Ultrafine Grinder 10-2000kg/h 80-320mesh

Large WFM -Series Ultrafine Grinding Vibration Mill

- Production Capacity: 10-2000kg/h

- Feeding Size: ≤ 10 mm

- Crushing fineness: 80-320mesh

- Motor power: 13.37-119kw

- Machine Weight:950-5500kg

- Price: USD10,800~USD37,384.

Small WFM -Series Ultrafine Grinding Vibration Mill

- Production Capacity: 2-60kg/h

- Feeding Size: ≤ 2 or ≤ 3mm

- Crushing fineness:200-1800mesh

- Amplitude:5-8mm

- Motor power: 1.5-11kw

- Machine Weight:150-1800kg

Industrial Food Mushroom Grinder Youtube Video

Parameters

| Item | Unit | WFM-10 | WFM-30 | WFM-50 | WFM-100 | WFM-200 |

| The number of grinding tube | piece | 1 | 1 | 1 | 1 | 1 |

| Effective volume | L | 10 | 30 | 50 | 100 | 200 |

| Amplitude | mm | 5 | 7 | 8 | 8 | 8 |

| Frequency | HZ | 24 | 24 | 24 | 24 | 24 |

| Dynamic strength | G | 6 | 6 | 7 | 7 | 7 |

| Power | Kw | 0.55 | 1.5 | 2.2 | 5.5 | 7.5 |

| Feed size | mm | < 2 | < 2 | < 2 | < 3 | < 3 |

| Discharging size | μm | < 10 | < 10 | < 10 | < 10 | < 10 |

| Reference yleld | kg/h | 2.5-3 | 7.5-10 | 10-20 | 20-40 | 50-80 |

| Equipment weight | kg | 150 | 500 | 750 | 1200 | 1800 |

| Dimensions | m | 0.6 × 0.5 × 0.7 | 1.0 × 0.7 × 1.2 | 1.0 × 0.7 × 1.2 | 1.1 × 0.8 × 1.4 | 1.2 × 1.0 × 1.6 |

Trade Capacity

| International Commercial Terms(Incoterms): | FOB, CIF, CFR | Terms of Payment: | LC, T/T, PayPal, Western Union |

| Average Lead Time | 60 working days | Main Markets | North America, South America, Europe, Southeast Asia/ Mideast, East Asia(Japan/ South Korea), Australia, Domestic |

| Nearest Port: | Ningbo Port; Shanghai Port | Factory Address: | JiangSu, China |

I. Introduction

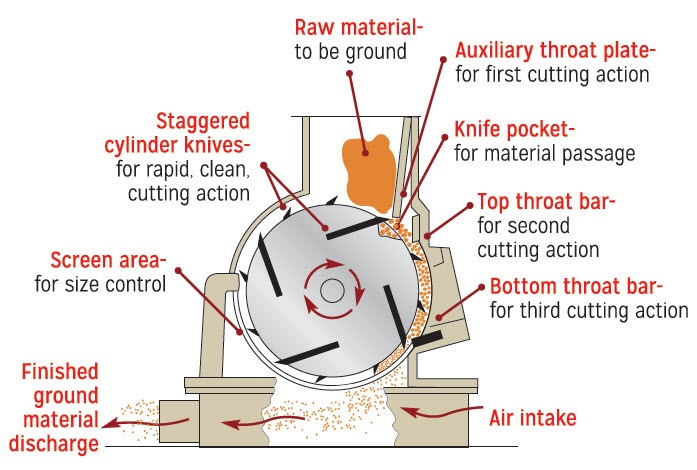

Ultrafine Grinder is the use of air separation, heavy grinding, shear to achieve the form of dry material ultrafine grinding equipment. It consists of a cylindrical grinding chamber, grinding wheel, grinding rail, fan, material collection system, etc. The material enters the cylindrical grinding chamber through the feeding port and is crushed by the grinding wheel moving in a circle along the grinding rail. The crushed material is brought out of the crushing chamber through the negative pressure air flow caused by the fan, and enters the material collection system, filtered through the filter bag, the air is discharged, the material and dust are collected, and the crushing is completed.

II. Types of Ultrafine Grinder:

Air flow crusher

The crushing mechanism mainly applicable to the air mill determines its wide range of application and high fineness of the finished product, typical materials are: super-hard diamond, silicon carbide, metal powder, etc., high purity requirements: ceramic color, medicine, biochemistry, etc., low temperature requirements: medicine, PVC. By changing the ordinary air of the air source to nitrogen, carbon dioxide and other inert gases, the machine can be made into an inert gas protection equipment, which is suitable for the crushing and grading processing of flammable and explosive materials.

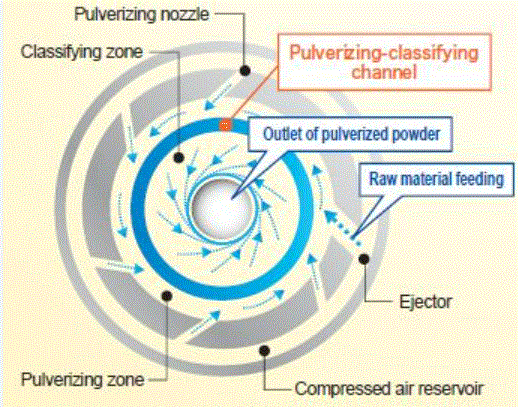

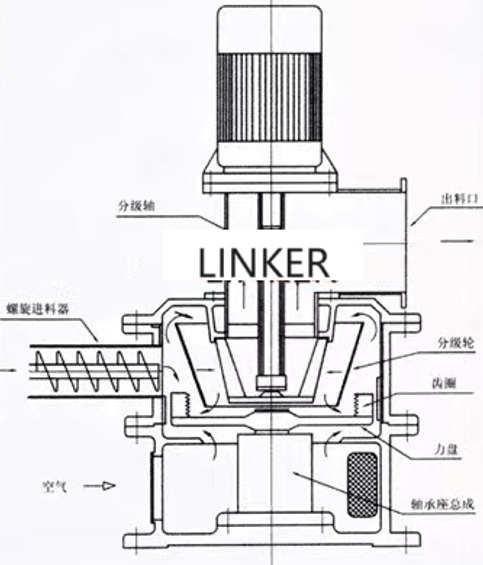

Working principle

Flow crusher, cyclone separator, dust collector and induced draft fan constitute a complete set of crushing system. After the compressed air is filtered and dried, it is sprayed into the grinding chamber at a high speed through the Laval nozzle. The materials are crushed by repeated collision, friction and shear at the intersection of multiple high-pressure air streams. The crushed materials move to the classification area with the updraft under the action of the fan, and the coarse and fine materials are separated under the strong centrifugal force generated by the high-speed rotating classification turbine. The fine particles that meet the particle size requirements enter the cyclone separator and dust collector through the grading wheel, and the coarse particles fall to the grinding zone and continue to be crushed.

Feature:

This type of pulverizer is suitable for very large output of chemical production and mine crushing operations;

Due to the need for a strong airflow to drive the material impact, the power consumption of the manufacturing airflow is quite large;

Takes up quite a lot of space.

Ball Mill

Pressure crusher

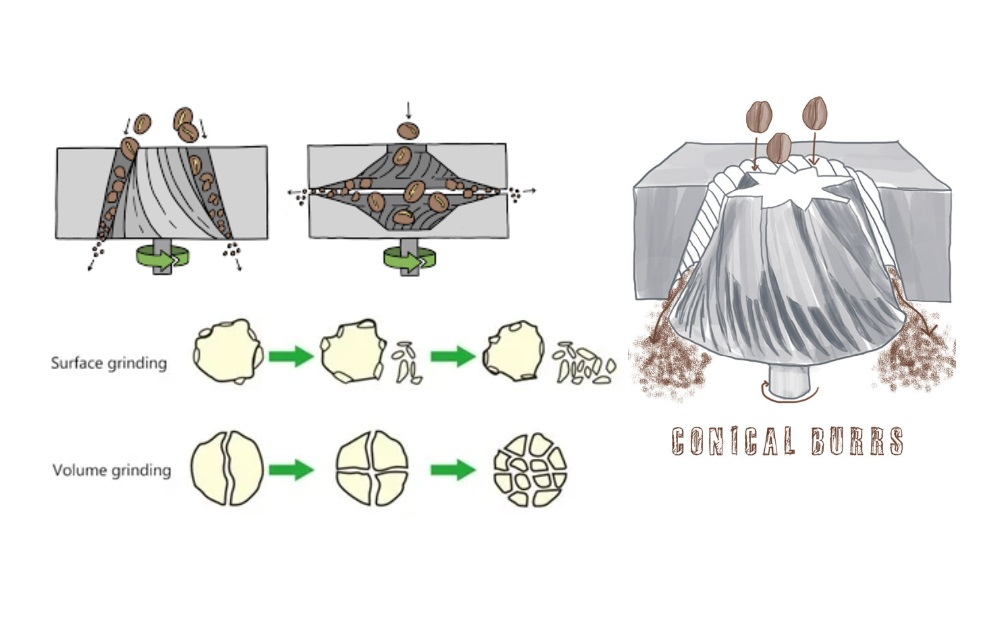

The design inspiration comes from the research ship used in China for thousands of years, the first by the hand of Taiwan mechanical design master preliminary shape, after combining the material flow theory and the principle of classification separation to further optimize the design, before and after 12 years to finalize the micron level crusher. In 2003, this series of models passed the particle size test and electron microscope test of the National Academy of Traditional Chinese Medicine, and obtained the Beijing new product certificate in the same year. Today, its series of products in China’s Chinese and western medicine industry, tea industry, cosmetics industry, food industry, feed industry, chemical industry, building materials industry, etc., have been well applied.

Working principle

The roller in the heavy grinding superfine mill is rotated and rotating, and the material is mixed with the heavy grinding shear principle as the main shearing force, so that the material is crushed to a certain fineness. This crushing principle can ensure that the standard of ultrafinx powder is reached or even higher without damaging the material, and the working temperature in the silo is relatively low without adding cooling facilities. Never exceed 45° to ensure that the material will not deteriorate due to high temperature.

peculiarity

Yields are relatively low;

The fineness of grinding can be adjusted;

Very low power consumption;

Small footprint;

Strong crushing ability for strong fiber materials.

The ball mill is the key equipment for crushing the material after it is broken. It is widely used in cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal beneficiation and glass ceramics and other production industries, for a variety of ores and other grindable materials dry or wet grinding. Ball mill is suitable for grinding various ores and other materials, is widely used in mineral processing, building materials and chemical industry, can be divided into dry and wet two kinds of grinding methods. According to different ore discharge methods, it can be divided into two types: lattice type and overflow type.

Working principle

Ball mill is composed of a horizontal cylinder, inlet and outlet hollow shaft and grinding parts, the cylinder is a long cylinder, the cylinder is equipped with a grinding body, the cylinder is made of steel plate, there is a steel lining plate and the cylinder is fixed, the grinding body is generally a steel ball, and is loaded into the cylinder according to different diameters and a certain proportion, the grinding body can also be used steel section. According to the particle size of the grinding material is selected, the material is loaded into the cylinder by the hollow shaft of the feed end of the ball mill. When the ball mill cylinder rotates, the grinding body is carried away by the cylinder on the nearby cylinder liner due to the action of inertia and centrifugal force and friction force. When it is brought to a certain height, it is thrown off due to its own gravity. The falling abrasive body acts like a projectile and shatters the material inside the cylinder.

peculiarity

This kind of equipment is mostly used in mines, coal companies, cement factories and other production units with high output requirements;

Dry grinding and wet grinding can be performed.

Vibrating Mill

Vibrating ultrafine mill using stainless steel bar as grinding medium, through the motor drive exciter to pulverizing bin for high-frequency circular vibration, driving the grinding medium to the material in the bin for beating, cutting, grinding, crushing principle with the ball mill has a certain similarity, but relative to the ball mill is different:

1, the ball mill grinding medium is spherical, the grinding medium is point-to-point contact, the friction surface is small, and the vibrating ultrafine grinder grinding medium is line-to-line contact, the friction surface is larger;

2, the grinding force of the grinding medium of the ball mill comes from the gravity of the medium, the grinding ball relies on the free fall movement of the material to knock, shear, grinding, and the vibrating ultrafine mill relies on the high-frequency circular vibration of the grinding medium driven by the grinding bin;

The above two points determine that the efficiency of the vibrating ultrafine mill is much higher than that of the ball mill, but at present, such equipment has the following defects:

1, compared with the ball mill, the structure is more complex and the cost is higher;

2, the need for the motor to drive the overall beating of the grinding bin, which limits the grinding bin can not be too large, so the output can not be compared with the large ball mill;

3, small vibrating ultrafinmicro mill more than the use of flipping structure for feeding, the operation is slightly laborious, but now some manufacturers have achieved the full automatic control of the whole equipment, the equipment can be one-click start, no longer need manpower for loading and unloading operation, but this technology has not been popularized, only a few manufacturers can do it.

Application scenario

Vibrating ultrafine mill can crush high sugar, high fiber materials, very suitable for ultrafine crushing of Chinese medicinal materials, and because of the small size of the equipment, high efficiency, so more suitable for Chinese medicinal materials. Clinics, hospitals, laboratories and other scenarios, large vibrating ultrafine mill can also be used for the production of pharmaceutical factories, because of simple cleaning, refueling is convenient, relative to the air flow ultrafine mill also has a certain advantage.

There are 3 ways of cooling down the grinder: water cooling system; air cooling system and liquid nitrogen freezing system. You can choose the right one if the grinder gets too hot. When machines goes too hot, the metal can expand, causing the grinding wheel to get stuck.

| Business Type: | Manufacturer/Factory | Main Products: | Mill, grinder, granulator, mixer, Crushing Equipment |

| Number of Employees: | 100 | Year of Establishment: | 2014.05 |

| Production Capacity | 5000Set/Year | After-sales Service: | Technical Support; on-line teach lessons |

| R&D Capacity: | ODM, OEM | Annual Output Value: | US$5 Million – US$10 Million |

| No. of R&D Staff: | 5 | No. of Production Lines: | 6 |

LK Mixer is a professional manufacturer for grinder, mixer and pulverizer. These machines are widely used in pharmaceutical, cosmetic, health care products and chemical industries. Our main product including granulating machine, grinder, mixer, dryer, etc. All mechanical products in accordance with the China GMP design requirements. And also we have other certifications such as CE, UL for motors.

Business Philosophy

“Quality is the main policy of sales” and “integrity is the principle of success” are the business philosophy of our people. We carry out one-year warranty, lifelong maintenance service, with technical consultation, with material test machine and other services, and long-term supply of equipment. Welcome new and old customers to negotiate cooperation!

Certifications:

Electric Cabinet with UL Certification

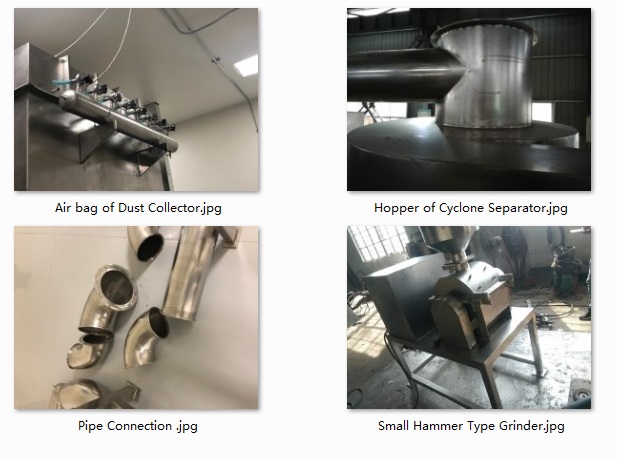

Cyclone Processor and Motors:

Spare Parts:

Small Machine Packing:

Small machine packed with export fumigation-free wooden cases, goes with bulk shipment or in container.

When packing small machines for sea shipment, it is important to take measures to ensure that the machines are protected from damage during transit. Here are some general steps that a manufacturer may follow when packing small machines for sea shipment:

- Clean and dry the machine: Before packing, the machine should be thoroughly cleaned and dried to prevent any moisture or debris from causing damage during transit.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack.

- Wrap the machine in protective material: The machine should be wrapped in a layer of protective material, such as bubble wrap or foam, to protect it from scratches and impact during transit.

- Place the machine in a sturdy box: The wrapped machine should then be placed in a sturdy box that is appropriate for the size and weight of the machine. The box should be made of durable material, such as corrugated cardboard or plywood, and should be able to withstand the rigors of sea transit.

- Add packing material: The box should be filled with packing material, such as packing peanuts or air pillows, to provide cushioning and prevent the machine from shifting during transit.

- Seal the box: The box should be securely sealed with high-quality packing tape to prevent it from opening during transit.

- Label the box: The box should be clearly labeled with the machine’s name, weight, and any other relevant information, as well as the destination address and contact information.

Overall, the goal is to pack the small machine in a way that will protect it from damage during transit and ensure that it arrives at its destination in good condition. It is important to follow proper packing procedures and use high-quality packing materials to minimize the risk of damage during sea shipment.

Large Machine Packing:

Packing a large machine for sea shipment can be a complex and challenging task. However, with careful planning and attention to detail, it is possible to pack a large machine for sea shipment in a way that will ensure that it arrives at its destination in good condition. Here are some general steps that a manufacturer may follow when packing up a large machine for sea shipment:

- Clean and prepare the machine: Before packing, the machine should be thoroughly cleaned and prepared. All fluids, such as oil or coolant, should be drained, and any loose or detachable parts should be removed.

- Disassemble the machine: If possible, the machine should be disassembled into its component parts to reduce its overall size and make it easier to pack. Each part should be carefully labeled and numbered to ensure that it can be easily reassembled at the destination.

- Protect delicate parts: Delicate or fragile parts should be wrapped in protective material, such as bubble wrap or foam, to protect them from damage during transit.

- Build a custom crate: A custom crate should be built around the machine to provide a secure and sturdy enclosure. The crate should be made of durable material, such as plywood, and should be designed to fit the machine snugly. The crate should also include braces or supports to prevent the machine from shifting during transit.

- Add cushioning material: The crate should be filled with cushioning material, such as packing peanuts or air pillows, to provide extra protection and prevent the machine from moving or shifting during transit.

- Securely fasten the machine: The machine should be securely fastened to the crate to prevent it from moving or shifting during transit. This may involve using straps, bolts, or other fasteners to hold the machine in place.

- Seal and label the crate: The crate should be securely sealed with high-quality packing tape, and should be clearly labeled with the machine’s name, weight, and any other relevant information. The destination address and contact information should also be clearly marked on the crate.

Overall, packing a large machine for sea shipment requires careful planning and attention to detail. It is important to use high-quality materials and follow proper packing procedures to ensure that the machine arrives at its destination in good condition. A professional packing and shipping company may be consulted to ensure that the machine is properly packed and prepared for sea shipment.

Customer Side Machine Groups Showcase Videos:

Dust Collector Shipment

Shipment – Packing Method

Two Large Industrial Grinder Ready to Ship

Shipment Show Case:

Operation Instruction

General Provisions

The operation instructions for a commercial grinder may vary depending on the specific model and manufacturer. However, here are some general guidelines that may apply to many high speed grinders:

- Safety precautions: Before operating the high speed grinder, it is important to review all safety precautions and warnings provided in the user manual. Safety precautions may include wearing appropriate personal protective equipment, such as eye protection and hearing protection, and avoiding loose clothing or jewelry that could become caught in the grinder.

- Preparation: The high speed grinder should be placed on a stable and level surface, and all necessary components should be assembled according to the manufacturer’s instructions. The grinder should also be connected to a power source that is appropriate for its voltage and wattage.

- Loading the grinder: The material to be ground should be loaded into the grinder according to the manufacturer’s instructions. Overloading the grinder may cause damage to the machine and result in poor grinding performance.

- Starting the grinder: The grinder should be started according to the manufacturer’s instructions. This may involve pressing a button, turning a dial, or flipping a switch. The user should ensure that their hands are clear of the grinder and that the material to be ground is positioned properly.

- Adjusting the speed and settings: The speed and other settings of the high speed grinder may be adjusted according to the material being ground and the desired outcome. The user should follow the manufacturer’s instructions for making adjustments to the grinder.

- Monitoring the grinding process: The user should monitor the grinding process to ensure that it is progressing smoothly and that the material is being ground to the desired size and consistency. Any issues or abnormalities should be addressed promptly to prevent damage to the machine.

- Shutting down the grinder: When the grinding process is complete, the grinder should be shut down according to the manufacturer’s instructions. The user should ensure that the machine is completely stopped and that all moving parts have come to a complete stop before attempting to clean or service the grinder.

Overall, the operation instructions for a commercial grinder may involve a number of steps and safety precautions. It is important to carefully review the manufacturer’s instructions and follow proper operating procedures to ensure safe and effective use of the machine.

Preparation Work

Before running a commercial grinder, there are several important preparation steps that should be taken to ensure safe and effective operation of the machine. Here are some general guidelines for preparing to run a high speed grinder:

- Read the user manual: The first step in preparing to run a high speed grinder is to carefully read the user manual provided by the manufacturer. The user manual will provide important information about the specific model of grinder being used, including its features, specifications, and safety precautions.

- Select the appropriate grinding wheel: The grinding wheel used in a high speed grinder should be selected based on the material being ground and the desired outcome. It is important to use the correct type of grinding wheel to prevent damage to the machine and ensure optimal grinding performance.

- Inspect the grinder: Before running the grinder, it is important to inspect it for any signs of damage or wear. The user should check for loose or missing components, cracks or other signs of damage to the machine’s housing or other parts, and any other issues that could affect the grinder’s operation.

- Install the grinding wheel: The grinding wheel should be installed according to the manufacturer’s instructions, making sure that it is securely fastened and aligned properly. The user should also check the wheel for any cracks or other signs of damage before installation.

- Secure the workpiece: The workpiece to be ground should be securely clamped or held in place before starting the grinder. This will help to ensure safe and effective operation and prevent the workpiece from becoming dislodged or damaged during grinding.

- Connect the power source: The high speed grinder should be connected to a power source that is appropriate for its voltage and wattage. It is important to use a properly grounded power source to ensure safe and reliable operation of the machine.

- Test run: Before beginning actual grinding operations, it may be useful to perform a test run to ensure that the grinder is functioning properly and that the grinding wheel is aligned and balanced properly. The user should follow the manufacturer’s instructions for performing a test run.

By following these preparation steps, users can ensure safe and effective operation of a high speed grinder and achieve optimal grinding results.

Treatment of inspection

Inspection of a commercial grinder is an important maintenance procedure that helps ensure safe and effective operation of the machine. Here are some general guidelines for inspecting a high speed grinder:

- Disconnect power source: Before performing any inspection or maintenance on a high speed grinder, the power source should be disconnected to prevent accidental startup.

- Check for wear and damage: The user should inspect the grinder for any signs of wear or damage, such as cracks in the housing, worn or damaged grinding wheels, or loose or missing parts. Any issues should be addressed promptly to prevent further damage to the machine.

- Check alignment and balance of grinding wheel: The grinding wheel should be inspected for proper alignment and balance, as these factors can affect the quality of the grinding operation. If the grinding wheel is not properly aligned or balanced, it should be adjusted or replaced as necessary.

- Check for proper lubrication: The high speed grinder should be inspected for proper lubrication, as inadequate lubrication can cause excessive wear and damage to the machine’s moving parts. The user should follow the manufacturer’s instructions for lubrication, and add lubricant as necessary.

- Inspect electrical components: The electrical components of the high speed grinder, including the wiring, switches, and control panel, should be inspected for any signs of wear, damage, or loose connections. Any issues should be addressed promptly to prevent electrical problems.

- Test run: After completing the inspection, it may be useful to perform a test run of the high speed grinder to ensure that it is functioning properly and that any issues have been addressed.

By following these inspection guidelines, users can help ensure safe and effective operation of a high speed grinder and minimize the risk of damage or injury during grinding operations.

Operation Attention

Running a commercial grinder can be a dangerous operation if proper precautions are not taken. Here are some general guidelines for safe operation of a high speed grinder:

- Personal protective equipment: The user should wear appropriate personal protective equipment, such as safety glasses, hearing protection, and gloves, to prevent injury from flying debris, noise, and contact with the grinding wheel.

- Secure workpiece: The workpiece being ground should be securely clamped or held in place to prevent it from becoming dislodged during grinding.

- Use proper grinding wheel: The user should select the appropriate grinding wheel for the material being ground and ensure that it is installed correctly and securely. The grinding wheel should be inspected for cracks or other damage before use.

- Adjust grinding wheel speed: The speed of the grinding wheel should be adjusted according to the manufacturer’s instructions to ensure optimal grinding performance and prevent damage to the machine or workpiece.

- Avoid excessive pressure: The user should avoid applying excessive pressure to the grinding wheel, as this can cause the wheel to overheat and wear out more quickly.

- Avoid overheating: The high speed grinder should not be operated continuously for extended periods of time, as this can cause overheating and damage to the machine.

- Monitor grinding operation: The user should closely monitor the grinding operation to ensure that the workpiece is being ground properly and that the grinding wheel is functioning correctly.

- Disconnect power source: After completing grinding operations, the power source should be disconnected to prevent accidental startup.

By following these guidelines, users can operate a high speed grinder safely and effectively, and achieve optimal grinding results. It is important to follow the manufacturer’s instructions and all applicable safety regulations when operating any type of machinery.

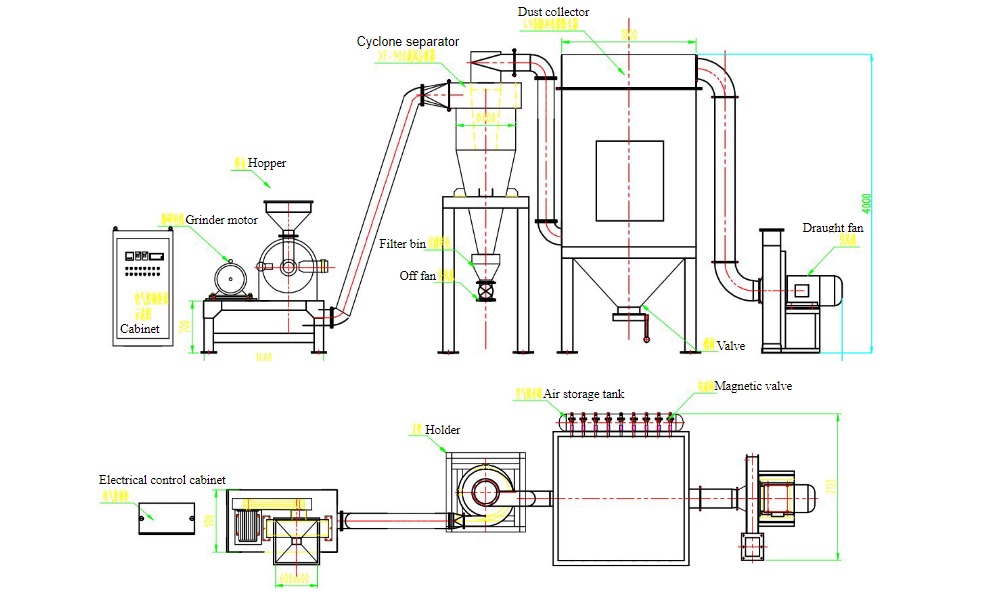

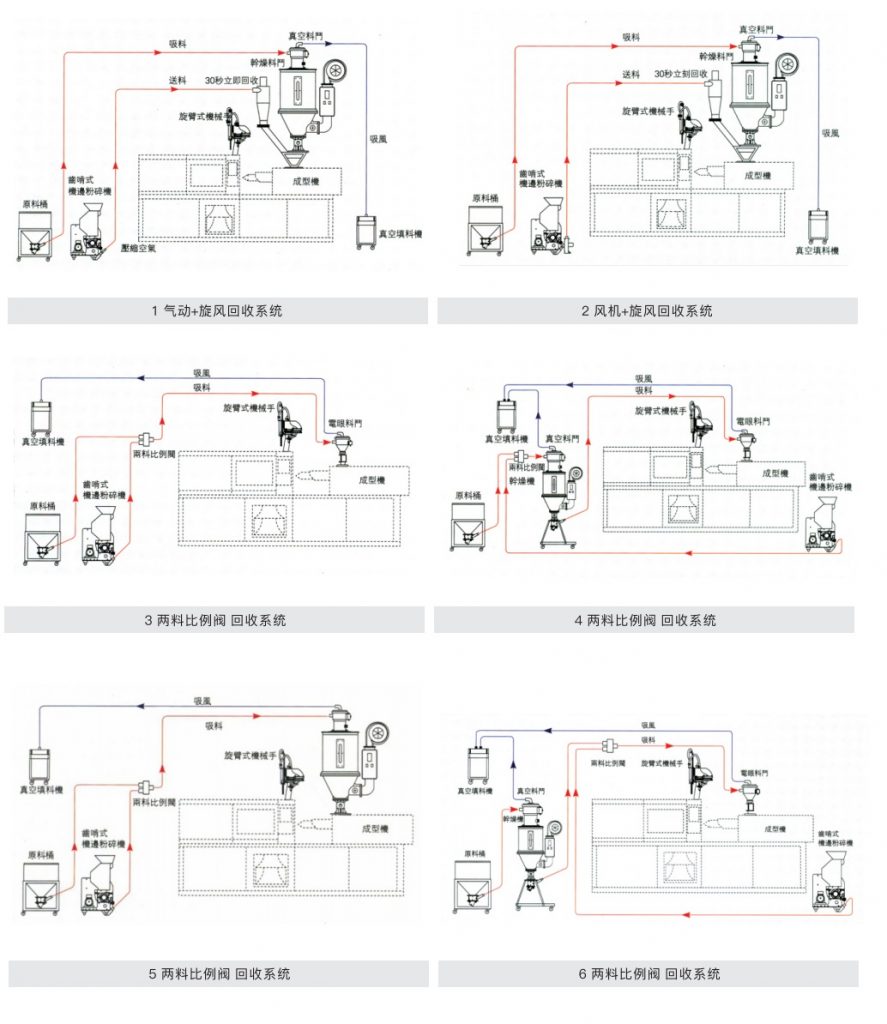

Installation Layout:

Applications Example Video Showcase:

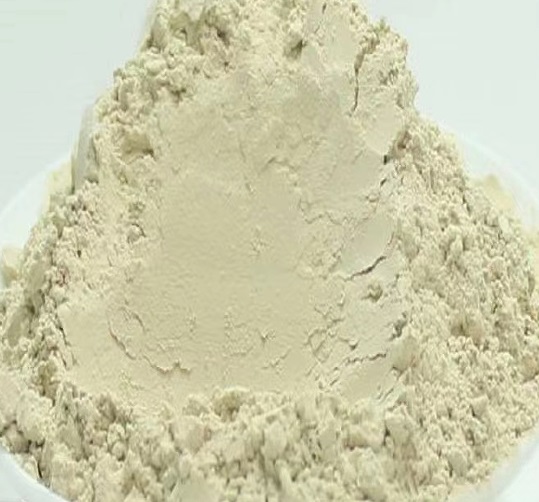

The Ultrafine Grinding machine can be widely used in Chinese medicine, Western medicine, pesticide, biology, cosmetics, food, feed, chemical, ceramics and other industries dry material ultrafine grinding needs. Especially for fiber, high toughness, such as cordyceps, tea, ganoderma and other materials crushing effect is more perfect.

Edible glucose Untrafine

Ultrafine 200mesh

Tea Ultrafine 300mesh

Dry Fruit Powder Untrafine 250mesh

Albumen Powder Ultrafine 325mesh

Coffee Bean Superfine 300mesh

Citric acid Super fine 200mesh

Soybean Powder Ultrafine 300mesh

Green Tea Superfine 300mesh

, and they play an important role in processing and utilizing mushrooms for various industrial applications.

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Mushroom Production Line Customization Solution:

Drying Machine + Grinding Machine + Sifter Machine + Mixing Machine + Packing Machine:

Production Line Customization Videos(See More Videos):

Other Food Mill Grinding Machine:

Blending and Mixing Machine for Sale

Granulating Machine for Sale:

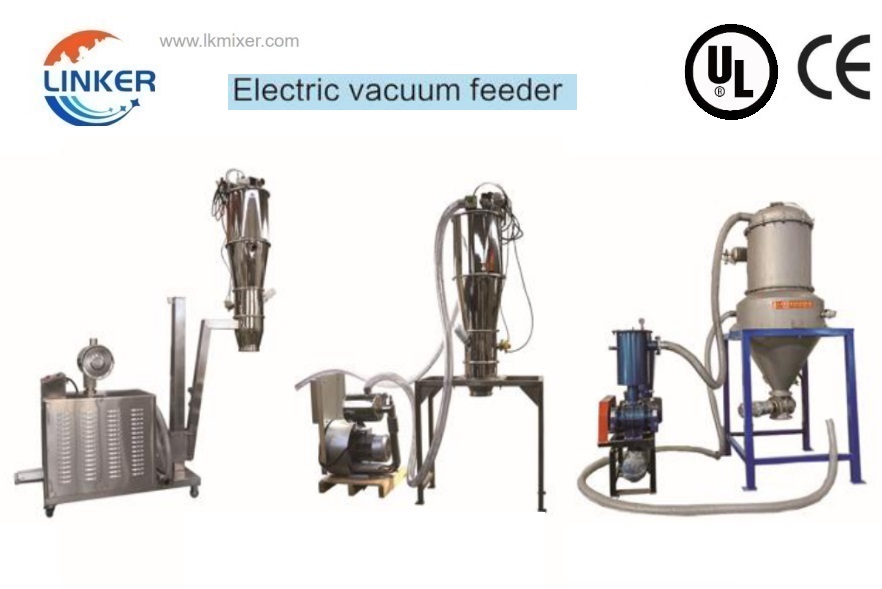

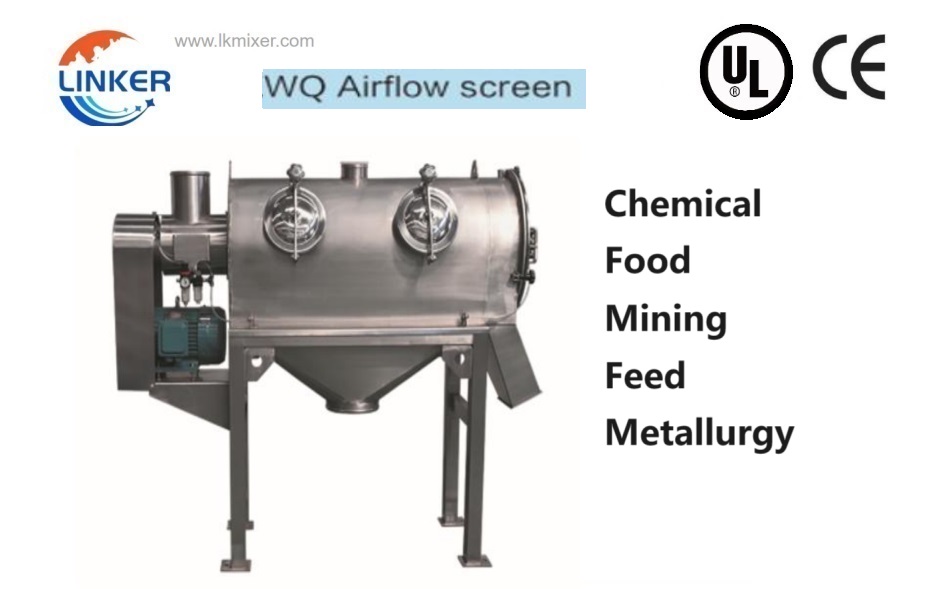

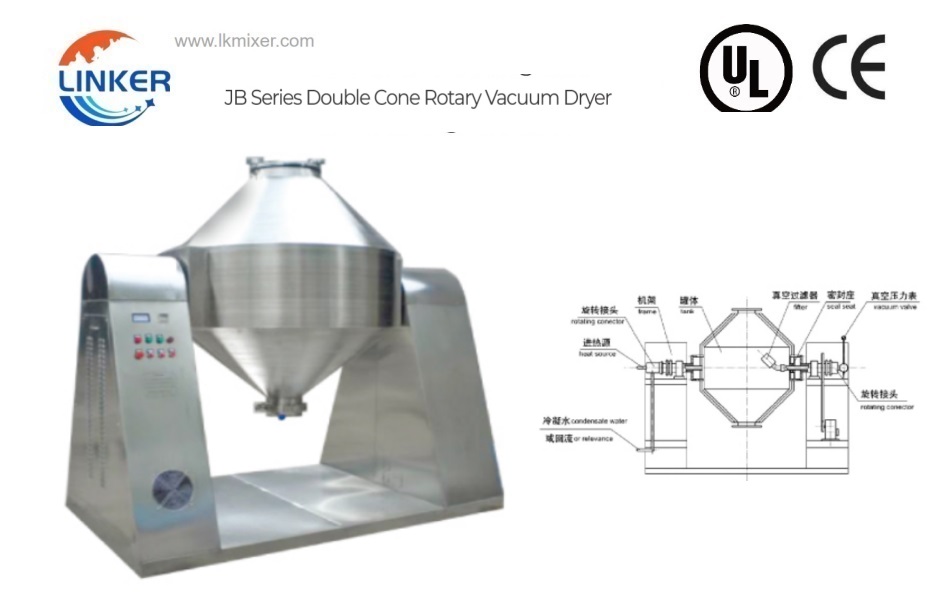

Auxiliary Machine for Sale:

Recommend Reading

WFM -Series Ultrafine Grinding Vibration Mill

- Production Capacity:2.5-80kg/h

- Feeding Size: ≤ 2 or ≤ 3mm

- Crushing fineness:<10μm

- Amplitude:5-8mm

- Motor power: 0.5-7.5kw

- Machine Weight:150-1800kg

Vibration Mill Introduction:

The machine of any fibrous, high toughness, high hardness, or with a certain moisture content material can be carried out effectively crushed, especially designed to increase drug bioavailability by pulverization requirements and with conventional methods can not meet the requirements applicable to Chinese cell wall fineness of materials. Low energy consumption and high efficiency: efficient best micronized equipment, and production/energy consumption is greater than the maximum. Design and manufacturing rose from 10 to 200 liters, monocular, binocular, three-cylinder and multi-cylinder arbitrary a continuous production can also batch production. Supported by air springs, support stiffness can be adjusted as needed. Barrel stability, the grinding trajectory almost circular, the energy conversion rate, and low noise. According to the grinding material requirements the grinding cylinder configuration of different materials and liners and grinding media, to ensure that the materials pollution. Configure the frequency amplitude modulation device and a cooling or heating system according to the material requirements.

Vibration Mill Application:

Nonmetallic mineral super fine crushing; Plant cells, traditional Chinese medicine the wall processing; Metal oxide, chemical industry, building materials, etc. Mineral super fine crushing: kaolin, graphite, calcite, feldspar, quartz, barite, through flash stone, talc, electrical stone, etc. The plant, Chinese traditional medicine the wall cells processing: the ganoderma Lucida valuable Chinese herbal medicine of Chinese caterpillar fungus dehydrated vegetable, fruit, Chinese herbal medicine cells the wall pieces production function fine powder. Building materials: concrete adulterating materials, the superfine cement, cement, coal ash cement, color ceramic material, etc. Oxide, electromagnetic material: oxidation silicon, alumina, zinc oxide, titanium, nickel oxide, oxidation antimony oxide, ferric oxide, rare earth, ferrite, etc. Other: metal powder, coal, CWM, activated carbon, carbon fiber, storage of light material, battery materials, pigment, coating material such as ultrafine grinding.

Vibration Mill Technical Parameters:

| Item | Unit | WFM-10 | WFM-30 | WFM-50 | WFM-100 | WFM-200 |

| The number of grinding tube | piece | 1 | 1 | 1 | 1 | 1 |

| Effective volume | L | 10 | 30 | 50 | 100 | 200 |

| Amplitude | mm | 5 | 7 | 8 | 8 | 8 |

| Frequency | HZ | 24 | 24 | 24 | 24 | 24 |

| Dynamic strength | G | 6 | 6 | 7 | 7 | 7 |

| Power | Kw | 0.55 | 1.5 | 2.2 | 5.5 | 7.5 |

| Feed size | mm | < 2 | < 2 | < 2 | < 3 | < 3 |

| Discharging size | μm | < 10 | < 10 | < 10 | < 10 | < 10 |

| Reference yleld | kg/h | 2.5-3 | 7.5-10 | 10-20 | 20-40 | 50-80 |

| Equipment weight | kg | 150 | 500 | 750 | 1200 | 1800 |

| Dimensions | m | 0.6 × 0.5 × 0.7 | 1.0 × 0.7 × 1.2 | 1.0 × 0.7 × 1.2 | 1.1 × 0.8 × 1.4 | 1.2 × 1.0 × 1.6 |

Video

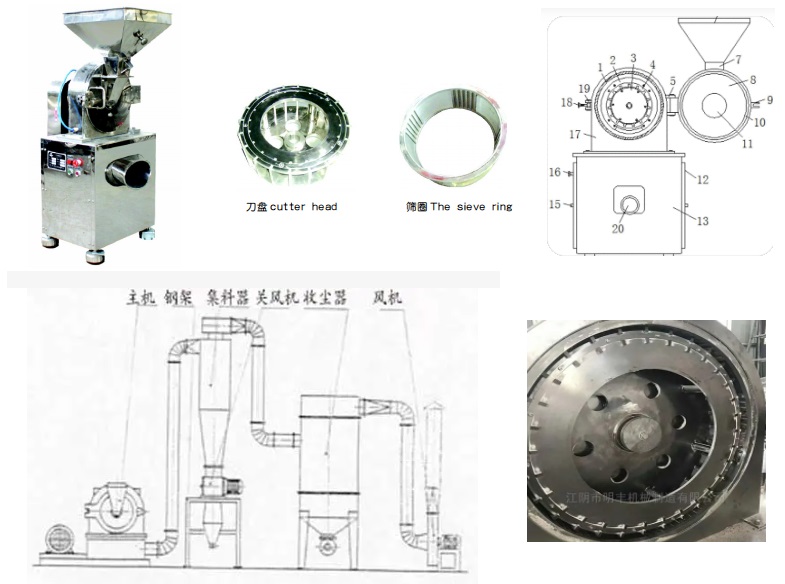

Crusher Knife

Vibration Mill Screen:

Screen Material: Support 304, 316 stainless steel screen customization.

Screen mesh: Support mesh size customization.

Shipment Picture:

About LKMixer

LKMixer is a professional manufacturer for fertilizer production line, grinder, mixer and granulator, shredder. These machines are widely used in food, pharmaceutical, cosmetic, health care products and chemical industries. The Food materials like Peanut, mushroom, seeds, potato, bean, tobacco, salt, cannabis, tea, Sugar, corn, Coffee, rice, pepper, grain as so on. Grinders have many types such as Pulse Dust Grinder which suitable for zero pollution environment, Turbine Mill which is suitable for coffee bean, 12-120mesh all can meet, Ultrafine Grinding Mill covers 80-200mesh, and also Winnowing Dust Grinder or other grinding machines like SF Hammer. Welcome to contact us for details. Contact us for more information. Proposal, catalog, quotation. Mobile/WhatsApp: +86 18019763531 Tel: +86 21 66037855 Email: sales@lkmixer.com

Contact Us

Recommend Products

Recover

Air Cooled Crusher

- Production Capacity:30-2200kg/h

- Feeding Size: ≤ 5 or ≤ 10

- Crushing fineness:30-120mm

Recouperate

High Coarse Crusher

- Production Capacity:10-2200kg/h

- Feeding Size:≤ 100

- Crushing fineness:0.5-20

Recover

Universal Grinder

- Production Capacity:20-3500kg/h

- Feeding Size:6-15mm

- Crushing fineness:10-150mm

Recouperate

Pulse Dust Grinder

- Production Capacity:20-3500kg/h

- Feeding Size:6-15mm

- Crushing fineness:10-150mm

What is an ultrafine grinder?

An ultrafine grinder is a machine used to grind and crush solid materials, typically materials that are not easily processed by other grinding machines. This type of grinder can produce very fine powders from materials with a hardness of up to 10 on the Mohs scale, which is a measure of a material’s hardness.

Ultrafine grinders typically operate using a combination of mechanical grinding and air pressure, which helps to break down the materials and create a fine powder. They are commonly used in industries such as pharmaceuticals, cosmetics, and food processing, where very fine powders are required for various applications.

Ultrafine grinders can be designed in a variety of configurations, including jet mills, pin mills, and ball mills. Each type of ultrafine grinder has its own advantages and disadvantages, and the specific type used will depend on the material being processed and the desired end product.

What are the different types of ultra fine grinders?

There are several types of ultrafine grinders available in the market, each designed for specific applications and with its own unique features. Some of the common types of ultrafine grinders are:

Jet mill: Jet mills use high-speed compressed air or steam to produce ultrafine particles. The material to be ground is fed into the grinding chamber where it is accelerated and impacted by the high-speed jets of gas. This type of mill is typically used for materials with a Mohs hardness of up to 10.

Pin mill: Pin mills use a series of rotating pins inside a stationary grinding chamber to crush and grind materials. The pins can be either intermeshing or counter-rotating, and they impact the material at high speed. Pin mills are often used for grinding materials that are not easily broken down by other methods.

Ball mill: Ball mills use steel balls or other grinding media to grind materials into fine particles. The balls are rotated inside a cylindrical chamber, and the material is crushed and ground by the impact of the balls. This type of mill is often used for grinding materials that are brittle and require a fine powder.

Fluid energy mill: Fluid energy mills use a stream of high-pressure air or gas to grind and pulverize materials. The material to be ground is fed into the grinding chamber, where it is impacted by the high-velocity gas stream. Fluid energy mills are often used for materials with a low melting point or for heat-sensitive materials.

Vibrating mill: Vibrating mills use an eccentrically mounted grinding tube with a vibrating motion to grind and disperse materials. The vibration creates a high frequency and low amplitude motion that helps to break down the material into ultrafine particles.

Each type of ultrafine grinder has its own advantages and disadvantages, and the choice of equipment will depend on the specific requirements of the application.

Which mill is categorized as ultrafine grinder?

Jet mills, pin mills, and ball mills can all be categorized as ultrafine grinders. These mills are capable of producing very fine particles and powders, and are commonly used in industries such as pharmaceuticals, food processing, and cosmetics, where ultrafine particles are required for various applications. The specific type of mill used as an ultrafine grinder will depend on the material being processed and the desired end product.

Which mode of size reduction is used by ultrafine grinders?

Ultrafine grinders use mechanical grinding and air pressure to achieve size reduction. In these machines, the material to be ground is fed into a grinding chamber, where it is subjected to mechanical forces such as impact, compression, and attrition. As the material is ground, it is also exposed to a stream of high-pressure air or gas, which helps to break down the particles and create a fine powder.

The combination of mechanical grinding and air pressure allows ultrafine grinders to achieve a very fine particle size, often in the sub-micron or nanometer range. This makes them particularly useful for applications that require very small particle sizes, such as in the pharmaceutical, cosmetics, and food industries.

Which is best in ultra grinder?

The best type of ultrafine grinder to use will depend on the specific application and the material being processed. Some factors to consider when choosing an ultrafine grinder include:

Particle size requirement: The desired particle size of the final product will help determine the type of ultrafine grinder to use. Different types of grinders are better suited for producing specific particle sizes.

Material hardness: The hardness of the material being ground will affect the choice of ultrafine grinder. Some materials require more aggressive grinding methods to break them down into fine particles.

Production volume: The required production volume will also influence the choice of ultrafine grinder. Some types of grinders are better suited for high-volume production than others.

Maintenance and operating costs: The cost of maintaining and operating the grinder should also be considered when choosing an ultrafine grinder.

Some popular types of ultrafine grinders include jet mills, pin mills, and ball mills. Ultimately, the best choice of ultrafine grinder will depend on the specific needs of the application and the material being processed.