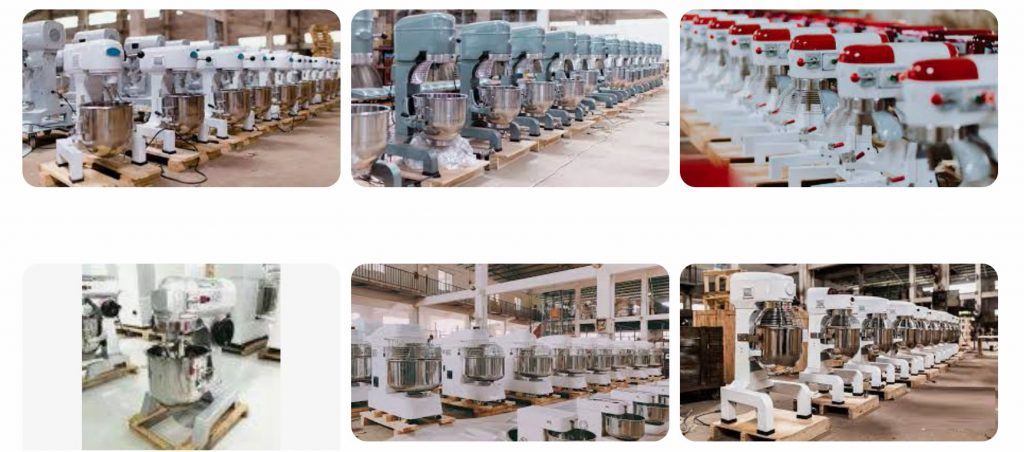

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

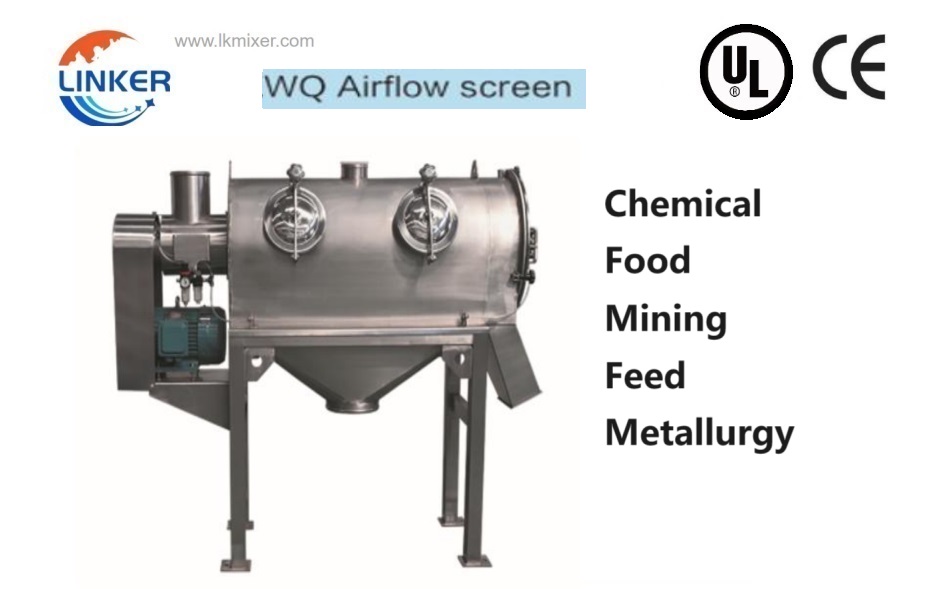

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Electric Cabinet with UL Certification

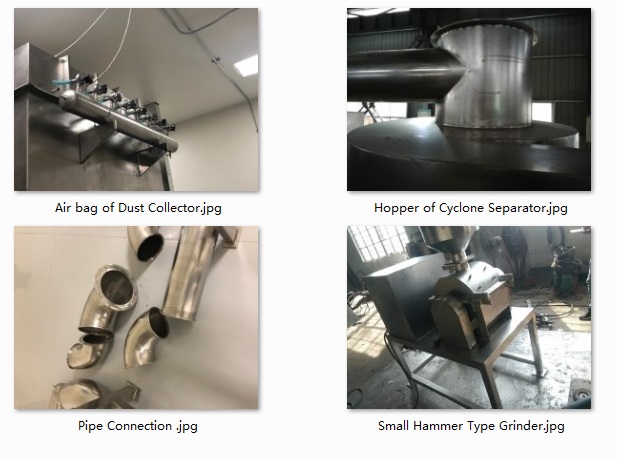

Cyclone Processor and Motors:

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

Large Machine Packing:

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Domestic Shipment Show Case:

Operation Instruction

General Provisions

The first reprint machine, shredder driver must be trained, to achieve the “three understanding” (understand the structure, understand the performance, understand the principle), “four” (will use, will maintain, will maintain, will deal with the fault), after the training test qualified, obtain a certificate, quasi post operation.

Article 2 Cooperate closely with the scraper conveying driver of the working face and the belt conveyor driver of the transportation lane, make unified signal contact, and start and stop in order. When large lump coal and gangue are accumulated and spilled at the feed port of the crusher, the operation of the scraper conveyor should be stopped. If there are large lumps of coal, gangue cannot enter the broken plane or there are metal objects, it must be shut down for treatment.

Preparation Work

1. Tools: wrench, pliers, screwdriver, hammer, spade, etc.

2, necessary spare parts: all kinds of short chain, chain link, bolts, nuts, crusher insurance dowel, etc.;

3. Lubricating oil and turbine oil

Treatment of inspection

1, motor, reducer, hydraulic coupling, head, tail and other parts of the connection must be complete, intact, tight. Reducer, hydraulic shaft joint should have no oil leakage, oil leakage, oil quantity should be appropriate.

2, signal must be sensitive and reliable, no signal is not allowed to start. Make sure the spray sprinklers are in good condition.

3. Power cables and operation lines must be hung neatly without being squeezed;

4, the coal, gangue, sundries near the nose and the coal dust of the motor and reducer must be cleaned;

5, face scraper conveyor head and reprint machine tail lap to be suitable;

6. The scraper chain plate is of moderate importance, and the scraper and screws must be fully fastened;

7, reprinting machine walking trolley must be stable and reliable;

8. When the machine is partly turned on, the operation of each part should have no abnormal sound, and the scraper, chain and connecting ring should have no torsion, twist and bend deformation;

9. The roadway support at the shredder and shredder must be intact and firm.

10, the safety protection net and protection device of the crusher, to ensure that no deformation no failure, safe and reliable;

11. The roadway support of the reprinting machine and the shredder must be intact and firm.

Precautions

Trial run

1. Switch on the power grid switch;

2. Manually press the click button for the trial run of the machine;

3. Start and idling for 1 ~2 weeks;

4. Joint operation of reprinting machine and shredder;

5. Check that there is no abnormality and send a startup signal.

6, the operation of the machinery and motor should be no vibration, sound and humidity should be normal, the bearing temperature should not exceed 75℃, motor temperature should not exceed the nameplate provisions.

7. The chain tightness of the reprinting machine must be consistent. Under the condition of full load, the chain tightness is not allowed to exceed the length of two chain rings.

8. After the fusible plug or fried piece of the joint of the reprinting machine is damaged, wood or other materials shall not be used instead.

9. The safety device of the protective net of the crusher should be kept in good condition, and should be checked frequently in the working process. If there is any damage, it should be stopped immediately.

10, reprinting machine tail protection and other safety devices must be ensured intact.

11, transfer and transfer machine.

(1) Clean the floating coal and gangue in the tail, on both sides of the fuselage and under the bridge;

(2) Protect cables, water pipes, oil pipes, and hang them neatly;

(3) Check the roadway support, and push the reprinting machine under the condition of ensuring safety;

(4) The walking trolley and the tail frame of the belt conveyor should have good contact, do not run off, and have good lap after moving, prevent large plastics from hurting the tape, and ensure smooth coal flow;

(5) After the transfer machine, the nose and tail should be kept flat, straight and stable, and the jack live rod should be recovered.

Operation Attention

1, plastic crusher and power unit to install firmly. If need long-term fixed operation, plastic crusher should be fixed on the cement base; If the plastic crusher is needed for mobile operation, the unit should be installed on a base made of Angle iron, and ensure that the power machine (diesel engine or motor) and the belt pulley groove of the plastic crusher are in the same rotary plane. 2. After the installation of the plastic crusher, the fasteners of all parts should be checked and tightened if they are loose. At the same time to check the belt tightness is appropriate.

3. Before starting the plastic crusher, first rotate the rotor by hand to check whether the jaw, hammer and rotor are flexible and reliable, whether there is collision in the crushing room, whether the rotating direction of the rotor is consistent with the direction indicated by the arrow of the machine, and whether the lubrication of the power machine and plastic crusher is good.

4, do not casually replace the belt pulley, in case the speed is too high resulting in the explosion of the crushing chamber, or the speed is too low affecting the working efficiency of the crusher.

5. After starting the plastic crusher, it should be kept idling for 2~3min, and then feeding after there is no abnormal phenomenon.

6, the work should always pay attention to the operation of the plastic crusher, first of all, the feeding should be uniform, to prevent blocking the crushing chamber; Second, don’t overwork for a long time. If there is vibration, noise, bearing and body temperature is too high, spraying material and other phenomena, should immediately stop the machine for inspection, troubleshooting before continuing to work.

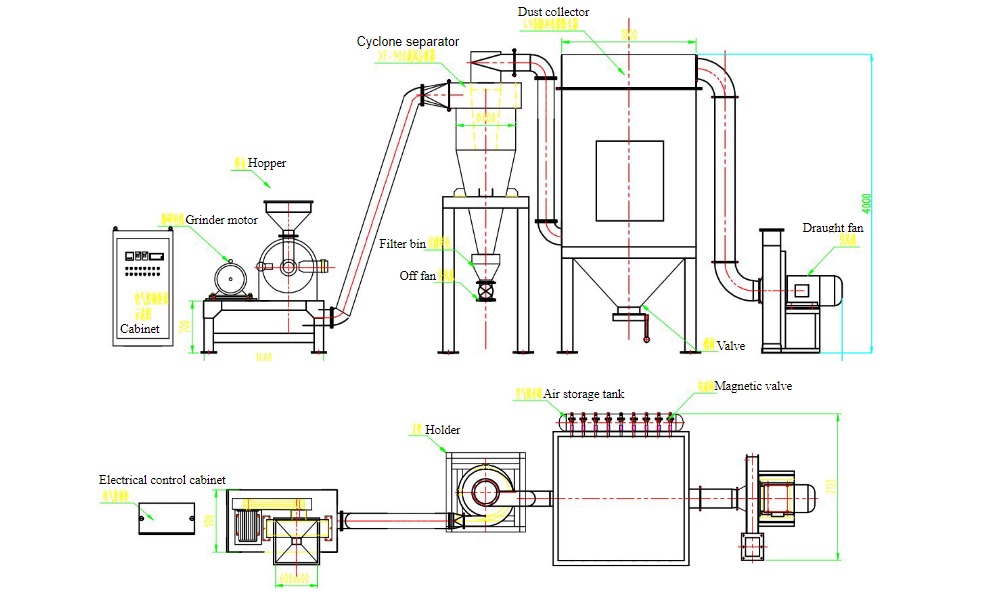

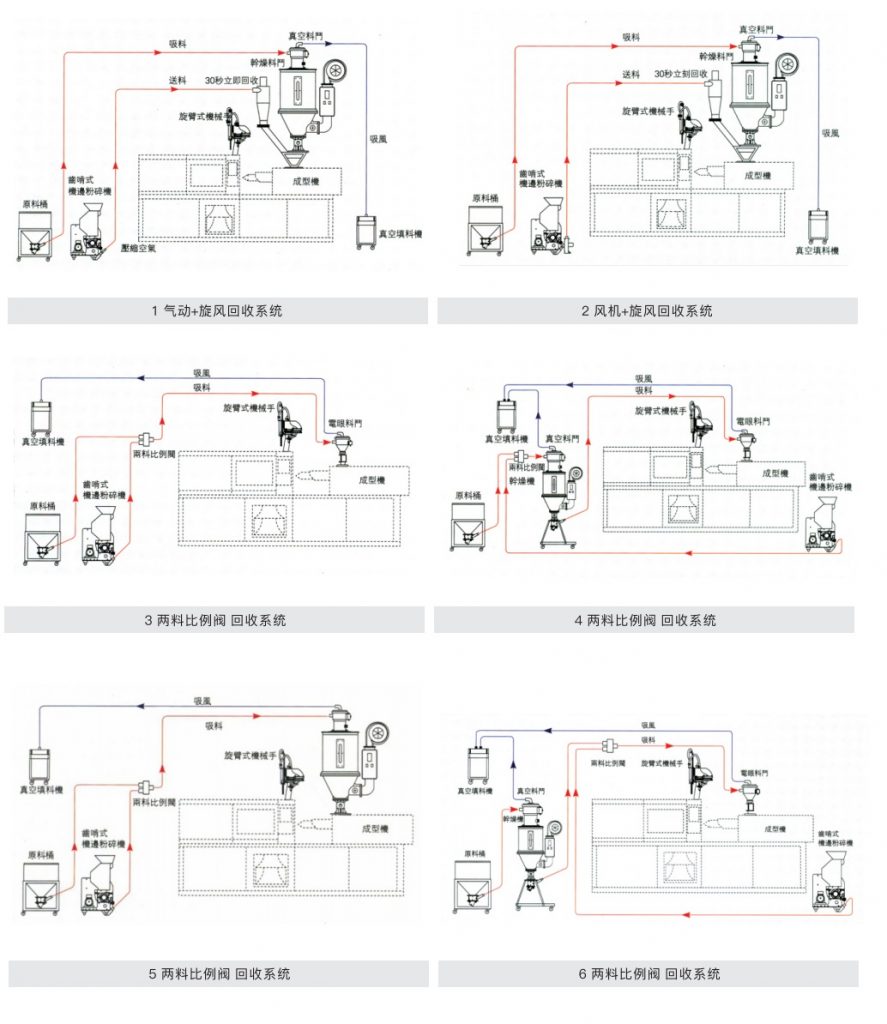

Installation Layout:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

High Speed Grinder:

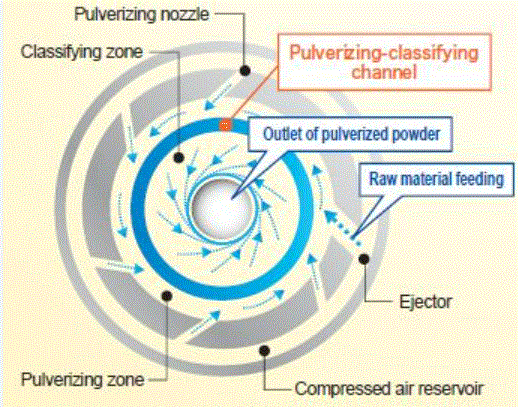

Pulverizer:

Ampere of Motors Customization for Pepper Mill:

| KW | HP | Ampere |

| 75kw | 100HP | 135A |

| 55kw | 75HP | 99A |

| 30kw | 40HP | 54A |

| 22kw | 30HP | 39A |

| 2.2kw | 3HP | 3.9A |

| 1.5kw | 2HP | 2.7A |

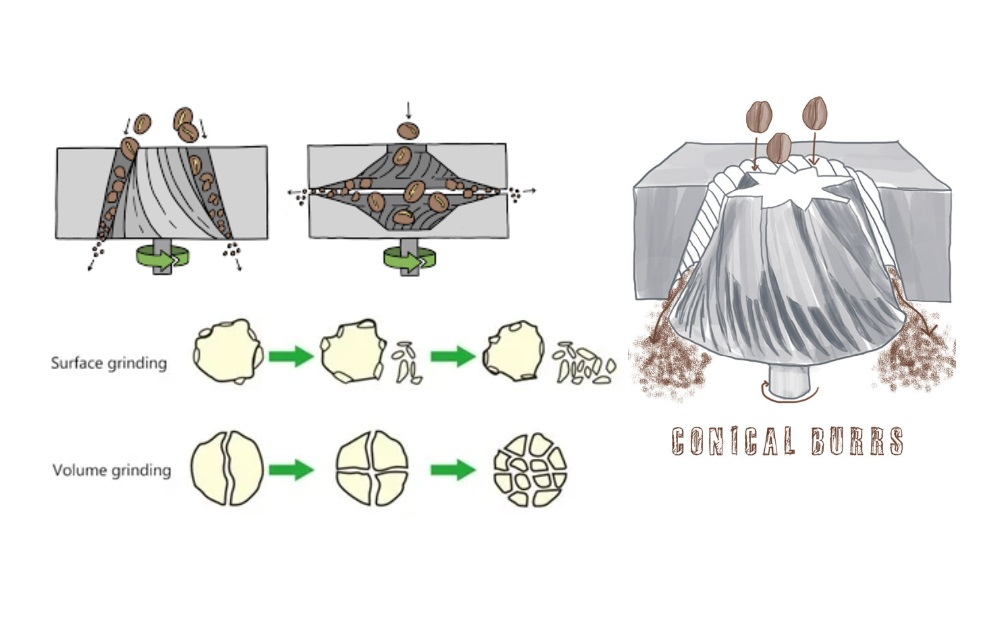

Coffee Grinder Youtube Video (WFJ Turbine Type Grinder is Suitable for baked Coffee Bean)

Coffee Grinder Youtube Video (Hammer Type is NOT suitable for baked Coffee Bean, because it’s too oil.)

FAQ(Click and See More)

How to choose the right models?

Choose small or large ? Calculate your current customer capacity request, this is to get a estimate capacity needs. To think about you only for small quantity use or large quantity. Do you want to expand your customer base so that need to expand your capacity in near future? If yes, you can order larger machine instead of small machine. If not, smaller one is more suitable for you.

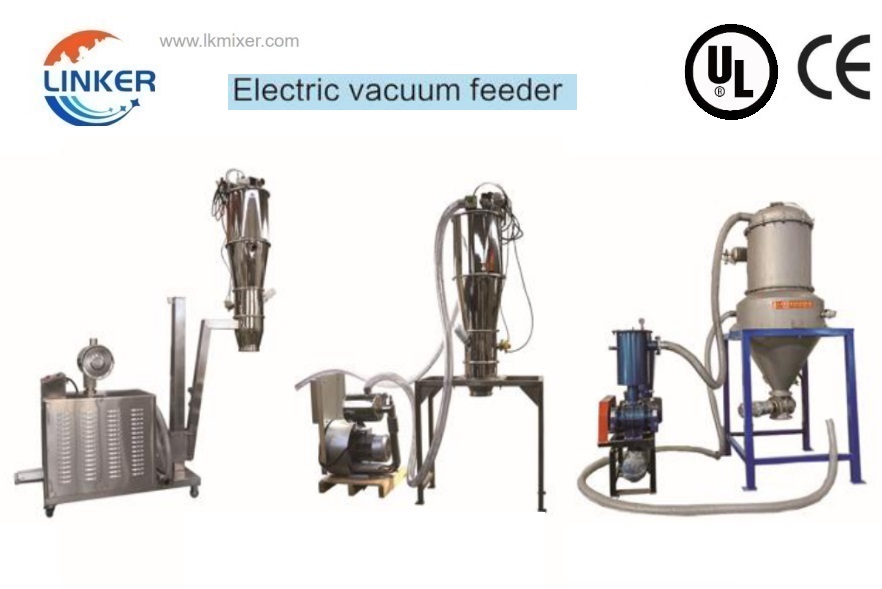

– Choose single or whole group? Single machine is cheaper and easy to move from here to there, space location are also easy. Whole group machine including material feeder, main machine, cyclone sperator and rotary valve. Whole group machine not easy to move cause of link of each portions. But whole group also advantages such as easy to dust collect, save manpower. Think about clearly what you want, we would know which is right to choose.

– If you think about your customers and volume, you’ll be off to a good start in knowing what you need from your grinder.

How to design my factory layout?

Right size is definitely important for grinder business.

If your business is small, you may not have the space to accommodate a large grinder. Read keep in mind, While, that a smaller grinder doesn’t have to mean that it’s not able output as much as a bigger one.

On the contrary, if you have a lot of space, you may require different things from your grinder.

For example, you may want to have dust collector and material feeder for your enviornment production and operation convenience.

What’s the difference between industrial large electric coffee grinder and a coffee shop?

Industrial coffee grinders can grind very large quantities of coffee bean to powder, Coffee shop can buy from factory and sell to customer or buy small coffee grinder to grind the powder by themselves.

How to estimate the Speed of coffee grinder machine that I need?

Speed is an easy to estimate: We have an estimate capacity for each coffee grinder machine. To more accuracy test, you can have sample of coffee bean to do trail test for each model. This can helps us to get a more accurate capacity volume. We test and calculate how many KG/hour or pounds/hour that we can get for each model, then you can choose how many quantity for each model that you need.

LK coffee bean grinder capacity range from 2.5kg/h to 3000kg/hour for your choose. You can always find the right model no matter you are laboratory want the small machine or a large factory want big machine.

How to ensure your coffee bean machine Quality?

Quality is of paramount importance to just about everyone, and it should be to you, too.

Customers always want the quality in their purchasing, and they will keep long term business with high quality supplier.

Always offering high-quality coffee bean grinder machine to our customers will earn us a solid reputation with them.

Keeps in mind about quality, we ensure our quality through following items:

– Material: we use 304 or 316 stainless steel body, 316 stainless steel for raw material contact portion.

The material of body always decide by customer, we will confirm the material type with you before you load order.

– Cooling Water System: jaket design allow ooler temperatures while grinding, preventing the burning of the coffee.

– Grinding Disc and Knife Cutter Design: The industry standard in material for grinding discs is steel, but there are different types of steel to choose from, such as die-cast and tungsten carbide. Good disc and knife design helps cut the material efficienctly. This also ensure the high quality of result mesh fineness.

Is it Convenience to operate machine in grinding?

Convenience to operate for your employees and yourself is also very important.

Your operator may need to carry the material back and forth in batches. Your operator may need to stop machine to clear and clean machine frequently. Your operator may also need to do screens the size of fineness after grinding and then put the inqualified powder back to machine to do grinding second time.

Yes, these are all the problems. But LINKER Pulverizer helps you reduce or solve these probems. You only need to buy the whole set group, which including automatically feeding system, grinding main machine, cyclone separator system, screen system after grinding and even an back material system back to grinder.

Save the manpower also helps to save the cost.